- Joined

- Feb 19, 2020

- Threads

- 121

- Messages

- 12,883

The primer only removes excess from carburetor metering chamber along some surplus fuel. Now when metering diaphragm has stiffen, metering needle valve worn, or the main nozzle check valve is defective then you get flooding but would have to replaced in order to resolve the flooding.

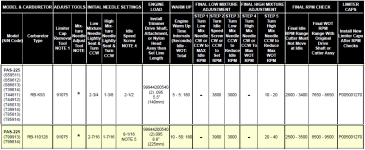

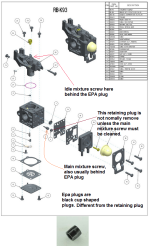

I had offered to provide the carburetor tuning instructions but you have fail to post the equipment model number so I am assuming you want to keep us in the dark so I stepping out of this thread. Beside if the carb still has EPA plugs you would need the 2.5mm extraction tool (3 mm if the plugs are damaged).

And members please stop cocking attitudes. Even I get annoyed at those that asking for help but not willing to provide info needed and those that post unnecessary comments so I usually just bow out without posting nasty comments.

Besides this time of the year for me is the start of the busy season. Right now I got a full work in my shop; already getting backlogged so I will be spending a lot less time on the forum.

I had offered to provide the carburetor tuning instructions but you have fail to post the equipment model number so I am assuming you want to keep us in the dark so I stepping out of this thread. Beside if the carb still has EPA plugs you would need the 2.5mm extraction tool (3 mm if the plugs are damaged).

And members please stop cocking attitudes. Even I get annoyed at those that asking for help but not willing to provide info needed and those that post unnecessary comments so I usually just bow out without posting nasty comments.

Besides this time of the year for me is the start of the busy season. Right now I got a full work in my shop; already getting backlogged so I will be spending a lot less time on the forum.