You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Craftsman LT4000 spitting/sputtering and backfiring after riding for 5mins

#1

C

cjones636

C

cjones636

I Have a Craftsman LT4000 Riding lawnmower with the kohler cv14s engine. Late in the year last year it started spitting, sputtering and backfiring then would die. It would do this after about an hour of mowing. If i tried to start it back up, it would backfire loudly. If i waited 10 mins, it would start back up and i could finish my work.

Now, it will do the exact same thing mentioned above, but it's happening more frequently, like ever 5mins!

I've changed plugs and checked the spark with a voltage meter and by placing the plug up against the engine, and it had a nice strong blue spark.

I Carried my voltage meter with me, and when it died i jump of and checked the voltage again, and everything was good.

A Mechanic told me it was the safety switches shortening out, so i disconnected all of them and it's still happening.

I Check the fuel shutoff solenoid on the bottom of the carb and touched it to the engine and the plunger worked good!

I Also removed (now replaced) the fuel shutoff solenoid with a bolt, some washers and a gasket (to make sure it wasn't faulty) and it still doing the samething.

Today, i rode it around until it started spiting and sputtering and checked the voltage on the battery, and it checked out fine.

When it starts spitting and sputtering, if i move the choke under middle ways, it will stay running without spitting and sputtering, and then i can slowly move the choke back up to the mowing position and it will run, but as soon as i engage the blade again, it will start spitting and sputter again, so i will have to disengage the blade and it will stay running half choke.

Now, it will do the exact same thing mentioned above, but it's happening more frequently, like ever 5mins!

I've changed plugs and checked the spark with a voltage meter and by placing the plug up against the engine, and it had a nice strong blue spark.

I Carried my voltage meter with me, and when it died i jump of and checked the voltage again, and everything was good.

A Mechanic told me it was the safety switches shortening out, so i disconnected all of them and it's still happening.

I Check the fuel shutoff solenoid on the bottom of the carb and touched it to the engine and the plunger worked good!

I Also removed (now replaced) the fuel shutoff solenoid with a bolt, some washers and a gasket (to make sure it wasn't faulty) and it still doing the samething.

Today, i rode it around until it started spiting and sputtering and checked the voltage on the battery, and it checked out fine.

When it starts spitting and sputtering, if i move the choke under middle ways, it will stay running without spitting and sputtering, and then i can slowly move the choke back up to the mowing position and it will run, but as soon as i engage the blade again, it will start spitting and sputter again, so i will have to disengage the blade and it will stay running half choke.

#3

C

cjones636

Can you link me to the overhaul kit (if allowed)?

C

cjones636

Sounds like carb needs cleaned out and overhaul kit put in it.

Can you link me to the overhaul kit (if allowed)?

#4

M

motoman

M

motoman

Does it have hydraulic lifters? If not the pros may say check valve adjustment . My Intek did that before valve train failure.

#5

davbell22602

Need your numbers thats on the flywheel cover for rebuilt kit.

davbell22602

Can you link me to the overhaul kit (if allowed)?

Need your numbers thats on the flywheel cover for rebuilt kit.

#6

C

cjones636

C

cjones636

Here is a video that i took Saturday while riding using this mower. I Wanted to show what was happening so some expert could tell me whats up.. I Just figured out how to get the video off my phone :laughing:

#7

C

cjones636

Anyone think the carb is the issue here? I Would think it would run like crap when started if it was the carb. It runs fine up until 5 mins of mowing then it starts doing whats in the video. You think i should take it off the carb and clean it real good without the rebuild kit?

C

cjones636

Here is a video that i took Saturday while riding using this mower. I Wanted to show what was happening so some expert could tell me whats up.. I Just figured out how to get the video off my phone :laughing:

Anyone think the carb is the issue here? I Would think it would run like crap when started if it was the carb. It runs fine up until 5 mins of mowing then it starts doing whats in the video. You think i should take it off the carb and clean it real good without the rebuild kit?

#8

BustedKnuckles

BustedKnuckles

I don't have speakers at work so I skipped the video.

If moving the choke lever changes the conditions, I would suspect a dirty fuel bowl. I would change the fuel line (if hard and brittle feeling), install a new fuel filter and remove the carb bowl to clean it and the jet both (use wire or a toothpick). Check the float while your there and make sure the needle moves freely. I would use come carb cleaner to spray through the fuel inlet (both ways) to make sure any debris is not left behind. Re-install and verify the repair.

Good luck!

If moving the choke lever changes the conditions, I would suspect a dirty fuel bowl. I would change the fuel line (if hard and brittle feeling), install a new fuel filter and remove the carb bowl to clean it and the jet both (use wire or a toothpick). Check the float while your there and make sure the needle moves freely. I would use come carb cleaner to spray through the fuel inlet (both ways) to make sure any debris is not left behind. Re-install and verify the repair.

Good luck!

#9

Fish

Fish

Run it until it acts up again, then reach back and take off the fuel cap and see if it evens back out.

#10

C

cjones636

I Already done that, it didn't help.

Here some new information regarding this.. Today i said to myself, i'm going to try something. You know, on the throttle where it says "Here for mowing" (even with the rabbit)? Well, i took the throttle and moved it down just a **** hair and it ran for a solid hour! Then i went up to the upper field to mow it, and moved the throttle back up to the normal mowing position and made 3 passes and she started spitting and sputtering, died, than backfired!

I Finally got it started back after a few mins of cussing and kicking the wheel, and it would just not run for long no mater where i moved the throttle too!

C

cjones636

Run it until it acts up again, then reach back and take off the fuel cap and see if it evens back out.

I Already done that, it didn't help.

Here some new information regarding this.. Today i said to myself, i'm going to try something. You know, on the throttle where it says "Here for mowing" (even with the rabbit)? Well, i took the throttle and moved it down just a **** hair and it ran for a solid hour! Then i went up to the upper field to mow it, and moved the throttle back up to the normal mowing position and made 3 passes and she started spitting and sputtering, died, than backfired!

I Finally got it started back after a few mins of cussing and kicking the wheel, and it would just not run for long no mater where i moved the throttle too!

#12

C

cjones636

Would the valves cause this too? If i had a filler gauge i would check and see if they needed adjusted.. I Already eliminated everything else as the cause except the valves and carb... Everyone online keeps telling me it the carbs, everyone in the real world (lol) keeps telling me other things that i've already checked. I Guess there is one way to find out, is to take the dang carb off tomorrow and clean it.

C

cjones636

I still say its a carb issue.

Would the valves cause this too? If i had a filler gauge i would check and see if they needed adjusted.. I Already eliminated everything else as the cause except the valves and carb... Everyone online keeps telling me it the carbs, everyone in the real world (lol) keeps telling me other things that i've already checked. I Guess there is one way to find out, is to take the dang carb off tomorrow and clean it.

#13

C

cjones636

C

cjones636

Today i took the carb off and i was surprised to see how very clean it was on the inside, it looked brand new! But i did notice something strange with the float. Isn't the float supposed to lay level when i have the carb up side down? Because if it is, mine is not!!! it's way off!

After giving it a cleaning, it's still doing the same thing!

After giving it a cleaning, it's still doing the same thing!

#14

Fish

Fish

I say you have something floating in the tank or collapsing fuel lines that intermittently shut of fuel flow. Run it again until it starts acting up with the hood off, then quickly pull the fuel line off at the carb and crank, carefull of the pulsing fuel!.

#15

davbell22602

davbell22602

I'd drain gas tank, clean it out real good. Then replace fuel lines and fuel filter. If it didnt have a fuel filter then add one in the fuel line.

#16

C

cjones636

Did that today...

Replaced fuel lines, Cleaned tank, added a new filter (air and fuel), rebuilt carb.... Still done the same thing..... But, as soon as it went dead i jumped off the mower and checked the spark again, and the spark was orange, not blue!

C

cjones636

I'd drain gas tank, clean it out real good. Then replace fuel lines and fuel filter. If it didnt have a fuel filter then add one in the fuel line.

Did that today...

Replaced fuel lines, Cleaned tank, added a new filter (air and fuel), rebuilt carb.... Still done the same thing..... But, as soon as it went dead i jumped off the mower and checked the spark again, and the spark was orange, not blue!

#17

davbell22602

Sounds like coil has short in it or going bad. Check air gap on coil and make sure its .010.

davbell22602

Did that today...

Replaced fuel lines, Cleaned tank, added a new filter (air and fuel), rebuilt carb.... Still done the same thing..... But, as soon as it went dead i jumped off the mower and checked the spark again, and the spark was orange, not blue!

Sounds like coil has short in it or going bad. Check air gap on coil and make sure its .010.

#18

C

cjones636

I Don't have a Filler gauge, but i used a business card to set the gap a week back.. You know of a fool-proof way to test the coil?

C

cjones636

Sounds like coil has short in it or going bad. Check air gap on coil and make sure its .010.

I Don't have a Filler gauge, but i used a business card to set the gap a week back.. You know of a fool-proof way to test the coil?

#19

C

cjones636

C

cjones636

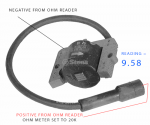

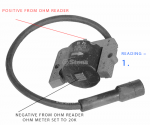

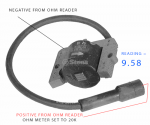

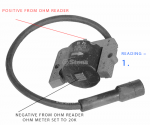

I Tested my coil with my multimeter set at 20k ohme iron core to the tab on the coil (the wire coming from the engine connected to the coil) on the coil and the reading stayed at 1.. Than i tested the coil from the iron core to the spark plug wire and it was 9.3. Started the engine and let it ran for 5 min before going dead, than i immediately tested it again and i got the same reading from the iron core to the tab, but this time from the iron core to the spark plug wire i got over 11.xx (i think it was 11.43).

#20

C

cjones636

C

cjones636

I Got to thinking this moring when i was sawing up wood and getting it busted up, if the coil is going bad, how am i able to run it for so long by just moving the throttle down just a **** hair off the the rabbit? My cousin and another guy told me that it sounds like its using up the gas faster than it should, and that the float should be laying parallel at by holding the carb at a slight angle, and barely sink into the carb when i hold the carb perfectly horizontal. Mine does neither!

Here is some images i took the other day of the carb.

Here is some images i took the other day of the carb.

#21

EngineMan

Spark color determines virtually nothing. The hottest spark is ultraviolet which we can't see. Blue spark is cold in comparison to ultra-violet. Orange and yellow come from particles of sodium in the air ionizing in the high energy of the spark gap.

EngineMan

Did that today...

Replaced fuel lines, Cleaned tank, added a new filter (air and fuel), rebuilt carb.... Still done the same thing..... But, as soon as it went dead i jumped off the mower and checked the spark again, and the spark was orange, not blue!

Spark color determines virtually nothing. The hottest spark is ultraviolet which we can't see. Blue spark is cold in comparison to ultra-violet. Orange and yellow come from particles of sodium in the air ionizing in the high energy of the spark gap.

#23

M

motoman

M

motoman

Since you have a number of issues I will chime in on general engine basis. I have said before that the coils may not be just coils and may be helped with electronics components such as capacitors and transistors. These are produced in levels to withstand heat. I'm guessing if they are there they are not the best and may fail. Typical failed transistor response at hot is to quit working until cool. Next this float deal. In the good ole days there were specs for float stroke- you bent a tang for full droop (bowl low) and one for shut off (inlet valve shut). These settings were provided by the engine manufacturer. Otherwise starvation or flooding could result. Also on wide open throttle the combustion pressures are max which can expose a weak spark. I have been where you are and it drives you nuts. Good luck:thumbsup:

#24

C

cjones636

yup, its a walbro

C

cjones636

Is that a Walbro LMK carburetor..? if not can you post the numbers that are on it..!

yup, its a walbro

#26

C

cjones636

Here is before and after... There was no orange spark, but it was hard to get a spark.. I Basically had to hold the tip to the engine to get a spark.

C

cjones636

yup, its a walbro

Here is before and after... There was no orange spark, but it was hard to get a spark.. I Basically had to hold the tip to the engine to get a spark.

#27

Fish

Fish

Just plug in a good plug on your coil lead, and hold the side of the plug against the block to test.

#28

EngineMan

Wouldn't make any differences by the engine number, someone may have fitted a different carb to it, that is why I ask if it was a LMK.

EngineMan

Find the tag on your engine and post it's model and spec numbers.

Wouldn't make any differences by the engine number, someone may have fitted a different carb to it, that is why I ask if it was a LMK.

#29

C

cjones636

I Did purchase the mower from a local repair shop years ago, but it ran fine up until late last year.

C

cjones636

Wouldn't make any differences by the engine number, someone may have fitted a different carb to it, that is why I ask if it was a LMK.

I Did purchase the mower from a local repair shop years ago, but it ran fine up until late last year.

#30

EngineMan

There will be or should be numbers on the carb. but going by the photos you posted it maybe this one, if not find the numbers on the carb and post up.

https://www.dropbox.com/s/iolyxhgf1...sed on Kohler Command and Courage Single .pdf

EngineMan

I Did purchase the mower from a local repair shop years ago, but it ran fine up until late last year.

There will be or should be numbers on the carb. but going by the photos you posted it maybe this one, if not find the numbers on the carb and post up.

https://www.dropbox.com/s/iolyxhgf1...sed on Kohler Command and Courage Single .pdf

#31

Fish

I have no clue as to why you would say that. Depending on his model/spec numbers, he may or may not have adjustable valves and/or Smartspark,

which are important things to know if you want to diagnose the problems.

I would say that he just needs to adjust the valves, if he has the engine with adjustable valves.

What the heck is the problem with knowing what engine these guys have to try and give an intelligent response????

What if it has adjustable valves and Smartspark? Would that change your advice any at all?

Fish

Wouldn't make any differences by the engine number, someone may have fitted a different carb to it, that is why I ask if it was a LMK.

I have no clue as to why you would say that. Depending on his model/spec numbers, he may or may not have adjustable valves and/or Smartspark,

which are important things to know if you want to diagnose the problems.

I would say that he just needs to adjust the valves, if he has the engine with adjustable valves.

What the heck is the problem with knowing what engine these guys have to try and give an intelligent response????

What if it has adjustable valves and Smartspark? Would that change your advice any at all?

#32

Fish

Fish

Here is the link to the Kohler manual, I am just guessing if it is the right series, since we have no model/spec number. Heck, the picks didn't look like a Magnum.....

http://kohlerengines.com/onlinecatalog/pdf/tp_2339_d.pdf

http://kohlerengines.com/onlinecatalog/pdf/tp_2339_d.pdf

#33

B

buzzpa

I had the same problem with my mower and had a difficult time finding the cure. ... Then I happened to see something sloshing around in the fuel tank. ... It was dried grass and I then remembered that a few weeks before I noticed that my fuel tank cap was off and that while mowing must have allowed the grass inside. ... I drained the tank and removed it to clean it out and that was the problem. ... Has been working great ever since. ... Hope this helps.

B

buzzpa

I Have a Craftsman LT4000 Riding lawnmower with the kohler cv14s engine. Late in the year last year it started spitting, sputtering and backfiring then would die. It would do this after about an hour of mowing. If i tried to start it back up, it would backfire loudly. If i waited 10 mins, it would start back up and i could finish my work.

Now, it will do the exact same thing mentioned above, but it's happening more frequently, like ever 5mins!

I've changed plugs and checked the spark with a voltage meter and by placing the plug up against the engine, and it had a nice strong blue spark.

I Carried my voltage meter with me, and when it died i jump of and checked the voltage again, and everything was good.

A Mechanic told me it was the safety switches shortening out, so i disconnected all of them and it's still happening.

I Check the fuel shutoff solenoid on the bottom of the carb and touched it to the engine and the plunger worked good!

I Also removed (now replaced) the fuel shutoff solenoid with a bolt, some washers and a gasket (to make sure it wasn't faulty) and it still doing the samething.

Today, i rode it around until it started spiting and sputtering and checked the voltage on the battery, and it checked out fine.

When it starts spitting and sputtering, if i move the choke under middle ways, it will stay running without spitting and sputtering, and then i can slowly move the choke back up to the mowing position and it will run, but as soon as i engage the blade again, it will start spitting and sputter again, so i will have to disengage the blade and it will stay running half choke.

I had the same problem with my mower and had a difficult time finding the cure. ... Then I happened to see something sloshing around in the fuel tank. ... It was dried grass and I then remembered that a few weeks before I noticed that my fuel tank cap was off and that while mowing must have allowed the grass inside. ... I drained the tank and removed it to clean it out and that was the problem. ... Has been working great ever since. ... Hope this helps.

#35

R

ronwhite

R

ronwhite

Sounds like the problem I had once. after about an hour of cutting it would sputter and act like it was out of gas or something. after trying lots of things, decided that the next time it happened I would stop and refill gas tank to top. that worked for me, I could fill it up and then finish my mowing. I have since removed the carb and cleaned it up good. end of problem for me.

Also had that problem when it would sputter and shut down. but those were random shutdowns but same symtoms as other problem. turned out to be ignition module.

Also had that problem when it would sputter and shut down. but those were random shutdowns but same symtoms as other problem. turned out to be ignition module.

#36

N

nagman

I had the same issue.

I replace the entire fuel line from the tank forward. I made sure the tank cap hole was clear. I changed the fuel filter. I changed the coil. What finally fixed it was taking the carb apart. I put the parts in an ultrasonic cleaner (Harbor Freight, cheap) and I could not believe how black the cleaning fluid got. I changed the cleaner solution twice and ran the parts through several cycles until it finished with the cleaner fluid fairly clean after the cycle. I put it all back together and it is now running great. i can only surmise that the internal passages inside the carb body were clogged up.

Hope this helps.

N

nagman

Sounds like the problem I had once. after about an hour of cutting it would sputter and act like it was out of gas or something. after trying lots of things, decided that the next time it happened I would stop and refill gas tank to top. that worked for me, I could fill it up and then finish my mowing. I have since removed the carb and cleaned it up good. end of problem for me.

Also had that problem when it would sputter and shut down. but those were random shutdowns but same symtoms as other problem. turned out to be ignition module.

I had the same issue.

I replace the entire fuel line from the tank forward. I made sure the tank cap hole was clear. I changed the fuel filter. I changed the coil. What finally fixed it was taking the carb apart. I put the parts in an ultrasonic cleaner (Harbor Freight, cheap) and I could not believe how black the cleaning fluid got. I changed the cleaner solution twice and ran the parts through several cycles until it finished with the cleaner fluid fairly clean after the cycle. I put it all back together and it is now running great. i can only surmise that the internal passages inside the carb body were clogged up.

Hope this helps.

#37

S

smilinjak

Smilinjak

S

smilinjak

With the carb off, float and needle removed blow out the inlet passage from the float side with compressed air. The dead bug that comes out will be the critter that has "bugged" you for so long. Leave your electrical test equipment in the shop, your problem is fuel starvation. If the bug doesn't solve your problem replace the fuel lines and shut off valve. I'll be watching for your results.I Got to thinking this moring when i was sawing up wood and getting it busted up, if the coil is going bad, how am i able to run it for so long by just moving the throttle down just a **** hair off the the rabbit? My cousin and another guy told me that it sounds like its using up the gas faster than it should, and that the float should be laying parallel at by holding the carb at a slight angle, and barely sink into the carb when i hold the carb perfectly horizontal. Mine does neither!

Here is some images i took the other day of the carb.

View attachment 17355

View attachment 17356

View attachment 17358

View attachment 17357

Smilinjak

#38

M

mxsmith4

M

mxsmith4

I'd agree with several of the posts here pointing to the carburetor, I had similar symptoms on my 20HP Intek and a rebuild of the carb fixed it. Also check the gas cap to see if the vent is clogged.

#39

L

lwrowland

I would make sure the fuel filter is installed in correct direction it sounds like what I did to my generator

L

lwrowland

I'd agree with several of the posts here pointing to the carburetor, I had similar symptoms on my 20HP Intek and a rebuild of the carb fixed it. Also check the gas cap to see if the vent is clogged.

I would make sure the fuel filter is installed in correct direction it sounds like what I did to my generator

#41

R

Rebeldad1

R

Rebeldad1

Sounds like fuel starvation. so......

2 things. you are either getting fuel or your not (What???)

not getting fuel..... pull the fuel line off the carb and let the fuel run into something. Should flow evenly till the tank goes empty. That's good.

if not check the inside of the tank to make sure its clean and the outlet is clear and clean. While you are at it replace the fuel line. They rot from the inside out. They can block internally and restrict flow or flat out stop it.

Getting fuel. .... several things here.

Fuel not being delivered by carb = float sticking.

Vapor lock.... several things

Engine getting too hot. Clean the head and engine of all gunk and debris. Fuel line running close to the engine causing fuel to boil in fuel line. Head gasket failure.

Take the hood off and mow see if it helps.

FUEL PM. stay away from fuel with ethanol in it.

2 things. you are either getting fuel or your not (What???)

not getting fuel..... pull the fuel line off the carb and let the fuel run into something. Should flow evenly till the tank goes empty. That's good.

if not check the inside of the tank to make sure its clean and the outlet is clear and clean. While you are at it replace the fuel line. They rot from the inside out. They can block internally and restrict flow or flat out stop it.

Getting fuel. .... several things here.

Fuel not being delivered by carb = float sticking.

Vapor lock.... several things

Engine getting too hot. Clean the head and engine of all gunk and debris. Fuel line running close to the engine causing fuel to boil in fuel line. Head gasket failure.

Take the hood off and mow see if it helps.

FUEL PM. stay away from fuel with ethanol in it.

#42

C

cjones636

Yea it is....lol

I Just haven't messed with it during the winter due to being sick... I Would get better than would be sick again off and on throughout the whole winter. I Haven't even used the internet much... I Have an open on both end shed, and it was cold this year too! But i'm about to get out there and get with it here soon before spring and see if i can get this thing fixed. And the Carb is a LMK.

C

cjones636

You never know, its time for a update on this...!

Yea it is....lol

I Just haven't messed with it during the winter due to being sick... I Would get better than would be sick again off and on throughout the whole winter. I Haven't even used the internet much... I Have an open on both end shed, and it was cold this year too! But i'm about to get out there and get with it here soon before spring and see if i can get this thing fixed. And the Carb is a LMK.

#44

C

cjones636

C

cjones636

Since it was nice out today i removed the Ignition Coil and tested it with my multimeter. I Set it 20k OHM and it read 9.60.

#47

C

cjones636

That was secondary.. The primary (i'm guessing this would be the primary).. I touched the negative to the center iron core and the positive to the kill switch tab and it didn't read, it just stayed on 1.

C

cjones636

Was that with the primary winding or the secondary...?

That was secondary.. The primary (i'm guessing this would be the primary).. I touched the negative to the center iron core and the positive to the kill switch tab and it didn't read, it just stayed on 1.

#48

EngineMan

EngineMan

It seems that the coil is OK, then its back to the carb, because a lean mixture will also give you backfire, so recheck it.

#49

Fish

Fish

Here is the procedure for adjusting the valve lash on the CV14 models that have adjustable valves, I would suggest you look in this area. Just take off you valve cover and look.

Attachments

#50

C

cjones636

When i run the mower for 5-10 mins it's starts spitting and sputtering then it shuts down then backfires then. It will not restart until it cools down for several mins. If i run it for a few mins then manually shut it down, it doesn't backfire at all. I had another mower that would do nearly the same thing and that was getting spark. My father quickly diagnosed it as it being the coil going bad (he was a mechanic, i am not lol). He took one off an extra engine i had laying around and replaced it with the one that he said was going bad and i never had trouble out of it again. If i had an extra coil that would work on this engine, i would check and see before buying one because money is REAL tight and i want to make damn sure that it isn't the coil before blowing money on one that i did not need. I always thought that i should get a reading from the primary when i touched the negative to the center iron core, and the positive to the kill switch tab, but i didn't get a reading.. It just stayed on one (1).

My father cannot bail me out anymore when i get stumped because he had a massive stroke several years ago and he still can't move on one side of his body or speak.

C

cjones636

It seems that the coil is OK, then its back to the carb, because a lean mixture will also give you backfire, so recheck it.

When i run the mower for 5-10 mins it's starts spitting and sputtering then it shuts down then backfires then. It will not restart until it cools down for several mins. If i run it for a few mins then manually shut it down, it doesn't backfire at all. I had another mower that would do nearly the same thing and that was getting spark. My father quickly diagnosed it as it being the coil going bad (he was a mechanic, i am not lol). He took one off an extra engine i had laying around and replaced it with the one that he said was going bad and i never had trouble out of it again. If i had an extra coil that would work on this engine, i would check and see before buying one because money is REAL tight and i want to make damn sure that it isn't the coil before blowing money on one that i did not need. I always thought that i should get a reading from the primary when i touched the negative to the center iron core, and the positive to the kill switch tab, but i didn't get a reading.. It just stayed on one (1).

My father cannot bail me out anymore when i get stumped because he had a massive stroke several years ago and he still can't move on one side of his body or speak.

#51

EngineMan

EngineMan

Testing the magneto

The magneto, like the ignition coil on an automobile, contains two windings:

A primary with a few turns of heavy wire.

A high voltage secondary with thousands of turns of super fine wire.

In an automobile, the battery supplies the primary current; in a magneto, the magnet on the flywheel

moving past the core at high speed acts as a generator and induces current in the primary.

As the magnets spin past the pole pieces of the magneto core, the points are closed and current builds up

in the low voltage winding (and flux builds up in the core). At or slightly before Top Dead Center

(TDC), the current (and flux) should be maximum and at this instant the points open. The flux then

collapses (and the condenser (capacitor) across the points acts as a snubber allowing the current to

bypass the open points and preventing arcing at the point contacts). This rapid decrease in flux results in

coupling of the stored energy to the turn high voltage winding and results in up to 10,000 V or more at

the spark plug.

(For EE types, this is somewhat similar in basic operation to the fly-back converter in a switch-mode

power supply except that the moving magnet supplies the input power instead of the rectified AC line

and the points act as the switch instead of a power transistor.)

The secondary will always be accessible for testing but the primary of an electronic ignition may be not

be due to the electronic components:

Secondary: 3 K ohms (maybe a little higher but not open). Much lower would indicate a shorted

winding.

Primary (if non-electronic and accessible): very low - guessing less than an ohm.

Wires can break due to corrosion or vibration. This would result in an open winding - infinite resistance.

Shorts can develop between adjacent windings or to the core. This may be detectable as reduced

resistance but without knowing exactly what it should be, there is no way of knowing if a slight

discrepancy represents a problem or just slight variations in design or manufacturing.

A more complete test would involve checking the 'Q' or doing what is called a 'ring' test and even more

for an electronic ignition. This requires special equipment. Therefore, it is best to swap in a known good

unit. They are not that expensive.

Electronic ignition - There is likely a single potted module which includes the circuitry and

ignition coil. If anything goes wrong with this module, replacement is the only option. Once the

wiring and resistance of the secondary has been checked, there are really no addition tests that can

be performed on an electronic ignition module without special equipment. A defective ignition

module will have to be replaced.

So replacing with a known good or new one seems to be the only way of knowing for sure..!

The magneto, like the ignition coil on an automobile, contains two windings:

A primary with a few turns of heavy wire.

A high voltage secondary with thousands of turns of super fine wire.

In an automobile, the battery supplies the primary current; in a magneto, the magnet on the flywheel

moving past the core at high speed acts as a generator and induces current in the primary.

As the magnets spin past the pole pieces of the magneto core, the points are closed and current builds up

in the low voltage winding (and flux builds up in the core). At or slightly before Top Dead Center

(TDC), the current (and flux) should be maximum and at this instant the points open. The flux then

collapses (and the condenser (capacitor) across the points acts as a snubber allowing the current to

bypass the open points and preventing arcing at the point contacts). This rapid decrease in flux results in

coupling of the stored energy to the turn high voltage winding and results in up to 10,000 V or more at

the spark plug.

(For EE types, this is somewhat similar in basic operation to the fly-back converter in a switch-mode

power supply except that the moving magnet supplies the input power instead of the rectified AC line

and the points act as the switch instead of a power transistor.)

The secondary will always be accessible for testing but the primary of an electronic ignition may be not

be due to the electronic components:

Secondary: 3 K ohms (maybe a little higher but not open). Much lower would indicate a shorted

winding.

Primary (if non-electronic and accessible): very low - guessing less than an ohm.

Wires can break due to corrosion or vibration. This would result in an open winding - infinite resistance.

Shorts can develop between adjacent windings or to the core. This may be detectable as reduced

resistance but without knowing exactly what it should be, there is no way of knowing if a slight

discrepancy represents a problem or just slight variations in design or manufacturing.

A more complete test would involve checking the 'Q' or doing what is called a 'ring' test and even more

for an electronic ignition. This requires special equipment. Therefore, it is best to swap in a known good

unit. They are not that expensive.

Electronic ignition - There is likely a single potted module which includes the circuitry and

ignition coil. If anything goes wrong with this module, replacement is the only option. Once the

wiring and resistance of the secondary has been checked, there are really no addition tests that can

be performed on an electronic ignition module without special equipment. A defective ignition

module will have to be replaced.

So replacing with a known good or new one seems to be the only way of knowing for sure..!

#52

Fish

Are you going to remove the valve cover and show us a pic of the rocker arms? Can you put up the spec numbers off of the tag on the engine?

Fish

Would the valves cause this too? If i had a filler gauge i would check and see if they needed adjusted.. I Already eliminated everything else as the cause except the valves and carb... Everyone online keeps telling me it the carbs, everyone in the real world (lol) keeps telling me other things that i've already checked. I Guess there is one way to find out, is to take the dang carb off tomorrow and clean it.

Are you going to remove the valve cover and show us a pic of the rocker arms? Can you put up the spec numbers off of the tag on the engine?

#53

T

tybilly

WHERE CAN I FIND ONE OF THESE DARN EXPENSIVE TESTERS!! lol,I remember merc o tronic but they don't make those anymore.

T

tybilly

Testing the magneto

The magneto, like the ignition coil on an automobile, contains two windings:

A primary with a few turns of heavy wire.

A high voltage secondary with thousands of turns of super fine wire.

In an automobile, the battery supplies the primary current; in a magneto, the magnet on the flywheel

moving past the core at high speed acts as a generator and induces current in the primary.

As the magnets spin past the pole pieces of the magneto core, the points are closed and current builds up

in the low voltage winding (and flux builds up in the core). At or slightly before Top Dead Center

(TDC), the current (and flux) should be maximum and at this instant the points open. The flux then

collapses (and the condenser (capacitor) across the points acts as a snubber allowing the current to

bypass the open points and preventing arcing at the point contacts). This rapid decrease in flux results in

coupling of the stored energy to the turn high voltage winding and results in up to 10,000 V or more at

the spark plug.

(For EE types, this is somewhat similar in basic operation to the fly-back converter in a switch-mode

power supply except that the moving magnet supplies the input power instead of the rectified AC line

and the points act as the switch instead of a power transistor.)

The secondary will always be accessible for testing but the primary of an electronic ignition may be not

be due to the electronic components:

Secondary: 3 K ohms (maybe a little higher but not open). Much lower would indicate a shorted

winding.

Primary (if non-electronic and accessible): very low - guessing less than an ohm.

Wires can break due to corrosion or vibration. This would result in an open winding - infinite resistance.

Shorts can develop between adjacent windings or to the core. This may be detectable as reduced

resistance but without knowing exactly what it should be, there is no way of knowing if a slight

discrepancy represents a problem or just slight variations in design or manufacturing.

A more complete test would involve checking the 'Q' or doing what is called a 'ring' test and even more

for an electronic ignition. This requires special equipment. Therefore, it is best to swap in a known good

unit. They are not that expensive.

Electronic ignition - There is likely a single potted module which includes the circuitry and

ignition coil. If anything goes wrong with this module, replacement is the only option. Once the

wiring and resistance of the secondary has been checked, there are really no addition tests that can

be performed on an electronic ignition module without special equipment. A defective ignition

module will have to be replaced.

So replacing with a known good or new one seems to be the only way of knowing for sure..!

WHERE CAN I FIND ONE OF THESE DARN EXPENSIVE TESTERS!! lol,I remember merc o tronic but they don't make those anymore.

#54

jhngardner367

jhngardner367

Hi! New guy here.

Try a simple test. When it sputters ,spray some carb cleaner at the carb mount area.If it straightens out,it's warping,and sucking air.

I've worked on a few of these,and they had slight warping problem , when warmed up.

Pulling the choke,or letting off the load, evens it out.

Try a simple test. When it sputters ,spray some carb cleaner at the carb mount area.If it straightens out,it's warping,and sucking air.

I've worked on a few of these,and they had slight warping problem , when warmed up.

Pulling the choke,or letting off the load, evens it out.

#56

C

cjones636

C

cjones636

Been extremely busy this year and just now getting around to tinkering with it again. The fuel was leaking trough the fuel solenoid. I Rebuilt the carb (replaced, float, seat, needle) and it was still leaking. I replaced the fuel solenoid with a bowl nut and it hasn't leaked a drop since. The mower runs now. The problem is now that it just periodically sputters like it's going to crap out, than it never does. It also smokes a little out the exhaust when i engage the blade. Does the carb need adjusted? Also, my mower now refuse to turn off with the key!!! lol

#57

C

cjones636

C

cjones636

Update for those that are having the same problem... Mine was indeed the coil. I haven't had a problem with it since i replaced it with a new one.

#58

B

bertsmobile1

Just so you know,

When you engage the blades, it puts a load on the mower which in turn causes the govenor to back off which allows the throttle to open right up.

Same as in your old car with a carb, thomp the foot to the floor and engine runs rich for a moment & blow black smoke for a second or two.

This actually is good as it shows the govenor is working properly.

B

bertsmobile1

Been extremely busy this year and just now getting around to tinkering with it again. The fuel was leaking trough the fuel solenoid. I Rebuilt the carb (replaced, float, seat, needle) and it was still leaking. I replaced the fuel solenoid with a bowl nut and it hasn't leaked a drop since. The mower runs now. The problem is now that it just periodically sputters like it's going to crap out, than it never does. It also smokes a little out the exhaust when i engage the blade. Does the carb need adjusted? Also, my mower now refuse to turn off with the key!!! lol

Just so you know,

When you engage the blades, it puts a load on the mower which in turn causes the govenor to back off which allows the throttle to open right up.

Same as in your old car with a carb, thomp the foot to the floor and engine runs rich for a moment & blow black smoke for a second or two.

This actually is good as it shows the govenor is working properly.

#59

EngineMan

It will not turn off because you have taken the fuel solenoid off, so replace it or a new seal, and it will smoke a little under load.

EngineMan

Been extremely busy this year and just now getting around to tinkering with it again. The fuel was leaking trough the fuel solenoid. I Rebuilt the carb (replaced, float, seat, needle) and it was still leaking. I replaced the fuel solenoid with a bowl nut and it hasn't leaked a drop since. The mower runs now. The problem is now that it just periodically sputters like it's going to crap out, than it never does. It also smokes a little out the exhaust when i engage the blade. Does the carb need adjusted? Also, my mower now refuse to turn off with the key!!! lol

It will not turn off because you have taken the fuel solenoid off, so replace it or a new seal, and it will smoke a little under load.

#60

B

bertsmobile1

the fuel solenoif does not stop the engine normally.

the magneto cut out stops the engine.

The fuel solenoid blocks off the main jet to prevent toxic unburned fuel vapours from ending all life on earth Oh and making the exhaust go bang.

B

bertsmobile1

It will not turn off because you have taken the fuel solenoid off, so replace it or a new seal, and it will smoke a little under load.

the fuel solenoif does not stop the engine normally.

the magneto cut out stops the engine.

The fuel solenoid blocks off the main jet to prevent toxic unburned fuel vapours from ending all life on earth Oh and making the exhaust go bang.

#61

EngineMan

That is true, so he needs to check the kill side of things ie (wiring) key switch.

EngineMan

the fuel solenoif does not stop the engine normally.

the magneto cut out stops the engine.

The fuel solenoid blocks off the main jet to prevent toxic unburned fuel vapours from ending all life on earth Oh and making the exhaust go bang.

That is true, so he needs to check the kill side of things ie (wiring) key switch.

#62

G

gregjo1948

G

gregjo1948

When it sputters and stops, pull off the gas line after the pump & before the carb, (aim it away from hot parts) crank it over to see if it's pumping fuel. If it's not, could be faulty pump or the hose that pulls vacuum from the valve cover. gregjo1948