You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Pins on Toro MX5060 don't work

#1

J

jcworks

J

jcworks

2013 Toro MX5060 (50") zero turn. It doesn't matter if the pins are pulled out or pushed in, the machine still moves. It doesn't seem to disengage the transaxle for manually pushing the mower. For mowing, the machine works fine.

Today I tested to see if the machine would move with the pins pushed in. I pushed the pins in on both sides, started the mower and could drive it same as I've always done. I then pulled them out as they should be for driving. A long time ago I suspected something was not right because its very hard to push manually. Pushing it manually is the only time this matters. Otherwise it moves as it should when mowing. But the pins (both sides) do not appear to be disengaging the transaxle. What's wrong here? Expensive to fix ?

Today I tested to see if the machine would move with the pins pushed in. I pushed the pins in on both sides, started the mower and could drive it same as I've always done. I then pulled them out as they should be for driving. A long time ago I suspected something was not right because its very hard to push manually. Pushing it manually is the only time this matters. Otherwise it moves as it should when mowing. But the pins (both sides) do not appear to be disengaging the transaxle. What's wrong here? Expensive to fix ?

#3

J

jcworks

J

jcworks

I'm pushing them in, and with that small ring on the pin latched behind the frame. That small ring is not visible when I push them in. So I assume they're "latched" in. This last time (today) I laid down on the floor and pushed them in as far as they would go before I started the engine. The machine still moves. I assume I'm doing it right, I don't know what else I could do it should be as simple as pushing it in with that ring on the pin latched behind the body (red) of the machine. I also reached under there with my hand and pushed the arm that the pins are attached and pushed them as far as they would go. Same results.

I've noticed this just today....it may be something, maybe not. With the engine running if I push the pins in as far as they go with my fingers and holding it there I can feel something --- like something touching spinning gears

I've noticed this just today....it may be something, maybe not. With the engine running if I push the pins in as far as they go with my fingers and holding it there I can feel something --- like something touching spinning gears

#4

StarTech

StarTech

Then something is definitely not right but I am not there to look for myself so other will need to chime in. It does appear you have the HydroGear ZT2800 units.

#5

J

jcworks

J

jcworks

Thanks Star Tech. It sounds like this will likely be taking out both transaxles and looking inside them. Sounds really expensive....and thats IF I can find a shop qualified at that.

Right now I'm thinking since I can use it I might wait for fall when the mowing season is over; and I don't really want to spend big bucks on it right now.

Right now I'm thinking since I can use it I might wait for fall when the mowing season is over; and I don't really want to spend big bucks on it right now.

#6

B

bertsmobile1

B

bertsmobile1

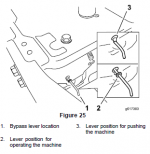

Other way round

You pull them OUT to dissengage and push in to engage

So they come out and the ring prevents them pulling back in so you can push the mower

You pull them OUT to dissengage and push in to engage

So they come out and the ring prevents them pulling back in so you can push the mower

#7

J

jcworks

J

jcworks

#8

B

bertsmobile1

B

bertsmobile1

Sorry about that

All of the ones I have played with were in for drive & out for push .

All of the ones I have played with were in for drive & out for push .

#9

StarTech

StarTech

And it is a little weird on how they says to do it. Personally I yet one that pushes to disengage here in my shop.

#10

B

bertsmobile1

B

bertsmobile1

Starting to sound more like a printing error .

If you get under there and have a good look the rod usually goes to an arm which slides on a protrusion in the case.

That protrusion will have a detent in the run position to hold the bypass lever in the run position

Usually when you pull the wire you can feel the resistance as you pull the arm out of the detent then it goes slack

Some actually have detents at both open & closed positions , another of those little differences that create variant numbers and drive techs crazy trying to find replacements for obsolete drives .

If you get under there and have a good look the rod usually goes to an arm which slides on a protrusion in the case.

That protrusion will have a detent in the run position to hold the bypass lever in the run position

Usually when you pull the wire you can feel the resistance as you pull the arm out of the detent then it goes slack

Some actually have detents at both open & closed positions , another of those little differences that create variant numbers and drive techs crazy trying to find replacements for obsolete drives .

#11

D

Divot

D

Divot

I have the 2800 hydro on my gravely and I went through this once when I got stuck. You have to pull them out and latch them in a small notch on the pin to the frame to disengage the trans not just pull out It was frustrating because my field of view was obstructed with a mower sunk in mud. Finally got lucky and noticed the tiny notch and once engaged it rolled easily

#12

S

SamB

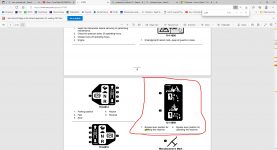

HOWEVER: This is a copy and paste from the Toro manual. Same as other posts. Mine are opposite! Go figure.

S

SamB

That's how my HyrdoGear transmissions work on my CZ42175. "IN" is Drive, "Out " is disengaged.Other way round

You pull them OUT to dissengage and push in to engage

So they come out and the ring prevents them pulling back in so you can push the mower

HOWEVER: This is a copy and paste from the Toro manual. Same as other posts. Mine are opposite! Go figure.

Attachments

#13

J

jcworks

J

jcworks

Bertsmobile1, the pin is connected to an arm as you say. But there is not resistance at all that I can feel. It just slides back and forth as if not connected to anything.....both sides. Another thing l didnt mention is those pins are not straight. They are both in a rather oddly bent shape. Maybe supposed to be that way, l don't know. I

'll try to get under there and take a look again when l get home next week. l'll be back on here with what l see. Maybe l'll post a picture or video if this site allows it

'll try to get under there and take a look again when l get home next week. l'll be back on here with what l see. Maybe l'll post a picture or video if this site allows it

#14

J

jcworks

J

jcworks

And it is a little weird on how they says to do it. Personally I yet one that pushes to disengage here in my shopSt

#15

J

jcworks

J

jcworks

StarTech and bertsmobile1, I have uploaded two short videos of this issue to Youtube so you can see what I'm seeing. Here they are. [This is the first time I've uploaded to Youtube. I hope I got it right]

#16

J

jcworks

J

jcworks

SamB frankly it has me baffled. The videos I posted (hope they are visible) shows what I'm going through. The machine moves whether the pin (levers) are in or out. The trans is never disengaged.That's how my HyrdoGear transmissions work on my CZ42175. "IN" is Drive, "Out " is disengaged.

HOWEVER: This is a copy and paste from the Toro manual. Same as other posts. Mine are opposite! Go figure.

#17

B

bertsmobile1

It is not spring loaded it just slides left right very smoothly

The resistance in the lap bar is provided by external springs &/or air cylinders

Go to Toro & download the service manual and the parts book

B

bertsmobile1

The motion control simply moves the swash plate inside the transmission.Bertsmobile1, the pin is connected to an arm as you say. But there is not resistance at all that I can feel. It just slides back and forth as if not connected to anything.....both sides. Another thing l didnt mention is those pins are not straight. They are both in a rather oddly bent shape. Maybe supposed to be that way, l don't know. I

'll try to get under there and take a look again when l get home next week. l'll be back on here with what l see. Maybe l'll post a picture or video if this site allows it

It is not spring loaded it just slides left right very smoothly

The resistance in the lap bar is provided by external springs &/or air cylinders

Go to Toro & download the service manual and the parts book

#18

B

bertsmobile1

B

bertsmobile1

In video 1 the lever you are moving is the bypass valve, not the brake

The brake is on the other side

There is no connection between the bypass lever & the brake

The brake is electronic & connected to the lap bars via a module which regularly breaks down .

with no load on the wheels they will rotate with the bypass open or closed

But with the bypass open you should be able to grab the wheel & stop it

With the bypass close you should not be able to stop them turning .

The brake is on the other side

There is no connection between the bypass lever & the brake

The brake is electronic & connected to the lap bars via a module which regularly breaks down .

with no load on the wheels they will rotate with the bypass open or closed

But with the bypass open you should be able to grab the wheel & stop it

With the bypass close you should not be able to stop them turning .

#19

J

jcworks

J

jcworks

bertsmobile1, hmmmm. I can hear the brake engaging and disengaging when you turn the ignition on or off - or, move the steering control arms in or out. So I think the brake is working like it should. When I tried to roll it I turned the ignition to the ON position and I'd hear the brake; then push the steering arms in and you hear the brake again (disengaging). So, I don't know, if the module you mentioned was not working right I'd think I wouldn't hear the brake at all. I don't know. Anyway, I'm mowing with it.In video 1 the lever you are moving is the bypass valve, not the brake

The brake is on the other side

There is no connection between the bypass lever & the brake

The brake is electronic & connected to the lap bars via a module which regularly breaks down .

with no load on the wheels they will rotate with the bypass open or closed

But with the bypass open you should be able to grab the wheel & stop it

With the bypass close you should not be able to stop them turning .

#20

J

jcworks

J

jcworks

bertsmobile1, you may be right about the printing error -- I don't know. I just know when I try to push it, it feels the same whether the pins or in or out. Its always been like this. Now, I'm an old guy but still you'd think it'd push pretty easy one way or the other. But of course I'm always doing this on grass too. I think next time I have it in the shop for something I'll make an attempt to have the guy come look at it while I'm there. See these two videos showing it.

I hope with the videos maybe you can see something I can't.

#21

B

bertsmobile1

B

bertsmobile1

The pins do not control the brake they control the bypass valve between the pump & motor .

The brake is a toothed plate which engages with a toothed wheel on the side of your transmission

Here is a little video that explains how it works

Toro brake module

Now as to your bypass valves

When there is no load on the wheels some oil will go through the motors so on a jack the wheels will spin, pins in or out .

Having said that the control rods are thin & do bend so check that the lever on the side of the box that you keep on thinking is the brake ( which it is not ) moves to the end of its travel, if not then straiten or bend the wire as needed .

To disengage the brake manually you have to get under the mower and remove the brake rods from the brake module .

The brake is on the INSIDE of the transmissions wher the arm you are playing with os on the OUTSIDE of the transmissions.

The instructions for doing this are in your owners manual.

If you have lost yours then it is a free download from Toro but you will need the numbers off the mowers ID tag to make sure you get the correct one .

The brake is a toothed plate which engages with a toothed wheel on the side of your transmission

Here is a little video that explains how it works

Toro brake module

Now as to your bypass valves

When there is no load on the wheels some oil will go through the motors so on a jack the wheels will spin, pins in or out .

Having said that the control rods are thin & do bend so check that the lever on the side of the box that you keep on thinking is the brake ( which it is not ) moves to the end of its travel, if not then straiten or bend the wire as needed .

To disengage the brake manually you have to get under the mower and remove the brake rods from the brake module .

The brake is on the INSIDE of the transmissions wher the arm you are playing with os on the OUTSIDE of the transmissions.

The instructions for doing this are in your owners manual.

If you have lost yours then it is a free download from Toro but you will need the numbers off the mowers ID tag to make sure you get the correct one .

#22

J

jcworks

J

jcworks

bertsmobile1, (As to putting it on a jack and seeing the wheels move): Thanks for explaining that, I didn't know that. So, the video of me demonstrating the wheels spinning does NOT even apply to my complaint about being hard to manually push. From what you just said the video doesn't really illustrate anything. Thanks for that

A - (As for the parking brake not being connected in any way to the pins): Yes, I knew that. Thanks.

B - The only time this issue is an issue for me is when I get the mower stuck (like in the ditch) and I have to pull it out with the truck. Or, for example once the drive belt broke and I had to push it up on a trailer to take it to the shop. All other times the mower works as it should -- forward and backward. In those two incidents I just stated the manual says push the pins in to disengage the trans. Its that that does not seem to work. I push the pins in, turn the ignition to ON, and pull the control arms inward like in driving mode. Its then that it does not seem to make any difference. The time I had to load it on a trailer because the drive belt broke I had to get someone to help me push it and line it up to the tailgate, and push it up onto the trailer. It was tough. The wheels were rolling but was real difficult for two men to push up the ramp. And, I thought it was way to difficult for two men to push even on the ground. So, its not the electric parking brake that I thought was the issue; but whether the pins are are disengaging the trans.

B - (As for the pins being bent): Yes, they are thin like you said. They do have what I'd call a dog-leg bend to them.....I think both of them. And I think they came that way as they both have the same bend (I think). I'll have to take another look at that just to be sure. And, they do seem to move to the end of its travel. I'll go back and check that on both sides.

C - It does not matter whether the pins are pushed in or out; makes no difference at all in operating the machine. I can drive it forward or backward with the pins in either position.

A - (As for the parking brake not being connected in any way to the pins): Yes, I knew that. Thanks.

B - The only time this issue is an issue for me is when I get the mower stuck (like in the ditch) and I have to pull it out with the truck. Or, for example once the drive belt broke and I had to push it up on a trailer to take it to the shop. All other times the mower works as it should -- forward and backward. In those two incidents I just stated the manual says push the pins in to disengage the trans. Its that that does not seem to work. I push the pins in, turn the ignition to ON, and pull the control arms inward like in driving mode. Its then that it does not seem to make any difference. The time I had to load it on a trailer because the drive belt broke I had to get someone to help me push it and line it up to the tailgate, and push it up onto the trailer. It was tough. The wheels were rolling but was real difficult for two men to push up the ramp. And, I thought it was way to difficult for two men to push even on the ground. So, its not the electric parking brake that I thought was the issue; but whether the pins are are disengaging the trans.

B - (As for the pins being bent): Yes, they are thin like you said. They do have what I'd call a dog-leg bend to them.....I think both of them. And I think they came that way as they both have the same bend (I think). I'll have to take another look at that just to be sure. And, they do seem to move to the end of its travel. I'll go back and check that on both sides.

C - It does not matter whether the pins are pushed in or out; makes no difference at all in operating the machine. I can drive it forward or backward with the pins in either position.

#23

B

bertsmobile1

B

bertsmobile1

OK so I am onboard now.

Remember I am not standing there next to you drinking your beer & farting so all we have to go in is the words you posted .

It would appear the bypass valves are not working as designed.

My first thought would be to see if you could move the levers further back than the bypass rod pulls them .

When the bypass is open ( push mode ) the wheels should spin easily but not as free as a car in neutral

If it was just one then the prospect of a defective drive would present itself but not for both of them unless some idiot removed the bypass rods rotated the bypass valves a full turn then put the rods back on

Remember I am not standing there next to you drinking your beer & farting so all we have to go in is the words you posted .

It would appear the bypass valves are not working as designed.

My first thought would be to see if you could move the levers further back than the bypass rod pulls them .

When the bypass is open ( push mode ) the wheels should spin easily but not as free as a car in neutral

If it was just one then the prospect of a defective drive would present itself but not for both of them unless some idiot removed the bypass rods rotated the bypass valves a full turn then put the rods back on

#24

J

jcworks

J

jcworks

I think I see what you mean. Do you think maybe this is something I could correct at home? I mean if the rod (pins) are removable would I be able to rotate those valves manually and then reattach the pins? Or maybe best let the shop do that. I'm not nearly as well-versed as you in this stuff but I get the mental picture those valves inside the trans are like a choke on a lawnmower carbuerator.

I agree. These forums are really good so people can discuss stuff; but its not quite like a face to face, and all we can go by is printed word. Thats good, but it has its limits.

I agree. These forums are really good so people can discuss stuff; but its not quite like a face to face, and all we can go by is printed word. Thats good, but it has its limits.

#25

B

bertsmobile1

B

bertsmobile1

I ask people to get a copy of the parts book for their mower so they can at least use the correct terms

In most cases & toro is one of them it is a free download ( service manual for your mower is free too ) because it then makes it clear what the thinga ma bobby that screws into the do dad is .

Unless the responder is very familiar with the exact model, most of us pull up the parts manual before we attempt to answer a question so I don't think it is an onerous task to ask the mower owner to do the same thing.

When we are all singing from the same song sheet you can get beautiful sounds.

The bypass valve is just a ball valve like you us for water ( although some are a cone ) but the same thing

If the release rod pushes down on a pin then they are a piston valve .

The rods should just twist a bit then slide out of the arms .

I have occasionally come across some mowers where the bypass rod has been bent by something so wont fully open and have had 1 & only 1 in 11 years where the oil had so much debris in it that it had blocked the bypass valve off .

In most cases & toro is one of them it is a free download ( service manual for your mower is free too ) because it then makes it clear what the thinga ma bobby that screws into the do dad is .

Unless the responder is very familiar with the exact model, most of us pull up the parts manual before we attempt to answer a question so I don't think it is an onerous task to ask the mower owner to do the same thing.

When we are all singing from the same song sheet you can get beautiful sounds.

The bypass valve is just a ball valve like you us for water ( although some are a cone ) but the same thing

If the release rod pushes down on a pin then they are a piston valve .

The rods should just twist a bit then slide out of the arms .

I have occasionally come across some mowers where the bypass rod has been bent by something so wont fully open and have had 1 & only 1 in 11 years where the oil had so much debris in it that it had blocked the bypass valve off .

#26

J

jcworks

J

jcworks

Gotcha. Understood and makes sense.

Its a 2013 Toro MX5060. Model # 74641. Serial # 313001378. 300 hrs on the time meter.

THE FOLLOWING IS FROM https://www.toro.com/en/parts/partdetails?id=40409&iid=422583&pid=468474

Here are the parts:

LEFT HAND BYPASS ROD Part #: 121-2965 . #19 in the schematic.

FLAT WASHER Part #: 3256-22. #29 in the schematic which shows (2). My machine has just (1), both sides right & left

PIN-COTTER [HAIR .080 NO.2] Part #: 1-806003

BYPASS ARM KIT Part #: 107-2489 Replaces 112-9852 , #34 in the schematic of 2nd attachment

The bypass rods connect to the bypass arm kit. left side and right. The arm kit slides back and forth horizontally

Its a 2013 Toro MX5060. Model # 74641. Serial # 313001378. 300 hrs on the time meter.

THE FOLLOWING IS FROM https://www.toro.com/en/parts/partdetails?id=40409&iid=422583&pid=468474

Here are the parts:

LEFT HAND BYPASS ROD Part #: 121-2965 . #19 in the schematic.

FLAT WASHER Part #: 3256-22. #29 in the schematic which shows (2). My machine has just (1), both sides right & left

PIN-COTTER [HAIR .080 NO.2] Part #: 1-806003

BYPASS ARM KIT Part #: 107-2489 Replaces 112-9852 , #34 in the schematic of 2nd attachment

The bypass rods connect to the bypass arm kit. left side and right. The arm kit slides back and forth horizontally

Attachments

#27

B

bertsmobile1

B

bertsmobile1

Doubt that the numbers of washers would make any difference

The arm they connect to moves about 1/4 to 1/8 of a turn

The rods used to be heavy with a spring so when you got to the end of the travel of the arm the spring just stretched and most were spring loaded to return to the run position .

Then some stinge worked out you could remove the spring and just make the rod thin so it would flex .

So put the rod in the push position then put your finger on the arm and see if it moves back any further

This is easier said than done .

If the arm moves further back than the rod can pull it , bend the rod a little more .

The arm they connect to moves about 1/4 to 1/8 of a turn

The rods used to be heavy with a spring so when you got to the end of the travel of the arm the spring just stretched and most were spring loaded to return to the run position .

Then some stinge worked out you could remove the spring and just make the rod thin so it would flex .

So put the rod in the push position then put your finger on the arm and see if it moves back any further

This is easier said than done .

If the arm moves further back than the rod can pull it , bend the rod a little more .

#28

J

jcworks

J

jcworks

I agree with you on the change by someone to remove that spring. I've seen similar stuff like that so much the last 20 years or so. You get something that works just great, and eventually some new guru comes along and "improves" it. I "think" I did that before to see if it would move further. Bert this has been an issue so long and my memory isnt as good as it use to be so I'm not 100% sure I did it the way you describe , that its, pushing the arm instead of the rod. That makes sense. If I did do that before it would not go any further.

However, I can't try that until I get the machine back from the shop. The starter is shot. Yesterday I cranked it up but had to pour a little gas in the air intake before it would start after sitting up all winter. The starter has been whining for a couple of years. I knew it would be toast sooner or later. It barely turned over when I tried to crank the engine -- dragging real bad. I had a brand new battery in it. So after it cranked yesterday I decided I'd better get it on the trailer while its running and before I got stuck again with not being able to get it on the trailer. I am having them put on a new starter and while its there a new fuel and air filter. I know the starter won't be cheap. Also, I told them about this not disengaging issue to check out too. I don't have a real good feel they'll solve that though. They cautioned me about having to go into the trans; I could tell they did not really want to have to do that. Maybe their mechanics weren't well versed in dealing with that. Or maybe it was because of the cost. I don't know, I'm just guessing on all that. But he indicated that if they could not fix it externally it might be best to just leave well enough alone as I can mow with it. We'll see. He said I'll have to wait a couple weeks or so. So I cant do the test with the arm till I get it back. You're right, this will be easier said than done.

*I just had a thought on the bypass arm. Assuming that the shop cannot fix the disengaging issue externally, I'm wondering if I removed the cotter pin and the bypass rod from the bypass arm and then push the bypass arm forward as far as possible. If the machine continues to not disengage I'd think that would tell me its an internal issue. If it does disengage it would have to be it has something to do with the bypass rods. Maybe I'm putting cart before the horse -- and just wait to see what they tell me.

However, I can't try that until I get the machine back from the shop. The starter is shot. Yesterday I cranked it up but had to pour a little gas in the air intake before it would start after sitting up all winter. The starter has been whining for a couple of years. I knew it would be toast sooner or later. It barely turned over when I tried to crank the engine -- dragging real bad. I had a brand new battery in it. So after it cranked yesterday I decided I'd better get it on the trailer while its running and before I got stuck again with not being able to get it on the trailer. I am having them put on a new starter and while its there a new fuel and air filter. I know the starter won't be cheap. Also, I told them about this not disengaging issue to check out too. I don't have a real good feel they'll solve that though. They cautioned me about having to go into the trans; I could tell they did not really want to have to do that. Maybe their mechanics weren't well versed in dealing with that. Or maybe it was because of the cost. I don't know, I'm just guessing on all that. But he indicated that if they could not fix it externally it might be best to just leave well enough alone as I can mow with it. We'll see. He said I'll have to wait a couple weeks or so. So I cant do the test with the arm till I get it back. You're right, this will be easier said than done.

*I just had a thought on the bypass arm. Assuming that the shop cannot fix the disengaging issue externally, I'm wondering if I removed the cotter pin and the bypass rod from the bypass arm and then push the bypass arm forward as far as possible. If the machine continues to not disengage I'd think that would tell me its an internal issue. If it does disengage it would have to be it has something to do with the bypass rods. Maybe I'm putting cart before the horse -- and just wait to see what they tell me.

#29

B

bertsmobile1

B

bertsmobile1

yes that would work but you will need something to stop the valve arm springing back

Internally most are spring loaded to the drive position

Internally most are spring loaded to the drive position

#30

J

jcworks

J

jcworks

OK. I understand. Thanks. I'll be waiting to see what the dealer says and if its unchanged I'll do this when I get it back. I'll let you know in a couple weeks or so. Thanks, Bert

#31

J

jcworks

J

jcworks

OK. I understand. Thanks. I'll be waiting to see what the dealer says and if its unchanged I'll do this when I get it back. I'll let you know in a couple weeks or so. Thanks, Bert

#32

J

jcworks

J

jcworks

OK. I understand. Thanks. I'll be waiting to see what the dealer says and if its unchanged I'll do this when I get it back. I'll let you know in a couple weeks or so. Thanks, Bert

#33

J

jcworks

J

jcworks

bertmobile1,

UPDATE: I went to the shop to check on the progress and talked to the mechanic that would be doing the work. He said they were waiting on parts; they had determined the trans seemed OK and had plenty of pressure for operation . And they had determined the only thing it could be was the brake box (or maybe he called it braker box). It was a black box looking thing visible if you lifted the seat. It may be the same thing mentioned in the video you sent to me. Any way its an electronic thing and he said that had influence too over disengaging the trans. I don't know -- I'm not a mower mechanic, I'm just vaguely familiar with what makes them go. So, I'm waiting to see how this goes and if it fixes the disengagement issue.

UPDATE: I went to the shop to check on the progress and talked to the mechanic that would be doing the work. He said they were waiting on parts; they had determined the trans seemed OK and had plenty of pressure for operation . And they had determined the only thing it could be was the brake box (or maybe he called it braker box). It was a black box looking thing visible if you lifted the seat. It may be the same thing mentioned in the video you sent to me. Any way its an electronic thing and he said that had influence too over disengaging the trans. I don't know -- I'm not a mower mechanic, I'm just vaguely familiar with what makes them go. So, I'm waiting to see how this goes and if it fixes the disengagement issue.

#34

B

bertsmobile1

B

bertsmobile1

I think they are spinning you a line

But time will tell

AFAIK all the brake module dose is to move the toothed locking plates onto the toothed wheels to lock the axels .

It also has a set of contacts to lock out the starter motor unless the brakes are on

Never had to touch one to push a Time Cutter unless the battery was flat as the brake module is spring loaded on .

But time will tell

AFAIK all the brake module dose is to move the toothed locking plates onto the toothed wheels to lock the axels .

It also has a set of contacts to lock out the starter motor unless the brakes are on

Never had to touch one to push a Time Cutter unless the battery was flat as the brake module is spring loaded on .

#35

J

jcworks

Just from our conversation and my learning from you I would think the issue has something to do with those by-pass valves that the bypass arm is connected to. I'm wondering if those bypass valves lift out once you disconnect the bypass arm?? Or if you have to tear into the trans to take a look at that. (*Speaking of the trans, the fluid has never been changed because I was told by two different dealers there was no need to do that till about 500 hrs. It has 300 on it.

J

jcworks

Well I hope you're wrong but I have a gut feeling you're right. When they call me that its ready, if it doesn't freely roll with the rods pushed in I won't want to pay for a part that didn't solve the problem -- they're probably not a cheap part. I'll guess I'll cross that difficult bridge if and when I get to it. The guy at the repair & parts counter is usually a pretty straight up guy. So we'll see. On concrete I "think" it should roll freely with just the push of just your hands.I think they are spinning you a line

But time will tell

AFAIK all the brake module dose is to move the toothed locking plates onto the toothed wheels to lock the axels .

It also has a set of contacts to lock out the starter motor unless the brakes are on

Never had to touch one to push a Time Cutter unless the battery was flat as the brake module is spring loaded on .

Just from our conversation and my learning from you I would think the issue has something to do with those by-pass valves that the bypass arm is connected to. I'm wondering if those bypass valves lift out once you disconnect the bypass arm?? Or if you have to tear into the trans to take a look at that. (*Speaking of the trans, the fluid has never been changed because I was told by two different dealers there was no need to do that till about 500 hrs. It has 300 on it.

#36

B

bertsmobile1

B

bertsmobile1

Not as far as I know

I no longer repair any hydros, I am not set up for it, my workshop is on a farm so there is a lot of fine dust / pollen / seeds blowing around .

There is a specialist workshop 1/2 hour away who do an excellent job and give me a full 12 month warranty on their work.

Plus they come back fully purged with the correct grade of oil s for me it is just a pull then replace .

As for you having a defective valve in your drive, never heard of it happening .

The chances of you having the the only 2 would be remote and especially as the left & right drives are not made as a set .

I no longer repair any hydros, I am not set up for it, my workshop is on a farm so there is a lot of fine dust / pollen / seeds blowing around .

There is a specialist workshop 1/2 hour away who do an excellent job and give me a full 12 month warranty on their work.

Plus they come back fully purged with the correct grade of oil s for me it is just a pull then replace .

As for you having a defective valve in your drive, never heard of it happening .

The chances of you having the the only 2 would be remote and especially as the left & right drives are not made as a set .

#37

J

jcworks

J

jcworks

bertsmobile1, they called that it was ready so I went to pick it up and tested it before to see if i could push it. There was no change. The wheels do roll but with a heck of a lot of pushing just the same as it was before. The only thing left that I can see now is its internal inside the trans. And probably like you said....the bypass valves. You'd surely think though it would not be the same on both sides. I can mow with it just fine. Its just when you have to push it , for whatever reason. He said there was another one just like it, but it was a 4225, not an MX5060 like mine is. So I tried to push it and I could. It was hard too, but it was a lot easier than mine. He attributed that to mine is a bigger mower and heavier and mine has the welded steel deck and not the stamped deck the 4225 had. So, mine probably is heavier I dont doubt that. But you can still run it with the bypass rods pushed in or pulled out....doesn't matter, it still drives either way. Weird...I know. I'd sure like to put this question to your friend over the phone that works on hydros.

#38

B

bertsmobile1

B

bertsmobile1

To put it in plain language

Total Bull Dust

I have TimeCutters, Z-Masters & even Titans in my run & they all easily push, even on grass with the by-pass open .

Your mowers should have HydroGear ZT-2800 transmissions and they should roll freely with the bypass fully open

As suggested before, get under the mower & check that the bypass valve moves all the way to the end of it's travel before the rods you pull get to the lock ring

If necessary remove the bypass rods , and move the lever on the gear box by hand ( they can be a little stiff )

I would almost gurantee that the arm ( lever if you like ) is not moving all the way that it should .

As for what else you can do try writing ( not phoning ) to HydroGear and ask why their units installed on your mower do not roll freely.

You will need the model & serial numbers from the stickers on them .

And the weight of the mower means nothing unless you are pushing up hill.

I had a friend who worked at the Jet base and they used to have "drag races" to see who could pull a 727 the furthest in 2 minutes and a 727 ( even empty ) weighs a lot more than your mower .

I would also write to Toro and ask them if the mower should push freely and tell them exactly what your dealer told you ( name the dealer & the person if you know it ) .

Toro do not tollerate poor customer service and in particular dealers who lie to customers .

When you write to HydroGear & Toro, have the parts book open and use the correct names & part numbers so they know exactly what you are talking about . If you start talking about "pins" your request will get nowhere .

Total Bull Dust

I have TimeCutters, Z-Masters & even Titans in my run & they all easily push, even on grass with the by-pass open .

Your mowers should have HydroGear ZT-2800 transmissions and they should roll freely with the bypass fully open

As suggested before, get under the mower & check that the bypass valve moves all the way to the end of it's travel before the rods you pull get to the lock ring

If necessary remove the bypass rods , and move the lever on the gear box by hand ( they can be a little stiff )

I would almost gurantee that the arm ( lever if you like ) is not moving all the way that it should .

As for what else you can do try writing ( not phoning ) to HydroGear and ask why their units installed on your mower do not roll freely.

You will need the model & serial numbers from the stickers on them .

And the weight of the mower means nothing unless you are pushing up hill.

I had a friend who worked at the Jet base and they used to have "drag races" to see who could pull a 727 the furthest in 2 minutes and a 727 ( even empty ) weighs a lot more than your mower .

I would also write to Toro and ask them if the mower should push freely and tell them exactly what your dealer told you ( name the dealer & the person if you know it ) .

Toro do not tollerate poor customer service and in particular dealers who lie to customers .

When you write to HydroGear & Toro, have the parts book open and use the correct names & part numbers so they know exactly what you are talking about . If you start talking about "pins" your request will get nowhere .

#39

J

jcworks

J

jcworks

Thanks bertsmobile1. I'll look up Hydro and write to them (email if they have that), and the same with Toro. But first, I'll see if I can remove those two rods from the by pass arm like you said and push the bypass arm any further than it goes with the rods attached to it. I may have to tie the arms in place to test it, or maybe use duct tape to hold it because it moves very freely now. I've got some stuff going on at home I've got to get to today first.To put it in plain language

Total Bull Dust

I have TimeCutters, Z-Masters & even Titans in my run & they all easily push, even on grass with the by-pass open .

Your mowers should have HydroGear ZT-2800 transmissions and they should roll freely with the bypass fully open

As suggested before, get under the mower & check that the bypass valve moves all the way to the end of it's travel before the rods you pull get to the lock ring

If necessary remove the bypass rods , and move the lever on the gear box by hand ( they can be a little stiff )

I would almost gurantee that the arm ( lever if you like ) is not moving all the way that it should .

As for what else you can do try writing ( not phoning ) to HydroGear and ask why their units installed on your mower do not roll freely.

You will need the model & serial numbers from the stickers on them .

And the weight of the mower means nothing unless you are pushing up hill.

I had a friend who worked at the Jet base and they used to have "drag races" to see who could pull a 727 the furthest in 2 minutes and a 727 ( even empty ) weighs a lot more than your mower .

I would also write to Toro and ask them if the mower should push freely and tell them exactly what your dealer told you ( name the dealer & the person if you know it ) .

Toro do not tollerate poor customer service and in particular dealers who lie to customers .

When you write to HydroGear & Toro, have the parts book open and use the correct names & part numbers so they know exactly what you are talking about . If you start talking about "pins" your request will get nowhere .

#40

B

bertsmobile1

B

bertsmobile1

Don't have to go that far

release the brake as per the instructions in your owners manual

Slip the wheel off so you can see the bypass valve arm,

Rotate the axel with your hand so you have a comparison point

clean the area where the bypass arm moves around

move the arm with your finger as far as it will go then with the other hand try to rotate the axel

I should be substantially easier to do

Mark where the arm ends up on the housing

go round the back & pull the bypass control rods ( wires ) out & lock them into place .

Check the position of the bypass arm against your previous mark.

If it is short of where your finger moved it to and if it was very free when you moved it with your fingers then grab the wire with some lockjaws & bend it till the arm moves all the way.

I have needed to do this only twice in 10 years

Once it was delivered like that, the other time it was a branch

OTOH I regularly have to dig out packed in dust that is preventing full travel of the bypass arm .

release the brake as per the instructions in your owners manual

Slip the wheel off so you can see the bypass valve arm,

Rotate the axel with your hand so you have a comparison point

clean the area where the bypass arm moves around

move the arm with your finger as far as it will go then with the other hand try to rotate the axel

I should be substantially easier to do

Mark where the arm ends up on the housing

go round the back & pull the bypass control rods ( wires ) out & lock them into place .

Check the position of the bypass arm against your previous mark.

If it is short of where your finger moved it to and if it was very free when you moved it with your fingers then grab the wire with some lockjaws & bend it till the arm moves all the way.

I have needed to do this only twice in 10 years

Once it was delivered like that, the other time it was a branch

OTOH I regularly have to dig out packed in dust that is preventing full travel of the bypass arm .

#41

J

jcworks

J

jcworks

Thats some good information you gave me. Thanks. I'll try to look at it tomorrow. I tried once before to turn the axle by hand: jacked up the back end, took one of the wheels off, and push the bypass rod forward. The video on the 2nd page of this post shows that. But I'll do it again if I have no more odd jobs to do. I'll take some photos, maybe some closeups if I can; or maybe another video . Whatever this is I think it came from the factory like this. But not BOTH hydros. I myself can see thats highly unlikely. I've never been able to push it easily. It takes all I've got to even begin to make the wheels turn; but I'm 76 but not doing too bad for that age. I called the shop I bought it from today and asked them "what would make an MX5060 drive in forward or reverse regardless whether the bypass rods are in or out"? He had no idea, he said he'd never seen that. His guess was something internal in the transaxle, maybe a stuck valve or something to do with those valves....like you said. I said "well its that way on both sides". If the problem was just on one side, when you push both rods in then only the bad side would make the wheel move. He was puzzled. What is so odd is its both sides pull no matter where the bypass rods are positioned. So, I'll try to do what you said tomorrow. I'll let you know.

#42

B

bertsmobile1

B

bertsmobile1

FWIW

I 'test' hydros while the mower is on my tilt trailer

With the trailer at full tilt I try to push it

If it moves & stops when I stop then the hydro is good

If it rolls a little & stops the hydro is good

if it rolls slowly all the way to the end then the hydros are on the way out

If it rockets away when the brake is released then the hydros are cactus

If I have pushed the mower onto the trailer and all the tyres are inflated then they will always roll off without any pushing the instant the brake is released .

That is how easy they should roll

I 'test' hydros while the mower is on my tilt trailer

With the trailer at full tilt I try to push it

If it moves & stops when I stop then the hydro is good

If it rolls a little & stops the hydro is good

if it rolls slowly all the way to the end then the hydros are on the way out

If it rockets away when the brake is released then the hydros are cactus

If I have pushed the mower onto the trailer and all the tyres are inflated then they will always roll off without any pushing the instant the brake is released .

That is how easy they should roll

#43

J

jcworks

J

jcworks

Ok. My trailer doesn't tilt. I know that type of trailer though. I had one with an atv on it. The one I have now has a tailgate that raises up vertical and lowers down to the ground.

#44

J

jcworks

J

jcworks

Here's the latest on this ongoing saga. I called Hydro-Gear and got a real good guy on the phone (I wish all customer service people were as good as him). The first two letters on the model # were ZH and he said it was the ZT 2800 -- like you said. He said in order to test the internal I should push the bypass arm (the horizontal flat plate) forward or backward with my thumb and see if you felt a spring resistance. I jacked the machine up, took the wheel off. The bypass rod was sliding the bypass arm back and forth just as I'd always seen. So I tried what he said and I was able to move that bypass arm forward a little bit with my thumb. It wasn't much, but I could tell with repeated pushing and letting it go there was a spring resistance tension. Then, pushing the bypass arm to the rear it of course effortlessly slides to one point. From that point I could push it with my thumb and feel the spring resistance a little more so than when I pushed it forward with my thumb. Either way it seemed to me the spring tension he mentioned was there. I told him I tried rotating the axle with the bypass arm pushed forward as far as i could with my thumb but still couldn't rotate the axle freely. He said there would be some tension there because there was 5 pistons in there with some of them having pressure on them all the time, but that he wheels would roll. Bottom line: He said since I could feel the spring tension that told him the internal was working as it should. He thinks its an issue with the "linkage" as he called it. I said by linkage do you mean the bypass rod and he said yes, for some reason the control arm is not being pushed as far as it should. I don't know, thats probably true.

I think I need to say this: With the rods pulled back the rods just lay in the slot loosely. They don't look to be "locked in".....just laying there. With the rods pushed forward there is that small washer-looking retainer that you push through the hole and drop the rod down in the slot. I also checked to see if the rods would go any further once I pushed them in. They did. I felt it lunge a little with an added push. The same when I pulled them back, once I met a resistance I pulled some more and it would move some more. I'm thinking (rightly or wrongly) maybe these rods have been bent so much with sticks in the yard that they aren't functioning as they should. I have lots of trees and sticks in the yard. Those rods have some bent places on them I'm pretty sure came from the factory like that - but maybe not all of it. They are not a "straight" rod. I think tomorrow I'll take those rods off both sides and see if they are uniform. If so, and they are identical then they're not out of shape. I think I may find some variation though. If so I'll bend them like you suggested, thereby lengthening them a little. If nothing else just buy some new ones and put them on. They can't be but a few bucks.

I think I need to say this: With the rods pulled back the rods just lay in the slot loosely. They don't look to be "locked in".....just laying there. With the rods pushed forward there is that small washer-looking retainer that you push through the hole and drop the rod down in the slot. I also checked to see if the rods would go any further once I pushed them in. They did. I felt it lunge a little with an added push. The same when I pulled them back, once I met a resistance I pulled some more and it would move some more. I'm thinking (rightly or wrongly) maybe these rods have been bent so much with sticks in the yard that they aren't functioning as they should. I have lots of trees and sticks in the yard. Those rods have some bent places on them I'm pretty sure came from the factory like that - but maybe not all of it. They are not a "straight" rod. I think tomorrow I'll take those rods off both sides and see if they are uniform. If so, and they are identical then they're not out of shape. I think I may find some variation though. If so I'll bend them like you suggested, thereby lengthening them a little. If nothing else just buy some new ones and put them on. They can't be but a few bucks.

#45

B

bertsmobile1

B

bertsmobile1

Well that is a good result

And about what I had expected would be the problem

The most common cause I find is dust & crud building up around the little arm prevening it moving the full distance it should .

Yours sounds like some corrosion on the shafts so check them from time to time for signs of oil leaking

Very dissapointed by the service you got from the shop and I would advise finding another one to deal with

Usually the best service comes from people like Star & myself who are freelance & only do repairs or a non franchised repair shop that only does repairs and resells used mowers.

We have to be good because there is no new equipment sales profits to fall back upon & we need happy satisified customers to tell others how good we fixed their mowers .

And thanks for coming back

Not only does it close the thread but it will provide the answer for others in the future .

And about what I had expected would be the problem

The most common cause I find is dust & crud building up around the little arm prevening it moving the full distance it should .

Yours sounds like some corrosion on the shafts so check them from time to time for signs of oil leaking

Very dissapointed by the service you got from the shop and I would advise finding another one to deal with

Usually the best service comes from people like Star & myself who are freelance & only do repairs or a non franchised repair shop that only does repairs and resells used mowers.

We have to be good because there is no new equipment sales profits to fall back upon & we need happy satisified customers to tell others how good we fixed their mowers .

And thanks for coming back

Not only does it close the thread but it will provide the answer for others in the future .

#46

J

jcworks

J

jcworks

"Usually the best service comes from people like Star & myself who are freelance & only do repairs or a non franchised repair shop that only does repairs and resells used mowers."

Man, you are right about that.

Its not real easy finding a good and knowledgable mechanic. I have found one for my truck. He's straight up and tells you if you're overthinking things and when to forget something and move on. In something like hydros I didn't know where to turn to locally. Yes, I'll not use that one again.

Now, on to checking out those bypass rods. I think Toro should have made them out of heavier duty steel rods, like maybe 1/8". Anyway, I'm going to look at those when this rain all blows out. Also, I need to wash all that crud out from those hydros with a water hose, or maybe take it to the self service car wash would be better.

In addition, the Hydro guy told me I needed to change hydro oil, at 300 hours he said I was well past time to change it; even though two Toro dealers both said to wait till 500 hours. I'm wondering if this is something I can do myself without much risk. I think the manual has instructions on that.

Man, you are right about that.

Its not real easy finding a good and knowledgable mechanic. I have found one for my truck. He's straight up and tells you if you're overthinking things and when to forget something and move on. In something like hydros I didn't know where to turn to locally. Yes, I'll not use that one again.

Now, on to checking out those bypass rods. I think Toro should have made them out of heavier duty steel rods, like maybe 1/8". Anyway, I'm going to look at those when this rain all blows out. Also, I need to wash all that crud out from those hydros with a water hose, or maybe take it to the self service car wash would be better.

In addition, the Hydro guy told me I needed to change hydro oil, at 300 hours he said I was well past time to change it; even though two Toro dealers both said to wait till 500 hours. I'm wondering if this is something I can do myself without much risk. I think the manual has instructions on that.

#47

B

bertsmobile1

B

bertsmobile1

Only tick with hydro oil changes is keep everything spotless

This means tou have to properly clean around the fill port before you even think about removing it.

A quick wipe around with an oily rag will not do.

Agan the tranny makers have instructions about how to do it .

Once refilled the air has to be removed from the system

This is best done by jacking the wheels off the ground then following the instruction but remember to have the engine running as slowly as it will go

If run at full spped you can froth the oil in place of displacing the air

And it is pot luck

Some times 6 x R & F cycles & you are good to go other times you can spend a couple of days.

This means tou have to properly clean around the fill port before you even think about removing it.

A quick wipe around with an oily rag will not do.

Agan the tranny makers have instructions about how to do it .

Once refilled the air has to be removed from the system

This is best done by jacking the wheels off the ground then following the instruction but remember to have the engine running as slowly as it will go

If run at full spped you can froth the oil in place of displacing the air

And it is pot luck

Some times 6 x R & F cycles & you are good to go other times you can spend a couple of days.

#48

Hammermechanicman

Hammermechanicman

Interesting. I just finished servicing another Toro Timecutter. This one was the Z with a steering wheel. It has the goofy automatic electric parking brake. This is the 3rd timecutter that the bypass rods do nothing. They all have the automatic electric parking brake. The bypass rods appear to do nothing.

#49

B

bertsmobile1

B

bertsmobile1

Wellit won't go anywhere till you disconnect that idiot automatic electric brake

I remember the first one I came across, having to turn the key switch on and off all the time to prevent the brake locking on before I got my hands on the Toro manual which explained how to disable the brake

So the brake makes the mower safer for the customer bu way more dangerous for the service technician

I remember the first one I came across, having to turn the key switch on and off all the time to prevent the brake locking on before I got my hands on the Toro manual which explained how to disable the brake

So the brake makes the mower safer for the customer bu way more dangerous for the service technician

#50

G

Gord Baker

G

Gord Baker

Try it both ways. If it still does not disengage (possible but doubtful decal is wrong) RTFM and if that does not describe the problem just run it!

#51

J

jcworks

J

jcworks

Well, here's what I did. I jacked the wheels off the ground and took them off to get to those bypass rods. I took both off and compared them and they "looked" identical to me but mirror opposites of course (right and left). I couldn't see any differences in the rods such as bent out of shape. The right side bypass arm had a lot of gunk around it, so I cleaned that off and sprayed WD40 to help clean it off. The left side didn't have that gunk. With my thumb I pushed and released the bypass arms forward over and over and over again. And the same going backward. That "seemed" to free it up some, although it moves ever so slightly so its hard for me as a non-mechanic to tell. With some nylon cord I tied off each side with the bypass arm pulled forward to the max . I could not turn the axles by hand, but I could take a pry bar and roll them (the elec brake off of course). I reassembled everything and thought this through a bit. I pushed the bypass rods a bit inward (toward the trans). I did this thinking this might lengthen the rods thereby making the flange push the bypass arm further so the little flange on the rod would have more pressure against the slot its suppose to lock against. Earlier Bert mentioned maybe try bending the rods a bit. I did that on both sides and the left side "seemed" to roll a bit easier than the right side.I did this for both sides, right and left. Afterwards, I cranked it up, and as I tried to back it up the machine spun to the left going backwards. I pulled it forward again to straighten it up and backed up again. It did the same. I had forgotten to pull the rods out ! That told me the left side was now disengaged. Bert appears to have been right. So.....the left side is now disengaging and maybe my manipulation of the rods did the trick. This seems to lend to somewhat to what Hammermechanicman is saying. I'll test it again when the weather clears out, and maybe bend the right side rod a bit more to keep pressure on that little flange on the rod against the frame and hopefully disengage the right side. Rightly or wrongly, it just seems that those rods are either not stiff enough to begin with; or ever so slightly shorter than they should be. Whatever, manually pushing the rods inward toward the trans is what I think made the left side disengage as it should. This may lend to what Hammermechanicman said.

I still wonder if there is an issue on the right side since only that side had a gunk buildup around it. But I'm not going to worry over that.

I still wonder if there is an issue on the right side since only that side had a gunk buildup around it. But I'm not going to worry over that.

#52

J

jcworks

Hammermechanicman, it sure seems the rods do nothing ! The wheels will roll (with the elec brake disengaged) but it takes two men to push it. I'm with you, the bypass rods are an issue. I "seem" to have fixed one side for now -- see my last response. I'll try to get the right side disengaging like I did the left; but if I don't I may just take Gord Baker's advice and forget it and run it.

J

jcworks

Interesting. I just finished servicing another Toro Timecutter. This one was the Z with a steering wheel. It has the goofy automatic electric parking brake. This is the 3rd timecutter that the bypass rods do nothing. They all have the automatic electric parking brake. The bypass rods appear to do nothing.

Hammermechanicman, it sure seems the rods do nothing ! The wheels will roll (with the elec brake disengaged) but it takes two men to push it. I'm with you, the bypass rods are an issue. I "seem" to have fixed one side for now -- see my last response. I'll try to get the right side disengaging like I did the left; but if I don't I may just take Gord Baker's advice and forget it and run it.