You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Holy Smokes Stihl's prices.

#1

PTmowerMech

PTmowerMech

Bought a new MS271 yesterday. $500 friggin bucks. Apparently Stihl's don't even come with a case now a days. The guy threw in a file.

#3

ILENGINE

ILENGINE

Nephew put a down payment/deposit on a new skid steer in February. Quote at that time was $27,500 skid steer finally arrived Monday at the dealer and he is finalizing the finance. And oh by the way they had two price increases since the deposit. The new price is $31,965

#4

StarTech

StarTech

Just thank the former president for adding those European tariffs along with Russia/Ukraine war, Covid 19, and the all the generated inflation. The European tariffs were primarily on Steel and Aluminum products. The current president just ended those tariffs in October and it will take time for things to get back to normal again. Some items of the new agreement will not even take place until January 2023. On top of that Stihl is having find new source for parts that were made in the Ukraine factories; therefore, their production costs will raise.

#5

R

RayMcD

R

RayMcD

Ain't what they used to be, notice where they are now made...Bought a new MS271 yesterday. $500 friggin bucks. Apparently Stihl's don't even come with a case now a days. The guy threw in a file.

#6

B

bertsmobile1

B

bertsmobile1

Stihl is like all large manufacturers in that they have multiple factories

It is part of the serial number code

Top shelf commercial units are made in Germany & the USA

Second tier models are made in Italy, Spain & Argentina

Throw away quality for cheapskates is made in China .

If people stopped buying garbage the factories would stop making garbage

But while idiots buy 100% on price more stuff will come out of the cheapest place to make it

The greater the volume that is made for idiots the less volume that goes through the quality plants so the dearer the top shelf models will become .

The consumers of the planet have been hood winked by the directors of big companies who have been buying stuff from 3rd world factories & selling it at 20 to 100 times the cost price so they can pay themselves multi million dollar bonuses .

Since the GFC company profits have increased 600% executive wages have risen 2000% workers wages have risen 28% ( slightly less than inflation ) .

This is what happens particularly in the USA when you have weak governments run by parties desperate for money to pay for massive advertising campaigns in order to brain wash the population to vote them into power, regardless of their colour .

Government of the poor by the rich for the rich to entrench the position of the rich who are allowed to be above the laws , as weak as they are .

And if you think this is tosh look at the prices for goods from China when bought in the tens of thousands and compare that to the "cheap" price from H, Lowes, Wallys AmmoZone etc etc etc

Add up the published amounts spent by both parties at all levels of government including town square and then ask where did all this money come from.

The answer is YOU and the total amount exceeds what is spent on social security .

It is part of the serial number code

Top shelf commercial units are made in Germany & the USA

Second tier models are made in Italy, Spain & Argentina

Throw away quality for cheapskates is made in China .

If people stopped buying garbage the factories would stop making garbage

But while idiots buy 100% on price more stuff will come out of the cheapest place to make it

The greater the volume that is made for idiots the less volume that goes through the quality plants so the dearer the top shelf models will become .

The consumers of the planet have been hood winked by the directors of big companies who have been buying stuff from 3rd world factories & selling it at 20 to 100 times the cost price so they can pay themselves multi million dollar bonuses .

Since the GFC company profits have increased 600% executive wages have risen 2000% workers wages have risen 28% ( slightly less than inflation ) .

This is what happens particularly in the USA when you have weak governments run by parties desperate for money to pay for massive advertising campaigns in order to brain wash the population to vote them into power, regardless of their colour .

Government of the poor by the rich for the rich to entrench the position of the rich who are allowed to be above the laws , as weak as they are .

And if you think this is tosh look at the prices for goods from China when bought in the tens of thousands and compare that to the "cheap" price from H, Lowes, Wallys AmmoZone etc etc etc

Add up the published amounts spent by both parties at all levels of government including town square and then ask where did all this money come from.

The answer is YOU and the total amount exceeds what is spent on social security .

#7

PTmowerMech

I wished I could've waited for the prices to come down. But I've almost never seen a price decrease.

PTmowerMech

Just thank the former president for adding those European tariffs along with Russia/Ukraine war, Covid 19, and the all the generated inflation. The European tariffs were primarily on Steel and Aluminum products. The current president just ended those tariffs in October and it will take time for things to get back to normal again. Some items of the new agreement will not even take place until January 2023. On top of that Stihl is having find new source for parts that were made in the Ukraine factories; therefore, their production costs will raise.

I wished I could've waited for the prices to come down. But I've almost never seen a price decrease.

#8

Hammermechanicman

Hammermechanicman

Them creamsicles be getting expensiveBought a new MS271 yesterday. $500 friggin bucks. Apparently Stihl's don't even come with a case now a days. The guy threw in a file.

#10

Hammermechanicman

Hammermechanicman

Watch me set the internet on fire.

Non-Genuine Complete Repair Parts for Stihl MS361, MS341

www.hlsproparts.com

#11

StarTech

There is pitch, gauge, tooth style, and DL count. Also the Stihl bar is most likely shorter than labeled. Several I installed were nearly an inch shorter what they claimed if you measure as they show how to measure them.

But anyways the 16" MS271 appears to use the .325 .063 67DL BNC setup which can be either semi chisel or chisel tooth. Then of there is a safety version or Pro version. There is also a few other options but they are not common. Like ripping vs crosscut chains.

StarTech

Got to be carefully on chains. As it depends what bar specs are. Oregon and Sabre chains are around $30 retail for this saw. Just be thankful that you are not wanting a carbide tipped chain. They are about 5X the price or more. I paid $140 cost for a 18" 3/8lp chain about 6 yrs ago.16 inch chain is $36.95

There is pitch, gauge, tooth style, and DL count. Also the Stihl bar is most likely shorter than labeled. Several I installed were nearly an inch shorter what they claimed if you measure as they show how to measure them.

But anyways the 16" MS271 appears to use the .325 .063 67DL BNC setup which can be either semi chisel or chisel tooth. Then of there is a safety version or Pro version. There is also a few other options but they are not common. Like ripping vs crosscut chains.

#12

PTmowerMech

Chainsaw chains and bars is something I really need to study up on. I don't even stock them, sell them or even sharpen them. I can sharpen them. I've always sharpened my own. And done a few for customers. But only very few.

My MS271 came with a 20" bar.

PTmowerMech

Got to be carefully on chains. As it depends what bar specs are. Oregon and Sabre chains are around $30 retail for this saw. Just be thankful that you are not wanting a carbide tipped chain. They are about 5X the price or more. I paid $140 cost for a 18" 3/8lp chain about 6 yrs ago.

There is pitch, gauge, tooth style, and DL count. Also the Stihl bar is most likely shorter than labeled. Several I installed were nearly an inch shorter what they claimed if you measure as they show how to measure them.

But anyways the 16" MS271 appears to use the .325 .063 67DL BNC setup which can be either semi chisel or chisel tooth. Then of there is a safety version or Pro version. There is also a few other options but they are not common. Like ripping vs crosscut chains.

Chainsaw chains and bars is something I really need to study up on. I don't even stock them, sell them or even sharpen them. I can sharpen them. I've always sharpened my own. And done a few for customers. But only very few.

My MS271 came with a 20" bar.

#13

PTmowerMech

PTmowerMech

I was just checking out the carburetor on this model. $65 for a OEM. Not bad. But those adjustments look like they take a tool I don't have.

GENUINE STIHL MS271 MS291 CARBURETOR (C1Q-S246) - NEW TAKE OFF | eBay

FOR SALE IS A NEW, STIHL, CARBURETOR, REMOVED FROM A NEW STIHL MS271 CHAINSAW THAT WAS PARTED FOR PARTS. THEY ARE TESTED BEFORE PARTING. IF THE CARBURETOR DOES NOT FIX YOUR PROBLEM, YOU HAVE ANOTHER ISSUE.

www.ebay.com

#14

Hammermechanicman

Hammermechanicman

It has the metal caps you need to remove to adjust the carb.

If you are going to service chainsaws you really need to study up on chains and get real chain grinder. One issue you will have is that finding parts lists for most saws. A good way to get some good saw knowledge is to buy one of the stihl clone kits from HL supply and spend some Utube time learning and putting it together. A box of parts with no directions.

On the side of the bar will be markings telling pitch, gauge and drive links. Probably a semi chisel safety chain. Which i hate.

If you are going to service chainsaws you really need to study up on chains and get real chain grinder. One issue you will have is that finding parts lists for most saws. A good way to get some good saw knowledge is to buy one of the stihl clone kits from HL supply and spend some Utube time learning and putting it together. A box of parts with no directions.

On the side of the bar will be markings telling pitch, gauge and drive links. Probably a semi chisel safety chain. Which i hate.

#15

ILENGINE

ILENGINE

Those are pinned limiter caps that can only be turned like 1/4 turn with a straight screwdriver. Kind of like the original plastic limiter caps that you would pop off and press back on. Except in this case the limiter caps are metal and steel pinned in.

#16

Hammermechanicman

Hammermechanicman

The metal ones are easily removed with just an allen wrench and are reuseable.

#17

PTmowerMech

I was looking for markings on my 08S, but didn't see any. .

As far as servicing saws, 99% of my customers have only had carburetor problems. Or a bad bearing. I did a crank seal last year.

But you are correct. I'm in an area that's heavily populated with loggers and firewood guys. So I'm going to have to learn more about them.

My 08S and my MS 180C are about to go on my bench and get my full attention.

PTmowerMech

It has the metal caps you need to remove to adjust the carb.

If you are going to service chainsaws you really need to study up on chains and get real chain grinder. One issue you will have is that finding parts lists for most saws. A good way to get some good saw knowledge is to buy one of the stihl clone kits from HL supply and spend some Utube time learning and putting it together. A box of parts with no directions.

On the side of the bar will be markings telling pitch, gauge and drive links. Probably a semi chisel safety chain. Which i hate.

I was looking for markings on my 08S, but didn't see any. .

As far as servicing saws, 99% of my customers have only had carburetor problems. Or a bad bearing. I did a crank seal last year.

But you are correct. I'm in an area that's heavily populated with loggers and firewood guys. So I'm going to have to learn more about them.

My 08S and my MS 180C are about to go on my bench and get my full attention.

#18

B

bertsmobile1

He put a dozen hooks on his side fence so his timber contractors ( mostly carpenters ) can drop them off onto their peg he sharpens them then returns them to their hook so they can pick them up when they pass very early in the morning.

I do the same thing and it works a treat although I only have 4 who get me to sharpen a lot of chains

Good Saw that 08s

B

bertsmobile1

I picked up a trick from a riding palI was looking for markings on my 08S, but didn't see any. .

As far as servicing saws, 99% of my customers have only had carburetor problems. Or a bad bearing. I did a crank seal last year.

But you are correct. I'm in an area that's heavily populated with loggers and firewood guys. So I'm going to have to learn more about them.

My 08S and my MS 180C are about to go on my bench and get my full attention.

He put a dozen hooks on his side fence so his timber contractors ( mostly carpenters ) can drop them off onto their peg he sharpens them then returns them to their hook so they can pick them up when they pass very early in the morning.

I do the same thing and it works a treat although I only have 4 who get me to sharpen a lot of chains

Good Saw that 08s

#19

StarTech

StarTech

I hand sharpen chains for years until I ran into 8 chains took at least 8 new files out and left me with blisters. I now use an Oregon chain grinder but started with what turned out to be a piece of junk chain grinder sold by HFT. Just after a few months it was so sloppy I was having finish the chains by hand. When I got my Oregon grinder, the HFT one went into the trash after I took it apart.

Now using a chain grinder does have a learning curve as manufacture and chain style has different grinding profiles. But most are either 55/30/0 or 55/25/0. Some OEM chain specs wanting a 10 degree down angle but you can use the zero down angle. And depth gauges also need to check after all the cutters are done. Now on a rare occasion I do get rip chains which are usually done 55/10/0.

The main problem with grinder sharpen is the sharper operator tries to go too fast or take off too much at once. When they do they blue the cutters and harden so much that no one can hand sharpen the chains later.

Now the grinder will a slight flake burr on LH cutters which cause by the stone only turning one way. Most of that comes when the chain first touches wood. There are some more expensive units that have reverse grinding mode. About any these grinder can have a reverse added if you know how and don't modifying the electrical as the motor is a DC motor. It more a safety issue as to why most don't have reverse just something breaks off.

Now using a chain grinder does have a learning curve as manufacture and chain style has different grinding profiles. But most are either 55/30/0 or 55/25/0. Some OEM chain specs wanting a 10 degree down angle but you can use the zero down angle. And depth gauges also need to check after all the cutters are done. Now on a rare occasion I do get rip chains which are usually done 55/10/0.

The main problem with grinder sharpen is the sharper operator tries to go too fast or take off too much at once. When they do they blue the cutters and harden so much that no one can hand sharpen the chains later.

Now the grinder will a slight flake burr on LH cutters which cause by the stone only turning one way. Most of that comes when the chain first touches wood. There are some more expensive units that have reverse grinding mode. About any these grinder can have a reverse added if you know how and don't modifying the electrical as the motor is a DC motor. It more a safety issue as to why most don't have reverse just something breaks off.

#20

Hammermechanicman

Hammermechanicman

I was looking for markings on my 08S, but didn't see any. .

As far as servicing saws, 99% of my customers have only had carburetor problems. Or a bad bearing. I did a crank seal last year.

But you are correct. I'm in an area that's heavily populated with loggers and firewood guys. So I'm going to have to learn more about them.

You got an 08S? I would clean that thing up and make it a wall hanger.

My 08S and my MS 180C are about to go on my bench and get my full attention.

#22

Hammermechanicman

Hammermechanicman

Most of the Oregon grinders are made in italy by Tecomec. Most of them are capacitor start motors and if you spin it backwards fast enough then turn it on they will run backwards. I have been looking for a DPDT switch that is the same size as the existing one so i can make it reversing like they used to be before the government made them "better". If you do lots of chains the CBN wheels are great but if you use them on dirty chains they will clog up and leave a big burr. A quick application of brake cleaner on a rag fixes that. You would be suprised how many people hand file their chains but never adjust the rakers.I hand sharpen chains for years until I ran into 8 chains took at least 8 new files out and left me with blisters. I now use an Oregon chain grinder but started with what turned out to be a piece of junk chain grinder sold by HFT. Just after a few months it was so sloppy I was having finish the chains by hand. When I got my Oregon grinder, the HFT one went into the trash after I took it apart.

Now using a chain grinder does have a learning curve as manufacture and chain style has different grinding profiles. But most are either 55/30/0 or 55/25/0. Some OEM chain specs wanting a 10 degree down angle but you can use the zero down angle. And depth gauges also need to check after all the cutters are done. Now on a rare occasion I do get rip chains which are usually done 55/10/0.

The main problem with grinder sharpen is the sharper operator tries to go too fast or take off too much at once. When they do they blue the cutters and harden so much that no one can hand sharpen the chains later.

Now the grinder will a slight flake burr on LH cutters which cause by the stone only turning one way. Most of that comes when the chain first touches wood. There are some more expensive units that have reverse grinding mode. About any these grinder can have a reverse added if you know how and don't modifying the electrical as the motor is a DC motor. It more a safety issue as to why most don't have reverse just something breaks off.

#23

StarTech

StarTech

I not surprised as I have seen a lot of chains that complain about having to bear down on the bars even the chains are sharp. But that just allows me to sell new bars. And lot of those that hand sharpen chains don't know to sharpen chains in the first place. Some think just because they long shavings they got the chain filed right. Once sharpen a chain for one those guys they just quit and bring the chains to me for me to do it.

I just got in a nice looking Poulan 4620 is ruined because the owner was too cheap to replace that Intenz bar, Just keep cranking on the bar nuts. Engine find so I will keep it for parts. Too bad the crankcase is NLA.

Oh I tried the reverse spinning on my Oregon grinder. It worked until the first there was a heavy load then it started going back the other way.

Kinda thought about the CBN wheels but right now the current wheels are holding up very good. Only had to re profile them a few times so far in the last two years. It mainly the 1/4 depth gauge wheel that is wearing the most. Just squared that one back up last week.

Sometimes I see lots of chain then long dry period I don't even see a chainsaw. Kinda depends on the weather. When stormy lots of saws; when quite no saws. Sorta like with mowers no grass cutting, no mowers. Just sending next to last mower this season. It got a large bill at $1077 but one had a new RH transaxle installed. Now I got to get the F525 oil drain replaced then I can plan on doing a physical inventory but I got get in about $500 in storage containers (straight wall for palletizing and for keep the mice out) as I have expanded my inventory size yet again. Not the cheapest container they are what works for me.

What ever happen to reducing it I was at the start of pandemic at 27K, now I at nearly 40K cost but doing inventory will clear out some that as some items are not there due a computer error that I am still recouping from. Some parts are still inbound.

I just got in a nice looking Poulan 4620 is ruined because the owner was too cheap to replace that Intenz bar, Just keep cranking on the bar nuts. Engine find so I will keep it for parts. Too bad the crankcase is NLA.

Oh I tried the reverse spinning on my Oregon grinder. It worked until the first there was a heavy load then it started going back the other way.

Kinda thought about the CBN wheels but right now the current wheels are holding up very good. Only had to re profile them a few times so far in the last two years. It mainly the 1/4 depth gauge wheel that is wearing the most. Just squared that one back up last week.

Sometimes I see lots of chain then long dry period I don't even see a chainsaw. Kinda depends on the weather. When stormy lots of saws; when quite no saws. Sorta like with mowers no grass cutting, no mowers. Just sending next to last mower this season. It got a large bill at $1077 but one had a new RH transaxle installed. Now I got to get the F525 oil drain replaced then I can plan on doing a physical inventory but I got get in about $500 in storage containers (straight wall for palletizing and for keep the mice out) as I have expanded my inventory size yet again. Not the cheapest container they are what works for me.

What ever happen to reducing it I was at the start of pandemic at 27K, now I at nearly 40K cost but doing inventory will clear out some that as some items are not there due a computer error that I am still recouping from. Some parts are still inbound.

#24

Hammermechanicman

Hammermechanicman

I bought the flat CBN raker wheel for $100 but i actually like the "pink" raker wheel better which i profiled to round over the front of the depth gauges. Makes the chains run smoother.

#25

B

bertsmobile1

B

bertsmobile1

Interesting

Like Star I use a single angle for most chains except for arbourist , but I only have 1 of them as they usually hand sharpen because they know how to do it

Because just about all trees down here are hard woods with a capital H I use steeper angles .

Never thought about profiling the raker wheel to cut a curve but I will give it a try.

BEcause people are cheap, stupid & lazy I don't do many chains except after a bushfire when everyone is cutting burned trees and a burn't Iron bark is a tough customer on any chain.

However you can get a 5 pack of garbage Chinese or Indian chain for $ 25 which is $ 5/ chain and as I charge $ 10 to sharpen chains most will happily risk their arms & legs by using the junk chain which seems to wear the side plates faster than the cutters dull .

It gets people off side when I too refuse to sharpen the chain because it is too dangerous to use which is the same as the "thieving" chain saw shop told them who obviously ( in the mind of the fool ) was lieing to them in order to sell more "overpriced" chain

Like Star I use a single angle for most chains except for arbourist , but I only have 1 of them as they usually hand sharpen because they know how to do it

Because just about all trees down here are hard woods with a capital H I use steeper angles .

Never thought about profiling the raker wheel to cut a curve but I will give it a try.

BEcause people are cheap, stupid & lazy I don't do many chains except after a bushfire when everyone is cutting burned trees and a burn't Iron bark is a tough customer on any chain.

However you can get a 5 pack of garbage Chinese or Indian chain for $ 25 which is $ 5/ chain and as I charge $ 10 to sharpen chains most will happily risk their arms & legs by using the junk chain which seems to wear the side plates faster than the cutters dull .

It gets people off side when I too refuse to sharpen the chain because it is too dangerous to use which is the same as the "thieving" chain saw shop told them who obviously ( in the mind of the fool ) was lieing to them in order to sell more "overpriced" chain

#26

ILENGINE

www.stihl.com

www.stihl.com

ILENGINE

I use a Silvey 510 which has the bidirectional motor and the 10 degree down angle built into the system with the CBN wheels. So it sharpens all chains with the 10 degree angle. My first electric sharpener was a Silvey 300. I do semi chisel at 30 degrees and full chisel at 25 degrees. I started with a Sthil fg2 before going to electric sharpeners.I hand sharpen chains for years until I ran into 8 chains took at least 8 new files out and left me with blisters. I now use an Oregon chain grinder but started with what turned out to be a piece of junk chain grinder sold by HFT. Just after a few months it was so sloppy I was having finish the chains by hand. When I got my Oregon grinder, the HFT one went into the trash after I took it apart.

Now using a chain grinder does have a learning curve as manufacture and chain style has different grinding profiles. But most are either 55/30/0 or 55/25/0. Some OEM chain specs wanting a 10 degree down angle but you can use the zero down angle. And depth gauges also need to check after all the cutters are done. Now on a rare occasion I do get rip chains which are usually done 55/10/0.

The main problem with grinder sharpen is the sharper operator tries to go too fast or take off too much at once. When they do they blue the cutters and harden so much that no one can hand sharpen the chains later.

Now the grinder will a slight flake burr on LH cutters which cause by the stone only turning one way. Most of that comes when the chain first touches wood. There are some more expensive units that have reverse grinding mode. About any these grinder can have a reverse added if you know how and don't modifying the electrical as the motor is a DC motor. It more a safety issue as to why most don't have reverse just something breaks off.

FG 2 filing tool - FG 2 filing tool: Sharpen saw chains precisely and professionally

STIHL FG 2 filing tool for professional saw chain maintenance: On a table or workbench ✓ Good sharpening result ✓ Buy now!

#27

Hammermechanicman

Hammermechanicman

Silvey made a nice machine. Not many of them around me. I have 2 of the oregon 620 hydraulic grinders. One is set up just to do rakers as i am lazy and tired of changing wheels. I may buy a third one to setup for 2 different wheel thicknesses. Most chains are at 55 and 30 with rakers at .020 unless customer wants something different.I use a Silvey 510 which has the bidirectional motor and the 10 degree down angle built into the system with the CBN wheels. So it sharpens all chains with the 10 degree angle. My first electric sharpener was a Silvey 300. I do semi chisel at 30 degrees and full chisel at 25 degrees. I started with a Sthil fg2 before going to electric sharpeners.

FG 2 filing tool - FG 2 filing tool: Sharpen saw chains precisely and professionally

STIHL FG 2 filing tool for professional saw chain maintenance: On a table or workbench ✓ Good sharpening result ✓ Buy now!www.stihl.com

#28

StarTech

StarTech

That should be .025 for the rakers (depth gauges) on 3/8lp and .325 chains but .030 does better on 3/8 std chains.

#29

Hammermechanicman

Hammermechanicman

Most of everything my customers are cutting is dead ash and 020 works best fir them. On my personal chains i run rakers at 030. I have 2 saws with 25" bars and i have 12 full chisel chains for bucking lots of big ash. I have a 36" bar but i ain't man enough to lug that around long before my back says "NO".That should be .025 for the rakers (depth gauges) on 3/8lp and .325 chains but .030 does better on 3/8 std chains.

#30

sgkent

sgkent

in my book when one prints 1 zillion dollars and passes it out as freebees, prices on things will go up. One votes in economic idiots, socialists, and communists, and expect prices to go up. That is how it has always worked in countries that take that route. NOTHING is free in life. When we gave up the steel industry we lost the ability to make things here. When the New SF Bay bridge was built 10 years ago, the steel beams HAD to come from China because NO foundry in the USA had the capacity to make them. We shuttered all those plants. That bothers me, it may not bother others. When one pays $$$ for a product made in the USA, it is only because the cost of labor is so much higher in the USA than overseas. That is not a bad thing if that labor cost puts food on one's plate and a roof over their head. And it isn't like the RR workers got what they wanted from the present admin this week. Wait until those costs reaches the goods being sold. Cost of fuel is headed up again too according to industry analysts.

Just thank the former president for adding those European tariffs along with Russia/Ukraine war, Covid 19, and the all the generated inflation. The European tariffs were primarily on Steel and Aluminum products. The current president just ended those tariffs in October and it will take time for things to get back to normal again. Some items of the new agreement will not even take place until January 2023. On top of that Stihl is having find new source for parts that were made in the Ukraine factories; therefore, their production costs will raise.

#31

B

bertsmobile1

B

bertsmobile1

We all like to blame the sector we do not like for the problems we suffer from .

Reds will blame the blues for everything and Blues will do the opposite as if politicians were actually in control

They are not and have not been for the past 40 years if not longer .

The problem is very weak company law and a legal decision made by a NY court that allowed shareholders to sue directors for lost profits because of a bad decision .

This changed the whole balance of power between share holders & management and conflated the risks that are inherit with share to the certaincy of a bank deposit .

So if steel plant A decided to retain steel mills in the USA while steel mill B closed their mill & imported steel from elsewhere and made a bigger profit than steel mill A did, then the directors of mill A are open to prosecution by their shareholders for loss of profits reducing the dividend.

And this happens on a daily basis forced along by litigation funders who sue for free taking a share of a successful outcome.

Thus now days the COURTS have changed the duty of directors from care & responsible use of shareholdrs money to the requiremant to absolutely maximize the share holders dividends regardless of the cost to the nation , the workers or the company and that gets decided on a quarter by quarter basis.

Now the COURTS decided that whatever generates the highest PROFIT to EQUITY is the only responsible use of shareholders money and that will always be importing from the cheapest supplier then selling at the highest possible price locally.

Since the Vietnam war when the USA bankrupted itself over an idiot idological war that both the French & British warned them was a hopeless case money printing has almost zero effect on inflation as the USA abandoned the GOLD STANDARD & floated the US $ .

Thus the actual value of a US $ is what a wealth funds speculates it will be on the exchange market .

If the treasury issues bonds that are bought by the Fed reserve bank then the actual "debt " is zero because the money is "owed" to themselves .

IF the bonds get sold to private enterprise ( or foreign Governments ) then the debt is in fact real & has to be repaid so fuels inflation .

Current inflation is all about the share traders & commodity traders PUSHING up prices by generating short supply hysteria ( which never actually happened apart from fertilizer in the USA ) and companies using this hysteria to hide the fact that they increased their selling price by 40% to cover a 5% increase in costs.

Perfect example I buy a cheese that last year was $ 3 / lb ( Aus)

Dairy farmers had a cut in their milk price but the cheese is now $ 6/ lb supposedly because of increased fuel & energy costs .

If you look at everything that has gone up carefully you will see nothng other than the same profiteering tha back in the WWII days would have had the factory management thrown into goal .

Reds will blame the blues for everything and Blues will do the opposite as if politicians were actually in control

They are not and have not been for the past 40 years if not longer .

The problem is very weak company law and a legal decision made by a NY court that allowed shareholders to sue directors for lost profits because of a bad decision .

This changed the whole balance of power between share holders & management and conflated the risks that are inherit with share to the certaincy of a bank deposit .

So if steel plant A decided to retain steel mills in the USA while steel mill B closed their mill & imported steel from elsewhere and made a bigger profit than steel mill A did, then the directors of mill A are open to prosecution by their shareholders for loss of profits reducing the dividend.

And this happens on a daily basis forced along by litigation funders who sue for free taking a share of a successful outcome.

Thus now days the COURTS have changed the duty of directors from care & responsible use of shareholdrs money to the requiremant to absolutely maximize the share holders dividends regardless of the cost to the nation , the workers or the company and that gets decided on a quarter by quarter basis.

Now the COURTS decided that whatever generates the highest PROFIT to EQUITY is the only responsible use of shareholders money and that will always be importing from the cheapest supplier then selling at the highest possible price locally.

Since the Vietnam war when the USA bankrupted itself over an idiot idological war that both the French & British warned them was a hopeless case money printing has almost zero effect on inflation as the USA abandoned the GOLD STANDARD & floated the US $ .

Thus the actual value of a US $ is what a wealth funds speculates it will be on the exchange market .

If the treasury issues bonds that are bought by the Fed reserve bank then the actual "debt " is zero because the money is "owed" to themselves .

IF the bonds get sold to private enterprise ( or foreign Governments ) then the debt is in fact real & has to be repaid so fuels inflation .

Current inflation is all about the share traders & commodity traders PUSHING up prices by generating short supply hysteria ( which never actually happened apart from fertilizer in the USA ) and companies using this hysteria to hide the fact that they increased their selling price by 40% to cover a 5% increase in costs.

Perfect example I buy a cheese that last year was $ 3 / lb ( Aus)

Dairy farmers had a cut in their milk price but the cheese is now $ 6/ lb supposedly because of increased fuel & energy costs .

If you look at everything that has gone up carefully you will see nothng other than the same profiteering tha back in the WWII days would have had the factory management thrown into goal .

#32

StarTech

Personal, business, and polities are all give and take things. Neither one gets everything thing they want. So they piss and moan to high heaven when they don't get exactly they want. It like the railway workers if they got exactly what they were asking for they just turn around and demand more. Oh I had a boss that provided 3 day a year paid sick leave. Then he was bitching because he had to pay for one day. I told to take the pay and stick it up his backside.

As for that so-called free stimulus money someone was complaining about causing prices to increase it not my fault as I never got a darn penny of it as the IRS has so refused to even get my account straighten out. But government still claims they spent it even though they haven't. I have been trying to get it straighten out for the last three years.

The product producers get very little for their wares, it is what we call men that get a lot of what the consumer pays for products. As my company procurement officer I can see a lot of the middle costs which why I buy in bulk a lot of the time a lot closer to producer source especially hardware items. I see no reason to pay a MTD distributor $3 for a screw when I order packs of 50 for 0.60 ea and sell to my customer at half of my distributor's price.

Personally I not just complaining about my costs, I actually am doing something about it locally. You just got buckled down and manage what you got and cut out some of the extras.

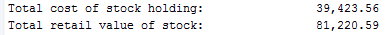

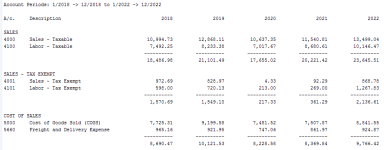

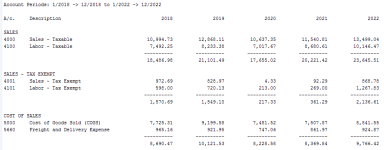

As I said in the past I am a very small company but I have made a profit every year small as it is. Here is the last five years. As you can see I took a pretty good hit in 2020 because of the turn down and but have through management and good customers I have recover fairly nicely. I can tell a lot the users here really couldn't even survive on what I make for a living as they just can't manage what they got to work with. I am posting my net income as there be those saying those are fake numbers and they are sorta as I have re-invested about of it into new inventory. Anyway this is not bad considering I nearly went out of business in 2014 due to my mother's health problems that required my full attention. I just had to temporarily close down and send all customers to other shops.

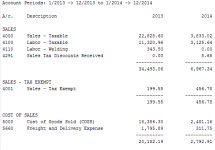

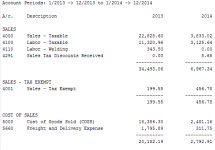

And below is the income/expense from the 2013/2014 years that showed how much my income had dropped due to my mother health problems. The above figures are also the result of me having to move my shop and reset my customer base.

Every year I have lower my over parts costs until this year as now I am at a level where I am at the distributor's pricing. But even at this level I am acquiring new sources that can lower my costs vs retail sale price. Stens at the beginning of the year increased my discount rate and I just brought online Rotary in October so I can buy their products direct now which will increase my profits on their products.

StarTech

That what I have seen for years myself as independent voter. From the outside it looks like a bunch of spoiled brats frighting over a cookie to me.We all like to blame the sector we do not like for the problems we suffer from .

Reds will blame the blues for everything and Blues will do the opposite as if politicians were actually in control

Personal, business, and polities are all give and take things. Neither one gets everything thing they want. So they piss and moan to high heaven when they don't get exactly they want. It like the railway workers if they got exactly what they were asking for they just turn around and demand more. Oh I had a boss that provided 3 day a year paid sick leave. Then he was bitching because he had to pay for one day. I told to take the pay and stick it up his backside.

As for that so-called free stimulus money someone was complaining about causing prices to increase it not my fault as I never got a darn penny of it as the IRS has so refused to even get my account straighten out. But government still claims they spent it even though they haven't. I have been trying to get it straighten out for the last three years.

The product producers get very little for their wares, it is what we call men that get a lot of what the consumer pays for products. As my company procurement officer I can see a lot of the middle costs which why I buy in bulk a lot of the time a lot closer to producer source especially hardware items. I see no reason to pay a MTD distributor $3 for a screw when I order packs of 50 for 0.60 ea and sell to my customer at half of my distributor's price.

Personally I not just complaining about my costs, I actually am doing something about it locally. You just got buckled down and manage what you got and cut out some of the extras.

As I said in the past I am a very small company but I have made a profit every year small as it is. Here is the last five years. As you can see I took a pretty good hit in 2020 because of the turn down and but have through management and good customers I have recover fairly nicely. I can tell a lot the users here really couldn't even survive on what I make for a living as they just can't manage what they got to work with. I am posting my net income as there be those saying those are fake numbers and they are sorta as I have re-invested about of it into new inventory. Anyway this is not bad considering I nearly went out of business in 2014 due to my mother's health problems that required my full attention. I just had to temporarily close down and send all customers to other shops.

And below is the income/expense from the 2013/2014 years that showed how much my income had dropped due to my mother health problems. The above figures are also the result of me having to move my shop and reset my customer base.

Every year I have lower my over parts costs until this year as now I am at a level where I am at the distributor's pricing. But even at this level I am acquiring new sources that can lower my costs vs retail sale price. Stens at the beginning of the year increased my discount rate and I just brought online Rotary in October so I can buy their products direct now which will increase my profits on their products.