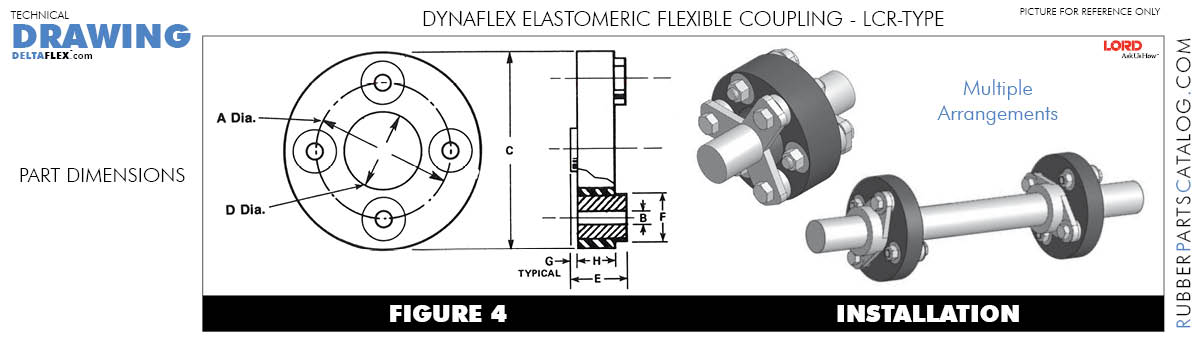

My coupler was two round rubbers with an aluminum block in between. Two 3/8 bolts attach it to the crank pulley and two 3/8 bolts attach it to the hydro's.

They are spaced 2.5" apart on both ends. I made a coupler out of 3/4" black pipe with threaded flanges on each end. I welded each flange where the threads are so it won't come apart when it's spinning. The pic Blaze sent wasn't in the manual Mike sent me. I'm sure it would work if I could find one. I.m nervous about the one I fabricated taking out the hydro pump cause it's not balanced. I did have to jack up on the coupler I made to get the bolts to line up cause the motor and hydro pulleys are not lined up perfectly. They are about 3/8" off. When it's running there is a slight wobble. Any advice would be appreciated.

They are spaced 2.5" apart on both ends. I made a coupler out of 3/4" black pipe with threaded flanges on each end. I welded each flange where the threads are so it won't come apart when it's spinning. The pic Blaze sent wasn't in the manual Mike sent me. I'm sure it would work if I could find one. I.m nervous about the one I fabricated taking out the hydro pump cause it's not balanced. I did have to jack up on the coupler I made to get the bolts to line up cause the motor and hydro pulleys are not lined up perfectly. They are about 3/8" off. When it's running there is a slight wobble. Any advice would be appreciated.