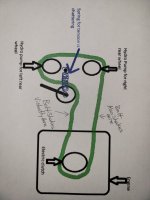

I did watch underneath with it running, and the clutch and hydro pulleys looked smooth, but I haven't had someone work the lap bars while I watch, so I'll give that a try. Forgive my crude drawing, but this explains my issue and shows how the belt is routed. The drawing view is from underneath looking up. Thanks

crude is fine by me

belts shred because they are forced to run against some thing that is not moving

A for instance would be a stick jambed between one of the pulleys & the mower frame

or being on the wrong side of a belt keeper or even a bent fan blade .

If you have the old shredded belt some photos of it would be good because the damage to the belt & it's position will point to the MODE of failure .

Some thing stuck right down deep in one of the pulleys will cause the belt to flick and damage the belt at intervals roughy equal to the circumference of the offending pulley and damaged the root of the V

The tension pulley should run smooth & silently if not it can jamb & force the belt to slide over it which tears the back of the cover .

weak tension spring can cause the belt to flutter as does a belt that is too long .

I test bent tension by grabbing the belt between the right hydro & engine pulley

Pulling the belt towards the engine pulley should cause the engine pulley to rotate right through compression if the tension is correct

Not easy to get your paws in there and of course the brakes must be off .

Frames are known to crack & hydros come loose .

Get the heaviest person around to stand on the frame over the engine then walk back a few feet and have a good look at the wheels

You are checking for them tilting in at the top

If you post th full mower model & serial number I will see if I can pull up an IPL to check for belt keepers

Quite a few mowers have them forward of the hydro pulleys where you can not see or feel them .