You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Governor issues after changing sump

#1

Gary House

Gary House

I have a Husky 24v48 riding mower with a Briggs 44n877 engine. After mowing one day I heard a loud popping noise and discovered something happened to the seal from the sump to the block. I removed the engine and found the sump was cracked. I bought a new one and installed it but when I started the engine it would run wide open. I adjusted the governor as indicated in the repair manual but it didn't fix the problem. I was wondering if I somehow didn't set the governor mechanism in the engine to the proper position. I'm just not sure. Any help would be appreciated. Thanks.

#2

B

bertsmobile1

B

bertsmobile1

Take the sump off again and check what caused the sump to break which was most likely the bits of the failed governor .

#3

shadetree#1

shadetree#1

Post up the COMPLETE model, type and code of your engine.

What caused the sump on your engine to crack? (most likely it did not come from the factory cracked)

What caused the sump on your engine to crack? (most likely it did not come from the factory cracked)

#4

Gary House

Gary House

Thanks for the response. I saw no evidence of anything broken or amiss in the engine. The engine had plenty of oil in it. When the noise occurred, I could see oil coming from between the sump and the engine block just above the oil filter. I could also see the sealant protruding from between the two parts. There apparently is no gasket for the sump, just sealant. No broken parts. Nothing. I have no idea what caused it. The governor and related parts all looked fine. I am planning on taking the sump off again. I was just wondering if the governor has to be set to a specific point.Take the sump off again and check what caused the sump to break which was most likely the bits of the failed governor .

#5

B

bertsmobile1

B

bertsmobile1

The governor does not need to be positioned in a particular way but the shaft has to make contact with the pin on the end of the governor.

I is very easy to assemble it upside down.

Sorry o go off on a tangent but you said the sump was cracked & required replacement

Sumps do not spontaneously crack, something cracks them .

Remember you have seen the sump we have only read your desriptions

I is very easy to assemble it upside down.

Sorry o go off on a tangent but you said the sump was cracked & required replacement

Sumps do not spontaneously crack, something cracks them .

Remember you have seen the sump we have only read your desriptions

#6

Gary House

Gary House

Thank you. The mower is 5 1/2 years old and has 165 hours of use. I purchased it in June of 2017. The sump was definitely not cracked before this incident last year. Here are the numbers on the engine. 44N877--0003G1--160718YG.Post up the COMPLETE model, type and code of your engine.

What caused the sump on your engine to crack? (most likely it did not come from the factory cracked)

#7

Gary House

Gary House

Hi. I attached a photo of the old sump. It has several lines which certainly looks like cracks. They may be casting marks but the new one I bought didn't have those lines.The governor does not need to be positioned in a particular way but the shaft has to make contact with the pin on the end of the governor.

I is very easy to assemble it upside down.

Sorry o go off on a tangent but you said the sump was cracked & required replacement

Sumps do not spontaneously crack, something cracks them .

Remember you have seen the sump we have only read your desriptions

Attachments

#8

shadetree#1

shadetree#1

Briggs twin cylinder OHV.

You said in a previous post that no gasket was used just sealant.

You can go to this link and see a gasket set for your engine and the sump gasket #12.

You say you bought it NEW.

Appears Wilbur may have been into the engine and did not use a gasket.

I do not know about those popping sounds you heard unless the engine maybe blowed a head gasket and pressurized the sump and blowed out the sealant?????????? When you get governor control you may still have popping noises?????

Those cracks in the sump may be casting flaws???????????

Now for the governor itself..

Do you have the Briggs Intek twin cylinder OHV SERVICE manual?

If you have done the above static gov adjust and the governor is still not operating do the static governor adjustment AGAIN and tighten the clamp nut on the governor arm to specs. I've seen those governor shafts coming out of the engine slip (rotate) on the arm if you just use a nut driver and/or a weak wrist. Be careful and tighten the clamp nut to specs but do not break the clamp. That Governor shaft coming out of the motor only moves about 45 degrees or little over 1/8 inch rotation on those engine for full governor control on the LONG carb governor lever. You can test the full rotation of the shaft CW and CCW with the 1/4 inch nut driver on the end of the shaft with the engine NOT RUNNING. If the arm slips due to not being clamped good the engine will run wide open. Also make sure the governor spring is connected properly.

I've seen first hand what you describe when the governor arm and or sump has been removed and re-installed due to the arm slipping on the shaft. On some Briggs engines I had to remove the governor arm bolt and turn it around opposite direction so as the lock nut was more easily accessible using straight extensions.

I've even adjusted the Static governor adjustment backwards (so as the governor would hold the engine at idle when started) to make sure the governor shaft is rotating or attempting to pull the throttle towards idle.

When starting the engine after adjusting the gov hold the carb throttle shaft manually at idle start the engine and then slowly let the gov take control.

You can manually keep the engine from over speeding and ruining itself until you get/see correct gov control.

Let us know what you see/find?????????

You said in a previous post that no gasket was used just sealant.

You can go to this link and see a gasket set for your engine and the sump gasket #12.

You say you bought it NEW.

Appears Wilbur may have been into the engine and did not use a gasket.

I do not know about those popping sounds you heard unless the engine maybe blowed a head gasket and pressurized the sump and blowed out the sealant?????????? When you get governor control you may still have popping noises?????

Those cracks in the sump may be casting flaws???????????

Now for the governor itself..

Do you have the Briggs Intek twin cylinder OHV SERVICE manual?

If you have done the above static gov adjust and the governor is still not operating do the static governor adjustment AGAIN and tighten the clamp nut on the governor arm to specs. I've seen those governor shafts coming out of the engine slip (rotate) on the arm if you just use a nut driver and/or a weak wrist. Be careful and tighten the clamp nut to specs but do not break the clamp. That Governor shaft coming out of the motor only moves about 45 degrees or little over 1/8 inch rotation on those engine for full governor control on the LONG carb governor lever. You can test the full rotation of the shaft CW and CCW with the 1/4 inch nut driver on the end of the shaft with the engine NOT RUNNING. If the arm slips due to not being clamped good the engine will run wide open. Also make sure the governor spring is connected properly.

I've seen first hand what you describe when the governor arm and or sump has been removed and re-installed due to the arm slipping on the shaft. On some Briggs engines I had to remove the governor arm bolt and turn it around opposite direction so as the lock nut was more easily accessible using straight extensions.

I've even adjusted the Static governor adjustment backwards (so as the governor would hold the engine at idle when started) to make sure the governor shaft is rotating or attempting to pull the throttle towards idle.

When starting the engine after adjusting the gov hold the carb throttle shaft manually at idle start the engine and then slowly let the gov take control.

You can manually keep the engine from over speeding and ruining itself until you get/see correct gov control.

Let us know what you see/find?????????

#9

B

bertsmobile1

But that is a good start so we now know we are not looking for some other damage .

I won't add to what Shadetree has just posted because it is good enough and will just get you confused ( too many chiefs is never a good idea ) apart from mentioning that "Taryl Fixes All " on Youtube does a reassembly of the governor which is good a lot of what else that is on there is bad .

B

bertsmobile1

Yes it is a crack but it is a casting flaw and should have gone back into the furnace not on an engine .Hi. I attached a photo of the old sump. It has several lines which certainly looks like cracks. They may be casting marks but the new one I bought didn't have those lines.

But that is a good start so we now know we are not looking for some other damage .

I won't add to what Shadetree has just posted because it is good enough and will just get you confused ( too many chiefs is never a good idea ) apart from mentioning that "Taryl Fixes All " on Youtube does a reassembly of the governor which is good a lot of what else that is on there is bad .

#11

Gary House

Gary House

Thanks. I appreciate all your suggestions. I'm going to attempt to start the engine in a little while. I had to charge the battery because the mower hasn't been started in several months.Briggs twin cylinder OHV.

You said in a previous post that no gasket was used just sealant.

You can go to this link and see a gasket set for your engine and the sump gasket #12.

You say you bought it NEW.

Appears Wilbur may have been into the engine and did not use a gasket.

I do not know about those popping sounds you heard unless the engine maybe blowed a head gasket and pressurized the sump and blowed out the sealant?????????? When you get governor control you may still have popping noises?????

Those cracks in the sump may be casting flaws???????????

Now for the governor itself..

Do you have the Briggs Intek twin cylinder OHV SERVICE manual?

If you have done the above static gov adjust and the governor is still not operating do the static governor adjustment AGAIN and tighten the clamp nut on the governor arm to specs. I've seen those governor shafts coming out of the engine slip (rotate) on the arm if you just use a nut driver and/or a weak wrist. Be careful and tighten the clamp nut to specs but do not break the clamp. That Governor shaft coming out of the motor only moves about 45 degrees or little over 1/8 inch rotation on those engine for full governor control on the LONG carb governor lever. You can test the full rotation of the shaft CW and CCW with the 1/4 inch nut driver on the end of the shaft with the engine NOT RUNNING. If the arm slips due to not being clamped good the engine will run wide open. Also make sure the governor spring is connected properly.

I've seen first hand what you describe when the governor arm and or sump has been removed and re-installed due to the arm slipping on the shaft. On some Briggs engines I had to remove the governor arm bolt and turn it around opposite direction so as the lock nut was more easily accessible using straight extensions.

I've even adjusted the Static governor adjustment backwards (so as the governor would hold the engine at idle when started) to make sure the governor shaft is rotating or attempting to pull the throttle towards idle.

When starting the engine after adjusting the gov hold the carb throttle shaft manually at idle start the engine and then slowly let the gov take control.

You can manually keep the engine from over speeding and ruining itself until you get/see correct gov control.

Let us know what you see/find?????????

#12

Gary House

Gary House

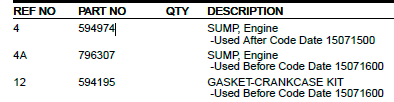

I did make sure I ordered the correct sump. I searched for a gasket set on Jack's small engines but with the date code on my engine it did not show a gasket so I used a high temp silicone sealer.Reference IPL.

The sump was change July 16, 2015. The OPs engine was made July 18, 2016. So first did the OP order the correct sump (594974)? If so then no gasket other RTV was used.

View attachment 63400

Now the earlier sump did use the 0.015 Gasket and new screws.

As for the old sump I see both castings and cracking.

#13

Gary House

Gary House

Ok. I figured out my problem. I failed to see the rod coming from the throttle on the carb. I hooked it up and now it works as it is supposed to. You'll have to excuse me, I'm old. Thanks for all your help. I'm sorry if I wasted your time.

#14

StarTech

Sometimes we don't see the trees for forest. We all at one time or the other been there ourselves. I one time got distracted and forget to tighten a oil drain bolt to spec. We lost a Mack 18 wheeler engine because the plug came out and the driver couldn't the big red light on the dash until the engine stopped. Dang cell phone was part of the problem.

StarTech

Well if you learned and we all learned something from your mistake then it was a complete waste of time. At least you was willing the admit you slipped up and let us know the final solution.Ok. I figured out my problem. I failed to see the rod coming from the throttle on the carb. I hooked it up and now it works as it is supposed to. You'll have to excuse me, I'm old. Thanks for all your help. I'm sorry if I wasted your time.

Sometimes we don't see the trees for forest. We all at one time or the other been there ourselves. I one time got distracted and forget to tighten a oil drain bolt to spec. We lost a Mack 18 wheeler engine because the plug came out and the driver couldn't the big red light on the dash until the engine stopped. Dang cell phone was part of the problem.

#15

shadetree#1

shadetree#1

Thanks for the comeback.

I need to start paying more attention to the engine code when looking at IPL's for Briggs engines.

I need to start paying more attention to the engine code when looking at IPL's for Briggs engines.