You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Hustlers Raptor XDX help

#1

E

Engine207

E

Engine207

Hi all!

First post here, so go easy on me, boys! Went out to start my 2021 Hustler Raptor XDX, and all I got was a click. Checked the battery at 12.9V (which had been on a trickle), verified the 15A fuse was good, made sure my deck clutch was pushed down, and my drive arms were fully out. When I look at my hour meter, there’s a little icon that flashes in the run position, but solid in the off position.

I just cut the grass last week without any problems and parked it in the garage. I believe my mower thinks the interlock parking brake isn’t fully engaged. I’d appreciate some help troubleshooting, adjusting or bypassing the interlock. TIA!

First post here, so go easy on me, boys! Went out to start my 2021 Hustler Raptor XDX, and all I got was a click. Checked the battery at 12.9V (which had been on a trickle), verified the 15A fuse was good, made sure my deck clutch was pushed down, and my drive arms were fully out. When I look at my hour meter, there’s a little icon that flashes in the run position, but solid in the off position.

I just cut the grass last week without any problems and parked it in the garage. I believe my mower thinks the interlock parking brake isn’t fully engaged. I’d appreciate some help troubleshooting, adjusting or bypassing the interlock. TIA!

#2

R

Rivets

R

Rivets

Here is my procedure for diagnosing electrical problems on tractors. With a little tweaking it works on Z-turns. I’m thinking you may have a bad battery, which these tests will confirm or deny.

Electrical problems can be very easy or very difficult, depending on four things.

1. How well you understand basic electricity.

2. What tools you have and know how to use.

3. How well you follow directions.

4. You don't overlook or assume anything and verify everything.

Remember we cannot see what you are doing. You are our eyes, ears and fingers in solving this problem. You must be as accurate as you can when you report back. The two basic tools we will ask you to use are a test light and a multi-meter. If you have an assistant when going through these tests it would be very helpful. These steps work the best when done in order, so please don't jump around. Now let's solve this problem.

First, check the fuse(s), check battery connections for corrosion (clean if necessary) and voltage - above 12.5 volts should be good. Check and make sure the chassis ground is clean and tight.

Second, check for power from the battery to one of the large terminals on the solenoid. One of the wires is connected directly to the battery and has power all the time so one of the large terminals should light a test light or show 12 volts on a meter at all times.

Third, check for power at the small terminal of the solenoid while depressing the clutch/brake pedal and holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch). If your solenoid is a four wire solenoid, check both small wire terminals as one is ground and the other is power from the ignition switch. If your solenoid is a three wire solenoid, make sure the solenoid body is not corroded where it bolts to the chassis of the mower as this is your ground path back to the battery. If in doubt, remove the solenoid and clean the mounting area down to bare metal. If there is no power to the small terminal then your problem is most likely a safety switch, ignition switch or in the wiring.

Fourth, check for power on the other large terminal of the solenoid while holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch).

Fifth, check for power at the starter while holding the key in the start position (assistant again).

Sixth, check your ground circuit back to the battery.

After you have gone through each of the above steps, let us know what happened when you did each step. At that point we will have great info to tell you how to proceed. Remember you are our eyes, ears, and fingers, so please be as accurate as possible.

Be as specific as possible with voltage readings as this will help diagnose your problem quicker. If you do not know how to perform the above checks, just ask and I will try to guide you through it. Youtube also has some videos and as you know a picture is worth a thousand words

Electrical problems can be very easy or very difficult, depending on four things.

1. How well you understand basic electricity.

2. What tools you have and know how to use.

3. How well you follow directions.

4. You don't overlook or assume anything and verify everything.

Remember we cannot see what you are doing. You are our eyes, ears and fingers in solving this problem. You must be as accurate as you can when you report back. The two basic tools we will ask you to use are a test light and a multi-meter. If you have an assistant when going through these tests it would be very helpful. These steps work the best when done in order, so please don't jump around. Now let's solve this problem.

First, check the fuse(s), check battery connections for corrosion (clean if necessary) and voltage - above 12.5 volts should be good. Check and make sure the chassis ground is clean and tight.

Second, check for power from the battery to one of the large terminals on the solenoid. One of the wires is connected directly to the battery and has power all the time so one of the large terminals should light a test light or show 12 volts on a meter at all times.

Third, check for power at the small terminal of the solenoid while depressing the clutch/brake pedal and holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch). If your solenoid is a four wire solenoid, check both small wire terminals as one is ground and the other is power from the ignition switch. If your solenoid is a three wire solenoid, make sure the solenoid body is not corroded where it bolts to the chassis of the mower as this is your ground path back to the battery. If in doubt, remove the solenoid and clean the mounting area down to bare metal. If there is no power to the small terminal then your problem is most likely a safety switch, ignition switch or in the wiring.

Fourth, check for power on the other large terminal of the solenoid while holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch).

Fifth, check for power at the starter while holding the key in the start position (assistant again).

Sixth, check your ground circuit back to the battery.

After you have gone through each of the above steps, let us know what happened when you did each step. At that point we will have great info to tell you how to proceed. Remember you are our eyes, ears, and fingers, so please be as accurate as possible.

Be as specific as possible with voltage readings as this will help diagnose your problem quicker. If you do not know how to perform the above checks, just ask and I will try to guide you through it. Youtube also has some videos and as you know a picture is worth a thousand words

#3

E

Engine207

The dealer where I bought it told me that the AGM batteries have very short lives without being kept on a trickle. After messing with my last battery for weeks, he just replaced it with the one in there.

I’d also previous problem with starting that was solved with another battery.

E

Engine207

I’ll give you some additional history to consider.Here is my procedure for diagnosing electrical problems on tractors. With a little tweaking it works on Z-turns. I’m thinking you may have a bad battery, which these tests will confirm or deny.

Electrical problems can be very easy or very difficult, depending on four things.

1. How well you understand basic electricity.

2. What tools you have and know how to use.

3. How well you follow directions.

4. You don't overlook or assume anything and verify everything.

Remember we cannot see what you are doing. You are our eyes, ears and fingers in solving this problem. You must be as accurate as you can when you report back. The two basic tools we will ask you to use are a test light and a multi-meter. If you have an assistant when going through these tests it would be very helpful. These steps work the best when done in order, so please don't jump around. Now let's solve this problem.

First, check the fuse(s), check battery connections for corrosion (clean if necessary) and voltage - above 12.5 volts should be good. Check and make sure the chassis ground is clean and tight.

Second, check for power from the battery to one of the large terminals on the solenoid. One of the wires is connected directly to the battery and has power all the time so one of the large terminals should light a test light or show 12 volts on a meter at all times.

Third, check for power at the small terminal of the solenoid while depressing the clutch/brake pedal and holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch). If your solenoid is a four wire solenoid, check both small wire terminals as one is ground and the other is power from the ignition switch. If your solenoid is a three wire solenoid, make sure the solenoid body is not corroded where it bolts to the chassis of the mower as this is your ground path back to the battery. If in doubt, remove the solenoid and clean the mounting area down to bare metal. If there is no power to the small terminal then your problem is most likely a safety switch, ignition switch or in the wiring.

Fourth, check for power on the other large terminal of the solenoid while holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch).

Fifth, check for power at the starter while holding the key in the start position (assistant again).

Sixth, check your ground circuit back to the battery.

After you have gone through each of the above steps, let us know what happened when you did each step. At that point we will have great info to tell you how to proceed. Remember you are our eyes, ears, and fingers, so please be as accurate as possible.

Be as specific as possible with voltage readings as this will help diagnose your problem quicker. If you do not know how to perform the above checks, just ask and I will try to guide you through it. Youtube also has some videos and as you know a picture is worth a thousand words

The dealer where I bought it told me that the AGM batteries have very short lives without being kept on a trickle. After messing with my last battery for weeks, he just replaced it with the one in there.

I’d also previous problem with starting that was solved with another battery.

#4

E

Engine207

E

Engine207

- I checked the 15A fuse and it’s intact

- I checked the battery connectionsand there was no corrosion. Voltage at the terminals shows 12.64 volts

- I checked the chassis ground it’s clean and tight

- I checked the power from the battery to one of the large terminals on the solenoid. It was 12.54V

- I checked power at the small terminal of the solenoid while depressing the clutch/brake pedal and holding the key in the start position. It jumped around a little, but seemed to be around 129 mV

- I checked for power on the other large terminal of the solenoid while holding the key in the start position. It was about 12.3V

- I checked for power at the starter while holding the key in the start position (assistant again). It was 129 mV

- I checked the ground circuit back to the battery. It showed continuity from the battery to the chassis

#5

R

Rivets

R

Rivets

I agree, but do one more check. Touch a jumper lead from solenoid to battery terminal to small solenoid start terminal. Starter kicks in, your assumption is correct.

#6

E

Engine207

E

Engine207

Gotcha. This is to eliminate the solenoid and the starter itself as the problem, yes?I agree, but do one more check. Touch a jumper lead from solenoid to battery terminal to small solenoid start terminal. Starter kicks in, your assumption is correct.

#8

E

Engine207

E

Engine207

Surprisingly, I’ve not done this before. Can I get a quick walk-through? What wire gauge does the jumper lead need to be? Is there a particular connection order? Do u remove the jumper wire after it starts? Any particular do’s/dont’s, etc?Touch a jumper lead from solenoid to battery terminal to small solenoid start terminal.

#9

R

Rivets

R

Rivets

Any good jumper wire will work. You will see a few sparks, you just touch the small terminal. If the starter engages and spins the engine remove the jumper and the starter should stop.

#10

E

Engine207

E

Engine207

So, if the starter has turned the engine over, and I remove the jumper, that won’t cut the engine, will it?

I’m hoping to get it started, cut the grass, then deal with the permanent repairs (new sensors? ignition switch?).

I’m hoping to get it started, cut the grass, then deal with the permanent repairs (new sensors? ignition switch?).

#11

R

Rivets

R

Rivets

You need the key in the run position and parking brake on for the unit to keep running. If the engine fails to start you may have a short some where in the wiring harness or a bad safety switch also.

#12

E

Engine207

E

Engine207

So I tried the solenoid small solenoid jump test with the battery on run, and it fired right up. Jumper wire got super hot, but it started. I mowed the whole 7 acres without shutting it off (in-flight refueling), but when I was finally done and did turn the key off, it just clicked. Jumper again, started it right up.

small solenoid jump test with the battery on run, and it fired right up. Jumper wire got super hot, but it started. I mowed the whole 7 acres without shutting it off (in-flight refueling), but when I was finally done and did turn the key off, it just clicked. Jumper again, started it right up.

So…it’s probably not the starter, ignition switch, or interlock, right? But pretty safe to say it’s the solenoid itself…right?

So…it’s probably not the starter, ignition switch, or interlock, right? But pretty safe to say it’s the solenoid itself…right?

#13

R

Rivets

R

Rivets

NO, not the solenoid. By jumping straight to solenoid you proved it was good. Either key switch or one of the safety switches. Need to get out your test light or meter and start tracing all wires from the S terminal on the key switch to the small terminal on the solenoid. Post the entire model number from the ID tag and we will try to find you a wiring diagram.

#14

E

Engine207

I have a Hustler Raptor XDX - HTRDXS054KAWFR691VA

Model # 939835

E

Engine207

Oh, gotcha! What I jumped was one solenoid terminal (the one showing 12.6V) to the other (129 mV). It was actually an accident, as I was trying to jump the + post of the battery to both.NO, not the solenoid. By jumping straight to solenoid you proved it was good. Either key switch or one of the safety switches. Need to get out your test light or meter and start tracing all wires from the S terminal on the key switch to the small terminal on the solenoid. Post the entire model number from the ID tag and we will try to find you a wiring diagram.

I have a Hustler Raptor XDX - HTRDXS054KAWFR691VA

Model # 939835

#15

R

Rivets

R

Rivets

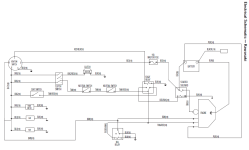

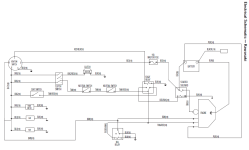

Page 25 of this manual may help you out. https://www.manualslib.com/manual/955624/Hustler-Raptor.html#manual

#16

E

Engine207

E

Engine207

Thank you. Downloaded!!

So we’re narrowing down the culprit here, right? Either the handle sensors saying ‘I’m not in park’ when I’m trying to start, or the ignition switch somehow isn’t letting the current flow to the solenoid?

I needed a few spare parts, so I ordered a $25 oem ignition switch with em. I realize it may be fine and the problem is a simple adjustment of the handlebars, but according to the manual, adjusting those is supposed to be ‘trained maintenance personnel’. Does Internet University count?

if it turns out to be something with the handles after all, I’ll have to figure out how to do it (or find a buddy with a trailer, to take it to the dealer!). I’d love to just override the whole thing, but safety…I know.

So we’re narrowing down the culprit here, right? Either the handle sensors saying ‘I’m not in park’ when I’m trying to start, or the ignition switch somehow isn’t letting the current flow to the solenoid?

I needed a few spare parts, so I ordered a $25 oem ignition switch with em. I realize it may be fine and the problem is a simple adjustment of the handlebars, but according to the manual, adjusting those is supposed to be ‘trained maintenance personnel’. Does Internet University count?

if it turns out to be something with the handles after all, I’ll have to figure out how to do it (or find a buddy with a trailer, to take it to the dealer!). I’d love to just override the whole thing, but safety…I know.

#17

L

LMPPLUS

L

LMPPLUS

Engine207, If you have a DC voltage tester, check for power to your solenoid control wire and to the battery terminal to the starter when you turn the key on, if you have power to control wire and not to starter you got a bad solenoid, if you have power to starter and it only hums you got a bad starter. By the way whats the engine on this mower?Hi all!

First post here, so go easy on me, boys! Went out to start my 2021 Hustler Raptor XDX, and all I got was a click. Checked the battery at 12.9V (which had been on a trickle), verified the 15A fuse was good, made sure my deck clutch was pushed down, and my drive arms were fully out. When I look at my hour meter, there’s a little icon that flashes in the run position, but solid in the off position.

I just cut the grass last week without any problems and parked it in the garage. I believe my mower thinks the interlock parking brake isn’t fully engaged. I’d appreciate some help troubleshooting, adjusting or bypassing the interlock. TIA!

#18

L

LMPPLUS

L

LMPPLUS

PS: Your safety sensors are not part of the starter circuit, if they are bad it should turn over but not have any fire to the plug.

#19

R

Rivets

R

Rivets

LMPPLUS, safety switches (sensors) ARE part of the starting circuit. Second, if you read the entire thread, he has tested the components and found that the solenoid is good.

#21

F

Freddie21

F

Freddie21

Couple things, You may have a bad battery, solenoid, starter or locked engine. You indicated 127mv at the starter lead of the solenoid when the key is turned. This should be 12v as the solenoid passes the 12 from the battery connection to the starter. If the solenoid is clicking and the starter is not turning, then I would think bad solenoid. You can test in one of two ways: Use car jumper cables and put one of the red leads to the starter large red connection and touch the other end to the battery Pos+ terminal. If the starter spins, bad solenoid. Second way, using a larger screw driver jump the two large red connections of the solenoid together, same thing with the starter spinning. This is not the preferred way and is usually done if you stuck in the field and don't \have a jumper wire.

If the starter does not spin, but just clicks, it mat be locked against the flywheel or bad itself. Before testing, make sure you can rotate the engine by hand 360 degrees. Will be tight. If it doesn't turn remove the engine cover, get rid of any critters or grass and see if the starter gear is meshed with the flywheel. If it's ok, then remove the spark plug and see if you can rotate the engine.

If the starter does not spin, but just clicks, it mat be locked against the flywheel or bad itself. Before testing, make sure you can rotate the engine by hand 360 degrees. Will be tight. If it doesn't turn remove the engine cover, get rid of any critters or grass and see if the starter gear is meshed with the flywheel. If it's ok, then remove the spark plug and see if you can rotate the engine.

#22

R

Rivets

R

Rivets

Only time I’ve ever seen safety sensors wired in an ignition system is when you have a battery ignition system. This style of system has been discontinued in 95% of all lawn and garden equipment. Otherwise the parts of a magneto ignition system are key switch, wire going from key switch to coil, (which is known as the kill wire) coil, and spark plug.

#23

D

dhawk

D

dhawk

Engine 207, I have that same raptor model, 18hp Kawasaki engine, had the same problem mowed the yard went t the shop, shut her down and blew the deck and engine compartment out with air, got on and tried to start and nothing. Ran the procedures as explained here still nothing, jumped the solenoid across and it started. I then started at the switch and ohmed the start switch each post ohmed thru even the post from the start post with the key held to start, then I ohmed the wire from start post to solenoid and Wa-La broken wire just behind the connector, replaced the post connector, problem solved. this is just one more quick check that may help you out. Good Luck.

#24

H

heyinway

H

heyinway

Battery can show proper voltage but low on amperage. I see that all the time. Safety switches rarely fail.

#25

D

Divot

THANK YOU FOR BEING SO THOROUGH. WOW

No wonder I read these post so much.

you’re brilliant!

D

Divot

Oh my. I’m going to share this procedure and save it myselfHere is my procedure for diagnosing electrical problems on tractors. With a little tweaking it works on Z-turns. I’m thinking you may have a bad battery, which these tests will confirm or deny.

Electrical problems can be very easy or very difficult, depending on four things.

1. How well you understand basic electricity.

2. What tools you have and know how to use.

3. How well you follow directions.

4. You don't overlook or assume anything and verify everything.

Remember we cannot see what you are doing. You are our eyes, ears and fingers in solving this problem. You must be as accurate as you can when you report back. The two basic tools we will ask you to use are a test light and a multi-meter. If you have an assistant when going through these tests it would be very helpful. These steps work the best when done in order, so please don't jump around. Now let's solve this problem.

First, check the fuse(s), check battery connections for corrosion (clean if necessary) and voltage - above 12.5 volts should be good. Check and make sure the chassis ground is clean and tight.

Second, check for power from the battery to one of the large terminals on the solenoid. One of the wires is connected directly to the battery and has power all the time so one of the large terminals should light a test light or show 12 volts on a meter at all times.

Third, check for power at the small terminal of the solenoid while depressing the clutch/brake pedal and holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch). If your solenoid is a four wire solenoid, check both small wire terminals as one is ground and the other is power from the ignition switch. If your solenoid is a three wire solenoid, make sure the solenoid body is not corroded where it bolts to the chassis of the mower as this is your ground path back to the battery. If in doubt, remove the solenoid and clean the mounting area down to bare metal. If there is no power to the small terminal then your problem is most likely a safety switch, ignition switch or in the wiring.

Fourth, check for power on the other large terminal of the solenoid while holding the key in the start position (you may need an assistant to sit in the seat to override the safety switch).

Fifth, check for power at the starter while holding the key in the start position (assistant again).

Sixth, check your ground circuit back to the battery.

After you have gone through each of the above steps, let us know what happened when you did each step. At that point we will have great info to tell you how to proceed. Remember you are our eyes, ears, and fingers, so please be as accurate as possible.

Be as specific as possible with voltage readings as this will help diagnose your problem quicker. If you do not know how to perform the above checks, just ask and I will try to guide you through it. Youtube also has some videos and as you know a picture is worth a thousand words

THANK YOU FOR BEING SO THOROUGH. WOW

No wonder I read these post so much.

you’re brilliant!

#26

C

Cheeseoreno

C

Cheeseoreno

What "Rivet" stated is correct BUT there is one more thing to look for. I had the same issue and when I pulled out my Ignition key assembly I noticed that the starter would click AND Run if I pulled. If I pushed it would not. I found the RED wire had broken inside the insulation. Make sure you buy an excellent quality Crimper if you go that route. I purchased a Klein that releases once the correct amount of crimp is established. Too many times in the past I crimped but not enough so the connection became bad again.Hi all!

First post here, so go easy on me, boys! Went out to start my 2021 Hustler Raptor XDX, and all I got was a click. Checked the battery at 12.9V (which had been on a trickle), verified the 15A fuse was good, made sure my deck clutch was pushed down, and my drive arms were fully out. When I look at my hour meter, there’s a little icon that flashes in the run position, but solid in the off position.

I just cut the grass last week without any problems and parked it in the garage. I believe my mower thinks the interlock parking brake isn’t fully engaged. I’d appreciate some help troubleshooting, adjusting or bypassing the interlock. TIA!

#27

W

WSD

W

WSD

That was concise, detailed help you provided and structured well to derive a solution without getting lost in the weeds.

If I can ever help anyone here I'll keep your directions in mind as an example. So many of these "helpful" replies on here are someone's guess at what's wrong other than guidance through a systematic troubleshooting process. Nicely done.

If I can ever help anyone here I'll keep your directions in mind as an example. So many of these "helpful" replies on here are someone's guess at what's wrong other than guidance through a systematic troubleshooting process. Nicely done.

#28

W

WSD

W

WSD

And I know about getting lost in the weeds trying to figure an issue out. My Lazer ZX has not 1 but 3 separate microprocessors running the mower and engine. Going slowly and by the book has seemed to actually save me time in the long run. My $0.02

#29

Mr. Mower

Mr. Mower

This is a very informative thread on the subject.

Thanks to all those who have contributed.

Thanks to all those who have contributed.

#30

D

davis2

D

davis2

I would like to add that some people while trying to help, should read all posts before replying. It would eliminate confusion, and make an easier read. Thank you.

#31

E

Engine207

E

Engine207

Sorry it’s been awhile since I posted on my own thread, but had family in for Father’s Day.

Now…when I left off, I was able to start the mower by jumping the two solenoid posts together. I havent gone back through and inspected every wire connection with the tester, but I did gamble $25 that it was the ignition switch, and lost. After replacing it, the same “click” result.

So if it starts with a solenoid-to-solenoid jump every time, am i proving my solenoid works? The jumper starts it with the old switch and the new switch…is it reasonable to conclude it’s not the safety sensors; not the ignition switch; not the battery; not the starter; and not the engine itself? Am I down to a bad wiring connection? I guess I’ll just re-read the whole wire tracing business and try that.

On the upside, this is my start-up “key”

I found an old piece of romex with some heavy gauge wire, so my jumper is pretty solid and no more heat!

Now…when I left off, I was able to start the mower by jumping the two solenoid posts together. I havent gone back through and inspected every wire connection with the tester, but I did gamble $25 that it was the ignition switch, and lost. After replacing it, the same “click” result.

So if it starts with a solenoid-to-solenoid jump every time, am i proving my solenoid works? The jumper starts it with the old switch and the new switch…is it reasonable to conclude it’s not the safety sensors; not the ignition switch; not the battery; not the starter; and not the engine itself? Am I down to a bad wiring connection? I guess I’ll just re-read the whole wire tracing business and try that.

On the upside, this is my start-up “key”

I found an old piece of romex with some heavy gauge wire, so my jumper is pretty solid and no more heat!

#32

B

bertsmobile1

B

bertsmobile1

All your piece of wire proves is the wire can carry enough current to power the starter motor.

You found the problem back in post # 4 the red/black wire at the base of the solenoid does not show battery voltage when the key is in the S position

I do not have an XDX wiring diagram so the remainder is based on the Raptor SD

The solenoid gets its trigger voltage from the starting/ignition relay via a red & black wire

There should be one or more relays look for on e that has a red & black wire

IT should click when you turn the key to start

If you want information that is exactly right for your mower we need your model & serial numbers so we can download the service manual from Hustler .

You found the problem back in post # 4 the red/black wire at the base of the solenoid does not show battery voltage when the key is in the S position

I do not have an XDX wiring diagram so the remainder is based on the Raptor SD

The solenoid gets its trigger voltage from the starting/ignition relay via a red & black wire

There should be one or more relays look for on e that has a red & black wire

IT should click when you turn the key to start

If you want information that is exactly right for your mower we need your model & serial numbers so we can download the service manual from Hustler .

#33

StarTech

StarTech

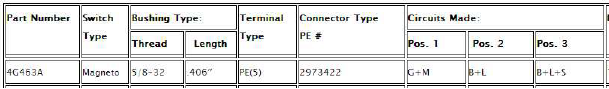

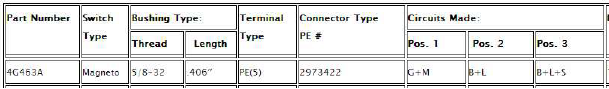

Bert you said you need the schematic and now you do have it.

In the schematic switch lettering becomes as follows

L = R

M = K

S = S

B = B

Can be PTO or either one of the lap bar switches. Can even be a bad start relay or wiring issues. But with the OP able to start the mower either the seat switch has been enabled or the PTO switch, lap bar switches, and start relay is operating but has bad contacts. The question then is "Is the start relay operating?".

In the schematic switch lettering becomes as follows

L = R

M = K

S = S

B = B

Can be PTO or either one of the lap bar switches. Can even be a bad start relay or wiring issues. But with the OP able to start the mower either the seat switch has been enabled or the PTO switch, lap bar switches, and start relay is operating but has bad contacts. The question then is "Is the start relay operating?".

#34

B

bertsmobile1

B

bertsmobile1

Tar Star

Looks to be close enough to the same as all of the other Raptor models

He is getting a couple of mv on the red/black wire at the solenoid according to post #4

Now as you know the kill relay is working because it runs and shuts off swap the relays over

If it cranks and starts then you just had a bad base connection at the relay .

Give both bases a good spray with WD 40, contact cleaner etc then coat liberally with contact grease and plug both of them back in and go mow

If it cranked but did not start then the relay is deceased

If it did not crank at all then either the red / black from the key switch is not providing battery voltage or the tan / red is not supplying battery voltage

Now unless you have 3 hands it is good to make up 4 short jumpers with a male blade terminal at each end ( we call them patch leads just to confuse everyone and make us sound smart )

You will use these to bypass various switches

Pull the plug off the key switch you just replaced and check the switch makes to connections that Star has printed

If so then connect the red to the red / black then go and check for battery voltage at the relay which should click when you jump the plug

If you now have battery voltage at the relay base on the red / black wire ( note there are 2 of them & only one should show voltage at this stage ) and the relay does not click then the black ground wire is faulty

If that checks out OK then move the jumper at the key switch plug to join the B + R (or L ) which should be an orange wire

Back probe ( stick the probe into the wire end of the plug ) the PTO plug .

Both orange wires should be 12V and with the knob down the tan wire opposite an orange should also show 12 V while the orange / red should show no voltage

There should reverse when you pull the knob up.

If this is the case pull the plug and jump the orange + tan wires

Now comes the fun part .

Find where Hustler has hidden the lap bar switches

One will have 2 tan wires , you test it next

Back probe with the arm in should have 12 V on one side .

Back probe with the arm out , should have 12 V on both sides

Yes = switch is good , pull the plug & put another jumper in and go to the other side

Same story the tan should show 12V arm in and both wires should show 12 V arm out

If it also proves to be good then the tan / red wire is broken between the lap bar & the relay plug

IF you do not want to mess around with a meter then you can make a double jumper with 2 wires on one terminal

Then you plug the double into the red wire then the other 2 into the red / black + the orange

This way when you jump the bad plug the engine will crank

Looks to be close enough to the same as all of the other Raptor models

He is getting a couple of mv on the red/black wire at the solenoid according to post #4

Now as you know the kill relay is working because it runs and shuts off swap the relays over

If it cranks and starts then you just had a bad base connection at the relay .

Give both bases a good spray with WD 40, contact cleaner etc then coat liberally with contact grease and plug both of them back in and go mow

If it cranked but did not start then the relay is deceased

If it did not crank at all then either the red / black from the key switch is not providing battery voltage or the tan / red is not supplying battery voltage

Now unless you have 3 hands it is good to make up 4 short jumpers with a male blade terminal at each end ( we call them patch leads just to confuse everyone and make us sound smart )

You will use these to bypass various switches

Pull the plug off the key switch you just replaced and check the switch makes to connections that Star has printed

If so then connect the red to the red / black then go and check for battery voltage at the relay which should click when you jump the plug

If you now have battery voltage at the relay base on the red / black wire ( note there are 2 of them & only one should show voltage at this stage ) and the relay does not click then the black ground wire is faulty

If that checks out OK then move the jumper at the key switch plug to join the B + R (or L ) which should be an orange wire

Back probe ( stick the probe into the wire end of the plug ) the PTO plug .

Both orange wires should be 12V and with the knob down the tan wire opposite an orange should also show 12 V while the orange / red should show no voltage

There should reverse when you pull the knob up.

If this is the case pull the plug and jump the orange + tan wires

Now comes the fun part .

Find where Hustler has hidden the lap bar switches

One will have 2 tan wires , you test it next

Back probe with the arm in should have 12 V on one side .

Back probe with the arm out , should have 12 V on both sides

Yes = switch is good , pull the plug & put another jumper in and go to the other side

Same story the tan should show 12V arm in and both wires should show 12 V arm out

If it also proves to be good then the tan / red wire is broken between the lap bar & the relay plug

IF you do not want to mess around with a meter then you can make a double jumper with 2 wires on one terminal

Then you plug the double into the red wire then the other 2 into the red / black + the orange

This way when you jump the bad plug the engine will crank