You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

LTX1000 Transaxle seems a bit too noisy?

#1

L

LTX1000

L

LTX1000

I had a LT1000 17 HP that ran good for 8 years, but hit a branch that locked up the blades. From that point on it wouldn't start. The crank shaft bent and through the timing off and the governor was shot. The repair shop who was checking it out told me, it would cost more to repair than it was worth. The shop repair owner had 2002 Craftsman LTX1000 18 HP in fairly good shape, but it has been sitting up for about 2 years. He said you can have it if you don't mind pulling the engine and installing it in your mower. They were too busy to work on it and the lead time would be 9 weeks. With a little minor repairs I got it up and running. I didn't swap the motors, I just worked on completing the repairs on the LTX1000 because it was in better shape than my LT1000.

Now for the question: The Transaxle sounds a bit noisier than to the LT1000 that has already went to the scrap yard. It works great, but has a grinding sound that I thought would go away with use.

Any advice would help, Change oil?, etc. I don't want to run it until it fails when I can do something to save it.

December 15 update: I removed the Hydro Gear Transaxle and changed the oil. The oil was dark gray with a little black slime. I replace the oil with 20w 50 as stated in the manual. I found one of the two idlers pulleys was froze up. I replaced both of them. The belt still had a lot of life in it.

Now to the bad part, Today was my test day without the mower attached. I checked everything and thought it was ready to go. With fingers crossed I started the engine and released the clutch without putting it in gear. The drive belt was working along with the idler pulleys and the drive pulley on the Transaxle. I depress the clutch and put it in gear. When I released the clutch nothing happened. I checked the neutral rod making sure it was in. I checked the linkage of the of the speed lever and it was connected to the transaxle and moving as it should. Remember, it was working but noisy before I removed it. In hindsight I should have replaced the idler pulleys and then tried it before pulling the transaxle. Now I need more help in solving this problem. When I replace the oil I made sure there was no trapped air. Did I miss a step in reinstalling the unit? Is it in the linkage that I could have screw? Is there a safety switch?

As far as I know, the previous owner bypassed them. I'm stumped. Help!!!!!

Now for the question: The Transaxle sounds a bit noisier than to the LT1000 that has already went to the scrap yard. It works great, but has a grinding sound that I thought would go away with use.

Any advice would help, Change oil?, etc. I don't want to run it until it fails when I can do something to save it.

December 15 update: I removed the Hydro Gear Transaxle and changed the oil. The oil was dark gray with a little black slime. I replace the oil with 20w 50 as stated in the manual. I found one of the two idlers pulleys was froze up. I replaced both of them. The belt still had a lot of life in it.

Now to the bad part, Today was my test day without the mower attached. I checked everything and thought it was ready to go. With fingers crossed I started the engine and released the clutch without putting it in gear. The drive belt was working along with the idler pulleys and the drive pulley on the Transaxle. I depress the clutch and put it in gear. When I released the clutch nothing happened. I checked the neutral rod making sure it was in. I checked the linkage of the of the speed lever and it was connected to the transaxle and moving as it should. Remember, it was working but noisy before I removed it. In hindsight I should have replaced the idler pulleys and then tried it before pulling the transaxle. Now I need more help in solving this problem. When I replace the oil I made sure there was no trapped air. Did I miss a step in reinstalling the unit? Is it in the linkage that I could have screw? Is there a safety switch?

As far as I know, the previous owner bypassed them. I'm stumped. Help!!!!!

Attachments

#6

B

bertsmobile1

B

bertsmobile1

So it looks like you have a Hydro-Gear 314-0510 transmission

IF it suddenly got noisy then you have a pulley bearing or belt problem

If it was always loud & just got louder then chances are the transmission is past it's use by date

Your mower dates from 2001 to 2005 so even if it is a late model, it is near 20 years old

The 314 was not a particularly robust unit and is good for 1000 to 1500 hours

So if the brake is not dragging then the trans is sending a message of good-bye

The cheap & nasty test is to park on a hill turn the engine off and give the mower a push down the hill.

If it resists being pushed and stops the instant you stop pushing then the tranny is good

If it takes off like a frightened bunny rabbit then the unit is shot

If it slowly continues to roll down the hill then an oil ( and filter ) change to a heavier grade of oil may add a few more seasons

IF it suddenly got noisy then you have a pulley bearing or belt problem

If it was always loud & just got louder then chances are the transmission is past it's use by date

Your mower dates from 2001 to 2005 so even if it is a late model, it is near 20 years old

The 314 was not a particularly robust unit and is good for 1000 to 1500 hours

So if the brake is not dragging then the trans is sending a message of good-bye

The cheap & nasty test is to park on a hill turn the engine off and give the mower a push down the hill.

If it resists being pushed and stops the instant you stop pushing then the tranny is good

If it takes off like a frightened bunny rabbit then the unit is shot

If it slowly continues to roll down the hill then an oil ( and filter ) change to a heavier grade of oil may add a few more seasons

#8

O

OldDiyer

O

OldDiyer

Would-A Could-A Should-A saved the other unit till the new to you unit was all setup but I'm sure you are not alone. If it is a bad transaxle, is it possible to get the other unit back or at least remove the axle from it? Maybe it's just like Bert said and may be brake or pully noise.

#9

L

LTX1000

Oh! what drives the cooling fan? Should it be free wheeling in either direction when the transmission is not engaged? It feels like the center of the fan hub may be stripped out.

L

LTX1000

I don't know the history of the mower, e.g. hours. When I got the engine running, I put it in gear the first time with my fingers crossed not knowing what to expect being it was sitting up for two years out in the weather. It moved forward, noisy, but no slip or drag. I moved forward and back in low several times increasing the distance a little each time. I then went through all the gears driving around the yard. The noise stayed at the same level no matter what speed or in forward or reverse. I kept the RPMs Constance at 3600. I didn't think about the idler pulley, clutch or PTO because the noise seemed to be coming from the rear. I jacked in the rear end up and rotated the wheels listening for a bearing noise. No noise there. Before I drop the transmission, I think I will check the idler pulley.So it looks like you have a Hydro-Gear 314-0510 transmission

IF it suddenly got noisy then you have a pulley bearing or belt problem

If it was always loud & just got louder then chances are the transmission is past it's use by date

Your mower dates from 2001 to 2005 so even if it is a late model, it is near 20 years old

The 314 was not a particularly robust unit and is good for 1000 to 1500 hours

So if the brake is not dragging then the trans is sending a message of good-bye

The cheap & nasty test is to park on a hill turn the engine off and give the mower a push down the hill.

If it resists being pushed and stops the instant you stop pushing then the tranny is good

If it takes off like a frightened bunny rabbit then the unit is shot

If it slowly continues to roll down the hill then an oil ( and filter ) change to a heavier grade of oil may add a few more seasons

Oh! what drives the cooling fan? Should it be free wheeling in either direction when the transmission is not engaged? It feels like the center of the fan hub may be stripped out.

#10

StarTech

StarTech

Whoa for a minute the model number posted says Hydrostatic transaxle but you are indicating Gear type transaxle. So which is it?

#11

L

LTX1000

L

LTX1000

TRACTOR - - MODEL NUMBER 917.272420

HYDRO GEAR TRANSAXLE - - MODEL NUMBER 314-0510

This is out of the manual. I found it online this morning. I copied this from the manual and pasted it here. I still refer to it as a transmission.

HYDRO GEAR TRANSAXLE - - MODEL NUMBER 314-0510

This is out of the manual. I found it online this morning. I copied this from the manual and pasted it here. I still refer to it as a transmission.

#12

L

LTX1000

L

LTX1000

if I leave the pull rod in the neutral position and release the clutch, very little noise. So, the noise starts when I start moving.Is the noise when you just release the brake/clutch or is it only when moving.

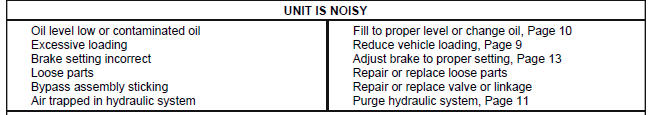

If moving troubleshooting.

View attachment 62914

#13

M

mechanic mark

www.searspartsdirect.com

Inspect Drive Belt & Idler Pulleys for replacement.

www.searspartsdirect.com

Inspect Drive Belt & Idler Pulleys for replacement.

www.searspartsdirect.com

www.searspartsdirect.com

www.searspartsdirect.com

www.searspartsdirect.com

www.searspartsdirect.com

Google "Craftsman Part #'s above" for best price plus tax & shipping.

www.searspartsdirect.com

Google "Craftsman Part #'s above" for best price plus tax & shipping.

M

mechanic mark

Official Craftsman 917272420 front-engine lawn tractor parts | Sears PartsDirect

Craftsman 917272420 front-engine lawn tractor parts - manufacturer-approved parts for a proper fit every time! We also have installation guides, diagrams and manuals to help you along the way!

Rally Lawn Tractor Ground Drive Fixed Idler Pulley 165936 parts | Sears PartsDirect

Rally Lawn Tractor Ground Drive Fixed Idler Pulley 165936 (replaced by 532165936) parts - manufacturer-approved parts for a proper fit every time! We also have installation guides, diagrams and manuals to help you along the way!

Lawn Tractor Blade Idler Pulley 127783 parts | Sears PartsDirect

Lawn Tractor Blade Idler Pulley 127783 (replaced by 532139245) parts - manufacturer-approved parts for a proper fit every time! We also have installation guides, diagrams and manuals to help you along the way!

Lawn Tractor Ground Drive Belt, 1/2 x 82-in 140294 parts | Sears PartsDirect

Lawn Tractor Ground Drive Belt, 1/2 x 82-in 140294 (replaced by 532140294) parts - manufacturer-approved parts for a proper fit every time! We also have installation guides, diagrams and manuals to help you along the way!

#14

StarTech

Second no the transaxle doesn't free wheel in neutral; unless, the bypass lever is placed in bypass position.

If you are able to rotate without the pulley turning then the transaxle most likely have overheated and the oil inside the transaxle is bad. But noisy unit are usually too far gone to be saved by simply changing the oil. Cavatation usually destroys the pump section as it allows metal to metal contact.

StarTech

To answer your question on the fan it is pin via lock nut to the pulley. So the pulley drives the fan.I don't know the history of the mower, e.g. hours. When I got the engine running, I put it in gear the first time with my fingers crossed not knowing what to expect being it was sitting up for two years out in the weather. It moved forward, noisy, but no slip or drag. I moved forward and back in low several times increasing the distance a little each time. I then went through all the gears driving around the yard. The noise stayed at the same level no matter what speed or in forward or reverse. I kept the RPMs Constance at 3600. I didn't think about the idler pulley, clutch or PTO because the noise seemed to be coming from the rear. I jacked in the rear end up and rotated the wheels listening for a bearing noise. No noise there. Before I drop the transmission, I think I will check the idler pulley.

Oh! what drives the cooling fan? Should it be free wheeling in either direction when the transmission is not engaged? It feels like the center of the fan hub may be stripped out.

Second no the transaxle doesn't free wheel in neutral; unless, the bypass lever is placed in bypass position.

If you are able to rotate without the pulley turning then the transaxle most likely have overheated and the oil inside the transaxle is bad. But noisy unit are usually too far gone to be saved by simply changing the oil. Cavatation usually destroys the pump section as it allows metal to metal contact.

#15

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

An important question was not answered and this is why it is important. The nopise could be a "simple" idler pulley that tensions the belt or the tranny. In neutral, let the pedal up and if the belt now in motion is spinning these ( or this) pulley and the tranny input shaft is spinning but doing no work, then if the nooise is present and not really different, then this is where to look. If the pulley inspection will tell you when it does no0t spin by hand ( engine off) smooth. 1,2,3 -pulley(S), input shaft, tranny.Whoa for a minute the model number posted says Hydrostatic transaxle but you are indicating Gear type transaxle. So which is it?

#16

StarTech

StarTech

I went and reread post #9 and the OP ask what drives the fan which tell it is a hydro and not a gear. Now he did throw off by saying he "when though all the gears" as hydros are continuously variable speed selection. So this still leaves the question as someone could have swapped the transaxle but i doubt it for fan is present.

#17

L

LTX1000

L

LTX1000

Well. I should have used my instinct about the fan free wheeling. The lock nut was not tight enough. There is no other retainer or pin that locks the fan to the pulley. Compression is the only thing that holds the fan from slipping. It appears who ever tighten the nut didn't hold the pulley while tightening. There's probably a torque spec. in the service manual.To answer your question on the fan it is pin via lock nut to the pulley. So the pulley drives the fan.

View attachment 62915

Second no the transaxle doesn't free wheel in neutral; unless, the bypass lever is placed in bypass position.

If you are able to rotate without the pulley turning then the transaxle most likely have overheated and the oil inside the transaxle is bad. But noisy unit are usually too far gone to be saved by simply changing the oil. Cavatation usually destroys the pump section as it allows metal to metal contact.

#19

F

Freddie21

F

Freddie21

From my experience, when the hydro is failing, it will tend to slow its top speed as it warms up. Usually after 10-15 mins of moving at full speed. Lowering and changing the oils to 20w50 may buy some time, but not a fix.

#20

rickpaulos

I've hit a number of objects, bricks, fence posts, culverts, etc and I have sheared the key under the flywheel more than once. That is surely more likely to happen than bending the crank shaft. The key is intended to shear before the crank gets damaged. And it will throw the timing way off, usually to the point where motor won't start. I wonder how thoroughly the shop checked out your old motor. A flywheel puller is the only specialty tool needed to replace the key.

rickpaulos

I know this isn't about your question but..I had a LT1000 17 HP that ran good for 8 years, but hit a branch that locked up the blades. From that point on it wouldn't start. The crank shaft bent and through the timing off and the governor was shot. The repair shop who was checking it out told me, it would cost more to repair than it was worth. The shop repair owner had 2002 Craftsman LTX1000 18 HP in fairly good shape, but it has been sitting up for about 2 years. He said you can have it if you don't mind pulling the engine and installing it in your mower. They were too busy to work on it and the lead time would be 9 weeks. With a little minor repairs I got it up and running. I didn't swap the motors, I just worked on completing the repairs on the LTX1000 because it was in better shape than my LT1000.

Now for the question: The Transaxle sounds a bit noisier than to the LT1000 that has already went to the scrap yard. It works great, but has a grinding sound that I thought would go away with use.

Any advice would help, Change oil?, etc. I don't want to run it until it fails when I can do something to save it.

I've hit a number of objects, bricks, fence posts, culverts, etc and I have sheared the key under the flywheel more than once. That is surely more likely to happen than bending the crank shaft. The key is intended to shear before the crank gets damaged. And it will throw the timing way off, usually to the point where motor won't start. I wonder how thoroughly the shop checked out your old motor. A flywheel puller is the only specialty tool needed to replace the key.