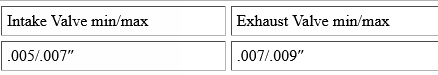

i was planning to grind down the valve end like 1mm and then recheck if it creates the proper valve clearance. basically i have a clearance tool like in the attached image and took the thinnest one and i could insert it thru where the valve closes against the head (right next to the piston), however with the exhaust valve i could not insert it thru (meaning a very tight close). seems like because of the lack of tight closing of the valve it creates a lack of compression. the exhaust valve closes tight and has valve clearance.

i took the image at top dead center (piston at top and valves fully closed). the bottom valve has a very small clearance while the top one does not at all (kinda hard to tell in the image).

i took the image at top dead center (piston at top and valves fully closed). the bottom valve has a very small clearance while the top one does not at all (kinda hard to tell in the image).