You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

John Deere L118 jerks, clicking noise (with Video)

#1

R

robmorren2

R

robmorren2

Looking for some help, I'm a John Deere newbie. I started dabbling with a complete rebuild of a mower deck, and a rocker gasket and head gasket replacement -- so that's how inexperienced I am.

Here is the problem I'm having right now with my L118. The lawn tractor jerks momentarily, slows down then takes off like something catches, and you can hear a clicking/popping noise while it happens. It happens much more regularly when turning tight circles. It will happen from time to time in a straight line as well, but it seems to smooth out more when going straight and will get up to speed like it normally would. Forward and reverse both work. In this video, I am going in a tight circle, as if I was rounding the base of a tree ...

Thanks in advance for your help!

Here is the problem I'm having right now with my L118. The lawn tractor jerks momentarily, slows down then takes off like something catches, and you can hear a clicking/popping noise while it happens. It happens much more regularly when turning tight circles. It will happen from time to time in a straight line as well, but it seems to smooth out more when going straight and will get up to speed like it normally would. Forward and reverse both work. In this video, I am going in a tight circle, as if I was rounding the base of a tree ...

Thanks in advance for your help!

#3

B

bertsmobile1

B

bertsmobile1

Things that cause this

Burned belt

Belt missing chunks

Broken clutch spring

Frozen idler pulley

Collapsed idler pulley bearing

Belt off rear pulley

All of these need the deck to be removed and your eyes under there

Burned belt

Belt missing chunks

Broken clutch spring

Frozen idler pulley

Collapsed idler pulley bearing

Belt off rear pulley

All of these need the deck to be removed and your eyes under there

#4

R

robmorren2

R

robmorren2

So I started tearing stuff off and I noticed something. I'm a rookie at this stuff and I noticed a rookie mistake I apparently made when changing the transmission belt...

Despite pulling the steering wheel shaft to put the belt around it, somehow the belt must have double over on one side when I slid the shaft back into place. So I had both sides of the belt on one side of the shaft, not circling around each side. I pulled the shaft up and guided the belt properly -- started it up, and it still has the same issue as before. I checked the pulley and shaft, and the splines looks good there. The fan looks fine.

Could that extra distance and friction of the belt going on the wrong side of the steering shaft somehow elongated the belt or something? The belt looks perfectly fine as far as wear or or cracks. I just replaced the belt and idler pulleys a couple weeks ago (which is when I made the mistake)

As for your checkpoints:

Burned belt - nothing visually wrong, but maybe stretched b/c of my mistake noted abovE?

Belt missing chunks - no chunks or cracks

Broken clutch spring - spring is in tact

Frozen idler pulley - spinning freely, just replaced recently

Collapsed idler pulley bearing - spline looks good

Belt off rear pulley - belt was attached

I'm going to try a new belt. If that doesn't solve the problem, am I looking at a bad transaxle? Some who have seen the video have said maybe a differential issue?

Thanks!!

Despite pulling the steering wheel shaft to put the belt around it, somehow the belt must have double over on one side when I slid the shaft back into place. So I had both sides of the belt on one side of the shaft, not circling around each side. I pulled the shaft up and guided the belt properly -- started it up, and it still has the same issue as before. I checked the pulley and shaft, and the splines looks good there. The fan looks fine.

Could that extra distance and friction of the belt going on the wrong side of the steering shaft somehow elongated the belt or something? The belt looks perfectly fine as far as wear or or cracks. I just replaced the belt and idler pulleys a couple weeks ago (which is when I made the mistake)

As for your checkpoints:

Burned belt - nothing visually wrong, but maybe stretched b/c of my mistake noted abovE?

Belt missing chunks - no chunks or cracks

Broken clutch spring - spring is in tact

Frozen idler pulley - spinning freely, just replaced recently

Collapsed idler pulley bearing - spline looks good

Belt off rear pulley - belt was attached

I'm going to try a new belt. If that doesn't solve the problem, am I looking at a bad transaxle? Some who have seen the video have said maybe a differential issue?

Thanks!!

#5

B

bertsmobile1

B

bertsmobile1

It CAN be a lot of things bu I have no intention of posting 1/2 a service manual on the forum.

This is particularly the case when 99% of the time the posted only gives us 10% of the story to work with .

So time for the whole story put your chair in front of a table with a desk lamp shining into your eyes and start confessing .

Was the mower doing this before you change the belt ?

Did you take photos before you started to ensure that the new belt was routed correctly ?

Can you pull the brake pedal up and if you do does it run better ?

I was originally ignoring the tight turns because when turning tight you put a lot of load on the transmission and if it is easier for a spring to stretch than move the mower that is exactly what the mower will do.

There is a small chance that the diff is playing up but for the moment I would ignore that because in 7 years of reparing I am yet to come across a blown diff in any mower.

Did you take the rear wheels off ?

If so did you replace the drive keys on the axles ?

When you replaced the belt did you replace both pulleys ?

If so did you put them back in the right order, flat to the front & V at the rear.

I am being deadly serious right now and this is the best information I can give any newbie ride on repairer.

John Deer write the worlds best repair manual, called "Technical manuals "

They make Windows for Dummies look complicated and are written so a person who does not know which end of a screwdriver to hold can understand what is written.

Each section starts with an explanation of how the bits work, followed by who to test them, what the tests mean & how to repair them.

Down side is quality does not come cheap so most will not buy one because they believe it all should be free to owners.

Buy a copy

This is particularly the case when 99% of the time the posted only gives us 10% of the story to work with .

So time for the whole story put your chair in front of a table with a desk lamp shining into your eyes and start confessing .

Was the mower doing this before you change the belt ?

Did you take photos before you started to ensure that the new belt was routed correctly ?

Can you pull the brake pedal up and if you do does it run better ?

I was originally ignoring the tight turns because when turning tight you put a lot of load on the transmission and if it is easier for a spring to stretch than move the mower that is exactly what the mower will do.

There is a small chance that the diff is playing up but for the moment I would ignore that because in 7 years of reparing I am yet to come across a blown diff in any mower.

Did you take the rear wheels off ?

If so did you replace the drive keys on the axles ?

When you replaced the belt did you replace both pulleys ?

If so did you put them back in the right order, flat to the front & V at the rear.

I am being deadly serious right now and this is the best information I can give any newbie ride on repairer.

John Deer write the worlds best repair manual, called "Technical manuals "

They make Windows for Dummies look complicated and are written so a person who does not know which end of a screwdriver to hold can understand what is written.

Each section starts with an explanation of how the bits work, followed by who to test them, what the tests mean & how to repair them.

Down side is quality does not come cheap so most will not buy one because they believe it all should be free to owners.

Buy a copy

#6

R

robmorren2

R

robmorren2

I appreciate you taking the time. I did spend several nights googling and youtubing before posting a thread, so I tried to be thorough ...

I did double check the belt this time (put a brand new one on). When I replaced the belt pulleys I did them one at a time so I wouldn't swap them. I did find both keys in the wheels like they should be (I was really hoping that was what the clicking noise was).

I took off the wheels and jacked up the back end with a chain hoist. I ran it with no wheels and the axles hanging free. I grabbed a rag and squeezed the smooth area of one side of the axle as it was spinning, and I did hear the clicking noise and felt a slip or loss of power very momentarily and repetitively. When I let off the pressure, it spun normally from what I could tell. I'm not sure if that signals differential issues or something?

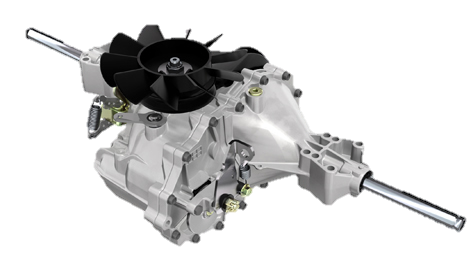

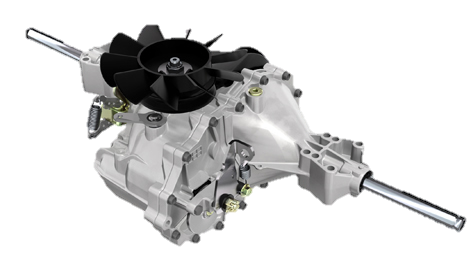

I'm getting a used T40 to swap out in the mean time. Hopefully the swap works, then I can crack into the old one and possibly repair it (assuming it was the issue). My brother and I both have Deeres that use the T40, so a spare would be nice to have in the shed.

Thanks again!

I did double check the belt this time (put a brand new one on). When I replaced the belt pulleys I did them one at a time so I wouldn't swap them. I did find both keys in the wheels like they should be (I was really hoping that was what the clicking noise was).

I took off the wheels and jacked up the back end with a chain hoist. I ran it with no wheels and the axles hanging free. I grabbed a rag and squeezed the smooth area of one side of the axle as it was spinning, and I did hear the clicking noise and felt a slip or loss of power very momentarily and repetitively. When I let off the pressure, it spun normally from what I could tell. I'm not sure if that signals differential issues or something?

I'm getting a used T40 to swap out in the mean time. Hopefully the swap works, then I can crack into the old one and possibly repair it (assuming it was the issue). My brother and I both have Deeres that use the T40, so a spare would be nice to have in the shed.

Thanks again!

#7

B

bertsmobile1

B

bertsmobile1

On the end of the axles is a spline with a gear.

So you may have stripped one of those.

The tranny is no a mower part so you will have to chase up them for tranny parts.

Should be a sticker both sides rear on the tranny with the maker & model number .

Probably a K 46

I gather this was a mower you bought 2nd hand .

And again I recommend getting your hand on the JD Tech manual

Cheaper than the labour cost on a simple service .

Around of 80% of what is on You Tube is trash , missinformation & prejudice .

Every one boast about how smart they were and how good the rubbish bodge was.

You don't see what happened 2 weeks latter when the mower crapped itself into oblivion.

As for Face Ache there is a good reason why it is free and at that price it is still poor value for money .

That being said, the 100 series of mowers is JD's lowest ( read cheapest ) end mower built down to a price low enough for big box discounters to carry them, in order to get sufficient volume through the mower factory to be able to make the better models at a reasonable price.

HAving said that the bottom end green one is still a better mower than the top end orange ones

So you may have stripped one of those.

The tranny is no a mower part so you will have to chase up them for tranny parts.

Should be a sticker both sides rear on the tranny with the maker & model number .

Probably a K 46

I gather this was a mower you bought 2nd hand .

And again I recommend getting your hand on the JD Tech manual

Cheaper than the labour cost on a simple service .

Around of 80% of what is on You Tube is trash , missinformation & prejudice .

Every one boast about how smart they were and how good the rubbish bodge was.

You don't see what happened 2 weeks latter when the mower crapped itself into oblivion.

As for Face Ache there is a good reason why it is free and at that price it is still poor value for money .

That being said, the 100 series of mowers is JD's lowest ( read cheapest ) end mower built down to a price low enough for big box discounters to carry them, in order to get sufficient volume through the mower factory to be able to make the better models at a reasonable price.

HAving said that the bottom end green one is still a better mower than the top end orange ones

#8

R

robmorren2

R

robmorren2

Yes, I bought it used and have had it 10 years or so. It's a Tuff Torq T40A ... Is there a way to test the axle splines without cracking open the case? I've got it pulled off now ...

Attachments

#9

B

bertsmobile1

B

bertsmobile1

No

The diff allows the wheels to turn in opposite directions

Clean the outside thoroughly

I am a bit **** but I degrease, then soda blast then pressure wash then blow dry .

Once dry prize off the FLAT rubber cup carefully tip it upside down and leave it a full day to drain Tuff Torque used to have all their IPL's on line and some not particularly good service manuals .

Check the pump & motor before you go overboard fixing any thing else because at 10 it could be getting very close to it's service life.

JD use 10W 40 oil & Tuff Torq recommend 20W 50 so going to a thicker oil can sometimes add another 5 years to the tranny depending upon just how bad it is scored

You are bordering on the edge of what I can help you with.

4 years ago a service agent set up who refurbished hydros so I take mine to an expert rather than buggerising around with them myself .

The factory is a positative pressure environment to keep dust out of the grubbins so keep it covered with a damp towel when open .

The diff allows the wheels to turn in opposite directions

Clean the outside thoroughly

I am a bit **** but I degrease, then soda blast then pressure wash then blow dry .

Once dry prize off the FLAT rubber cup carefully tip it upside down and leave it a full day to drain Tuff Torque used to have all their IPL's on line and some not particularly good service manuals .

Check the pump & motor before you go overboard fixing any thing else because at 10 it could be getting very close to it's service life.

JD use 10W 40 oil & Tuff Torq recommend 20W 50 so going to a thicker oil can sometimes add another 5 years to the tranny depending upon just how bad it is scored

You are bordering on the edge of what I can help you with.

4 years ago a service agent set up who refurbished hydros so I take mine to an expert rather than buggerising around with them myself .

The factory is a positative pressure environment to keep dust out of the grubbins so keep it covered with a damp towel when open .

#10

R

robmorren2

R

robmorren2

Thanks for the help. Hopefully the used one I'm shipping in just works well, and I can play around with the old one. Best case I figure it out and fix it for a spare, worst case I'll have a better idea of how JD / Tuff Torq transaxles work. A year ago I was intimidated by the idea of taking off the mower deck. I'm actually enjoying learning how to mess with these.

#12

B

bertsmobile1

B

bertsmobile1

Congratulation

First time I have ever seen a broken diff

Easy drop in parts but check the cylinder chest on both the pump & motor for gouges made by the shrapnel.

If the magnets have been ding their job it should be fine.

Otherwise Mulligans seem to be the best people for tranny parts

First time I have ever seen a broken diff

Easy drop in parts but check the cylinder chest on both the pump & motor for gouges made by the shrapnel.

If the magnets have been ding their job it should be fine.

Otherwise Mulligans seem to be the best people for tranny parts

#13

R

robmorren2

R

robmorren2

Thanks Bert. Looks like the parts are fairly cheap so I think I'm going to try to repair it just to see if I can. That definitely explains why it was such a god awful noise!

#14

M

mechanic mark

hydrodrives.com

Just in case it's available & free shipping.

hydrodrives.com

Just in case it's available & free shipping.

www.tufftorq.com

www.tufftorq.com

M

mechanic mark

T2-ADBE-2X1A-1CX1 - T2 Integrated Hydrostatic Transaxle

Description T2 Integrated Hydrostatic Transaxle Cross Reference Numbers T2-AABC-2X1A-1CX1, T2-AABC-2X1A-1CXX

Tech Tips -Using Tuff Torq repair kits on your hydrostatic transaxle

Tuff Torq has provided this brief article to insure that you have success using Tuff Torq repair kits on your hydrostatic transaxle

#15

R

robmorren2

R

robmorren2

Thanks for the links MM. I was able to order a differential repair kit for about $35 with shipping. I've got some Loctite Superflex Red RTV gasket maker that I think should work ok, so I could get out of this fairly cheaply. Most threads and videos I've found on K46/T40 suggest using 5w50, so that'll be another $30 or so in oil. Altogether, not too bad if I can do it right.

To get me by I rolled the dice and got a used unit on ebay for $170. I drained the oil (which actually looked pretty good) and cleaned the magnet (which also looked pretty clean). I don't know if it was spruced up for sale, but it appeared to be in great shape. I put some fresh 5w50 in, purged the air with a drill, and slapped in it. So far so good! So if I can repair my old one I'll have a spare for my mower and my brother's (his LA115 also uses the T40). I can tow my aerator and dethatcher with slightly less stress, lol.

To get me by I rolled the dice and got a used unit on ebay for $170. I drained the oil (which actually looked pretty good) and cleaned the magnet (which also looked pretty clean). I don't know if it was spruced up for sale, but it appeared to be in great shape. I put some fresh 5w50 in, purged the air with a drill, and slapped in it. So far so good! So if I can repair my old one I'll have a spare for my mower and my brother's (his LA115 also uses the T40). I can tow my aerator and dethatcher with slightly less stress, lol.

#16

B

bertsmobile1

B

bertsmobile1

When I service a fully sealed tranny and do not change the pump / motor unit ( down here they are $ 800 - $ 1000 , about 1/2 the new box price ) I went up to the next highest base viscosity

So I would advise to go to 10W 50 for your old box .

So I would advise to go to 10W 50 for your old box .

#17

R

robmorren2

R

robmorren2

I'm a novice DIY'er ... is the heavier weight basically to reduce seepage through worn seals and scored metal?

#18

B

bertsmobile1

B

bertsmobile1

YEp.

When they get old & start to slip I used to tip the old oil out & go one thicker

I can do it down here in OZ cause it dos not snow so no need for very low viscosity oil

Old leaky ( intenally ) K46 can run for quite a while when upped from the 10W 40 JD uses to 20W 50 .

If yu fit a new pump / motor then use the original specified grade as there is no wear to compensate for.

A few years ago a back yard machins shop started refurbishing Hydros so I no longer touch them

HE charges about 1/2 the parts price to machine the cylinder block & valve plate back to the original surface finish.

What I find amazing is no one does the same thing over there.

What has happened to the "land of oppertunity "

When they get old & start to slip I used to tip the old oil out & go one thicker

I can do it down here in OZ cause it dos not snow so no need for very low viscosity oil

Old leaky ( intenally ) K46 can run for quite a while when upped from the 10W 40 JD uses to 20W 50 .

If yu fit a new pump / motor then use the original specified grade as there is no wear to compensate for.

A few years ago a back yard machins shop started refurbishing Hydros so I no longer touch them

HE charges about 1/2 the parts price to machine the cylinder block & valve plate back to the original surface finish.

What I find amazing is no one does the same thing over there.

What has happened to the "land of oppertunity "

#19

T

tobybul

T

tobybul

I have a very similar situation with my JD L120 with only 248hours. It intermittently jerks and clicks especially going uphill or making tight turns with or without the mower deck. From onlline research these symptoms does not seem to point to a bad transaxle. Things I've done so far hoping to correct it are (1) replaced the transmission drive belt (2) replaced idler pulleys. This did not fix it. Next, (1) I took off the rear end and drained and replaced the transmission oil. This did not fix it. (2) I checked the splines of the drive shaft where the drive pulley is attached in case it might be damaged. Nothing there. What I noticed is the drive belt does not seem tout and wondering if it is slipping. Could it be that an idler spring is missing? Since I don't know how the original idler setup is supposed to look like I cant tell if some thing is missing or not. Does anyone have information on how the idler setup is supposed to look like?