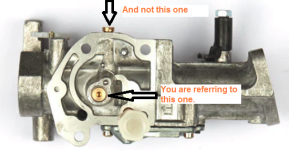

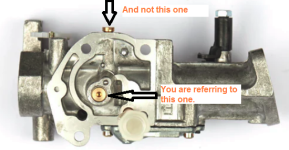

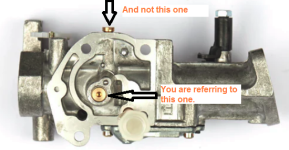

I have the adjustable idle screw.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Need orifice size of main jet for 5hp pulsa-jet carb

- Thread starter Telesis

- Start date

More options

Export thread- Joined

- Feb 19, 2020

- Threads

- 122

- Messages

- 12,902

Okay I see with clarification that you are referring the main nozzle jet. That one I don't know the size. Never had to check it. Now on extremely dirty carbs I have had to drill the steel next to it in the tower to clean out that area. When dealing with rusty tanks anything is possible.

In this case I would start with the smallest bit to clean out and work up to one that don't fit. Just these small bits are rather short so you might to follow up with some fine wire that fit thru the hole. BTW ultrasonics does fairly good of cleaning these areas but not a cure all.

ANd don't to install the filter screen on that tower. It will catch a lot of the large bits.

In this case I would start with the smallest bit to clean out and work up to one that don't fit. Just these small bits are rather short so you might to follow up with some fine wire that fit thru the hole. BTW ultrasonics does fairly good of cleaning these areas but not a cure all.

ANd don't to install the filter screen on that tower. It will catch a lot of the large bits.

Attachments

Thanks for the reply. I have a couple sets of micro-drills and I use a hand-held pin vise with them. As you indicated, I too have had kinda 50/50 luck with ultrasonics.Okay I see with clarification that you are referring the main nozzle jet. That one I don't know the size. Never had to check it. Now on extremely dirty carbs I have had to drill the steel next to it in the tower to clean out that area. When dealing with rusty tanks anything is possible.

In this case I would start with the smallest bit to clean out and work up to one that don't fit. Just these small bits are rather short so you might to follow up with some fine wire that fit thru the hole. BTW ultrasonics does fairly good of cleaning these areas but not a cure all.

View attachment 69120

ANd don't to install the filter screen on that tower. It will catch a lot of the large bits.

One last question. I've taken a closer look at the pics of the 498298 replacement carb and, like your pic above, I see the needle screw on the side but no spring. Is this a non-adjustable idle screw that is intended to be left fully seated? (I believe Rivets may have alluded to that as well) If so, it's the first time I've seen that. I guess you can teach a really old retired dog new tricks!

I appreciate your guy's input!

Things are getting clearer. I agree with Star, if you are going to try drilling it open start small and work your way up. I’ve been punching jets for many years, started with Zenith and Rochester carb, and can tell you there is no going back I you go to big. A trick I’ve learned, never try to hold jet in one hand and your pin vice in the other. Because of the drill size they break easily. I broke many before learning to clamp the jet in a hand vice and that vice in a bench vice. That way I have more control and can always drill down. Second, there should be a spring on the doe mixture screw. The purpose of the spring is to put tension on the screw to keep it from moving.

Thanks guys. First, the idle screw on mine is definitely adjustable as you can see in the pic. I think the new Briggs replacement is not adjustable (as well as the cheap Chinese knockoffs that cross to this). I think they are as Star describes.

Second, I don't know how the main jet we've been discussing is installed in the first place(or removed for that matter). There is no slot in it. Perhaps it's pressed in. No matter, as I'll drill/clean it in place by hand. The carb lays flat on a table so it's a pretty easy task. (I've broken a couple micro drills on other jobs as you describe Rivets so I can relate!)

Thanks again for all your insight!

Second, I don't know how the main jet we've been discussing is installed in the first place(or removed for that matter). There is no slot in it. Perhaps it's pressed in. No matter, as I'll drill/clean it in place by hand. The carb lays flat on a table so it's a pretty easy task. (I've broken a couple micro drills on other jobs as you describe Rivets so I can relate!)

Thanks again for all your insight!

I recall a discussion (in the '70s?) to the effect that a carb orifice needs to be reamed not drilled. Drilling supposedly leaves a pattern behind.Engine is a 5HP Briggs horizontal shaft I/C engine. 132212-0362-01 Carb part number: 492611

It utilizes a fixed jet in the pickup and mine is plugged. The engineer in me would like to know what the actual jet size is and then I can run a micro-drill in to clean it out. Based on my experience, I'm guessing I could use a .020 to start and the engine would likely be OK but that's a guess. I'm thinking it's bigger than that.

I've looked all over the net but can't find that piece of data. Maybe one of you know or have this common carb or equivalent on the shelf and could give me an idea how big it is.

Thanks in advance for your consideration. Any help appreciated. Thanks!

Use the old jet if it comes out into the new carb. If a new carb sometimes the main jet needs drilling. I'll bet if you really clean the old carb it will work fine. Find the size of the old jet by inserting micro drills until you find a "go, no go". size.