You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Piston Ring Installation

- Thread starter FuzzyDriver

- Start date

More options

Export threadFuzzyDriver

Well-Known Member

- Joined

- May 7, 2016

- Threads

- 13

- Messages

- 221

Thanks for the link, Hammer. I can't say it wouldn't have worked, but the principle doesn't look much different than the hose-clamp suggestion that I saw and tried (but forgot to mention in my previous post). If I had it, I'd try it.This would have helped.

CYLINDER PISTON RING COMPRESSOR TOOL KIT CHAINSAW FITS HUSQVARNA STIHL ECHO | eBay

Husqvarna, Jonsered, Echo, Stihl. Piston Ring Compressor Tool Kit. Includes 2 Piston Stop Tools. GET IT NOW. IT'S ON THE WAY! Quickest and Safest Ordering for you! Made in Italy.www.ebay.com

FuzzyDriver

Well-Known Member

- Joined

- May 7, 2016

- Threads

- 13

- Messages

- 221

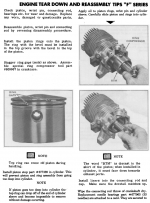

StarTech: As I said in my original post ("Following the tips in the service manual") I was already well aware of all this. Note that the only thing it says about piston installation is: "Apply oil to piston rings, wrist pin and cylinder. Carefully slide piston into cylinder." and it shows a photo with a label pointing to "Ring Compressor". Carefully slide piston into cylinder?! What were they thinking when they wrote that useless "tip"?? No part number given and, from other research I did, the compressor is not available anywhere. Before I started this saga, I printed my own copy of these pages and read them over and over, looking for anything useful with regard to piston installation. But there's nothing there. So no one is going to successfully insert their piston with this information. If you know of an easy, reliable method that works for future readers, please have at it! : )

StarTech

Lawn Royalty

- Joined

- Feb 19, 2020

- Threads

- 120

- Messages

- 12,817

I know you you following the instructions but you must read all of the installation instructions. The part that apparently didn't stick was the paragraph that instructed you to stagger the rings. The second sentence tells you to install the ring compressor. The showing inserting the piston shows that ring is assembly on the piston before installing the ring compressor.

BTW the ring compressor PN is given in the instructions I posted. PN 609967. It is about 84 usd plus shipping if available.

Now of course the manual don't give step by step instructions as they assume you have done this before, have a master tech teaching you, or at least you can think for yourself somewhat. Plus you got to remember these manuals are a lot times written by non technical personnel; therefore, they put in what they are instructed to do at times without questioning things.

It like the Hydro Gear BDP-21L I worked on yesterday. They don't give step by step instructions on how the assemble the pump. Apparently they didn't think about a tech assembling the pump cylinder while the pump is installed on the mower in the upright position. In that position every piston and spring falls out; unless, they are held in position. Do they tell how hold the those in, No.

BTW the ring compressor PN is given in the instructions I posted. PN 609967. It is about 84 usd plus shipping if available.

Now of course the manual don't give step by step instructions as they assume you have done this before, have a master tech teaching you, or at least you can think for yourself somewhat. Plus you got to remember these manuals are a lot times written by non technical personnel; therefore, they put in what they are instructed to do at times without questioning things.

It like the Hydro Gear BDP-21L I worked on yesterday. They don't give step by step instructions on how the assemble the pump. Apparently they didn't think about a tech assembling the pump cylinder while the pump is installed on the mower in the upright position. In that position every piston and spring falls out; unless, they are held in position. Do they tell how hold the those in, No.

Last edited:

FuzzyDriver

Well-Known Member

- Joined

- May 7, 2016

- Threads

- 13

- Messages

- 221

How is that apparent? Does it have anything to do with how to get the piston into the cylinder? Please don't assume that, when talking about how to get the piston into the cylinder, I didn't read other parts that don't address that concern - like staggering the rings. The interesting part of the stagger instructions, though it doesn't have anything to do with how to get it into the cylinder, was that the stagger is to either side of the pin opposite to the exhaust side, since everywhere else you look it says to have the gaps 180º apart.

I've installed rings lots of times, just never in an engine that doesn't have a removable head before.

I missed the compressor part number. Sorry. Jack's Small Engines has it for 92$, but I've found listed parts on their site before that they didn't actually have. The Walbro carburetor air filter cover comes to mind. For $92 I could spend a lot of tedious time working those rings in, heh heh.

Well, the issue you ran into yesterday is yet another example of a poorly written procedure. I was a nuclear power plant technical procedure and surveillance writer. I'd have gotten canned if I left out significant things like that, regardless of the training that the technicians had gone through (and there is TONS of training they go through).

I've installed rings lots of times, just never in an engine that doesn't have a removable head before.

I missed the compressor part number. Sorry. Jack's Small Engines has it for 92$, but I've found listed parts on their site before that they didn't actually have. The Walbro carburetor air filter cover comes to mind. For $92 I could spend a lot of tedious time working those rings in, heh heh.

Well, the issue you ran into yesterday is yet another example of a poorly written procedure. I was a nuclear power plant technical procedure and surveillance writer. I'd have gotten canned if I left out significant things like that, regardless of the training that the technicians had gone through (and there is TONS of training they go through).

Hammermechanicman

Lawn Addict

- Joined

- Jan 10, 2020

- Threads

- 69

- Messages

- 3,927

These finger pinch type ring compressors make installing pistons and rings a snap.Thanks for the link, Hammer. I can't say it wouldn't have worked, but the principle doesn't look much different than the hose-clamp suggestion that I saw and tried (but forgot to mention in my previous post). If I had it, I'd try it.

StarTech

Lawn Royalty

- Joined

- Feb 19, 2020

- Threads

- 120

- Messages

- 12,817

So Fuzzy you thought of every possible way someone can do something other than a set way of doing things. That great. But I still think someone could still a way that you didn't think of. But what I was doing was probably never though of as to installing the cylinder with 8 eight pistons and springs facing down loose. They just fall out if you are not good enough to figure out a way to prevent it. With only about half inch on the sides you cant just use your fingers either or try to reposition the pistons once fall out of the cylinder as all 8 got to go in all at once during the insertion. It can be done with enough thought and engineering outside the service manual which was done for on the bench servicing only.

One thing I have seen is our techs nowadays just don't seem to use their brains to think outside the service manuals. Most can't even figure their way out a wet paper bag with both ends open; unless, it is shown in detail in a manual. Many of us older guys know that service manuals don't cover everything in 100% detail. Plus many pieces of equipment I work on don't even have a written service manual.

Most 2 cycles I do the piston insertion on are done from the bottom of the cylinder as many OEMs provide a built-in taper. Even then a pick type tool maybe needed to center up the rings. Actually using a compression tool would be very hard to remove after insertion as the lower crankcase is not fully open after the piston is inserted. Now of course I am referring to chainsaws and string/bush cutters engines.

As for the many 2 cycles that I have worked on they also have locating pins to prevent the rings from rotating. Here in the online 1978 F engine manual I see no indication that they are used so the rings would be able rotate while the engine is in operation. Grant it that the rings may never rotate much since it just mainly an up down motion. The pins I referring prevent the rings ends from getting hung in an open port. Actually I have only seen one two cycle Lawn Boy and it was such a piece of junk it was not worth the effort to just look inside the engine. I just sent on its way to be recycled. So I have no knowledge of how the ports inside cylinder are done.

Hammer those pinch looks like they will work according to image I have here of an open notch in the cylinder. Another way is a sleeve of aluminum with pinch tabs and a pair of long bent needle nose vise grips to pinch it very close to tight so the piston can slide into the cylinder. Might even be able to use the medical retractors I have here that I modified for in areas like this. I have also use soda pop cans for this as they are thicker gauge metal most times than beer cans.

One thing I have seen is our techs nowadays just don't seem to use their brains to think outside the service manuals. Most can't even figure their way out a wet paper bag with both ends open; unless, it is shown in detail in a manual. Many of us older guys know that service manuals don't cover everything in 100% detail. Plus many pieces of equipment I work on don't even have a written service manual.

Most 2 cycles I do the piston insertion on are done from the bottom of the cylinder as many OEMs provide a built-in taper. Even then a pick type tool maybe needed to center up the rings. Actually using a compression tool would be very hard to remove after insertion as the lower crankcase is not fully open after the piston is inserted. Now of course I am referring to chainsaws and string/bush cutters engines.

As for the many 2 cycles that I have worked on they also have locating pins to prevent the rings from rotating. Here in the online 1978 F engine manual I see no indication that they are used so the rings would be able rotate while the engine is in operation. Grant it that the rings may never rotate much since it just mainly an up down motion. The pins I referring prevent the rings ends from getting hung in an open port. Actually I have only seen one two cycle Lawn Boy and it was such a piece of junk it was not worth the effort to just look inside the engine. I just sent on its way to be recycled. So I have no knowledge of how the ports inside cylinder are done.

Hammer those pinch looks like they will work according to image I have here of an open notch in the cylinder. Another way is a sleeve of aluminum with pinch tabs and a pair of long bent needle nose vise grips to pinch it very close to tight so the piston can slide into the cylinder. Might even be able to use the medical retractors I have here that I modified for in areas like this. I have also use soda pop cans for this as they are thicker gauge metal most times than beer cans.

Last edited:

bertsmobile1

Lawn Royalty

- Joined

- Nov 29, 2014

- Threads

- 65

- Messages

- 24,995

They work a treat as does the similar tools with a set of ratchet pliers to replace your fingers.Thanks for the link, Hammer. I can't say it wouldn't have worked, but the principle doesn't look much different than the hose-clamp suggestion that I saw and tried (but forgot to mention in my previous post). If I had it, I'd try it.

I inherited a set with the business

Now there was one question that has always bugged me

What are those 2 bent rods supposed to be used for ?

Hammermechanicman

Lawn Addict

- Joined

- Jan 10, 2020

- Threads

- 69

- Messages

- 3,927

"One thing I have seen is our techs nowadays just don't seem to use their brains to think outside the service manuals. Most can't even figure their way out a wet paper bag with both ends"

Stop talking about me. I am offended.

The pinch type compressors work good for both top and bottom of cylinder piston insertion. Once the rings start in the bore the plastic will spread wide enough to take off the piston. If you work on a lot of stihl chainsaws two must have tools are these and a tool to install the brake spring.

Stop talking about me. I am offended.

The pinch type compressors work good for both top and bottom of cylinder piston insertion. Once the rings start in the bore the plastic will spread wide enough to take off the piston. If you work on a lot of stihl chainsaws two must have tools are these and a tool to install the brake spring.