You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

DC Voltage Output

#1

B

bartles

B

bartles

Working on a B&S Model 254707-0120-01. Is there a way to determine the DC output of the B&S alternator, part number 592828/ superseded Part number 391529?

#2

Mower King

Mower King

Both AC & or DC output on mowers, can be measured with a OHM meter, while engine is running.Working on a B&S Model 254707-0120-01. Is there a way to determine the DC output of the B&S alternator, part number 592828/ superseded Part number 391529?

#3

R

Rivets

R

Rivets

You can get a pdf manual for your engine at this site, just follow the instructions. It is a secure site and the manual will contain testing instructions. https://www.mytractorforum.com/threads/briggs-statton-repair-manuals.242387/

#4

StarTech

StarTech

Then I must have been doing wrong all these years using volt and amp meters.Both AC & or DC output on mowers, can be measured with a OHM meter, while engine is running.

#6

B

bartles

B

bartles

Thanks to all for your replies... haven't started the engine yet. I just rebuilt it and have begun the mower restoration. I was thinking about installing a low amperage cooling fan to keep the cones and drums from getting hot. On later model Dixon's there was a fan on the top of the cone shaft. I'll just wait till engine start and measure the amp output then. Merry Christmas!!!

#7

A

artemjemmy

A

artemjemmy

I find the best way to measure if the battery is charging is to use a DC current clamp and put it on the positive battery terminal with the engine at full throttle and all of the accessories (and electric PTO, if applicable), and see if current is flowing into the battery. Fool proof method and very useful. Applies to cars too!Working on a B&S Model 254707-0120-01. Is there a way to determine the DC output of the B&S alternator, part number 592828/ superseded Part number 391529?

#8

Scrubcadet10

Scrubcadet10

That stator (DC ONLY) was previously 696578, and the rated amperage is only 3 amps at 3600 RPM.

I'd imagine the voltage ranges from 12 to 14.5 DC.

I'd imagine the voltage ranges from 12 to 14.5 DC.

#9

H

hlw49

H

hlw49

No matter what the amperage out put of the charging system the voltage output has to be more than a fully charged battery which is around 12.75 volts or over time the load on the battery would kill the battery since it would not be charging the battery.

#10

B

bertsmobile1

B

bertsmobile1

B & S stators are colour coded

After that there is 3 sizes of magnets

The outputs are listed in the "repower guide" and there is a poster that is all over the web

So if you care to post a photo of the plug on the end of the stator wires ( not the engine to mower plug ) we may have a chance of identifing it

The same stator can have several different outputs depending upon the magnet size and the regulator / rectifier used .

After that there is 3 sizes of magnets

The outputs are listed in the "repower guide" and there is a poster that is all over the web

So if you care to post a photo of the plug on the end of the stator wires ( not the engine to mower plug ) we may have a chance of identifing it

The same stator can have several different outputs depending upon the magnet size and the regulator / rectifier used .

#11

StarTech

StarTech

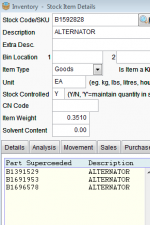

Attachments

#12

R

rustycat

R

rustycat

Do not use a ohm meter you must use a volt meter. Should be 12 volts or more up to 14 volts.Both AC & or DC output on mowers, can be measured with a OHM meter, while engine is running.

#13

J

joea99

If measuring the amps at the red cable connected to the battery, then the DC voltage will be greater than the battery voltage, or the amps could not be flowing. What the measured voltage might be will depend on the charged state of the battery. Of course in a "charging" state, one could not actually measure any difference between batter and rectifier output, allowing for any drop due to resistance of the wires.

J

joea99

No matter what the amperage out put of the charging system the voltage output has to be more than a fully charged battery which is around 12.75 volts or over time the load on the battery would kill the battery since it would not be charging the battery.

If measuring the amps at the red cable connected to the battery, then the DC voltage will be greater than the battery voltage, or the amps could not be flowing. What the measured voltage might be will depend on the charged state of the battery. Of course in a "charging" state, one could not actually measure any difference between batter and rectifier output, allowing for any drop due to resistance of the wires.

#14

T

Telesis

T

Telesis

Keep in mind that alternator is DC only and rated at 3 amps(2-4 on the wall chart). What makes it DC only is the fact they put a diode in series with the output wire which acts as a half-wave rectifier of the AC voltage being produced by the stator. They don't provide an AC voltage spec because the diode is encased in heat shrink tubing and there isn't a convenient way to get your voltmeter probe on the stator side of the diode(anode side). As others have indicated, the easiest way to check is simply measure the battery voltage with the engine off and then when it's running at wide open throttle(wot). If the latter is greater than the former by a volt or more(depending on the initial state of the battery), you can usually assume it's OK. You can see the 696578 alternator in the second row from the top on the attached chart.

Attachments

#15

A

AtRo Racing

A

AtRo Racing

Working on a B&S Model 254707-0120-01. Is there a way to determine the DC output of the B&S alternator, part number 592828/ superseded Part number 391529?

#16

A

AtRo Racing

Robbie

A

AtRo Racing

The eady way js to useWorking on a B&S Model 254707-0120-01. Is there a way to determine the DC output of the B&S alternator, part number 592828/ superseded Part number 391529?

You can use a clip on amp meter attached to the positive battery cable. To test remove the fuse from the alternator and run the engine noting the amp and voltage draw. Shut the engine off and reinstall the fuse. Start the engine. If the amp meter is showing positive amps and the voltage has increased then all is well. The biggest issue wrh is fhe wire touches the flywheel causing the battery not to charge.Working on a B&S Model 254707-0120-01. Is there a way to determine the DC output of the B&S alternator, part number 592828/ superseded Part number 391529?

Robbie

#17

T

txmowman

T

txmowman

Amps mean nothing in terms of DC voltage output. Unregulated AC output of any charging coil is 26 volts minimum. If you have that, check the DC voltage of the battery. If say, 12.7 volts, mower not running, check again at battery with mower running at high idle. At the battery should be a minimum of a .5 volt rise. So, 12.7 volts DC not running, should be 13.2 volts DC minimum, running at high idle. If that is the case, the battery would be charging.

#18

OzPete

OzPete

Txmowman is correct. The STATOR (aka the Alternator), under the flywheel actually produces between 24 and about 28 VOLTS of ALTERNATING CURRENT (AC) Yes, AC !

It doesn’t matter whether it’s a 1-Wire Stator, or a 2-Wire Stator, it’s output voltage is tested at 3,600 RPM and the Multimeter has to be set to measure AC. On many multimeters the symbol on the dial looks like this .. V~.

This goes for nearly all “under flywheel” charging systems on mowers & motorbikes etc which have to charge 12V batteries. On Briggs systems they vary the maximum outputted charging CURRENT (Amps) possible by using different sized magnets within the flywheel itself.

The AC current produced by the flywheel’s magnets rotating around the Stator is transformed (Rectified) into DC (Direct Current) by the use of a Rectifier-Regulator.

Because it’s job is to maintain a 12V battery, the Rectifier-Regulator is designed to output somewhere between 13.9 to 14.5 DC volts, which should be measured at the battery’s positive terminal using a DC Voltmeter with the engine at 3,000 RPM Minimum.

It doesn’t matter whether it’s a 1-Wire Stator, or a 2-Wire Stator, it’s output voltage is tested at 3,600 RPM and the Multimeter has to be set to measure AC. On many multimeters the symbol on the dial looks like this .. V~.

This goes for nearly all “under flywheel” charging systems on mowers & motorbikes etc which have to charge 12V batteries. On Briggs systems they vary the maximum outputted charging CURRENT (Amps) possible by using different sized magnets within the flywheel itself.

The AC current produced by the flywheel’s magnets rotating around the Stator is transformed (Rectified) into DC (Direct Current) by the use of a Rectifier-Regulator.

Because it’s job is to maintain a 12V battery, the Rectifier-Regulator is designed to output somewhere between 13.9 to 14.5 DC volts, which should be measured at the battery’s positive terminal using a DC Voltmeter with the engine at 3,000 RPM Minimum.

#19

H

hlw49

H

hlw49

That part no. does not show in the Briggs alternator chart but that style stator produces between 2-4 amps.

#20

Scrubcadet10

Scrubcadet10

The previous part number is, though. and it's a 3 amp.That part no. does not show in the Briggs alternator chart but that style stator produces between 2-4 amps.

#21

StarTech

StarTech

That one thing Briggs doesn't do and that is to keep charts and service manuals up to date. That's why I posted the supersede list so each of the previous number could be check against the chart. Some of the service info has been outdated for some time.

In this case it is just better to install a 9+ amp AC stator and used the rectifier/voltage regulator if the customer is wanting to do anything other than recharge the battery. Something like the tri circuit stator.

It is like the Briggs engine spec charts that are out of date. I have a personal copy of the non Vanguard chart that I have made numerous notes on as new updated SB and DSB info was published.

In this case it is just better to install a 9+ amp AC stator and used the rectifier/voltage regulator if the customer is wanting to do anything other than recharge the battery. Something like the tri circuit stator.

It is like the Briggs engine spec charts that are out of date. I have a personal copy of the non Vanguard chart that I have made numerous notes on as new updated SB and DSB info was published.

#23

T

Telesis

T

Telesis

With all do respect to txmowman and ozpete, it is not true that all alternators put out 26v minimum. One need only look at the chart I shared earlier, and specifically the 3rd row. You will note that the AC voltage output is shown in the chart. Those 4 put out 14VAC at WOT. If you'd like a more complete discussion, please refer to the excellent B&S "Engine Alternator Repower Guide". Just Google that and look on page 10 of the manual. [I didn't include a link because who knows how long it would be good for!] That section discusses testing AC voltage output of the various alternator types. The table on p 10 shows the wide range of voltages, depending on type. This is my 'go to' manual for all things 'alternator-related' for B&S engines.

[the manual is too big to upload here and I was not able to successfully open any of the manuals in Rivets' link provided in an earlier post. probably just 'old-man' syndrome on my part, lol!]

FWIW! Merry Christmas to all!

[the manual is too big to upload here and I was not able to successfully open any of the manuals in Rivets' link provided in an earlier post. probably just 'old-man' syndrome on my part, lol!]

FWIW! Merry Christmas to all!

#24

B

bertsmobile1

However while the part numbers are allover the place, the colour codes are fairly consistent so the chart was printed out A2 size, laminated & stuck on the inside door of the electric stuff cupboard

So I can work out what stator goes on which mower.

However I only stock two B & S stators , the late model 9 amp & 20 amp

If a replacement stator is required then I upgrade most of the unregulated ones to current regulated specs which down here is cheaper than chasing up old duel or tri circuit stators

B

bertsmobile1

Alternators were another "mystery to me " when I kicked off.That one thing Briggs doesn't do and that is to keep charts and service manuals up to date. That's why I posted the supersede list so each of the previous number could be check against the chart. Some of the service info has been outdated for some time.

In this case it is just better to install a 9+ amp AC stator and used the rectifier/voltage regulator if the customer is wanting to do anything other than recharge the battery. Something like the tri circuit stator.

It is like the Briggs engine spec charts that are out of date. I have a personal copy of the non Vanguard chart that I have made numerous notes on as new updated SB and DSB info was published.

However while the part numbers are allover the place, the colour codes are fairly consistent so the chart was printed out A2 size, laminated & stuck on the inside door of the electric stuff cupboard

So I can work out what stator goes on which mower.

However I only stock two B & S stators , the late model 9 amp & 20 amp

If a replacement stator is required then I upgrade most of the unregulated ones to current regulated specs which down here is cheaper than chasing up old duel or tri circuit stators

#25

T

txmowman

T

txmowman

With respect to Telesis, it was a "minimum" of 26 volts. Charging coils are limited by the size of the windings, the number of windings, the magnet strength and the rotating speed of the magnet. Unregulated is typically 30 to 40 volts, AC. It is then the regulators job to rectify to DC and charge the battery. When the battery is charged, the DC voltage goes to ground.

#26

T

txmowman

T

txmowman

The minimum is 26 volt because when converted from AC to DC, the voltage is cut in half. Half of 26 is 13, obviously. 13 volts is more than the 12.7 (roughly) to fully charge the battery. Typical DC from the regulator is in the 14 volt +/- area. Most regulator specs are up to 15 volts max.

#27

StarTech

StarTech

Well trying to explain this is going to be well over the heads of most. Plus it take several days of reading on my part to fully familiarize myself with the formulas (heck it been 40+ yrs since I knew these by heart.) But I do have my ARRL manuals on the shelf for reference

But txmowman your understanding of rectified DC circuits is lacking. Even your theory is off several volts. You got RMS voltages being converted to pulsing DC voltage ((0V to peak (RMS - rectifier voltage drop). First you must consider peak AC voltage, voltage drop the rectifier, the capacitance in the load, along with other factors.

Here is an example of what is actually at your 120 vac wall plug. It varies from zero to about 170v peak (or about 340 volts peak to peak) 60 times a second or 50 times a second outside the US. This why it can easily kill you along the amp capacity.

The reason Briggs don't give a voltage rating is that an unregulated DC circuit voltage is quite varied depending a which factors are present at the time of the voltage measurement.

But txmowman your understanding of rectified DC circuits is lacking. Even your theory is off several volts. You got RMS voltages being converted to pulsing DC voltage ((0V to peak (RMS - rectifier voltage drop). First you must consider peak AC voltage, voltage drop the rectifier, the capacitance in the load, along with other factors.

Here is an example of what is actually at your 120 vac wall plug. It varies from zero to about 170v peak (or about 340 volts peak to peak) 60 times a second or 50 times a second outside the US. This why it can easily kill you along the amp capacity.

The reason Briggs don't give a voltage rating is that an unregulated DC circuit voltage is quite varied depending a which factors are present at the time of the voltage measurement.

#28

Hammermechanicman

Hammermechanicman

What really happens is the spinning magnets are giviving a motivational speech to the electrons which makes them march back and forth and the diode picks out the good ones from the bad ones while the full wave regulator converts the ones with bad karma to good ones and then tells them all to go wait in the battery. It's not that complicated.

#29

StarTech

StarTech

Then comes along Covid-19 and some are just dropping dead along the way so they can't volt even if they make it to storage.

#30

T

Telesis

T

Telesis

Just to be clear txmowman, please take a look at the references I cited. They specifically state those particular units put out unregulated 14VAC. That's the stator output prior to any rectification or regulation. As Star indicated, your meter typically is reading RMS (root mean square) volts. [It may or may not be 'true RMS' depending on the quality of the meter, a detail that's not extremely relevant here. There is also something called 'average volts' which is also a detail we'll leave out here for brevity]

To convert from RMS volts to peak (of the AC) volts, you multiply by 1.414, which is the square root of 2. [I'll leave the formula details out] So, 14 x 1.414 = 19.8 (Vp) What that means is the unregulated AC voltage coming out of the stator goes from 0 to a positive peak of 19.8 volts down to 0 continuing to a negative peak of -19.8 volts and back to 0 in a sinusoidal fashion before being rectified and/or regulated. So Vp-p (voltage peak to peak) is 19.8 x 2 = 39.6 VAC

Again as Star indicated, the 120VAC you measure in your home is an RMS value. To find the peak(Vp), 120 x 1.414 = 169.7. Vp-p = 169.7 x 2 = 339.4

What does all this gibberish mean? Simply that a stator that puts out an unregulated 14VAC can be simply half-wave rectified with a single diode and with that 19.8 volt pulse, be able to charge a battery. There are caveats to this again which are beyond the scope of this discussion but suffice it to say this is the typical configuration used in the lower charging current (3 amp) systems.

Hope this helps!

To convert from RMS volts to peak (of the AC) volts, you multiply by 1.414, which is the square root of 2. [I'll leave the formula details out] So, 14 x 1.414 = 19.8 (Vp) What that means is the unregulated AC voltage coming out of the stator goes from 0 to a positive peak of 19.8 volts down to 0 continuing to a negative peak of -19.8 volts and back to 0 in a sinusoidal fashion before being rectified and/or regulated. So Vp-p (voltage peak to peak) is 19.8 x 2 = 39.6 VAC

Again as Star indicated, the 120VAC you measure in your home is an RMS value. To find the peak(Vp), 120 x 1.414 = 169.7. Vp-p = 169.7 x 2 = 339.4

What does all this gibberish mean? Simply that a stator that puts out an unregulated 14VAC can be simply half-wave rectified with a single diode and with that 19.8 volt pulse, be able to charge a battery. There are caveats to this again which are beyond the scope of this discussion but suffice it to say this is the typical configuration used in the lower charging current (3 amp) systems.

Hope this helps!

#31

Hammermechanicman

Hammermechanicman

When something with a battery comes in the shop i use an internal resistance type tester to find the health of the battery. Then i clean battery connections and start the equipment and run it up to about 3000 rpm and check voltage at battery to see if it is charging and then turn on any accessories like cluth and lights and measure voltage at batter for charging voltage. If it has about 13.5v or better i call it good and move on to other maintenance. I am sure the internet will tell me i am wrong but i try to not over think a lawn mower charging system. Don't really care if it is peak to peak, RMS or average volts. My meter is a true RMS meter but doesn't matter all that much.

#32

StarTech

Besides over thinking things can give you headaches and I don't need to add to my normal weekly headaches.

StarTech

That basically all we need to; unless, we designing a new system. It nice to know how they got there but normally all we to know is a system is operating within the design specs which in this case the 2-4 amps regulated spec. Now the output ampere can boosted a little by installing a regulator but not worth the expense of regulator; unless, you install the higher amperage stator in the first place. Otherwords beef up the charging system.When something with a battery comes in the shop i use an internal resistance type tester to find the health of the battery. Then i clean battery connections and start the equipment and run it up to about 3000 rpm and check voltage at battery to see if it is charging and then turn on any accessories like cluth and lights and measure voltage at batter for charging voltage. If it has about 13.5v or better i call it good and move on to other maintenance. I am sure the internet will tell me i am wrong but i try to not over think a lawn mower charging system. Don't really care if it is peak to peak, RMS or average volts. My meter is a true RMS meter but doesn't matter all that much.

Besides over thinking things can give you headaches and I don't need to add to my normal weekly headaches.

#33

T

Telesis

T

Telesis

I couldn't agree with you guys more! The simpler the better which is what I described(as you and others have) in post 14! However, the engineer in me finds it hard to ignore posts that contain untruths and/or misunderstandings. I treat these forums not only as a way to solve an individual's specific problem, but also to help others understand.

As I was taught in engineering school 40+ years ago... "Facts Are Our Friends!"

Enjoy!

As I was taught in engineering school 40+ years ago... "Facts Are Our Friends!"

Enjoy!

#34

Hammermechanicman

I always thought it was "don't cloud the issue with facts"

Always fun watching a newb tech using a meter.

Hammermechanicman

As I was taught in engineering school 40+ years ago... "Facts Are Our Friends!"

Enjoy!

I always thought it was "don't cloud the issue with facts"

Always fun watching a newb tech using a meter.

#35

T

Telesis

T

Telesis

Just like some folks with calculators..... 3.141592654 has to be the answer...'cuz the calculator says so'. I tutor high school kids in math and can't tell you how often this occurs these days!

We had a Senior Vice President at the automation company I worked for stand up in front of a large group of employees and open his presentation with "I want to start my presentation by saying I am unencumbered by the facts!" Funniest darn thing I'd heard from a SVP my entire career! LOL!

We had a Senior Vice President at the automation company I worked for stand up in front of a large group of employees and open his presentation with "I want to start my presentation by saying I am unencumbered by the facts!" Funniest darn thing I'd heard from a SVP my entire career! LOL!

#36

B

bertsmobile1

B

bertsmobile1

Yes there is a sharp cut off between the log tables / slide rule students , the calculator students & the computer students.

We had a physics professor who would put up an equation then promptly round every number up or down to the nearest 10 so we could do the maths in out heads

When some of the students complained about his technique his reply was

"I am trying, with very limited success to show you the how & why , the actual numbers are not important right now.

When you are sending a rocket to Pluto you can worry about the decimal places "

Then there was an engineering tutor who would fail any student who used too many decimal places in an answer .

Most of his problems would have a coarse dimension like 2' so any answer with a greater implied precision of 1/2 foot would be marked as a fail .

I was have a chat about this a while back with a friend.

I have noticed that for some reason all of the mower specs for torque are now in in.lbs which of course implies a precision of +/- 0.5 in.lbs

But the actual tollerances have not changed since they were noted in ft.lbs

I presume this is because of the advent of digital torque wrenches as very few mechanical ones are marked in in.lbs except some micrometer scale spring loaded ones which of course are the least accurate wrenches in the first place.

We had a physics professor who would put up an equation then promptly round every number up or down to the nearest 10 so we could do the maths in out heads

When some of the students complained about his technique his reply was

"I am trying, with very limited success to show you the how & why , the actual numbers are not important right now.

When you are sending a rocket to Pluto you can worry about the decimal places "

Then there was an engineering tutor who would fail any student who used too many decimal places in an answer .

Most of his problems would have a coarse dimension like 2' so any answer with a greater implied precision of 1/2 foot would be marked as a fail .

I was have a chat about this a while back with a friend.

I have noticed that for some reason all of the mower specs for torque are now in in.lbs which of course implies a precision of +/- 0.5 in.lbs

But the actual tollerances have not changed since they were noted in ft.lbs

I presume this is because of the advent of digital torque wrenches as very few mechanical ones are marked in in.lbs except some micrometer scale spring loaded ones which of course are the least accurate wrenches in the first place.

#37

T

txmowman

T

txmowman

Whatever, lol. You hacks on these forums are a joke. If you think it is any more complicated than what I explained, is only puffing your shallow ego.Well trying to explain this is going to be well over the heads of most. Plus it take several days of reading on my part to fully familiarize myself with the formulas (heck it been 40+ yrs since I knew these by heart.) But I do have my ARRL manuals on the shelf for reference

But txmowman your understanding of rectified DC circuits is lacking. Even your theory is off several volts. You got RMS voltages being converted to pulsing DC voltage ((0V to peak (RMS - rectifier voltage drop). First you must consider peak AC voltage, voltage drop the rectifier, the capacitance in the load, along with other factors.

Here is an example of what is actually at your 120 vac wall plug. It varies from zero to about 170v peak (or about 340 volts peak to peak) 60 times a second or 50 times a second outside the US. This why it can easily kill you along the amp capacity.

The reason Briggs don't give a voltage rating is that an unregulated DC circuit voltage is quite varied depending a which factors are present at the time of the voltage measurement.

#38

Hammermechanicman

Hammermechanicman

Somewhere in the barn i still have my old slide rule. Haven't used it since high school. Probably forgot how to use it by now. It is probably in the same box as my drafting board T square and triangles and french curves also not used since i found Sketchup. I think i threw out the Heathkit VTVM i built. Us old hack dinosaurs are fading away. Funny thing is i have a friend in his 20's with a degree in electrical engineering specializing in controls and he has me do electrical work on his house. You don't need a torque wrench any more. Just tighten till your bad elbow clicks.Yes there is a sharp cut off between the log tables / slide rule students , the calculator students & the computer students.

We had a physics professor who would put up an equation then promptly round every number up or down to the nearest 10 so we could do the maths in out heads

When some of the students complained about his technique his reply was

"I am trying, with very limited success to show you the how & why , the actual numbers are not important right now.

When you are sending a rocket to Pluto you can worry about the decimal places "

Then there was an engineering tutor who would fail any student who used too many decimal places in an answer .

Most of his problems would have a coarse dimension like 2' so any answer with a greater implied precision of 1/2 foot would be marked as a fail .

I was have a chat about this a while back with a friend.

I have noticed that for some reason all of the mower specs for torque are now in in.lbs which of course implies a precision of +/- 0.5 in.lbs

But the actual tollerances have not changed since they were noted in ft.lbs

I presume this is because of the advent of digital torque wrenches as very few mechanical ones are marked in in.lbs except some micrometer scale spring loaded ones which of course are the least accurate wrenches in the first place.

#39

Scrubcadet10

Ask 100 people the same question, you'll get 99 different answers.

Scrubcadet10

Star is a little more than a hack. Forums are public place so you often times won't see opinions you agree with.Whatever, lol. You hacks on these forums are a joke. If you think it is any more complicated than what I explained, is only puffing your shallow ego.

Ask 100 people the same question, you'll get 99 different answers.

#40

T

Telesis

T

Telesis

C'mon Hammer, it's like riding a bike....multiply two numbers using the C and D scales! Mine was the last engineering class in 1976 that the "slip-stick" was taught....a time when the TI SR-50 was the coveted dream machine calculator!

For the record txmowman, nobody is 'puffing their shallow ego.' We're just trying to set you straight. Take the feedback in the spirit in which it was intended, to educate. I realize it's hard to admit that your understanding of a topic is flat out wrong, on multiple levels. I guarantee you every one of us has done so here or elsewhere. But to sit there and insist that 2 x 2 = 5 and we are the 'hacks' for informing you it's really 4 speaks volumes, especially after you were provided with the technical sources right from B&S so you wouldn't have to take our word for it!

I still wish you a Happy New Year!

For the record txmowman, nobody is 'puffing their shallow ego.' We're just trying to set you straight. Take the feedback in the spirit in which it was intended, to educate. I realize it's hard to admit that your understanding of a topic is flat out wrong, on multiple levels. I guarantee you every one of us has done so here or elsewhere. But to sit there and insist that 2 x 2 = 5 and we are the 'hacks' for informing you it's really 4 speaks volumes, especially after you were provided with the technical sources right from B&S so you wouldn't have to take our word for it!

I still wish you a Happy New Year!

#41

StarTech

StarTech

Now now Telesis you know probably as well as I do 1 + 1 can equal 2 or more. <LOL>

But answers are relative as I do round off most my figures to within a hundredth or less just simplify things. And haven't used a slide rule since the late 70s. Things I fool with now a days is much simpler to work with. I just need to estimate a height of a tree by knowing the distance to the tree and the angle to the top. That way I don't crush the neighbor's automobile or take out the power line feeding the house when I fell a tree.

Actually machining things is where I got to be on the money when making parts. I got a 12" dial type caliper. Now I got to relearn how to use one.

But answers are relative as I do round off most my figures to within a hundredth or less just simplify things. And haven't used a slide rule since the late 70s. Things I fool with now a days is much simpler to work with. I just need to estimate a height of a tree by knowing the distance to the tree and the angle to the top. That way I don't crush the neighbor's automobile or take out the power line feeding the house when I fell a tree.

Actually machining things is where I got to be on the money when making parts. I got a 12" dial type caliper. Now I got to relearn how to use one.

#42

Hammermechanicman

Hammermechanicman

I thought i was hot stuff when i got a Ti55 calculator then taking calculus at community college they made us get HP35 calculators. I never did like the reverse polish notation thing to enter data. Of course i wasn't a calculus whiz either. When my son was going to university of Dayton as a sophomore he tutored upper classmen in calculus. Kid is way smarter than me but he still calls the old man to fix his stuff.C'mon Hammer, it's like riding a bike....multiply two numbers using the C and D scales! Mine was the last engineering class in 1976 that the "slip-stick" was taught....a time when the TI SR-50 was the coveted dream machine calculator!

For the record txmowman, nobody is 'puffing their shallow ego.' We're just trying to set you straight. Take the feedback in the spirit in which it was intended, to educate. I realize it's hard to admit that your understanding of a topic is flat out wrong, on multiple levels. I guarantee you every one of us has done so here or elsewhere. But to sit there and insist that 2 x 2 = 5 and we are the 'hacks' for informing you it's really 4 speaks volumes, especially after you were provided with the technical sources right from B&S so you wouldn't have to take our word for it!

I still wish you a Happy New Year!

#43

T

Telesis

T

Telesis

I'm here ROTFLMAO! You echoed my sentiments on RPN! Never bought an HP and to this day, I'm positive I still couldn't figure out how to properly enter a formula! (I love their test equip though) That's one thing I'm comfortable going to my grave never having learned! RIP RPN

Star, that's the technique we used with model rockets to determine apogee! Gotta luv Pythagoras!

"Give a man a fish, he eats for a day. Teach a man to fish, he eats for life!"

Star, that's the technique we used with model rockets to determine apogee! Gotta luv Pythagoras!

"Give a man a fish, he eats for a day. Teach a man to fish, he eats for life!"

#44

Mower King

Mower King

This thread has turned into a real pi**ing contest between a few.

The OP just wanted to know how to test DC output.....it was answered in the first 4 replies, now it's on page 5....LOL

The OP just wanted to know how to test DC output.....it was answered in the first 4 replies, now it's on page 5....LOL

#45

Hammermechanicman

And........?

Hammermechanicman

This thread has turned into a real pi**ing contest between a few.

The OP just wanted to know how to test DC output.....it was answered in the first 4 replies, now it's on page 5....LOL

And........?

#46

B

bertsmobile1

I did this just after the state electricity commission would not allow me to sit their certification tests for contractors because my Kroutkrammer ultrasound generator had a square CRO screen while all of Sperry Rand ones had the std round screens . The head engineer would not understand that the square was just a circle with 4 segments screened off and he claimed it could not give a true trace.

I did sit it a couple of years latter after using the Sperry gear at college so becoming familair with it but they still never allowed me to work for them.

Accoustic emissions is the only real time method of failure detection but even then most of the decision makers are accountants who have a zero understanding of physics unlike when KK kicked off in the 50's when some real people were in decision making positions.

B

bertsmobile1

One of my big mistakes in life was to abandon ultrasonics in favour of acoustic emissions .Somewhere in the barn i still have my old slide rule. Haven't used it since high school. Probably forgot how to use it by now. It is probably in the same box as my drafting board T square and triangles and french curves also not used since i found Sketchup. I think i threw out the Heathkit VTVM i built. Us old hack dinosaurs are fading away. Funny thing is i have a friend in his 20's with a degree in electrical engineering specializing in controls and he has me do electrical work on his house. You don't need a torque wrench any more. Just tighten till your bad elbow clicks.

I did this just after the state electricity commission would not allow me to sit their certification tests for contractors because my Kroutkrammer ultrasound generator had a square CRO screen while all of Sperry Rand ones had the std round screens . The head engineer would not understand that the square was just a circle with 4 segments screened off and he claimed it could not give a true trace.

I did sit it a couple of years latter after using the Sperry gear at college so becoming familair with it but they still never allowed me to work for them.

Accoustic emissions is the only real time method of failure detection but even then most of the decision makers are accountants who have a zero understanding of physics unlike when KK kicked off in the 50's when some real people were in decision making positions.

#47

Hammermechanicman

Actually

" Give a man a fish, he eats for a day. Teach a man to fish, he will spend way too much money on fishing gear and his wife will be pissed he is never around to do yard work."

Just sayin'

Hammermechanicman

"Give a man a fish, he eats for a day. Teach a man to fish, he eats for life!"

Actually

" Give a man a fish, he eats for a day. Teach a man to fish, he will spend way too much money on fishing gear and his wife will be pissed he is never around to do yard work."

Just sayin'

#48

B

bertsmobile1

Being able to plot linnear regression graphs from raw x-y data was a god send

It go so much use I went through 2 sets of batteries a year.

The lab staff use to borrow it on days when I was not on campus because it was quicker & easier to use than the universities IBM 360 and of course there was full days wait for the data center to convert the numbers into punch cards to feed the compiler with.

Remember compilers ?

The I got a part time job with pubic works and again the calculator spent more time with other staff than me

I mentioned I still had one some 20 years latter to a counter salesman at Jaycar ( electronics store ) and he just about had a fit so I gave it to him complete with original manual and book of equations.

Never paid for any electrical part again till I left the area , apparently they have quite a cult following

Still use the HP 27S I bought to replace it when batteries were no longer available for the 21 and I had cut open & repacked the carrier so many times it would no longer stay together .

The inbuilt stas that allow you to input a complete invoice then scroll back through every entry is really useful for fat fingers attached to failing eyes .

B

bertsmobile1

I initally bought a HP 21 because it was all I could affordI thought i was hot stuff when i got a Ti55 calculator then taking calculus at community college they made us get HP35 calculators. I never did like the reverse polish notation thing to enter data. Of course i wasn't a calculus whiz either. When my son was going to university of Dayton as a sophomore he tutored upper classmen in calculus. Kid is way smarter than me but he still calls the old man to fix his stuff.

Being able to plot linnear regression graphs from raw x-y data was a god send

It go so much use I went through 2 sets of batteries a year.

The lab staff use to borrow it on days when I was not on campus because it was quicker & easier to use than the universities IBM 360 and of course there was full days wait for the data center to convert the numbers into punch cards to feed the compiler with.

Remember compilers ?

The I got a part time job with pubic works and again the calculator spent more time with other staff than me

I mentioned I still had one some 20 years latter to a counter salesman at Jaycar ( electronics store ) and he just about had a fit so I gave it to him complete with original manual and book of equations.

Never paid for any electrical part again till I left the area , apparently they have quite a cult following

Still use the HP 27S I bought to replace it when batteries were no longer available for the 21 and I had cut open & repacked the carrier so many times it would no longer stay together .

The inbuilt stas that allow you to input a complete invoice then scroll back through every entry is really useful for fat fingers attached to failing eyes .

#49

OzPete

So, ... There isn't.

Because the B&S Alternator on that engine doesn't generate DC. It makes AC (Alternating Current). That's why it's called an Alternator.

If an electrical device makes DC then it's called a Generator.

OzPete

Someone should answer the actual question in the original post.Is there a way to determine the DC output of the B&S alternator,

So, ... There isn't.

Because the B&S Alternator on that engine doesn't generate DC. It makes AC (Alternating Current). That's why it's called an Alternator.

If an electrical device makes DC then it's called a Generator.

#50

B

bertsmobile1

B & S put out a chart which explains the differences between the various combinations of stator, magnets & regulators

So it is just a matter of checking the colour of the wire(s) from the stator , the colour of the connector then identifing the regulator ( where fitted ) .

If you want to be really **** you can remove the flywheel & measure the magnets.

Bartles ( the OP ) simply wanted to identify the system he had & find out it's output as B & S do not make mention of it in the parts books , just the numbers which change more often than my bed sheets .

B

bertsmobile1

We didSomeone should answer the actual question in the original post.

So, ... There isn't.

Because the B&S Alternator on that engine doesn't generate DC. It makes AC (Alternating Current). That's why it's called an Alternator.

If an electrical device makes DC then it's called a Generator.

B & S put out a chart which explains the differences between the various combinations of stator, magnets & regulators

So it is just a matter of checking the colour of the wire(s) from the stator , the colour of the connector then identifing the regulator ( where fitted ) .

If you want to be really **** you can remove the flywheel & measure the magnets.

Bartles ( the OP ) simply wanted to identify the system he had & find out it's output as B & S do not make mention of it in the parts books , just the numbers which change more often than my bed sheets .

#51

R

Rivets

R

Rivets

OzPete, you need to read the entire thread. Bert answered his question in post #10, when he directed the OP to download a Briggs repower guide. It contains all the information the OP should need to solve his problem. Everything else is just a lesson on electrical theory. Bert, sorry you beat me to replying, I’m bad.

#52

S

sootypipe

You did confirm. You were doing it wrong all those years too.

www.fluke.com

www.fluke.com

S

sootypipe

You know, if you can’t say anything useful or helpful, just don’t say anything at all. And some feedback for you: volts and amps are also units of measurement that come from a multimeter, i.e. Fluke sells “multimeters.”Then I must have been doing wrong all these years using volt and amp meters.

You did confirm. You were doing it wrong all those years too.

Multimeters | Fluke

Discover our range of multimeters and digital multimeters (DMMs). Fluke has been reliably used by electricians everywhere for their electrical testing needs.

#53

StarTech

StarTech

Yelp I did say that I use a volt meter to measure volts instead of using ohms meter. So I was wrong now the next time I need to check my battery voltage I use my ohms meter. Just wonder how many ohms should it read?

Well my current DVMM does ohms, amps, volts, frequency, inductance, and capacitance along diode check and a simple continuity checker. Of course it is limited to 10 amps which is why I 40/400 amp clamp for it. I also have 100 mhz oscilloscope that I could use until a few weeks ago when a mouse chew the pickup lead in two. I reckon he just wanted to see what was inside the cable.

Well my current DVMM does ohms, amps, volts, frequency, inductance, and capacitance along diode check and a simple continuity checker. Of course it is limited to 10 amps which is why I 40/400 amp clamp for it. I also have 100 mhz oscilloscope that I could use until a few weeks ago when a mouse chew the pickup lead in two. I reckon he just wanted to see what was inside the cable.

#54

S

SamB

S

SamB

bertsmobile1, can you answer a question about the stator sizes? Is a Briggs stator on a 40777 engine the physical size as a 31R777?Alternators were another "mystery to me " when I kicked off.

However while the part numbers are allover the place, the colour codes are fairly consistent so the chart was printed out A2 size, laminated & stuck on the inside door of the electric stuff cupboard

So I can work out what stator goes on which mower.

However I only stock two B & S stators , the late model 9 amp & 20 amp

If a replacement stator is required then I upgrade most of the unregulated ones to current regulated specs which down here is cheaper than chasing up old duel or tri circuit stators