You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Craftsman mower robot - Governor/choke issue - Stalls under load and won't restart when hot

#1

B

BGood

B

BGood

I recently completed a robotic lawnmower project using an old Craftsman push behind mulching mower (917.388621) with a 6.75hp engine (143.016702). Actually, the mower is not entirely robotic at this point, but computer control is in the plan for the next stage in its evolution. Right now, it is self propelled using wheelchair motors, standard 2.6ghz r/c remote radio control drone technology, and a real-time 5.8ghz FPV video feed.

The electronic technology seems to be working pretty well, but the reason for this posting here is because I suspect a basic problem with the gas mower engine. The mower's mission is wildfire mitigation of my steep backyard terrain which grows waist-high native grasses, thistle, cactus, and an occasional rattlesnake. The remote control and video feed is helpful in avoiding the latter.

The specific engine problem I'm having is that when the mower encounters particularly dense or stringy vegitation and I don't back it off quickly enough, it will stall and I can't get it started again with the pull rope. Then I have to wait up to 1/2 hour for it to cool off enough to restart. It always seems to start very easily when cool.

From internet research and my engine-savvy neighbor, we suspect the problem may be with the carburator and possibly the automatic choke / governor linkage. I ordered a replacement carb which has not arrived yet, but also have have not found any adjustment instructions for the governor linkage towards the rear of the engine. I notice that when the adjustment screw is loosened, and the governor arm is adjusted rearward, the throttle valve closes. The loading of the linkage spring (when the engine is cold) pulls the governor arm frontward which opens the butterfly throttle valve.

My neighbor suggested that the governor or choke system may be reducing fuel/air when engine rpm drops in advance of a stall, and this may be why the engine is stalling. I am more concerned about having to shlep the robot back up the hill to the workshop, or wait out with the cactus and snakes for it to cool off enough to restart.

Can anyone suggest an adjustment procedure for the governor/choke linkage that will: 1) provide additional fuel/air to prevent stalling; and 2) make the mower easier to start when hot?

Thanks so much for your suggestions.

The electronic technology seems to be working pretty well, but the reason for this posting here is because I suspect a basic problem with the gas mower engine. The mower's mission is wildfire mitigation of my steep backyard terrain which grows waist-high native grasses, thistle, cactus, and an occasional rattlesnake. The remote control and video feed is helpful in avoiding the latter.

The specific engine problem I'm having is that when the mower encounters particularly dense or stringy vegitation and I don't back it off quickly enough, it will stall and I can't get it started again with the pull rope. Then I have to wait up to 1/2 hour for it to cool off enough to restart. It always seems to start very easily when cool.

From internet research and my engine-savvy neighbor, we suspect the problem may be with the carburator and possibly the automatic choke / governor linkage. I ordered a replacement carb which has not arrived yet, but also have have not found any adjustment instructions for the governor linkage towards the rear of the engine. I notice that when the adjustment screw is loosened, and the governor arm is adjusted rearward, the throttle valve closes. The loading of the linkage spring (when the engine is cold) pulls the governor arm frontward which opens the butterfly throttle valve.

My neighbor suggested that the governor or choke system may be reducing fuel/air when engine rpm drops in advance of a stall, and this may be why the engine is stalling. I am more concerned about having to shlep the robot back up the hill to the workshop, or wait out with the cactus and snakes for it to cool off enough to restart.

Can anyone suggest an adjustment procedure for the governor/choke linkage that will: 1) provide additional fuel/air to prevent stalling; and 2) make the mower easier to start when hot?

Thanks so much for your suggestions.

#2

R

Rivets

R

Rivets

Notice that small plastic cap next to the primer bulb, about 7 o’clock? Under it you will find the idle jet. Remove and make sure it is clean. Here is a service manual for you engine. https://www.mymowerparts.com/pdf/Te...P-4-CYCLE-L-HEAD-FLAT-HEAD-ENGINES-692509.pdf

#3

B

BGood

B

BGood

Thanks for sending the service manual link, Rivets. I haven't fully researched my issue yet, but there is lots of info about carb and governor adjustment that gives me a much better picture of how things work. I'll take a look at the idle jet after a morning coffee primer.

#4

sgkent

sgkent

when a push mower is put into too dense a grass it will stall. That is normal. The hard restarting can be because it is flooded at that point. I learned this as a kid trying to mow grass that was too tall. I am 71 now. You need a different kind of mower or more powerful mower than a small push style mower. Or you need to mow more frequently. We used to go out with hoes once a year and knock it down. A flail mower or HD wacker might be able to pull it off.

#5

B

BGood

B

BGood

Good comment, sgkent. I also should sharpen the blade on the r/c mower. My larger 12 hp riding mower with 38" deck does not have similar stalling problems in tall grass, but it is too dangerous to use on the double fall line steeps.when a push mower is put into too dense a grass it will stall. That is normal. The hard restarting can be because it is flooded at that point. I learned this as a kid trying to mow grass that was too tall. I am 71 now. You need a different kind of mower or more powerful mower than a small push style mower. Or you need to mow more frequently. We used to go out with hoes once a year and knock it down. A flail mower or HD wacker might be able to pull it off.

#6

sgkent

sgkent

it is 12 HP. The smaller engine mowers don't have the power. Sharpening the blade will help but not all that much. The issue is in part the mower cannot discharge the mass it is cutting, Set the blade as high as it will go and make multiple passes, or hire some goats, which is how they handle it here.Good comment, sgkent. I also should sharpen the blade on the r/c mower. My larger 12 hp riding mower with 38" deck does not have similar stalling problems in tall grass, but it is too dangerous to use on the double fall line steeps.

#7

B

BGood

B

BGood

I removed the plastic cap and idle jet. It looks pretty clean to me, but when I insert a very thin copper wire into the hole in the end, it will not fully insert. Should I be able to see the inserted wire through the side holes?Notice that small plastic cap next to the primer bulb, about 7 o’clock? Under it you will find the idle jet. Remove and make sure it is clean. Here is a service manual for you engine. https://www.mymowerparts.com/pdf/Te...P-4-CYCLE-L-HEAD-FLAT-HEAD-ENGINES-692509.pdf

#8

R

Rivets

R

Rivets

Yes, sounds like you found your problem. I suggest you SLOWLY work a piece of stiff wire into the hole until you get it fully open. It may take a while, soaking it in carb cleaner helps. So does patience.

#9

sgkent

sgkent

no. If you look at that jet it has side holes. The end is likely plugged to the outside, because the air passage is other than to the outside thru the exterior end of the jet. I would be cautious about making changes until the air jet system is inspected better. The plug in it may be intentional. I have a couple carbs that are like that. Also the end is very shiny. Tighten it but do not overtighten it or it may crush the idle passage internally.

#10

S

skiman

S

skiman

well for one, you dont have any kind of choke setup...you have a primer bulb setup designed to place gas into the carb intake tube to allow the engine to start from the extra gas in the tube...you dont have autochoke or a choke flap at all...second...when does it stall out and how steep is your hill...are you going up the hill and this happens or down...if down hill...depending on the slope of the hill...youll experience fuel starvation because the gravity feed fuel from the tank is lower than the carb...you might want to consider remotely mounting the tank higher than the engine to insure the fuel always flows to the carb going up or down a hill...also check the fuel cap vent hole to make sure its got good air venting to take up for fuel loss when running...i suspect your biggest problem is the slope youre trying to cut...I recently completed a robotic lawnmower project using an old Craftsman push behind mulching mower (917.388621) with a 6.75hp engine (143.016702). Actually, the mower is not entirely robotic at this point, but computer control is in the plan for the next stage in its evolution. Right now, it is self propelled using wheelchair motors, standard 2.6ghz r/c remote radio control drone technology, and a real-time 5.8ghz FPV video feed.

The electronic technology seems to be working pretty well, but the reason for this posting here is because I suspect a basic problem with the gas mower engine. The mower's mission is wildfire mitigation of my steep backyard terrain which grows waist-high native grasses, thistle, cactus, and an occasional rattlesnake. The remote control and video feed is helpful in avoiding the latter.

The specific engine problem I'm having is that when the mower encounters particularly dense or stringy vegitation and I don't back it off quickly enough, it will stall and I can't get it started again with the pull rope. Then I have to wait up to 1/2 hour for it to cool off enough to restart. It always seems to start very easily when cool.

From internet research and my engine-savvy neighbor, we suspect the problem may be with the carburator and possibly the automatic choke / governor linkage. I ordered a replacement carb which has not arrived yet, but also have have not found any adjustment instructions for the governor linkage towards the rear of the engine. I notice that when the adjustment screw is loosened, and the governor arm is adjusted rearward, the throttle valve closes. The loading of the linkage spring (when the engine is cold) pulls the governor arm frontward which opens the butterfly throttle valve.

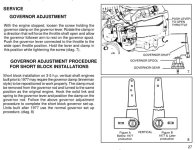

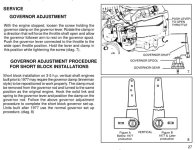

View attachment 61396

My neighbor suggested that the governor or choke system may be reducing fuel/air when engine rpm drops in advance of a stall, and this may be why the engine is stalling. I am more concerned about having to shlep the robot back up the hill to the workshop, or wait out with the cactus and snakes for it to cool off enough to restart.

Can anyone suggest an adjustment procedure for the governor/choke linkage that will: 1) provide additional fuel/air to prevent stalling; and 2) make the mower easier to start when hot?

Thanks so much for your suggestions.

#11

R

Rivets

R

Rivets

I’ve worked on these carbs a couple of times in the past and know what I’m talking about. These other guys need to read the manual. Sgkent, you are totally wrong. The OP has a Series 11 carb. That is the idle jet which has one hole vertically and one hole horizontally. They both need to be open. BGood, I recommend that you open the bottom oriface and your problem will be solved.

#12

sgkent

sgkent

think about what you just said. He is saying that a copper wire will not go all the way thru the jet from the hole on the bottom to the left hand side of the jet in the photo. He should not try to open the jet all the way thru to the left hand side. It only needs to be open on the three holes so go flame someone else.I’ve worked on these carbs a couple of times in the past and know what I’m talking about. These other guys need to read the manual. Sgkent, you are totally wrong. The OP has a Series 11 carb. That is the idle jet which has one hole vertically and one hole horizontally. They both need to be open. BGood, I recommend that you open the bottom oriface and your problem will be solved.

#13

R

Rivets

R

Rivets

You better stop working on any Tecumseh engines if you believe what you just posted. If you can read and understand pictures, take a look at the service manual I posted on how these carbs work. This jet has two operations, large horizontal holes will feel fuel straight through to the high speed circuit. The small vert hole, which in this case is plugged, feeds the idle circuit. That’s why it is called the idle jet. It’s size is .017” and needs to be kept Ed clean for both the starting and idle circuits. If you don’t understand what the manual says, maybe this one has more pictures to help you. http://www.tecumsehcarburetorguide.com/how-to-guide/

#14

B

BGood

B

BGood

Thanks for your comments, skiman. All of the stalls have been in thick grass on relatively flat terrain when the mower has bitten off more than it can chew. So I don't think that slope or up/down attitude is the issue. Also, I've found that the mower's light weight (135#), wimpy wheelchair motors, and poor wheel-ground traction preclude mowing uphill. Downhill is much easier. Not sure how to test the fuel cap vent hole.well for one, you dont have any kind of choke setup...you have a primer bulb setup designed to place gas into the carb intake tube to allow the engine to start from the extra gas in the tube...you dont have autochoke or a choke flap at all...second...when does it stall out and how steep is your hill...are you going up the hill and this happens or down...if down hill...depending on the slope of the hill...youll experience fuel starvation because the gravity feed fuel from the tank is lower than the carb...you might want to consider remotely mounting the tank higher than the engine to insure the fuel always flows to the carb going up or down a hill...also check the fuel cap vent hole to make sure its got good air venting to take up for fuel loss when running...i suspect your biggest problem is the slope youre trying to cut...

#15

B

BGood

B

BGood

I read through the Tecumseh references from Rivets and while much of the material is beyond my mechanical experience, I suspect that the interior cavity of the idle screw I removed may be more involved that I first thought. While the thin copper wire I could not push through the end orifice to the lateral holes was maybe 24-26 gauge, when I used a thinner tapered needle I could see the tip of the needle through the lateral holes but could not push it in any further. This suggests to me that the cavity is tapered and too small for the solid copper wire to pass through. Also, the lateral holes are different sizes. What this all means I'm not sure, but the repair manual does provide an adjustment procedure for the governor arm which I'm going to follow when I put everything back together. Hopefully with no parts left over. Thanks for the help!

#16

R

Rivets

R

Rivets

As I posted the bottom idle jet hole is .017”. Because I have them I use a micro drill to clean this jet when it becomes clogged. I start with #80 and proceed up to #78. Sometimes I need to go to a #77, which is .018”. You must be extremely careful that you don’t break the drill off in the jet, yes I’ve done this more than once.

#17

B

BGood

B

BGood

Following up on my tune-up progress with the stalling and hot restart problems with my robo mower gas engine, I've been addressing a variety of deferred maintenance issues that came along with purchase of the old mower used a a basis for the robot. Besides the carb diagnosis, idle jet cleaning, and governor adjustment already discussed, other issues include blade sharpening, oil change, spark plug, and ordering a cheap replacement carb if my DIY repairs failed. At this point the replacement carb has arrived and I discovered that the recommended spark plug gap is actually .030" rather than the larger .045" I re-gapped to. This makes me wonder if the oversize spark gap might have contributed to my warm restart problem?

But now that I have a new replacement carb in hand, have regapped the spark plug to the .030" spec, and concerns about the knowledge and specialized tools I don't have for a complete carb rebuild, my inclination is to install the replacement carb and make the governor adjustment described below from the repair manual Rivets provided.

Does this make sense to you more experienced gas engine guys? Assuming it does, is there any additional guidance you can suggest for the governor linkage adjustment?

Thanks.

But now that I have a new replacement carb in hand, have regapped the spark plug to the .030" spec, and concerns about the knowledge and specialized tools I don't have for a complete carb rebuild, my inclination is to install the replacement carb and make the governor adjustment described below from the repair manual Rivets provided.

Does this make sense to you more experienced gas engine guys? Assuming it does, is there any additional guidance you can suggest for the governor linkage adjustment?

Thanks.

#18

R

Rivets

R

Rivets

Before installing the new carb, I would install the properly gapped plug and adjust the governor. If that doesn’t solve the problem then I would install the carb.

#19

sgkent

sgkent

really. I never knew a small mower that would not stall on tall grass. Around here every spring I have a few neighbors who let the grass grow too tall. You can hear them on Saturdays in late spring, rrrrrrrrrrr thump. whiiiish, whiiiiish, whiiish, damn mower, rrrrrrrrrrrr, thump. Son of a ***** mower. whiiiish whiiish whisssh, rrrrrrrr thump. It is like a chorus of cicadas from all the yards that let it get too tall.

#20

B

bertsmobile1

B

bertsmobile1

Larger gaps = higher resistance

Higher resistance tends to force the spark to run down the side of the electrode at lower speeds

Usually it makes the engine harder to start cold .

Higher resistance tends to force the spark to run down the side of the electrode at lower speeds

Usually it makes the engine harder to start cold .

#21

B

BGood

B

BGood

I adjusted the governor linkage according to the procedure previously posted from the Tecumseh service manual (thanks Rivets), and tried mowing first with the repaired original carb, then with the replacement eBay carb.

The mower still has a tendancy to stall in high grass and is difficult to restart when warm. When starting to stall, engine RPMs drop, I back the mower off from the high grass using the r/c electric motors, and about half of the time the gas engine RPM continues to drop and eventually stalls, and about half of the time the engine RPMs slowly increase and eventually recovers. When there is a stall and I look under the mower expecting to find grass wrapped around the blade, I am surprised to see it is relatively clear.

I wonder if I adjusted the governor linkage correctly. I untightened the torx screw, moved the arm rearward until I felt resistance, then retightened the torx screw. I'm not sure if I should try moving the governor linkage arm more forward or backward. Should I also adjust the idle set screw? On the old carb it is in about 2 threads and on the replacement carb it is in a little more, about 3-1/2 threads.

Not sure what to do. I can't swap out the 6.75 hp Tecumseh engine for the 12 hp riding mower engine because the robot chassis is built around the Craftsman mulching mower. Another factor may be that the mower blade that came with the used Craftsman mower does not appear to be a mulching blade. Would swithching the blade out make a big difference?

Thanks for any ideas

The mower still has a tendancy to stall in high grass and is difficult to restart when warm. When starting to stall, engine RPMs drop, I back the mower off from the high grass using the r/c electric motors, and about half of the time the gas engine RPM continues to drop and eventually stalls, and about half of the time the engine RPMs slowly increase and eventually recovers. When there is a stall and I look under the mower expecting to find grass wrapped around the blade, I am surprised to see it is relatively clear.

I wonder if I adjusted the governor linkage correctly. I untightened the torx screw, moved the arm rearward until I felt resistance, then retightened the torx screw. I'm not sure if I should try moving the governor linkage arm more forward or backward. Should I also adjust the idle set screw? On the old carb it is in about 2 threads and on the replacement carb it is in a little more, about 3-1/2 threads.

Not sure what to do. I can't swap out the 6.75 hp Tecumseh engine for the 12 hp riding mower engine because the robot chassis is built around the Craftsman mulching mower. Another factor may be that the mower blade that came with the used Craftsman mower does not appear to be a mulching blade. Would swithching the blade out make a big difference?

Thanks for any ideas

#22

R

Rivets

R

Rivets

What have you set your top end governed speed at. Should be between 3200-3300 RPMs. If it is too low your engine will not keep up when it encounters a load. I’m assuming you opened the idle jet as I suggested earlier. This needs to be open as it supplies extra fuel to engine when you enter that long grass and the governor kicks in.

#23

sgkent

sgkent

have you tested compression on this mower? I have seen engines that have low compression refuse to recover once they start to stall. Meaning, the tall grass starts the stall, but when you back out the engine should recover quickly. The other cause can the mixture. As an engine loads down, the intake air flow slows and that affects mixture. Try a little richer, if that makes it worse, go a little leaner.

#24

F

fredeharle48

F

fredeharle48

I’m planning a project to build a remote controller lawn mower, relatively small scale PoC first to test Small scale will be a basic chassis setup in a skid-steer configuration with 2 drive wheels at the back and 2 idle wheels at the front (with future goals of changing to tracks); current wheels I’ve found are 120mm dia and total mass estimate will be around 15kg. It will be controlled by an r/c tx/rx feeding PMM into a microcontroller (Either Arduino or ESP8266… haven’t decided yet) which in turn signals a motor controller to feed power to either drive wheel. It needs to be capable of variable speed and run in forward & reverse. Based on reading other people’s similar projects here I think the overall concept will work but they often used 2nd hand wheelchair motors which I’ve not been able to source yet in Australia so looking for something more off the shelf. I’m good with microcontrollers & programming but new to motors & robotics in general.