You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

kevlar or rubber deck belt?

#1

J

Justwayne

J

Justwayne

Is it okay to use rubber blade belt or is kevlar much better? What is the factory murray lawnmower belt made of? The murray belt says its aramid and is more expensive 33$ with tax tho its brown in the murray package.

Do most 42" mowers come with rubber or kevlar for the blade belt and what about the drive belt?

Can anyone tell what material this is? This looks to be a black belt.

I was going to get a 810 belt just not sure if the rubber or kevlar. It is 10$ more for a kevlar belt what are the lifespans of each?

Do most 42" mowers come with rubber or kevlar for the blade belt and what about the drive belt?

Can anyone tell what material this is? This looks to be a black belt.

I was going to get a 810 belt just not sure if the rubber or kevlar. It is 10$ more for a kevlar belt what are the lifespans of each?

Attachments

#2

A

Auto Doc's

A

Auto Doc's

They all have a certain amount of rubber compound to hold the strengthening material such as Aramid or Kevlar.

The 8-ten belts are very good and hold up for a few years under regular use.

The 8-ten belts are very good and hold up for a few years under regular use.

#3

J

Justwayne

It says its just the cords that are kevlar but the other fabric coating keeps from stretching and durability or is it simply just a different color.

8tenparts.com

8tenparts.com

8tenparts.com

8tenparts.com

J

Justwayne

so you think for a 42" 17.5hp riding mower the rubber belt for 17$ would operate just as well as the aramid or kevlar belt for 27$? 037x88ma all the local places have aramid or kevlar belts for 20$ so im not so sure about the rubber belt.They all have a certain amount of rubber compound to hold the strengthening material such as Aramid or Kevlar.

The 8-ten belts are very good and hold up for a few years under regular use.

It says its just the cords that are kevlar but the other fabric coating keeps from stretching and durability or is it simply just a different color.

Deck Belt For Murray 37X88 037X88MA 710213 8972 75-135 690-500-0004

In-Stock Replacement Belt Replacement For OEM 37X88. Fits 42516x92B 425007x92C 425015x92A 42539A 42500x30B 42591x8A 425303x92B 42590x92A 42509x92B 425303x92A

Kevlar Belt For Murray John Deere Generac 37X88 037X88MA 710213 8972 75-135 M147044 GX21407 7101794

In-Stock Replacement Belt Replacement For OEM 37X88. Fits 20HP LX279 G110 LX289 LX280 S240 X350 X370 X570 X380 X390 X580 X384 X394 X584 42516x92B 425007x92C

#4

Hammermechanicman

Hammermechanicman

Kevlar generally refers to being wrapped in a kevlar fabric. Wrapped belts are used in clutching applications as they allow some slippage as they engage. Raw edge or unwrapped belts are not designed to be used in clutching applications. Kevlar wrapped belts are more durable than unwrapped belts. Not a fan of the 8ten stuff.

#5

A

Auto Doc's

A

Auto Doc's

This may help:

www.readability.com

www.readability.com

The Anatomy of a Mower Belt: Exploring the Materials, Construction, and Different Types of Belts Used in Various Mower Applications

Lawnmowers rely on more than engines and blades to operate efficiently. One of the most vital yet overlooked components is the belt system that powers critical functions like blade movement and wheel propulsion. Whether you’re a DIY enthusiast or a professional landscaper, understanding the...

#7

A

Auto Doc's

A

Auto Doc's

Yep, most DIY articles appear to be written by AI with a lot of filler words and very little technical content. On the other side of the spectrum are the technical articles from companies like Bando that jump all around with cross dimensional charts and fitment tables.

As for longevity of design, if using aftermarket designed belts, I prefer a Kevlar reinforced belt over a Nylon cord design.

The drive traction belt normally takes the most wear and heat simply for the lack of cooling air, so Kevlar is a better material. The deck belts generally last longer due to more cooling air and can be made from nylon reinforced cord material.

I am not sure what the poster is referring to when they say "rubber belt" an all-rubber belt would be much to light for any lawn mower application. Rubber is only a binding product used in the belt construction. The Kevlar, Aramid or Nylon cord is where the strength of the belt come from.

V-belts for mowers are designed to grip on the angled sides and not on the inner or outer circumferences/ flat surfaces.

When it comes down to what ultimately works, people should go with the manufacturers original belt when possible.

Why? Because they are designed for the machine. Belts that just say they will "fit" does not mean they have the correct profile design.

Examples: A belt that rides to far down in the bottom of a "V" pulley will slip because the side grip surface of the "V" is no longer functional. A belt that rides too high on the out edge of the "V" will wear a groove into the angled side face of the belt and eventually the belt will roll and twist or it will develop a "jump off the pulley" problem.

If cost is the deciding factor, that is strictly left up to the individual. OE belts are expensive, but doing a little research will usually reveal who actually makes them for the OE manufacturers.

As for longevity of design, if using aftermarket designed belts, I prefer a Kevlar reinforced belt over a Nylon cord design.

The drive traction belt normally takes the most wear and heat simply for the lack of cooling air, so Kevlar is a better material. The deck belts generally last longer due to more cooling air and can be made from nylon reinforced cord material.

I am not sure what the poster is referring to when they say "rubber belt" an all-rubber belt would be much to light for any lawn mower application. Rubber is only a binding product used in the belt construction. The Kevlar, Aramid or Nylon cord is where the strength of the belt come from.

V-belts for mowers are designed to grip on the angled sides and not on the inner or outer circumferences/ flat surfaces.

When it comes down to what ultimately works, people should go with the manufacturers original belt when possible.

Why? Because they are designed for the machine. Belts that just say they will "fit" does not mean they have the correct profile design.

Examples: A belt that rides to far down in the bottom of a "V" pulley will slip because the side grip surface of the "V" is no longer functional. A belt that rides too high on the out edge of the "V" will wear a groove into the angled side face of the belt and eventually the belt will roll and twist or it will develop a "jump off the pulley" problem.

If cost is the deciding factor, that is strictly left up to the individual. OE belts are expensive, but doing a little research will usually reveal who actually makes them for the OE manufacturers.

#9

W

Wrenchit

vbeltguys.com 6.99 shipping, for one or 50 of them.

$ 12.25

W

Wrenchit

I use nothing but Aramid belts on the Ventracs and lawn tractors I work on; they last twice as long as the OEMs.They all have a certain amount of rubber compound to hold the strengthening material such as Aramid or Kevlar.

The 8-ten belts are very good and hold up for a few years under regular use.

vbeltguys.com 6.99 shipping, for one or 50 of them.

037X88MA Murray Wrapped Aramid Lawn & Garden Replacement V-Belt

Default Title - $ 12.25 USD$ 12.25

#11

A

Auto Doc's

I'm curious why you say that. Have you used them for commercial purposes in the past, or regular seasonal residential use?

In the past 5 years, I have had no issues with any of the 8-ten belts, blades, spindles or pulleys.

Note: I do modify the sealed spindle bearings to make sure more grease can get in them.

A

Auto Doc's

Hi Freddie21,Stay away from 8Ten belts, short life.

I'm curious why you say that. Have you used them for commercial purposes in the past, or regular seasonal residential use?

In the past 5 years, I have had no issues with any of the 8-ten belts, blades, spindles or pulleys.

Note: I do modify the sealed spindle bearings to make sure more grease can get in them.

#12

W

Wrenchit

OEM Belts lasted 1/2 season. The Kevlar deck belts lasted 1 1/2 seasons. After using the Kevlar belts with great success on hundreds of mowers, I asked the customer to try one of these out, not expecting anything different under such harsh conditions. After it went so much longer (almost two years), that's all he will use on anything now. On top of that, what was costing him $400 a year in belts is now less than $70. This particular Kevlar belt is sourced from Indonesia, while all their cogged belts are US-made.

Engaging the clutch-driven belt at WOT doesn't do the belt any favors either, IMO.

So, operation also comes into play.

I'm all for OEM, but when there is a longer-lasting option, it's a no-brainer.

It just happens that these certain belts are very inexpensive compared to the OEMs.

When I order belts, I do not use AI.

I use 50 years of hands-on repair knowledge and a credit card.

W

Wrenchit

In this particular case, cost is not a deciding factor. This customer cuts 50 acres a week, every week, with two machines. Their place is a 97-acre campground that is rated in the top 10 in the entire U.S. To keep that rating, they have to keep the place looking manicured all year.Yep, most DIY articles appear to be written by AI with a lot of filler words and very little technical content. On the other side of the spectrum are the technical articles from companies like Bando that jump all around with cross dimensional charts and fitment tables.

As for longevity of design, if using aftermarket designed belts, I prefer a Kevlar reinforced belt over a Nylon cord design.

The drive traction belt normally takes the most wear and heat simply for the lack of cooling air, so Kevlar is a better material. The deck belts generally last longer due to more cooling air and can be made from nylon reinforced cord material.

I am not sure what the poster is referring to when they say "rubber belt" an all-rubber belt would be much to light for any lawn mower application. Rubber is only a binding product used in the belt construction. The Kevlar, Aramid or Nylon cord is where the strength of the belt come from.

V-belts for mowers are designed to grip on the angled sides and not on the inner or outer circumferences/ flat surfaces.

When it comes down to what ultimately works, people should go with the manufacturers original belt when possible.

Why? Because they are designed for the machine. Belts that just say they will "fit" does not mean they have the correct profile design.

Examples: A belt that rides to far down in the bottom of a "V" pulley will slip because the side grip surface of the "V" is no longer functional. A belt that rides too high on the out edge of the "V" will wear a groove into the angled side face of the belt and eventually the belt will roll and twist or it will develop a "jump off the pulley" problem.

If cost is the deciding factor, that is strictly left up to the individual. OE belts are expensive, but doing a little research will usually reveal who actually makes them for the OE manufacturers.

OEM Belts lasted 1/2 season. The Kevlar deck belts lasted 1 1/2 seasons. After using the Kevlar belts with great success on hundreds of mowers, I asked the customer to try one of these out, not expecting anything different under such harsh conditions. After it went so much longer (almost two years), that's all he will use on anything now. On top of that, what was costing him $400 a year in belts is now less than $70. This particular Kevlar belt is sourced from Indonesia, while all their cogged belts are US-made.

Engaging the clutch-driven belt at WOT doesn't do the belt any favors either, IMO.

So, operation also comes into play.

I'm all for OEM, but when there is a longer-lasting option, it's a no-brainer.

It just happens that these certain belts are very inexpensive compared to the OEMs.

When I order belts, I do not use AI.

I use 50 years of hands-on repair knowledge and a credit card.

#13

J

Justwayne

J

Justwayne

Do you know who manufactures to murray belts? Can pm me if private. You think the oem murray belt or a sten, oregen belt is best. Murray is 34$+tax Sten 24$ and oregon 28$. Home depot and lowes have the belt for 20$+ tax they just dont include a warranty.Stay away from 8Ten belts, short life.

#14

J

Justwayne

J

Justwayne

Oem belts for murray are kevlar belts or aramid the brown belt or are you referring to a different oem deck belt that is rubber? These last 1/2 season compared to kevlar oem or aftermarket deck belts that lasted 1 1/2 seasons?In this particular case, cost is not a deciding factor. This customer cuts 50 acres a week, every week, with two machines. Their place is a 97-acre campground that is rated in the top 10 in the entire U.S. To keep that rating, they have to keep the place looking manicured all year.

OEM Belts lasted 1/2 season. The Kevlar deck belts lasted 1 1/2 seasons. After using the Kevlar belts with great success on hundreds of mowers, I asked the customer to try one of these out, not expecting anything different under such harsh conditions. After it went so much longer (almost two years), that's all he will use on anything now. On top of that, what was costing him $400 a year in belts is now less than $70. This particular Kevlar belt is sourced from Indonesia, while all their cogged belts are US-made.

Engaging the clutch-driven belt at WOT doesn't do the belt any favors either, IMO.

So, operation also comes into play.

I'm all for OEM, but when there is a longer-lasting option, it's a no-brainer.

It just happens that these certain belts are very inexpensive compared to the OEMs.

When I order belts, I do not use AI.

I use 50 years of hands-on repair knowledge and a credit card.

#15

W

Wrenchit

W

Wrenchit

Since Briggs took over Murray, their belts are actually made by Briggs in the US and China.Do you know who manufactures to murray belts? Can pm me if private. You think the oem murray belt or a sten, oregen belt is best. Murray is 34$+tax Sten 24$ and oregon 28$. Home depot and lowes have the belt for 20$+ tax they just dont include a warranty.

#16

W

Wrenchit

The same belt I got from the Vbelt guys is 27.38 plus 6.99 shipping

I order between 50 and 100 belts every year, and have had no issues other than customers giving me the wrong length.

Just a tip,

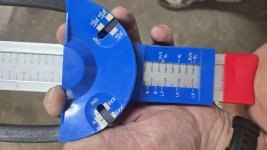

belt number often corresponds to the inside circumference. To get the outside circumference, you add 2 inches to the belt number. Conversely, if you measure the outside circumference, you subtract 2 inches to find the correct belt number. (This is for 1/2 inch belts only)

With 5/8" belts, A common rule of thumb is to subtract approximately 3 inches from the outside measurement to get the inside length for B-section (5/8) belts.

W

Wrenchit

I was referring to A Ventrac Deck belt. They are 162 inches long and 5/8 inches wide on top. Ventrac gets $85 for the belt, plus $10 drop ship fee, and then add shipping $.Oem belts for murray are kevlar belts or aramid the brown belt or are you referring to a different oem deck belt that is rubber? These last 1/2 season compared to kevlar oem or aftermarket deck belts that lasted 1 1/2 seasons?

The same belt I got from the Vbelt guys is 27.38 plus 6.99 shipping

I order between 50 and 100 belts every year, and have had no issues other than customers giving me the wrong length.

Just a tip,

belt number often corresponds to the inside circumference. To get the outside circumference, you add 2 inches to the belt number. Conversely, if you measure the outside circumference, you subtract 2 inches to find the correct belt number. (This is for 1/2 inch belts only)

With 5/8" belts, A common rule of thumb is to subtract approximately 3 inches from the outside measurement to get the inside length for B-section (5/8) belts.

#18

W

Wrenchit

Even more fun when the belts are shown in metric sizes and the belt is broken.

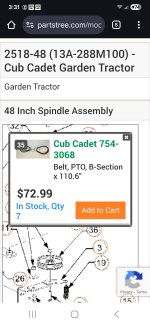

The last 42-inch Cub deck belt I received from them, was from Tennessee, which was a couple of weeks ago.

They do offer 1/2" sizes also, as in 82 1/2 ( I did have to call them for one with a 1/2 size for an old Sears Tractor)

Lots of aftermarkets will round up or down.

Good Point though!

From their website, regarding that part number.

$ 23.56$ 30.63

$6.99 shipping

W

Wrenchit

I don't work for them or receive anything from them. (Vbeltguys) I save a ton of money for myself and my customers. All I can say is that if they will hold up on a $40,000 commercial machine that runs daily, lawn and garden is a money saver. I wish they made a belt measuring tool that went up to 200 inches. LolHere is an example of aftermarket using the wrong measurement. The stens belt is 107" and should be B110. The belt pic is the one that actually fits. The stens is 3 inches short.View attachment 71338View attachment 71339View attachment 71340

Even more fun when the belts are shown in metric sizes and the belt is broken.

The last 42-inch Cub deck belt I received from them, was from Tennessee, which was a couple of weeks ago.

They do offer 1/2" sizes also, as in 82 1/2 ( I did have to call them for one with a 1/2 size for an old Sears Tractor)

Lots of aftermarkets will round up or down.

Good Point though!

From their website, regarding that part number.

754-3068 CUB CADET Wrapped Aramid Lawn & Garden Replacement V-Belt

$ 23.56 USD$ 23.56

$6.99 shipping

#19

W

Wrenchit

W

Wrenchit

Another point is, unless you have a new OEM belt, and you have to measure the old belt, how do you figure out how much it has stretched?Here is an example of aftermarket using the wrong measurement. The stens belt is 107" and should be B110. The belt pic is the one that actually fits. The stens is 3 inches short.View attachment 71338View attachment 71339View attachment 71340

#20

J

Justwayne

J

Justwayne

Do you know what the L stands for the length or how much groove there is? Some use the same size .50x89.25" but would may use a different L groove as the pulley is supposed to ride on the side of the belt. Any idea what 37x88MA is in L? Or if there is a different make or that belt john deere sizes or other that are the same in terms of size?I was referring to A Ventrac Deck belt. They are 162 inches long and 5/8 inches wide on top. Ventrac gets $85 for the belt, plus $10 drop ship fee, and then add shipping $.

The same belt I got from the Vbelt guys is 27.38 plus 6.99 shipping

I order between 50 and 100 belts every year, and have had no issues other than customers giving me the wrong length.

Just a tip,

belt number often corresponds to the inside circumference. To get the outside circumference, you add 2 inches to the belt number. Conversely, if you measure the outside circumference, you subtract 2 inches to find the correct belt number. (This is for 1/2 inch belts only)

With 5/8" belts, A common rule of thumb is to subtract approximately 3 inches from the outside measurement to get the inside length for B-section (5/8) belts.

#21

W

Wrenchit

W

Wrenchit

"L" in V belts stands for Light duty. Measurements will be the same.

Others are listed here:

Others are listed here:

- La: Outer (circumference) length1

- Le: Effective length2

- Ld: Datum length3

- Lp: Pitch length3, 4

- Lw: Working length3

- Certain conditions:

1 No belt stretch / tension applied

2 Length relative to the effective outside diameter of a sheave with belt stretch / tension applied

3 Length at the pitch diameter of the sheaves used with belt stretch / tension applied

4 Technically defined as “any circumferential line which keeps the same length when the belt is bent perpendicularly to its base” (ISO 1081:2013)

Li: Inner (circumference) length1