You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Electrical Issue? I’m out of ideas....

#1

A

AimmeAshley

A

AimmeAshley

Hi,

I have a John Deere D100 that I’m trying to troubleshoot and is driving me insane. This D100 has a Briggs and Stratton 31C777 engine that I think has an electrical issue.

Right now, I have NO SPARK with the kill wire attached to a new ignition coil. I ended up buying a new ignition coil (thinking that was the issue) and gapped/installed it correctly.

Without the kill wire attached, I can get the mower to start up and have the PTO engage. I can also move forward and reverse correctly. Basically, there doesn’t seem to be any issues with the mower running WITHOUT the kill wire attached to the ignition coil. Once I connect the kill wire back to the ignition coil, I won’t be able to get a spark anymore.

I used a multimeter to verify that the brake switch, PTO switch, RIS switch, and seat switch are functioning correctly. The only thing I haven’t verified is the ”RIO Switch” but I’m not sure if that exists in the John Deere D100 that I have. I can’t seem to find where that switch is. In the schematic, the “RIO Switch” seems to control “Forward/Neutral” and “reverse“ but I can’t physically find it.

What I find odd, is once I install the ignition coil, the kill tab is already grounded. Is this normal? If that’s the case, I don’t see how the mower will ever get spark if the kill tab is already grounded and having the kill wire connected.

I’d love some help. Thank you.

I have a John Deere D100 that I’m trying to troubleshoot and is driving me insane. This D100 has a Briggs and Stratton 31C777 engine that I think has an electrical issue.

Right now, I have NO SPARK with the kill wire attached to a new ignition coil. I ended up buying a new ignition coil (thinking that was the issue) and gapped/installed it correctly.

Without the kill wire attached, I can get the mower to start up and have the PTO engage. I can also move forward and reverse correctly. Basically, there doesn’t seem to be any issues with the mower running WITHOUT the kill wire attached to the ignition coil. Once I connect the kill wire back to the ignition coil, I won’t be able to get a spark anymore.

I used a multimeter to verify that the brake switch, PTO switch, RIS switch, and seat switch are functioning correctly. The only thing I haven’t verified is the ”RIO Switch” but I’m not sure if that exists in the John Deere D100 that I have. I can’t seem to find where that switch is. In the schematic, the “RIO Switch” seems to control “Forward/Neutral” and “reverse“ but I can’t physically find it.

What I find odd, is once I install the ignition coil, the kill tab is already grounded. Is this normal? If that’s the case, I don’t see how the mower will ever get spark if the kill tab is already grounded and having the kill wire connected.

I’d love some help. Thank you.

#2

R

Rivets

R

Rivets

Have you checked the key switch? Can you post the model number off the ID tag, so we can lookup the schematic.

#3

A

AimmeAshley

A

AimmeAshley

Hi,

Yes, I checked the ignition switch by fully unplugging it. I checked all positions. Without anything attached to it and at the Run position, M and G are open.

The model number of the D100 is:

1GXD100ELBB138416

Btw, is the kill wire tab at the ignition coil normally supposed to grounded to the engine chassis?

Yes, I checked the ignition switch by fully unplugging it. I checked all positions. Without anything attached to it and at the Run position, M and G are open.

The model number of the D100 is:

1GXD100ELBB138416

Btw, is the kill wire tab at the ignition coil normally supposed to grounded to the engine chassis?

#4

R

Rivets

R

Rivets

No, the kill wire should go back through the key switch. If you mean neutral safety switch, by RIO, it is located on the transmission, normally on top.

#5

B

bertsmobile1

B

bertsmobile1

And remember that the kill circuit is a ground circuit

As such if any of the kill wires are shorting to ground then the circuit is activated.

I generally use short jumpers to bypass the individual switches, one at a time.

Often it works out that while a switch works when you depress the plunger with your finger, when activated by the mower it does not .

If bypassing all of the switches yields the same result, then there has to be a ground short.

To find the ground short you can either use long jumpers tp connect from one plug socket to the next or disconnect the kill wire at the coil then work back through the wiring with a test lamp hooked up to the + terminal on the battery, cause you are looking for a ground .

Prime suspect will be the kill wire between the mower to engine plug & the coil

As such if any of the kill wires are shorting to ground then the circuit is activated.

I generally use short jumpers to bypass the individual switches, one at a time.

Often it works out that while a switch works when you depress the plunger with your finger, when activated by the mower it does not .

If bypassing all of the switches yields the same result, then there has to be a ground short.

To find the ground short you can either use long jumpers tp connect from one plug socket to the next or disconnect the kill wire at the coil then work back through the wiring with a test lamp hooked up to the + terminal on the battery, cause you are looking for a ground .

Prime suspect will be the kill wire between the mower to engine plug & the coil

#6

A

AimmeAshley

A

AimmeAshley

Sorry if I misspoke, but I meant the kill tab on the ignition coil itself. No one has given me an answer yet, but is that supposed to be grounded as soon as I bolt it on? That kill tab is measuring a short to ground as soon as I bolt it on.

I don’t see an actual switch on the transmission. All I see are two little circular nubs that stick up. They’re connected to a wire harness that is removable. Are the circular nubs the RIO switch?

I can certainly try removing each switch and testing them again, but I’m not sure if any of the switches are bad.

Right now I know that the kill wire is nudged between the engine chassis and starting motor, so maybe I can try to disconnect the starting motor and check the wire all the way through to make sure it’s not inadvertently grounding itself.

I don’t see an actual switch on the transmission. All I see are two little circular nubs that stick up. They’re connected to a wire harness that is removable. Are the circular nubs the RIO switch?

I can certainly try removing each switch and testing them again, but I’m not sure if any of the switches are bad.

Right now I know that the kill wire is nudged between the engine chassis and starting motor, so maybe I can try to disconnect the starting motor and check the wire all the way through to make sure it’s not inadvertently grounding itself.

#7

dougand3

Bet the kill wire is grounded inappropiately (insulation worn off) between coil tab and ign switch.

I'd examine the length of the M wire on key switch to the coil tab.

dougand3

Without the kill wire attached, I can get the mower to start up and have the PTO engage. I can also move forward and reverse correctly. Basically, there doesn’t seem to be any issues with the mower running WITHOUT the kill wire attached to the ignition coil. Once I connect the kill wire back to the ignition coil, I won’t be able to get a spark anymore.

If M and G are closed in the OFF position, then ign switch is working.Without anything attached to it and at the Run position, M and G are open.

Bet the kill wire is grounded inappropiately (insulation worn off) between coil tab and ign switch.

I'd examine the length of the M wire on key switch to the coil tab.

If key OFF = yes grounded. If Key ON = no ground. If yes, bet the kill wire is grounded before key switch = bad.No one has given me an answer yet, but is that supposed to be grounded as soon as I bolt it on? That kill tab is measuring a short to ground as soon as I bolt it on.

#8

Fish

Fish

On these engines, every time the flywheel turns, it produces a spark, the 12 volt system is out of the loop, and if 12 volts is introduced to this tab, it will destroy the coil. So if the engine runs fine without the coil hooked up, then your coil is fine, and your trouble is somewhere else.

When the coil is grounded by the switch/system, then the engine shuts off.

When the coil is grounded by the switch/system, then the engine shuts off.

#10

T

Telesis

T

Telesis

The RIO [Reverse Implement Option] switch is the yellow push button on the dash just below the throttle lever on the left. If you have the blades engaged and you shift to reverse, the moment you press the drive pedal, the engine will shut off. You must press the yellow RIO button before pressing the drive pedal in order to back up with the blades engaged.

FWIW!

FWIW!

#11

T

Telesis

T

Telesis

Correction: (I thought the D100 had the CVT auto trans but it doesn't! No drive pedal!) Your engine will die the moment you shift in reverse (with the blades engaged) unless you press the RIO button first!

#12

A

AimmeAshley

Thanks for your response!

With the ignition switch ON (Run position) and with the kill wire disconnected from ignition coil, the ignition coil's ground tab measures continuity to ground, which I find bizarre. The ignition coil's ground tab is always ground regardless of the key position.

With the ignition switch OFF, the resistance of the kill wire to ground is less than 1 Ohm, which I think is correct.

With the ignition switch ON, the resistance of the kill wire to the ground chassis is roughly 9.89 KOhms, which I'm not sure is considered shorted to chassis.

I will look more into the kill wire and make sure it's not kinked somewhere. The kill wire is routed behind the starter motor, and I've have yet to take off, so I still have that section to check. I guess I'm afraid of removing the starter motor, but I'll have to do it to verify

A

AimmeAshley

If M and G are closed in the OFF position, then ign switch is working.

Bet the kill wire is grounded inappropiately (insulation worn off) between coil tab and ign switch.

I'd examine the length of the M wire on key switch to the coil tab.

If key OFF = yes grounded. If Key ON = no ground. If yes, bet the kill wire is grounded before key switch = bad.

Thanks for your response!

With the ignition switch ON (Run position) and with the kill wire disconnected from ignition coil, the ignition coil's ground tab measures continuity to ground, which I find bizarre. The ignition coil's ground tab is always ground regardless of the key position.

With the ignition switch OFF, the resistance of the kill wire to ground is less than 1 Ohm, which I think is correct.

With the ignition switch ON, the resistance of the kill wire to the ground chassis is roughly 9.89 KOhms, which I'm not sure is considered shorted to chassis.

I will look more into the kill wire and make sure it's not kinked somewhere. The kill wire is routed behind the starter motor, and I've have yet to take off, so I still have that section to check. I guess I'm afraid of removing the starter motor, but I'll have to do it to verify

#13

A

AimmeAshley

If I'm reading the schematic correctly, placing this in reverse should close this switch, right? So, in reverse, this should be shorted, and in any forward position, it's open?

A

AimmeAshley

Is there any way to test this nub (or is this the switch)?Those two ”nubs” are the connection points for the transmission switch.

If I'm reading the schematic correctly, placing this in reverse should close this switch, right? So, in reverse, this should be shorted, and in any forward position, it's open?

#14

A

AimmeAshley

I've verified that there isn't any stray voltages on the kill wire. I tested it while switching between all the different combinations on the ignition switch.

A

AimmeAshley

Thank you for your reply.On these engines, every time the flywheel turns, it produces a spark, the 12 volt system is out of the loop, and if 12 volts is introduced to this tab, it will destroy the coil. So if the engine runs fine without the coil hooked up, then your coil is fine, and your trouble is somewhere else.

When the coil is grounded by the switch/system, then the engine shuts off.

I've verified that there isn't any stray voltages on the kill wire. I tested it while switching between all the different combinations on the ignition switch.

#15

A

AimmeAshley

A

AimmeAshley

Thanks, I'm aware of that! In the John Deere D100 manual, it strangely calls this button, the "RIS" button.Correction: (I thought the D100 had the CVT auto trans but it doesn't! No drive pedal!) Your engine will die the moment you shift in reverse (with the blades engaged) unless you press the RIO button first!

#16

StarTech

StarTech

IF you are using the continuity tester buzzer on the meter then yes it will buzz as the primary side of the coil has a resistance of 1.5-1.7 ohms which is below the thresh hole for the buzzer to buzz.

As said you it runs with the kill detached which mean the coil is fine and that you have a short somewhere in the kill circuit. It was noted about the wires running behind the start and engine's crankcase getting pinched and causing a short circuit. I have seen this several times over the years where DIYers accidentally get the wires caught there.I even seen fuses to get blown this way too.

RIO is Reverse Inhibit Operation

RIS is Reverse Inhibit System

They are basically the same thing. Both prevent mowing in reverse unless activated.

As said you it runs with the kill detached which mean the coil is fine and that you have a short somewhere in the kill circuit. It was noted about the wires running behind the start and engine's crankcase getting pinched and causing a short circuit. I have seen this several times over the years where DIYers accidentally get the wires caught there.I even seen fuses to get blown this way too.

RIO is Reverse Inhibit Operation

RIS is Reverse Inhibit System

They are basically the same thing. Both prevent mowing in reverse unless activated.

#17

Fish

Fish

Explain, I am not following.. I tested it while switching between all the different combinations on the ignition switch.

#18

T

Telesis

T

Telesis

Your interpretation of the schematic w.r.t. the RIO switch(S6 on your schematic?) is correct! That switch is only closed when in reverse. The RIS switch(S4 on your schematic?) is the push button on the dash which activates the RIO latching relay(K1 on your schematic?). FWIW, I suspect JD calls S4 the RIS(Reverse Implement Switch) on the schematic because that's exactly how they refer to it in the text of the operating manual on p20 in the section "Using The Reverse Implement Option (RIO)" and because they already called S6 the RIO switch on the schematic!

#19

R

Ranamow

R

Ranamow

Isn't there a one way diode that can go wrong on these systems?

One of the symptoms are, no spark with the kill wire attached.

One of the symptoms are, no spark with the kill wire attached.

#20

N

nobot

N

nobot

Are you sitting on the seat when you're doing your testing? If not, did you bypass the seat's kill switch? If you answer both of these "No" then that's your problem.

#21

B

BrianSki

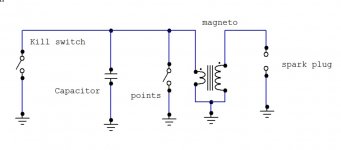

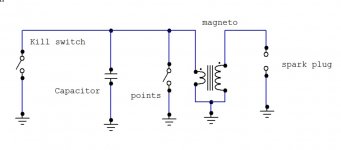

To answer your question. Yes the kill wire would read ground, but with a higher resistance as you mentioned in another post. You are reading the ground through the coil. This is a simple coil schematic of the coil system, that may help explain it better.

Not sure if you have points or an electronic system on that mower, but this gives you an idea what the ignition switch is doing to kill the coil. And how you are reading a ground through the coil.

B

BrianSki

Sorry if I misspoke, but I meant the kill tab on the ignition coil itself. No one has given me an answer yet, but is that supposed to be grounded as soon as I bolt it on? That kill tab is measuring a short to ground as soon as I bolt it on.

To answer your question. Yes the kill wire would read ground, but with a higher resistance as you mentioned in another post. You are reading the ground through the coil. This is a simple coil schematic of the coil system, that may help explain it better.

Not sure if you have points or an electronic system on that mower, but this gives you an idea what the ignition switch is doing to kill the coil. And how you are reading a ground through the coil.

#22

T

ttippetts

T

ttippetts

I have seen the LCD hour meter short internally causing it to go to ground. You might try disconnecting it

#23

D

dcox1

D

dcox1

Check your new coil and see if there is a tiny screw where the kill wire plugs on. If there is take the screw out and bend the edges back from the metal body of the coil and then plug your kill wire back on. I have found this on off brand coils. When the screw is in and you plug the kill wire on it grounds the coil out immediately. I had 2 coils like that.

#24

O

olie01

O

olie01

IF it has a Kawasaki engine it has a module M18 spark igniter on the side of engine block the coil ground goes to it, I found if it doesn't work the engine wouldn't start.

#25

G

Gord Baker

G

Gord Baker

Correct!The RIO [Reverse Implement Option] switch is the yellow push button on the dash just below the throttle lever on the left. If you have the blades engaged and you shift to reverse, the moment you press the drive pedal, the engine will shut off. You must press the yellow RIO button before pressing the drive pedal in order to back up with the blades engaged.

FWIW!

#26

W

wheelie

W

wheelie

Just throwing this in.. I just had a similar issue with a friends older Craftsman Indy Edition mower.. Tested checked gave up.. replaced the ignition switch and all the safety switches except one which I unplugged (2 wire) seat one..It would not start or It would start and sometimes die right off and sometimes you could get started mowing then it would shut down... Just for drill I pulled the PTO switch off a different mower and exchanged them.... Everything worked great.. ordered a new PTO switch and He has been mowing once a week and this was a month or more ago..

#27

A

AimmeAshley

A

AimmeAshley

To answer your question, I switched the multimeter to DC voltage and had one probe on the kill wire and the other on the battery negative terminal. Then, I switched the ignition switch from OFF, to run with lights, run and start mode to check to see if there were any stray voltage spikes. There weren't.Explain, I am not following.

#28

A

AimmeAshley

A

AimmeAshley

Thanks for your response! On my mower, I just don't see a physical switch for the RIO (S6). Should I just measure for continuity on the two nubs that I think are the switch?Your interpretation of the schematic w.r.t. the RIO switch(S6 on your schematic?) is correct! That switch is only closed when in reverse. The RIS switch(S4 on your schematic?) is the push button on the dash which activates the RIO latching relay(K1 on your schematic?). FWIW, I suspect JD calls S4 the RIS(Reverse Implement Switch) on the schematic because that's exactly how they refer to it in the text of the operating manual on p20 in the section "Using The Reverse Implement Option (RIO)" and because they already called S6 the RIO switch on the schematic!

#29

A

AimmeAshley

A

AimmeAshley

On the D100, I don't think there's an in-line diode with the kill wire. In my manual, only the D140 and above have the in-line diode.Isn't there a one way diode that can go wrong on these systems?

One of the symptoms are, no spark with the kill wire attached.

#30

A

AimmeAshley

A

AimmeAshley

Thanks for your suggestion. Yes, I've placed a weight on the seat to simulate having the seat switch engaged. I can also confirm the seat switch is working correctly because if I pull the PTO lever to ON, the kill wire will show open load, versus a short (with the ignition key at RUN) if I wasn't engaged properly.Are you sitting on the seat when you're doing your testing? If not, did you bypass the seat's kill switch? If you answer both of these "No" then that's your problem.

#31

A

AimmeAshley

After a long day at work and having to make dinner most nights, I might have to do it during the weekend. It just takes some extra will power to really look at the mower on a weekday

A

AimmeAshley

I guess I can start replacing switches even if they're checking out as good on my multimeter. Not sure if I'm at that point though. I've yet to remove the starter motor to check for a kink on the kill wire.Just throwing this in.. I just had a similar issue with a friends older Craftsman Indy Edition mower.. Tested checked gave up.. replaced the ignition switch and all the safety switches except one which I unplugged (2 wire) seat one..It would not start or It would start and sometimes die right off and sometimes you could get started mowing then it would shut down... Just for drill I pulled the PTO switch off a different mower and exchanged them.... Everything worked great.. ordered a new PTO switch and He has been mowing once a week and this was a month or more ago..

After a long day at work and having to make dinner most nights, I might have to do it during the weekend. It just takes some extra will power to really look at the mower on a weekday

#32

A

AimmeAshley

Thanks for sending this schematic! I think you're mentioning the kill wire, but I was actually asking about the kill tab on the ignition coil itself.

Are you saying the kill TAB is supposed to be grounded as soon as I bolt it on? Where is the kill tab on this schematic? Would it be considered the top left of the magneto?

I'm also not sure what a "points" versus "electronic" system means, but I think this is a "points" machine? There's no other electronics underneath the dash, if that's what your asking.

A

AimmeAshley

To answer your question. Yes the kill wire would read ground, but with a higher resistance as you mentioned in another post. You are reading the ground through the coil. This is a simple coil schematic of the coil system, that may help explain it better.

Not sure if you have points or an electronic system on that mower, but this gives you an idea what the ignition switch is doing to kill the coil. And how you are reading a ground through the coil.

View attachment 56793

Thanks for sending this schematic! I think you're mentioning the kill wire, but I was actually asking about the kill tab on the ignition coil itself.

Are you saying the kill TAB is supposed to be grounded as soon as I bolt it on? Where is the kill tab on this schematic? Would it be considered the top left of the magneto?

I'm also not sure what a "points" versus "electronic" system means, but I think this is a "points" machine? There's no other electronics underneath the dash, if that's what your asking.

#33

A

AimmeAshley

A

AimmeAshley

Thanks for your response! I'll try disconnecting it and seeing if that changes anything!I have seen the LCD hour meter short internally causing it to go to ground. You might try disconnecting it

#34

B

bertsmobile1

B

bertsmobile1

I go back to what was said in post # 4

Make up some short jumpers with a male spade on each end and jump the plugs according to how the switches would connect them

Do this one at a time thus you have bypassed the switch(s) till the problem resolves.

If this does not resolve the problem then there is a short or open circuit in the actual loom .

Armed with a circuit diagram start bypassing sections of the loom with longer wires, these will need a male on one end & a female on the other.

It is fairly common for a wire to fatigue at the crimp so depending on things like temperature or vibrations will make or break contact

Make up some short jumpers with a male spade on each end and jump the plugs according to how the switches would connect them

Do this one at a time thus you have bypassed the switch(s) till the problem resolves.

If this does not resolve the problem then there is a short or open circuit in the actual loom .

Armed with a circuit diagram start bypassing sections of the loom with longer wires, these will need a male on one end & a female on the other.

It is fairly common for a wire to fatigue at the crimp so depending on things like temperature or vibrations will make or break contact

#35

A

AimmeAshley

This is the one I ordered:

A

AimmeAshley

Thank you for replying. Definitely no screw on the kill wire.Check your new coil and see if there is a tiny screw where the kill wire plugs on. If there is take the screw out and bend the edges back from the metal body of the coil and then plug your kill wire back on. I have found this on off brand coils. When the screw is in and you plug the kill wire on it grounds the coil out immediately. I had 2 coils like that.

This is the one I ordered:

Amazon.com : Briggs and Stratton 595304 Magnet Armature, Black : Patio, Lawn & Garden

Amazon.com : Briggs and Stratton 595304 Magnet Armature, Black : Patio, Lawn & Garden

www.amazon.com

#36

L

lemerick

L

lemerick

The last one I worked on with the same issue the PTO lever had dropped down enough to not make contact with the safety switch and would not let the machine start. John Deere has a terrible setup on this safety and the tab on the lever just barely hit the plunger. After use of a couple of years there was enough play to allow the whole PTO arm assemble to drop down in the dash and not make contact with the safety plunger. The owner had everything replaced at a dealership for $200+ and within 2 months use was back to the same problem. I showed him how to pull up on the PTO arm before starting the mower and working it slightly to engage the switch so it would start. It is a pain but sure beats a $200+ fix that last less than 2 months!!

#37

B

BrianSki

It does look like this is a points machine... The points are usually under the flywheel. But you don't have a problem with that. I will break this down into sections.

Yes you are correct the tab on the coil is on the upper left. You should have a wire going to the points and a tab or wire going to the kill circuit. If you test the tab with no wire connected, it may show ground through the points, or through the coil itself. Since it runs with the wire connected, that seems to be working correctly.

I found another schematic of the wiring, but it may not be 100% for your tractor. It looks like there are 2 safety circuits.

One needs to be connected to get the starter to work. The PTO off (blades) and the clutch need to be pushed in to engage the starter. If the engine cranks (but no spark) that section would be ok.

Now the other safety section grounds the coil to kill the spark. When the switch is turned off, it grounds the wire that goes to the coil. Or when the seat is unoccupied WITH the PTO engaged it grounds the coil. (some tractors with reverse engaged with blades engaged it kills it also)

With your test meter, hook it to the wire that goes to the coil, with the wire disconnected from the coil. (The wire that runs when disconnected) When the key is in any position other than off, there should be no connection to ground. (infinity reading, toward the high numbers on the scale) If there is a low reading (close to 0), there is a short in the wiring or a bad switch. (remember key in run position) (Could also be whatever actuates the switch. If you find that wire grounded, you are on the right track. (I think you will)

If you find the connection grounded. (leave the meter connected) Unplug the safety switches one at a time to see if the reading goes to the high end of the scale. When it does you found the problem. You can also wiggle the wires to see if any are shorting against something, while watching the meter.

This should help you out. Let us know what you find.

B

BrianSki

Thanks for sending this schematic! I think you're mentioning the kill wire, but I was actually asking about the kill tab on the ignition coil itself.

Are you saying the kill TAB is supposed to be grounded as soon as I bolt it on? Where is the kill tab on this schematic? Would it be considered the top left of the magneto?

I'm also not sure what a "points" versus "electronic" system means, but I think this is a "points" machine? There's no other electronics underneath the dash, if that's what your asking.

To answer your question. Yes the kill wire would read ground, but with a higher resistance as you mentioned in another post. You are reading the ground through the coil. This is a simple coil schematic of the coil system, that may help explain it better.

Not sure if you have points or an electronic system on that mower, but this gives you an idea what the ignition switch is doing to kill the coil. And how you are reading a ground through the coil.

View attachment 56793

It does look like this is a points machine... The points are usually under the flywheel. But you don't have a problem with that. I will break this down into sections.

Yes you are correct the tab on the coil is on the upper left. You should have a wire going to the points and a tab or wire going to the kill circuit. If you test the tab with no wire connected, it may show ground through the points, or through the coil itself. Since it runs with the wire connected, that seems to be working correctly.

I found another schematic of the wiring, but it may not be 100% for your tractor. It looks like there are 2 safety circuits.

One needs to be connected to get the starter to work. The PTO off (blades) and the clutch need to be pushed in to engage the starter. If the engine cranks (but no spark) that section would be ok.

Now the other safety section grounds the coil to kill the spark. When the switch is turned off, it grounds the wire that goes to the coil. Or when the seat is unoccupied WITH the PTO engaged it grounds the coil. (some tractors with reverse engaged with blades engaged it kills it also)

With your test meter, hook it to the wire that goes to the coil, with the wire disconnected from the coil. (The wire that runs when disconnected) When the key is in any position other than off, there should be no connection to ground. (infinity reading, toward the high numbers on the scale) If there is a low reading (close to 0), there is a short in the wiring or a bad switch. (remember key in run position) (Could also be whatever actuates the switch. If you find that wire grounded, you are on the right track. (I think you will)

If you find the connection grounded. (leave the meter connected) Unplug the safety switches one at a time to see if the reading goes to the high end of the scale. When it does you found the problem. You can also wiggle the wires to see if any are shorting against something, while watching the meter.

This should help you out. Let us know what you find.

#38

B

BrianSki

Not to confuse you more... I am trying to find where the points hook up to the coil. Maybe through the kill wire. That may be giving you the reading. But then it would not run disconnected. Sometimes easier to see in person. (or it may have some hybrid ignition??)

B

BrianSki

Ok, just went over this... With the ignition switch ON, the kill wire reads 9.89K. Is that with it disconnected from the coil?? If so, disconnect your safeties one at a time until it goes to an infinity reading. Something is pulling it to ground. You may even try to unplug the key switch too, to make sure that would not be the problem.T

With the ignition switch OFF, the resistance of the kill wire to ground is less than 1 Ohm, which I think is correct.

With the ignition switch ON, the resistance of the kill wire to the ground chassis is roughly 9.89 KOhms, which I'm not sure is considered shorted to chassis.

Not to confuse you more... I am trying to find where the points hook up to the coil. Maybe through the kill wire. That may be giving you the reading. But then it would not run disconnected. Sometimes easier to see in person. (or it may have some hybrid ignition??)

#39

B

BrianSki

B

BrianSki

From what I seen in the schematics. The ones with a diode are 2 cylinders with 2 coils. The single cylinders did not have a diode.Isn't there a one way diode that can go wrong on these systems?

One of the symptoms are, no spark with the kill wire attached.

#40

T

Telesis

T

Telesis

Just to clarify, this is NOT a points machine. I happen to have a 31R977 on my bench and with the coil removed, the resistance from the kill terminal to the laminations is 1.6 ohms(using a Fluke 87-V) as suggested earlier. I'm guessing Aimme that when you measured from the kill tab on the magneto, to ground, with the kill wire removed, you interpreted the very low reading as the tab being grounded.

I also want to confirm that the RIO switch(not the RIS on the dash) is in the tranny, and you can check it by measuring across the two nubs and verifying it only shorts out when switched into reverse.

As lemerick suggested, does the blade lever make good physical contact with the switch when the blades are not engaged? On my JD D105, there is a spring on that lever to make sure it pulls in the switch button when you disengage the blades. Is that spring there? Does it appear to be pulling in the switch appropriately?

Finally, the value you measured of 9.89K ohms is suspect. I'd like you to repeat that test(disconnected kill wire, resistance between kill wire and ground), but with the positive battery lead disconnected(so it won't start). That way you can share the value in all 4 ign switch positions(off, run w lights, run, start)

Finally finally, Rivets, you asked early on for the vin #. Do you have access to the schematic and if so, can you post here?

I also want to confirm that the RIO switch(not the RIS on the dash) is in the tranny, and you can check it by measuring across the two nubs and verifying it only shorts out when switched into reverse.

As lemerick suggested, does the blade lever make good physical contact with the switch when the blades are not engaged? On my JD D105, there is a spring on that lever to make sure it pulls in the switch button when you disengage the blades. Is that spring there? Does it appear to be pulling in the switch appropriately?

Finally, the value you measured of 9.89K ohms is suspect. I'd like you to repeat that test(disconnected kill wire, resistance between kill wire and ground), but with the positive battery lead disconnected(so it won't start). That way you can share the value in all 4 ign switch positions(off, run w lights, run, start)

Finally finally, Rivets, you asked early on for the vin #. Do you have access to the schematic and if so, can you post here?

#41

B

BrianSki

Yes a schematic would be great. I tried looking one up and could not come up with anything very close.

It looks like grounding the coil kills the spark. So jumpering the switches would kill the coil. The switches need to be open to keep the coil firing. Except for the few switches that have closed circuits for the start circuit.

B

BrianSki

Telisis.... Thanks for the points info... pretty much all the mowers I worked on have either points or some kind of electronic ignition for the timing. Is this built into the coil?? It does not look like it has wires for electronic ignition.Just to clarify, this is NOT a points machine. I happen to have a 31R977 on my bench and with the coil removed, the resistance from the kill terminal to the laminations is 1.6 ohms(using a Fluke 87-V) as suggested earlier. I'm guessing Aimme that when you measured from the kill tab on the magneto, to ground, with the kill wire removed, you interpreted the very low reading as the tab being grounded.

.......

Finally finally, Rivets, you asked early on for the vin #. Do you have access to the schematic and if so, can you post here?

Yes a schematic would be great. I tried looking one up and could not come up with anything very close.

It looks like grounding the coil kills the spark. So jumpering the switches would kill the coil. The switches need to be open to keep the coil firing. Except for the few switches that have closed circuits for the start circuit.

#42

B

bertsmobile1

B

bertsmobile1

I see where you are confusing everything

You are measuring the primary resistance but probing from the kill tab to the laminations .

THIS CAN NOT BE DONE ON MAGNETOS WITH INBUILT TIMING CHIPS ( yes I am yelling )

Between that terminal & the coil windings is the hall effect trigger chip and the very act of measuring the resistance through it can fry the chip.

Now I know You tube is full of walking talking dildos who "show" equally mentally challenged how to "test" their coils but it is meaningless and if you un the probes wrong way round destructive .

All that is important is the wire that attaches to that terminal is either open circuit or ground and never ever shows any voltage.

The chip reads microvolts and a few milli volts from the 9V battery in most multimeters can fry it.

Even worse is most are very polarity sensitive and must be checked ( where appropriate ) with the red probe on the laminations & the black on the terminal

The only exception to this are the ones where the chip is remote to the coil so the coil is just that, a coil & most Kawasaki's where their chip is reverse polarity protected and normally closed .

As such the only tests to be done to magnetos is to remove the kill wire & check for a spark when the engine is cranked.

If none is found the magneto is fault

You can check the secondary resistance from the plug terminal to the laminations but as a lot of them have non replaceable HT leads it is a moot point so all you need to do is give the cap a tug, or replace it just in case .

You are measuring the primary resistance but probing from the kill tab to the laminations .

THIS CAN NOT BE DONE ON MAGNETOS WITH INBUILT TIMING CHIPS ( yes I am yelling )

Between that terminal & the coil windings is the hall effect trigger chip and the very act of measuring the resistance through it can fry the chip.

Now I know You tube is full of walking talking dildos who "show" equally mentally challenged how to "test" their coils but it is meaningless and if you un the probes wrong way round destructive .

All that is important is the wire that attaches to that terminal is either open circuit or ground and never ever shows any voltage.

The chip reads microvolts and a few milli volts from the 9V battery in most multimeters can fry it.

Even worse is most are very polarity sensitive and must be checked ( where appropriate ) with the red probe on the laminations & the black on the terminal

The only exception to this are the ones where the chip is remote to the coil so the coil is just that, a coil & most Kawasaki's where their chip is reverse polarity protected and normally closed .

As such the only tests to be done to magnetos is to remove the kill wire & check for a spark when the engine is cranked.

If none is found the magneto is fault

You can check the secondary resistance from the plug terminal to the laminations but as a lot of them have non replaceable HT leads it is a moot point so all you need to do is give the cap a tug, or replace it just in case .

#43

A

AimmeAshley

A

AimmeAshley

Thanks for your response. I plan on making some jumpers this weekend and trying your suggestion.I go back to what was said in post # 4

Make up some short jumpers with a male spade on each end and jump the plugs according to how the switches would connect them

Do this one at a time thus you have bypassed the switch(s) till the problem resolves.

If this does not resolve the problem then there is a short or open circuit in the actual loom .

Armed with a circuit diagram start bypassing sections of the loom with longer wires, these will need a male on one end & a female on the other.

It is fairly common for a wire to fatigue at the crimp so depending on things like temperature or vibrations will make or break contact

#44

A

AimmeAshley

The only thing that seems to be pulling the kill wire to ground right now is the ignition coil itself. I’ll have to remove the starter motor this weekend to double check that there’s no kink where the kill wire is mounted.

A

AimmeAshley

That is with the coil wire disconnected from the ignition coil.Ok, just went over this... With the ignition switch ON, the kill wire reads 9.89K. Is that with it disconnected from the coil?? If so, disconnect your safeties one at a time until it goes to an infinity reading. Something is pulling it to ground. You may even try to unplug the key switch too, to make sure that would not be the problem.

Not to confuse you more... I am trying to find where the points hook up to the coil. Maybe through the kill wire. That may be giving you the reading. But then it would not run disconnected. Sometimes easier to see in person. (or it may have some hybrid ignition??)

The only thing that seems to be pulling the kill wire to ground right now is the ignition coil itself. I’ll have to remove the starter motor this weekend to double check that there’s no kink where the kill wire is mounted.

#45

A

AimmeAshley

This is with the ignition switch on the run position.

I also just measured the RIO switch in the transmission (two nubs). I switched it to reverse, and it is showing low resistance. Switching it back neutral or any of gears makes it an open load. I think it’s working correctly.

The blade lever for the PTO is making good contact on the PTO switch. The spring is also looking pretty good as well. I disconnected the wire harness on that switch and made sure that it’s operating correctly.

With the +12V disconnected, and measuring from the disconnected kill wire to ground, I’m getting:

Ignition Switch OFF: 0.4 ohms

Ignition Switch Run w/lights: 9.32Kohms

Ignition Switch Run: 9.34Kohms

Ignition Switch Start: 9.33Kohms

I also have a digital copy of the schematic. Not sure if I’m allowed to post it.

A

AimmeAshley

Yes, with the kill wire detached, I measured from ground to the ignition coil’s kill tab. I re-did the measurement and it is currently measuring 0.3-0.4 ohms.Just to clarify, this is NOT a points machine. I happen to have a 31R977 on my bench and with the coil removed, the resistance from the kill terminal to the laminations is 1.6 ohms(using a Fluke 87-V) as suggested earlier. I'm guessing Aimme that when you measured from the kill tab on the magneto, to ground, with the kill wire removed, you interpreted the very low reading as the tab being grounded.

I also want to confirm that the RIO switch(not the RIS on the dash) is in the tranny, and you can check it by measuring across the two nubs and verifying it only shorts out when switched into reverse.

As lemerick suggested, does the blade lever make good physical contact with the switch when the blades are not engaged? On my JD D105, there is a spring on that lever to make sure it pulls in the switch button when you disengage the blades. Is that spring there? Does it appear to be pulling in the switch appropriately?

Finally, the value you measured of 9.89K ohms is suspect. I'd like you to repeat that test(disconnected kill wire, resistance between kill wire and ground), but with the positive battery lead disconnected(so it won't start). That way you can share the value in all 4 ign switch positions(off, run w lights, run, start)

Finally finally, Rivets, you asked early on for the vin #. Do you have access to the schematic and if so, can you post here?

This is with the ignition switch on the run position.

I also just measured the RIO switch in the transmission (two nubs). I switched it to reverse, and it is showing low resistance. Switching it back neutral or any of gears makes it an open load. I think it’s working correctly.

The blade lever for the PTO is making good contact on the PTO switch. The spring is also looking pretty good as well. I disconnected the wire harness on that switch and made sure that it’s operating correctly.

With the +12V disconnected, and measuring from the disconnected kill wire to ground, I’m getting:

Ignition Switch OFF: 0.4 ohms

Ignition Switch Run w/lights: 9.32Kohms

Ignition Switch Run: 9.34Kohms

Ignition Switch Start: 9.33Kohms

I also have a digital copy of the schematic. Not sure if I’m allowed to post it.

#46

A

AimmeAshley

I’m aware that these are solid state magnetos/ignition coils.

I don’t think this is an ignition coil issue. Like I said, with the kill wire detached from the ignition coil, the mower will start up.

What doesn’t make sense to me is why the kill tab shows that it’s shorted to ground as soon as I bolt it on without the kill wire attached. That’s what I’m having a hard time wrapping around my head.

I’ll look into using jumpers and checking behind the starter motor in the next couple of days!

A

AimmeAshley

Thanks for your response.I see where you are confusing everything

You are measuring the primary resistance but probing from the kill tab to the laminations .

THIS CAN NOT BE DONE ON MAGNETOS WITH INBUILT TIMING CHIPS ( yes I am yelling )

Between that terminal & the coil windings is the hall effect trigger chip and the very act of measuring the resistance through it can fry the chip.

Now I know You tube is full of walking talking dildos who "show" equally mentally challenged how to "test" their coils but it is meaningless and if you un the probes wrong way round destructive .

All that is important is the wire that attaches to that terminal is either open circuit or ground and never ever shows any voltage.

The chip reads microvolts and a few milli volts from the 9V battery in most multimeters can fry it.

Even worse is most are very polarity sensitive and must be checked ( where appropriate ) with the red probe on the laminations & the black on the terminal

The only exception to this are the ones where the chip is remote to the coil so the coil is just that, a coil & most Kawasaki's where their chip is reverse polarity protected and normally closed .

As such the only tests to be done to magnetos is to remove the kill wire & check for a spark when the engine is cranked.

If none is found the magneto is fault

You can check the secondary resistance from the plug terminal to the laminations but as a lot of them have non replaceable HT leads it is a moot point so all you need to do is give the cap a tug, or replace it just in case .

I’m aware that these are solid state magnetos/ignition coils.

I don’t think this is an ignition coil issue. Like I said, with the kill wire detached from the ignition coil, the mower will start up.

What doesn’t make sense to me is why the kill tab shows that it’s shorted to ground as soon as I bolt it on without the kill wire attached. That’s what I’m having a hard time wrapping around my head.

I’ll look into using jumpers and checking behind the starter motor in the next couple of days!

#47

B

bertsmobile1

B

bertsmobile1

SO toss that multimeter back into the tool cupboard

Do as was suggested way way back in post # 5

Make up some shot jumpers ( patch cords actually ) with a male spade terminal ( Yanks seem to call the forks for some unknown reason ) so they plug into the switch sockets .

One at a time bypass all of the switches at their plugs.

Still no joy then make up some 2' to 3' long with a male at one end & a female at the other

Using the schmetic run these wires from one plug socket to the next in circuit.

A PIA job but if you had done this 4 pages ago you would be mowing by now .

If you can not be bothered to do this then let me know & I will ignore this thread while it grows to the size of War and Peace

Do as was suggested way way back in post # 5

Make up some shot jumpers ( patch cords actually ) with a male spade terminal ( Yanks seem to call the forks for some unknown reason ) so they plug into the switch sockets .

One at a time bypass all of the switches at their plugs.

Still no joy then make up some 2' to 3' long with a male at one end & a female at the other

Using the schmetic run these wires from one plug socket to the next in circuit.

A PIA job but if you had done this 4 pages ago you would be mowing by now .

If you can not be bothered to do this then let me know & I will ignore this thread while it grows to the size of War and Peace

#48

R

Rivets

R

Rivets

Aimme, you are overthinking everything, and assuming things about electrical troubleshooting on small tractors which is getting you deeper in trouble. I’ve been following this thread and agree with Bert’s last post. You need to go back to post #5 and start over. Don’t ASSUME anything and forget everything you’ve done so far. If you can’t do that then I too will be looking for others who need help. We are here to help you, but if you don’t want to follow the directions the experienced techs have to offer, then you’re on your own.

#49

B

BrianSki

B

BrianSki

If it is on the device you are using to reply to the posts. Just above your where you are writing is a line with B I and some other things. If it is a picture, click on what looks like a picture, left of paper clip and it will let you post it. Or click on the paper clip and it will let you attach itI also have a digital copy of the schematic. Not sure if I’m allowed to post it.

#50

S

slomo

slomo

S

slomo

War and Peace LOL.SO toss that multimeter back into the tool cupboard

Do as was suggested way way back in post # 5

Make up some shot jumpers ( patch cords actually ) with a male spade terminal ( Yanks seem to call the forks for some unknown reason ) so they plug into the switch sockets .

One at a time bypass all of the switches at their plugs.

Still no joy then make up some 2' to 3' long with a male at one end & a female at the other

Using the schmetic run these wires from one plug socket to the next in circuit.

A PIA job but if you had done this 4 pages ago you would be mowing by now .

If you can not be bothered to do this then let me know & I will ignore this thread while it grows to the size of War and Peace

slomo

#51

A

AimmeAshley

A

AimmeAshley

Okay, I finally got a hold of jumpers.

I bypassed the PTO and brake switch by shorting both the purple and purple/white wires on each one.

I also bypassed the seat switch by placing a piece of business card between the tiny slot on pins 2 and 3.

I removed the starter motor and checked the kill wire to see if it was shorted to the engine chassis, and it wasn’t. I ended up placing electrical tape around the wire anyway and the starting motor back in place.

With all the bypass jumpers in place, and with the kill wire connected back to the ignition coil, I’m still not getting a spark.

Then, I removed the hour meter/service reminder. Behind the hour meter device are 4 tabs. With the hour meter removed, I measured the resistance from the ground tab (where the black wire would normally go) of the hour meter to where the tab where the white wire would normally be connected. This white wire would normally goback to the magneto on my D100 schematic. This gave me the 9.89KOhms that I normally saw from my kill wire to ground that I saw originally.

If the kill wire to ground is normally supposed to give me an open load with the ignition switch in the run position, then my gut feeling is the hour meter is internally shorted.

With the kill wire removed and the hour meter unplugged, the mower wouldn’t start. I guess the mower requires the hour meter to be plugged in be able to provide spark. Once I plugged it back in, with the Kill wire still removed from the ignition coil, the mower would start.

Looks like there’s an internal short from hour meter? Is there a way I can test out the hour meter, aside from my resistance checks?

If anyone has a similar mower, would someone be willing to remove the their hour meter and give me a resistance measurement from where it would normally connect from ground to magneto?

I bypassed the PTO and brake switch by shorting both the purple and purple/white wires on each one.

I also bypassed the seat switch by placing a piece of business card between the tiny slot on pins 2 and 3.

I removed the starter motor and checked the kill wire to see if it was shorted to the engine chassis, and it wasn’t. I ended up placing electrical tape around the wire anyway and the starting motor back in place.

With all the bypass jumpers in place, and with the kill wire connected back to the ignition coil, I’m still not getting a spark.

Then, I removed the hour meter/service reminder. Behind the hour meter device are 4 tabs. With the hour meter removed, I measured the resistance from the ground tab (where the black wire would normally go) of the hour meter to where the tab where the white wire would normally be connected. This white wire would normally goback to the magneto on my D100 schematic. This gave me the 9.89KOhms that I normally saw from my kill wire to ground that I saw originally.

If the kill wire to ground is normally supposed to give me an open load with the ignition switch in the run position, then my gut feeling is the hour meter is internally shorted.

With the kill wire removed and the hour meter unplugged, the mower wouldn’t start. I guess the mower requires the hour meter to be plugged in be able to provide spark. Once I plugged it back in, with the Kill wire still removed from the ignition coil, the mower would start.

Looks like there’s an internal short from hour meter? Is there a way I can test out the hour meter, aside from my resistance checks?

If anyone has a similar mower, would someone be willing to remove the their hour meter and give me a resistance measurement from where it would normally connect from ground to magneto?

#52

B

bertsmobile1

B

bertsmobile1

If the hourmeter is also the safety switch interlock then yes they do go bad.

Back test wires with the meter in place to ground.

If the white wire shows ANY ground connection then the hour meter is kaput .

Back test wires with the meter in place to ground.

If the white wire shows ANY ground connection then the hour meter is kaput .

#53

T

Telesis

T

Telesis

A couple things just to note. Your magneto is spec'd to output 12 VAC on the kill tab. The hour meter uses this to know if the engine is running or not(the white wire going to the hour meter #405). The hour meter does not increment with just the key on and 12 VDC present. The engine must be running. The kill tab behaves like any other in that when it's shorted to ground, spark is inhibited.

I have a D105 which electrically is essentially identical to yours. I disconnected the kill wire at the magneto and measured infinite resistance with the key in the run or run with lights, engine running or not. I measured 6.2 VAC from my magneto, engine running WOT, kill wire connected to rest of wiring or open circuit. Hour meter draws about 115 uA of AC current while running. I also wanted to know how much or little resistance the kill circuit would take to stop the running engine. In my case anything less than 27 ohms kills a running engine. Anything above does not. (I tried 9.89K ohm first. Didn't kill it!)

To test whether it's the hour meter causing your problem, disconnect it. You'll need to jumper the yellow wire(switched 12 VDC #401 on schematic) to the yellow/white wire(#407) which feeds the fuel solenoid and the RIO latch relay. When you did your test with it disconnected(no jumper) did you check for spark? If not, it probably didn't start because the fuel solenoid was not powered.

Finally, Bert, if you measure the resistance to ground from the white wire at the hour meter(or any other place in the kill circuit for that matter), you would be doing EXACTLY WHAT YOU SQUAWKED ABOUT EARLIER. The white wire goes to the magneto kill tab and unless you disconnect it at the mag, it will show 1.6 ohms, the primary resistance and you'd effectively be placing your ohmmeter between the kill tab and ground. Remember those microchips in there..... I for one am not too worried about damaging this magneto by measuring its resistance from kill tab to ground since it puts out 12 VAC on that same kill tab. Not to say others could be damaged. Comments apply to this one.

I have a D105 which electrically is essentially identical to yours. I disconnected the kill wire at the magneto and measured infinite resistance with the key in the run or run with lights, engine running or not. I measured 6.2 VAC from my magneto, engine running WOT, kill wire connected to rest of wiring or open circuit. Hour meter draws about 115 uA of AC current while running. I also wanted to know how much or little resistance the kill circuit would take to stop the running engine. In my case anything less than 27 ohms kills a running engine. Anything above does not. (I tried 9.89K ohm first. Didn't kill it!)

To test whether it's the hour meter causing your problem, disconnect it. You'll need to jumper the yellow wire(switched 12 VDC #401 on schematic) to the yellow/white wire(#407) which feeds the fuel solenoid and the RIO latch relay. When you did your test with it disconnected(no jumper) did you check for spark? If not, it probably didn't start because the fuel solenoid was not powered.

Finally, Bert, if you measure the resistance to ground from the white wire at the hour meter(or any other place in the kill circuit for that matter), you would be doing EXACTLY WHAT YOU SQUAWKED ABOUT EARLIER. The white wire goes to the magneto kill tab and unless you disconnect it at the mag, it will show 1.6 ohms, the primary resistance and you'd effectively be placing your ohmmeter between the kill tab and ground. Remember those microchips in there..... I for one am not too worried about damaging this magneto by measuring its resistance from kill tab to ground since it puts out 12 VAC on that same kill tab. Not to say others could be damaged. Comments apply to this one.

#54

A

AimmeAshley

You were right, I wasn’t getting +12V previously to the fuel solenoid after removing the hour meter.

Now I need to decide whether it’s worth buying the silly hour meter or just leaving the jumper in place.

Thanks so much for your suggestion and help!

A

AimmeAshley

Okay, with the hour meter disconnected, I also connected the kill wire back to the ignition coil, and then jumpered the yellow and yellow/white together and then....IT STARTED!A couple things just to note. Your magneto is spec'd to output 12 VAC on the kill tab. The hour meter uses this to know if the engine is running or not(the white wire going to the hour meter #405). The hour meter does not increment with just the key on and 12 VDC present. The engine must be running. The kill tab behaves like any other in that when it's shorted to ground, spark is inhibited.

I have a D105 which electrically is essentially identical to yours. I disconnected the kill wire at the magneto and measured infinite resistance with the key in the run or run with lights, engine running or not. I measured 6.2 VAC from my magneto, engine running WOT, kill wire connected to rest of wiring or open circuit. Hour meter draws about 115 uA of AC current while running. I also wanted to know how much or little resistance the kill circuit would take to stop the running engine. In my case anything less than 27 ohms kills a running engine. Anything above does not. (I tried 9.89K ohm first. Didn't kill it!)

To test whether it's the hour meter causing your problem, disconnect it. You'll need to jumper the yellow wire(switched 12 VDC #401 on schematic) to the yellow/white wire(#407) which feeds the fuel solenoid and the RIO latch relay. When you did your test with it disconnected(no jumper) did you check for spark? If not, it probably didn't start because the fuel solenoid was not powered.

Finally, Bert, if you measure the resistance to ground from the white wire at the hour meter(or any other place in the kill circuit for that matter), you would be doing EXACTLY WHAT YOU SQUAWKED ABOUT EARLIER. The white wire goes to the magneto kill tab and unless you disconnect it at the mag, it will show 1.6 ohms, the primary resistance and you'd effectively be placing your ohmmeter between the kill tab and ground. Remember those microchips in there..... I for one am not too worried about damaging this magneto by measuring its resistance from kill tab to ground since it puts out 12 VAC on that same kill tab. Not to say others could be damaged. Comments apply to this one.

You were right, I wasn’t getting +12V previously to the fuel solenoid after removing the hour meter.

Now I need to decide whether it’s worth buying the silly hour meter or just leaving the jumper in place.

Thanks so much for your suggestion and help!

#55

T

Telesis

T

Telesis

Terrific news! I'm fairly certain JD runs that power thru the hour meter as a cheap and dirty way to keep the average person from just unplugging it to 'save time'. Their warranty is based on both years and engine hours so if someone just unplugs it to save on the hours, it won't start because of the fuel solenoid! FWIW!

#56

mitchstein443

mitchstein443

What you just experienced is "engineered to fail". Almost every manufacturer is doing it, they design one part that is integral to make the device work fail so that the average consumer will throw it away and just buy a whole new device. I just went through that with a GE dishwasher. at almost exactly 3 years old the solenoid that controls circulate or drain valve selector failed. Upon removing it, it is clearly stamped on the solenoid .5 minutes on 10 minutes off for the duty cycle and they (GE) have it run for 3 minutes nonstop. so of course it always overheats and eventually becomes the fail point. Then they charge 89$ for the part and 125$ for a tech to ocme out and put it in (they claim it is not a consumer replaceable part). So ebay had the part for 18$... put it in, running like a champ... The washer cost 336$ brand new at homedepot or lowes...

#57

matt man

matt man

On these engines, every time the flywheel turns, it produces a spark, the 12 volt system is out of the loop, and if 12 volts is introduced to this tab, it will destroy the coil. So if the engine runs fine without the coil hooked up, then your coil is fine, and your trouble is somewhere else.

When the coil is grounded by the switch/system, then the engine shuts off.

Always check the spark plug too. I kicked myself a time or two, for notHi,

Yes, I checked the ignition switch by fully unplugging it. I checked all positions. Without anything attached to it and at the Run position, M and G are open.

The model number of the D100 is:

1GXD100ELBB138416

Btw, is the kill wire tab at the ignition coil normally supposed to grounded to the engine chassis?