In #19, you mention the engine lagging with drive wheels but no blade engagement. And I think there are a couple other mentions like this sprinkled thru the thread...

I'm not a mower guy, just a mech eng who likes this stuff better than netflix...but the engine dipping with drive wheels only would point to something making the hydraulic pumps working harder than designed. Wrong oil viscosity, plugged filter, bad pump bearing, general system neglect, collapsed hose, etc

Wouldn't have to seem excessive on its own, but when combined with blade engagement, the load package might be asking for more oomph than is available from the Kohler

Well, I think we can rule out the engine/carbs. After a full rebuild there is no change. I found some little things during the rebuild that were not perfect but fixed them as I went through it. The engine is operating as it should. But the problem still exists.

An interesting note. When I run the motor in the garage for 5 minutes, both plugs come out golden brown. When I mow with it, and she bogs down severely, I come back with carbon black #1 and pure white #2. I now believe this is just the behavior of this engine when it's at full throttle but externally bogged down. Somehow all the fuel ends up in #1 because the intake runner is shorter? I'm guessing of course, but it must be so.

Also, as noted before, when the blades engage the rpms dip for a second into the 2500-2800 range but then come back up fairly quickly. I believe this is normal behavior. When I hear lawn guys engage blades I feel it sounds the same. My old lawn tractor had the same behavior even. Coupled with the fact that the spindles all spin free with no obvious binding (checked when belt was off), I think we can rule out the deck/blades/PTO.

Which seems to leave only one thing as you mentioned. The Hydro system. I may open a new thread in the transmission forum but for the sake of this thread I'll go into it here too. What would cause a hydraulic system to have excess load?? I don't believe a clogged filter would do this as all filters should have a bypass valve. The fluid on the dipstick looks clean and of the right consistency (tank fluid compared to the bottle of manuf. recommended fluid that I have)

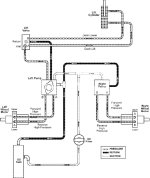

This mower has two separate pumps (L and R) that each run an independent wheel motor for it's respective side. In addition, the left side operates a hydraulic deck lift. (I'll attach a diagram).

1. That said, when I start mowing it seems like it takes about 10-20ft before it falls on its face. I feel like this points to a blockage of some sort (ie: runs great until pressure builds up and forces the system to bind somehow)

2. However, when on jack stands, operating the left stick full forward has no effect on rpms. Wheel spins like it should and literally the rpms don't even dip 1 rpm. Same with the right stick. So that indicates the blockage only occurs under load? See #3 next...

3. When mowing, operating the left stick (only) full forward causes rpms to drop to well under 2000. Same with right stick (only). No difference between the left and right. Remember each side is it's own independent system. On that note: I hope my lawn forgives me, it now has ruts.

4. As mentioned before, when mowing and the rpms drop, pulling the sticks back to neutral brings the rpms back to 3400+ (within a few seconds).

I don't know. Seeing that the left and right side both exhibit the same behavior, it makes me thing the problem is in the tank or filter part of the system. Maybe the filter is fubar'ed (maybe the bypass valve is not functioning in it)?? I guess I can buy a new filter.

I'm just so over this thing at this point. I'm real close to quitting and just parting her out.