You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Regulator voltage

#1

A

Arkus55

A

Arkus55

I have a B&S Vanguard engine 356776-3046-G1. It is installed on an old Scag SWZ 52" walk behind, pull start. I am having problems with the PTO clutch engagement. The PTO would engage at first. But if it was hot and shut off, it wouldn't engage again. Then it stopped working all together. I checked the air gap of the PTO and the ohms reading is within limits. At full throttle, the voltage coming from the stator is 38V ac. The output voltage is only 6-7V dc. I replaced the regulator/rectifier with the same outcome, somewhere aroung 8V dc. Am I missing something? I have double checked the grounds, etc. Again, this is a non-battery system. So there isn't any back voltage requirements that I can find.

#3

A

Arkus55

A

Arkus55

The regulator is bolted directly to the engine. The input comes from the alternator.Where is the voltage regulator connected to the engine ?

Attachments

#4

ILENGINE

ILENGINE

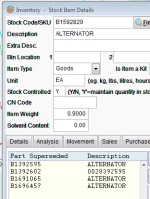

That engine calls for the 845907 regulator. Unless they changed something from they previous superceded part numbers that regulator is for the electric start engines which would need to supply 12v to the regulator to make it work.

#5

Hammermechanicman

Hammermechanicman

ILengine is correct. You need a battery to make the charging system work properly

#6

ILENGINE

ILENGINE

And the regulator in the OP picture is not the regulator that Briggs says fits that engine. That engine even has a different stator to regulator connection than Briggs claims. Looks like the 794360 regulator with the tri circuit stator. Not the 10-16 amp stator as what Briggs says fits the OP engine. Maybe something is wrong with the OP model-type number.ILengine is correct. You need a battery to make the charging system work properly

#7

A

Arkus55

A

Arkus55

The regulator is bolted directly to the engine. The input comes from the alternator.

Yes, either the tri circuit or 9 amp regulated stator. That’s the question/issue. I can’t find anything about testing this circuit without a battery. I have verified the model number (see attached). But this system worked, until it didn’t. So trying to figure out the problem. My son just bought this a month ago and I don’t have any experience with this type of mower.And the regulator in the OP picture is not the regulator that Briggs says fits that engine. That engine even has a different stator to regulator connection than Briggs claims. Looks like the 794360 regulator with the tri circuit stator. Not the 10-16 amp stator as what Briggs says fits the OP engine. Maybe something is wrong with the OP model-type number.

Attachments

#9

StarTech

StarTech

IL go to the Power Portal, part of the specs says tri-circuit stator setup. Then the stator is listed as a tri circuit in the IPL but then they list the 10-16 regulator. They are not compatiable. Looks to me like some mis-info provided in the IPL.

If the most of info provided is correct then the OP has the tri-circuit setup.

If the most of info provided is correct then the OP has the tri-circuit setup.

#10

22R

22R

My Kohler had a bad engine electrical connector that caused the same symptoms. The output wire of the Regulator going back to key switch the terminal connector was degrading. New connector and all good. may not be your issue but just another idea to check.

22R

22R

#11

V

VegetiveSteam

V

VegetiveSteam

The stator is putting out as it should and you've replace the regulator so you should be able to eliminate those two things as well as the flywheel magnets. Is the 6-7 vdc output voltage being checked with everything connected as it would normally be? If so, you should have at least battery voltage at the output side of the regulator. At that point your issue is somewhere between the voltage regulator and the battery. Wiring,key switch, connection, ect. If you're just checking the output side of the regulator without it being connected to the battery as mentioned, it will not function properly. The regulator has to be excited by battery voltage to work properly.I have a B&S Vanguard engine 356776-3046-G1. It is installed on an old Scag SWZ 52" walk behind, pull start. I am having problems with the PTO clutch engagement. The PTO would engage at first. But if it was hot and shut off, it wouldn't engage again. Then it stopped working all together. I checked the air gap of the PTO and the ohms reading is within limits. At full throttle, the voltage coming from the stator is 38V ac. The output voltage is only 6-7V dc. I replaced the regulator/rectifier with the same outcome, somewhere aroung 8V dc. Am I missing something? I have double checked the grounds, etc. Again, this is a non-battery system. So there isn't any back voltage requirements that I can find.

#12

ILENGINE

ILENGINE

In this guys application it is recoil start with no electric start therefore there is no battery to supply power to the regualtor. this engine is supposed to have the batteryless regulator to supply power to the clutch without a battery.The stator is putting out as it should and you've replace the regulator so you should be able to eliminate those two things as well as the flywheel magnets. Is the 6-7 vdc output voltage being checked with everything connected as it would normally be? If so, you should have at least battery voltage at the output side of the regulator. At that point your issue is somewhere between the voltage regulator and the battery. Wiring,key switch, connection, ect. If you're just checking the output side of the regulator without it being connected to the battery as mentioned, it will not function properly. The regulator has to be excited by battery voltage to work properly.

#13

V

VegetiveSteam

My next question would be was the stator voltage testing done while plugged into the rectifier or unplugged. If it was done unplugged, I'd plug it back in and check it again and see if that changes anything. A little bit of a load on the stator may drop that AC voltage quite a bit if it's compromised.

V

VegetiveSteam

Ah yes, I see where I read right past that in more than one spot even. I saw regulator in most of the posts so I made the wrong assumption that it was a regulator. Okay so it's a rectifier and yes, as mentioned unlike a regulator it would not need battery voltage to excite it.In this guys application it is recoil start with no electric start therefore there is no battery to supply power to the regualtor. this engine is supposed to have the batteryless regulator to supply power to the clutch without a battery.

My next question would be was the stator voltage testing done while plugged into the rectifier or unplugged. If it was done unplugged, I'd plug it back in and check it again and see if that changes anything. A little bit of a load on the stator may drop that AC voltage quite a bit if it's compromised.

#14

ILENGINE

ILENGINE

It is not all lost on you. Part of the issue also is the Briggs IPL shows the tri-circuit stator which would be correct for this application, but has a mistake in the IPL concerning the regulator. They are showing the 10-16 amp regulator/rectifier which is wrong for this engine, because that regulator would require a battery.Ah yes, I see where I read right past that in more than one spot even. I saw regulator in most of the posts so I made the wrong assumption that it was a regulator. Okay so it's a rectifier and yes, as mentioned unlike a regulator it would not need battery voltage to excite it.

My next question would be was the stator voltage testing done while plugged into the rectifier or unplugged. If it was done unplugged, I'd plug it back in and check it again and see if that changes anything. A little bit of a load on the stator may drop that AC voltage quite a bit if it's compromised.

#15

A

Arkus55

A

Arkus55

Thanks for the suggestion. I have checked the voltage directly from the regulator with the same results. I also went through and rewired everything. The previous owner had bypassed all kill switches. So I have a new PTO switch, a push button (The old one was a toggle switch), and all new wiring.My Kohler had a bad engine electrical connector that caused the same symptoms. The output wire of the Regulator going back to key switch the terminal connector was degrading. New connector and all good. may not be your issue but just another idea to check.

22R

#16

A

Arkus55

A

Arkus55

Can you suggest the correct part number for this application then? Obviously going off the IPL is incorrect.It is not all lost on you. Part of the issue also is the Briggs IPL shows the tri-circuit stator which would be correct for this application, but has a mistake in the IPL concerning the regulator. They are showing the 10-16 amp regulator/rectifier which is wrong for this engine, because that regulator would require a battery.

#17

A

Arkus55

A

Arkus55

I will definitely try that. I tested the stator with the rectifier disconnected. I assume you mean to back probe with the rectifier connected?Ah yes, I see where I read right past that in more than one spot even. I saw regulator in most of the posts so I made the wrong assumption that it was a regulator. Okay so it's a rectifier and yes, as mentioned unlike a regulator it would not need battery voltage to excite it.

My next question would be was the stator voltage testing done while plugged into the rectifier or unplugged. If it was done unplugged, I'd plug it back in and check it again and see if that changes anything. A little bit of a load on the stator may drop that AC voltage quite a bit if it's compromised.

#18

V

VegetiveSteam

V

VegetiveSteam

Yes. Sometimes just a little load can show that it's not working correctly.I will definitely try that. I tested the stator with the rectifier disconnected. I assume you mean to back probe with the rectifier connected?

#20

ILENGINE

ILENGINE

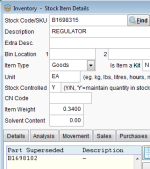

The close I can match it is the 794360 but just searching the 357667 comes up with them using 2 different regulators on the tri-circuit stator and a third which doesn't fit the tri-circuit system. The 794360 uses a single bolt mount. And the 798315 which is a two bolt mountCan you suggest the correct part number for this application then? Obviously going off the IPL is incorrect.

#22

ILENGINE

ILENGINE

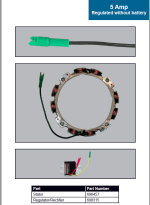

True, but the picture posted by the OP at post #3, the regulator only has one mounting bolt not two for the 698315IL if you had looked the image I posted it gives you the regulator for batteryless systems. PN 698102 superseded to 698315. It has a large electrolytic capacitor that serves as a mini battery to provide voltage feedback for the regulator.

View attachment 65380

View attachment 65381

#23

StarTech

StarTech

I understand that but it is probably the reason it is not working as someone installed the wrong one earlier. Or it was installed at the factory for a battery system. All I can go by is the info that Briggs provides.

Some techs think just if it connects it is the right one.

Some techs think just if it connects it is the right one.

#24

ILENGINE

ILENGINE

Installed at the factory for a battery system is a very good possibility. His engine does come with the steel ring gear flywheel and list an electric starter on the IPL.I understand that but it is probably the reason it is not working as someone installed the wrong one earlier. Or it was installed at the factory for a battery system. All I can go by is the info that Briggs provides.

Some techs think just if it connects it is the right one.

#25

A

Arkus55

A

Arkus55

Thank you for all the comments and suggestions. I checked the stator output voltage with the rectifier connected as suggested. It read 40 Vac with the PTO engaged. So that is working correctly. I also checked the rectifier output again, still at 8 Vdc. So I decided to prove a theory and connected a 12V battery inline (acting like a standard mower battery). The output from the rectifier was now around 13.8 - 14 Vdc. Which I believe means I ordered the wrong part and have been chasing my tail ever since.

Leason learned, I ordered a part that looked exactly the same assuming that it was correct instead of researching for myself. I'm not sure if there is an identical part number, single bolt vs 2 bolt design, that meets my needs. But at least I now have the proper direction.

Thanks again for the help!

Thanks for the help!!!

Leason learned, I ordered a part that looked exactly the same assuming that it was correct instead of researching for myself. I'm not sure if there is an identical part number, single bolt vs 2 bolt design, that meets my needs. But at least I now have the proper direction.

Thanks again for the help!

Please see my description of the troubleshoot I have completed at the bottom of the post. Is this thinking correct? I worked on helicopters for 24 years. But I am very weak on electrical (But learning!). The last question would be just to double check about the single mount bolt vs 2 bolts. If this is the correct rectifier and there isn't one with a single bolt, I will just drill and tap a second mounting hole.I understand that but it is probably the reason it is not working as someone installed the wrong one earlier. Or it was installed at the factory for a battery system. All I can go by is the info that Briggs provides.

Some techs think just if it connects it is the right one.

Thanks for the help!!!

#26

StarTech

StarTech

All I can go by is the service info Briggs provides. There might very well be one version but I have not seen any info on one that is for the battery less system.

Your tests did verify that you have the wrong regulator for your application.

Your tests did verify that you have the wrong regulator for your application.

#27

T

TobyU

T

TobyU

Yes, that's not going to work properly without a battery in the system but you could just order you a heavy duty enough diode and convert your 36 AC volts to DC and or possibly add a resistor so you would have between 12 and 15 volts all the time.

This would make the regulator unnecessary.

This would make the regulator unnecessary.

#28

StarTech

StarTech

It will take a huge wattage resistor that must be heatsinked and a diode that can handle 10-15 amp constant current. Yes the clutch only pulls around 3-5 amps but I have over rated my components by 50-100%. Borderline sizing only leads to early failures.

On top of that the in rush current could destroy the electric clutch. Is it really worth it to experiment trying to make an unregulated power supply for a non constant load.

On top of that the in rush current could destroy the electric clutch. Is it really worth it to experiment trying to make an unregulated power supply for a non constant load.