Yep, most DIY articles appear to be written by AI with a lot of filler words and very little technical content. On the other side of the spectrum are the technical articles from companies like Bando that jump all around with cross dimensional charts and fitment tables.

As for longevity of design, if using aftermarket designed belts, I prefer a Kevlar reinforced belt over a Nylon cord design.

The drive traction belt normally takes the most wear and heat simply for the lack of cooling air, so Kevlar is a better material. The deck belts generally last longer due to more cooling air and can be made from nylon reinforced cord material.

I am not sure what the poster is referring to when they say "rubber belt" an all-rubber belt would be much to light for any lawn mower application. Rubber is only a binding product used in the belt construction. The Kevlar, Aramid or Nylon cord is where the strength of the belt come from.

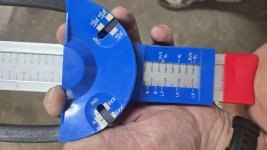

V-belts for mowers are designed to grip on the angled sides and not on the inner or outer circumferences/ flat surfaces.

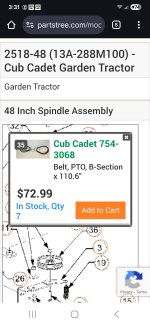

When it comes down to what ultimately works, people should go with the manufacturers original belt when possible.

Why? Because they are designed for the machine. Belts that just say they will "fit" does not mean they have the correct profile design.

Examples: A belt that rides to far down in the bottom of a "V" pulley will slip because the side grip surface of the "V" is no longer functional. A belt that rides too high on the out edge of the "V" will wear a groove into the angled side face of the belt and eventually the belt will roll and twist or it will develop a "jump off the pulley" problem.

If cost is the deciding factor, that is strictly left up to the individual. OE belts are expensive, but doing a little research will usually reveal who actually makes them for the OE manufacturers.

In this particular case, cost is not a deciding factor. This customer cuts 50 acres a week, every week, with two machines. Their place is a 97-acre campground that is rated in the top 10 in the entire U.S. To keep that rating, they have to keep the place looking manicured all year.

OEM Belts lasted 1/2 season. The Kevlar deck belts lasted 1 1/2 seasons. After using the Kevlar belts with great success on hundreds of mowers, I asked the customer to try one of these out, not expecting anything different under such harsh conditions. After it went so much longer (almost two years), that's all he will use on anything now. On top of that, what was costing him $400 a year in belts is now less than $70. This particular Kevlar belt is sourced from Indonesia, while all their cogged belts are US-made.

Engaging the clutch-driven belt at WOT doesn't do the belt any favors either, IMO.

So, operation also comes into play.

I'm all for OEM, but when there is a longer-lasting option, it's a no-brainer.

It just happens that these certain belts are very inexpensive compared to the OEMs.

When I order belts, I do not use AI.

I use 50 years of hands-on repair knowledge and a credit card.