You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Craftsman LT1000 with a Briggs & Stratton 31G777-0167E1 engine

#1

L

Legal v8

L

Legal v8

This engine has recently started having a problem with blowing oil out of the dipstick tube if removed during operation. It didn’t do this last season. I verified the crankcase breather is open and not clogged, checked the head gasket (it was GOOD before removal), and checked the cylinder bore for any damage. The bore looks perfect, though I haven’t removed the piston to look at the rings. The compression is very good and the engine does not smoke at all. I havent seen oil coming out of the fuel pump, but there is a little oil residue in the intake tube between the carburetor and cylinder head. pushrods are perfect, and the valves appear to be sealing well. I’m considering ordering a few gaskets, a set of piston rings, and just re-ringing it and hoping the problem clears up. Any ideas or help?

#2

R

Rivets

R

Rivets

From your description I suspect a blown head gasket. If you didn’t replace it when you inspected it, you should have, as they are not reusable. Proper torquing sequence and value are a requirement.

#3

L

Legal v8

I have read numerous threads about oil blowing from the dipstick tube. Bad head gasket, plugged crankcase breather, or bad rings. The bad rings comment is usually preceded by mention of the engine blowing smoke when running. My engine doesn’t smoke at all. Given the bore was as nice as it is and there isn’t a lot of carbon built up on the piston or head, and the compression is superb (based on plugging the hole with my finger and having it blow my finger away a good 1/4”), I don’t suspect the rings are stuck or broken. However, I will pull the crankcase apart and pull the piston to inspect It and the rings. just because the rings aren’t stuck and the oil ring is still doing it’s job, the compression rings might not be sealing well enough. The breather is clear and allowing air to flow through it, so I don’t believe that to be the problem.

This has me stumped; I’ve never had a Briggs engine with this problem.

L

Legal v8

The head is still off of it. as I said in the OP; The gasket that I removed had NOT failed. It did come apart when I pulled the head, and as such, will be replaced with a new one.From your description I suspect a blown head gasket. If you didn’t replace it when you inspected it, you should have, as they are not reusable. Proper torquing sequence and value are a requirement.

I have read numerous threads about oil blowing from the dipstick tube. Bad head gasket, plugged crankcase breather, or bad rings. The bad rings comment is usually preceded by mention of the engine blowing smoke when running. My engine doesn’t smoke at all. Given the bore was as nice as it is and there isn’t a lot of carbon built up on the piston or head, and the compression is superb (based on plugging the hole with my finger and having it blow my finger away a good 1/4”), I don’t suspect the rings are stuck or broken. However, I will pull the crankcase apart and pull the piston to inspect It and the rings. just because the rings aren’t stuck and the oil ring is still doing it’s job, the compression rings might not be sealing well enough. The breather is clear and allowing air to flow through it, so I don’t believe that to be the problem.

This has me stumped; I’ve never had a Briggs engine with this problem.

#4

L

Legal v8

L

Legal v8

I don‘t like throwing parts at something in hopes of it working, but I don’t think there is anything else that can be done. I’ll pull it all apart and replace the rings, clean the breather/filter assembly, and reassemble with all new gaskets. A youtuber that does a lot of small engine work says to replace the aluminum intake pushrod with another steel exhaust pushrod because the aluminum ones break; however mine was in pretty good shape. Does anyone have an opinion they’re willing to share on this?

#5

B

bertsmobile1

B

bertsmobile1

Whenever I need to adjust the valve lash I pull out the pushrods, check them for wear at the guide and reverse them

When an inlet needs repair it gets changed with a steel one .

Oil will throw up the dip stick tube because with the exception of the 3 crankshaft journals the rest of the engine is splash lubricated so there shoud be drops of oil being thrown everywhere some of which will get carried up te dip stick tube

I have seen some of those videos posted by idiot morons with less than no idea what they are blubbering about which is why I rarely advise to go anywhere other than factory & parts stores videos , Taryl , Donny Boy or Steves saloon ( although I have problems with beer drinking & wrenching ).

You can make a lot of money by posting rubbish as the time people spend abusing & critising you is metered so adds to your view time .

The breather should be a ONE WAY devise so it should blow out into the air filter & not suck

The theory is the engine pulls a slight vacuum in the crankcase to prevent leaks .

When an inlet needs repair it gets changed with a steel one .

Oil will throw up the dip stick tube because with the exception of the 3 crankshaft journals the rest of the engine is splash lubricated so there shoud be drops of oil being thrown everywhere some of which will get carried up te dip stick tube

I have seen some of those videos posted by idiot morons with less than no idea what they are blubbering about which is why I rarely advise to go anywhere other than factory & parts stores videos , Taryl , Donny Boy or Steves saloon ( although I have problems with beer drinking & wrenching ).

You can make a lot of money by posting rubbish as the time people spend abusing & critising you is metered so adds to your view time .

The breather should be a ONE WAY devise so it should blow out into the air filter & not suck

The theory is the engine pulls a slight vacuum in the crankcase to prevent leaks .

#6

L

Legal v8

I normally wouldn’t be so nutty about an engine of tractor, but this particular engine and tractor has a lot of sentimental value. I wish it were a V-Twin, but it does the job.

L

Legal v8

Yes, I know there should be a slight vacuum in the crankcase. The breather works one way as it should - flow direction is to the carburetor. I have to pull the whole engine apart to swap rings, so I’ll clean everything up inside the breather.Whenever I need to adjust the valve lash I pull out the pushrods, check them for wear at the guide and reverse them

When an inlet needs repair it gets changed with a steel one .

Oil will throw up the dip stick tube because with the exception of the 3 crankshaft journals the rest of the engine is splash lubricated so there shoud be drops of oil being thrown everywhere some of which will get carried up te dip stick tube

I have seen some of those videos posted by idiot morons with less than no idea what they are blubbering about which is why I rarely advise to go anywhere other than factory & parts stores videos , Taryl , Donny Boy or Steves saloon ( although I have problems with beer drinking & wrenching ).

You can make a lot of money by posting rubbish as the time people spend abusing & critising you is metered so adds to your view time .

The breather should be a ONE WAY devise so it should blow out into the air filter & not suck

The theory is the engine pulls a slight vacuum in the crankcase to prevent leaks .

I normally wouldn’t be so nutty about an engine of tractor, but this particular engine and tractor has a lot of sentimental value. I wish it were a V-Twin, but it does the job.

#7

StarTech

StarTech

When removing the Mica coated head gasket it must be carefully removed or you might not see the damage area. These engine has a tendency to blow between the cylinder and the push rod galley. Usually on the side opposite of the head and some damage might not be noticed to the untrained eye. Also these heads can warp which is why they should check with a straight edge. They need to perfectly flat.

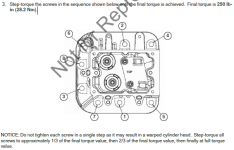

And torquing heads back down you should use at least a three step torque procedure. I just did a Kawasaki that per their service manual took seven steps. A total of 14 steps as there was two cylinder heads.

And of course it going to blow oil out the dipstick tube with the dipstick removed as you have bypass (disable) the breather's check valve system. Allowing to engine to full amount of air and blow full amount out. Basically you allowing the to breathe freely.

One note on smoking the modern oils don't smoke like the older oils. I have seen these engines with blown head gaskets to be consuming up to a half a quart of oil per gallon of gasoline burn and not smoke. I could oil burning but no smoke.

Here I don't simply tear an engine down before doing non invasive tests like leak down test with the rocker cover off. An leak down will point you in the right direction as to the problem with you suspect rings/cylinder or head gasket problem. But this takes some experience to recognize to differences in the test results.

And just throwing parts at problem definitely can get expensive without a good results; unless, you hit upon the problem.

And torquing heads back down you should use at least a three step torque procedure. I just did a Kawasaki that per their service manual took seven steps. A total of 14 steps as there was two cylinder heads.

And of course it going to blow oil out the dipstick tube with the dipstick removed as you have bypass (disable) the breather's check valve system. Allowing to engine to full amount of air and blow full amount out. Basically you allowing the to breathe freely.

One note on smoking the modern oils don't smoke like the older oils. I have seen these engines with blown head gaskets to be consuming up to a half a quart of oil per gallon of gasoline burn and not smoke. I could oil burning but no smoke.

Here I don't simply tear an engine down before doing non invasive tests like leak down test with the rocker cover off. An leak down will point you in the right direction as to the problem with you suspect rings/cylinder or head gasket problem. But this takes some experience to recognize to differences in the test results.

And just throwing parts at problem definitely can get expensive without a good results; unless, you hit upon the problem.

#8

B

bertsmobile1

B

bertsmobile1

I see it mostly with the Kawasaki twins

Oil spewing out the muffler but almost no smoke untill the air filter is choked with oil & causes the engine to run way too rich

Oil spewing out the muffler but almost no smoke untill the air filter is choked with oil & causes the engine to run way too rich

#9

L

Legal v8

L

Legal v8

Thanks for your input, fellas. The engine in question here is a 17.5hp Intek - it doesn’t smoke nor does the oil level drop. When I removed the head and head gasket, I removed it as carefully as I could being careful of the thin bridge between the bore and lifter/pushrod valley, which came off intact. The mica coating was still adhered on both sides of the gasket and there wasn‘t any evidence it burned through. I will try to post a photo of it for some secondary opinions though.

#10

R

Rivets

R

Rivets

Just my opinion, but when trying to reuse a head gasket on a Briggs engine you are only asking for trouble. Today’s gaskets are not like the ones produced 20 years ago and I never even think about reusing one.

#11

Hammermechanicman

Hammermechanicman

I have seen that engine run fine and not smoke running but blow a little smoke on starting and then a little oil and vapor out the breather tube. Prob was blown head gasket but you couldn't see a problem with the gasket. Looked fine. New gasKet and no smoke at startup or oil out the dipstick tube. Before splitting the crankcase i would just try a new head gasket. If the bore looks good i doubt rings are the problem.

#12

B

bertsmobile1

B

bertsmobile1

If you want a reuseable head gasket go to CoppergasketsUS and get one of Lanni's solid copper head gaskets .

Otherwise replace it unless you want to practice pulling engines apart

Otherwise replace it unless you want to practice pulling engines apart

#13

L

Legal v8

L

Legal v8

I don’t reuse head gaskets. Not even the ones from 20-30 years ago. I don’t trust gaskets that compress when torqued will ever seal the same as they did the very first time.Just my opinion, but when trying to reuse a head gasket on a Briggs engine you are only asking for trouble. Today’s gaskets are not like the ones produced 20 years ago and I never even think about reusing one.

#14

sgkent

sgkent

make sure the exhaust is open and free, and does not have any carbon build up on baffles or screens if there is a spark arrester on it. If the exhaust is slightly plugged it will raise combustion pressures and possibly cause blowby. You've checked the breather but check it again. If it is open to the air cleaner, which most dump into then pressure should not build up. Likewise, if there is too high an oil level or gasoline in the oil that can cause those symptoms too. A blown head gasket will show just a slight darkening in the affected area(s).

#15

L

Legal v8

Thank you to all who have responded. I’m sure a forum newbie with zero posts asking a silly question gets an eye roll or two. Usually the line I see given is “you should have used the forum search before making a new thread”. Thank you for not scolding me.

I have been an engine guy for 25+ years. My smallest engine I own is .049ci.. I know what I’m doing most of the time, and when I don’t, I’m pretty darn stubborn to ask for help. Thank you everyone.

L

Legal v8

Thanks for your input. I have checked all of this - the muffler was the first thing to come off and get looked at. Definitely not plugged. Pics attached of the parts. The head gasket has a couple small chips out of the edge in the area where they burn through, but this happened when I pulled it off. That costing is super flaky around the edges it seems. I don’t see solid evidence of the gasket failing to the degree it would need to to cause this, but maybe the gasket is permeable between the layers... I have to upload my photos to my photo host site due to their size. I’ll have these uploaded later this morning for all to see.make sure the exhaust is open and free, and does not have any carbon build up on baffles or screens if there is a spark arrester on it. If the exhaust is slightly plugged it will raise combustion pressures and possibly cause blowby. You've checked the breather but check it again. If it is open to the air cleaner, which most dump into then pressure should not build up. Likewise, if there is too high an oil level or gasoline in the oil that can cause those symptoms too. A blown head gasket will show just a slight darkening in the affected area(s).

Thank you to all who have responded. I’m sure a forum newbie with zero posts asking a silly question gets an eye roll or two. Usually the line I see given is “you should have used the forum search before making a new thread”. Thank you for not scolding me.

I have been an engine guy for 25+ years. My smallest engine I own is .049ci.. I know what I’m doing most of the time, and when I don’t, I’m pretty darn stubborn to ask for help. Thank you everyone.

#16

L

Legal v8

L

Legal v8

Here are some photos. The edges of the head gasket are pretty flaky - which I would expect for a 22 year old engine. The little specks chipped off beteeen the bore and lifter/pushrod valley while handling it after removal. I don’t see any evidence of combustion residue outside of the bore. Maybe you see something I don’t.

#17

StarTech

StarTech

Those areas between the cylinder and push rod are normal blown head damage. And I replaced quite a few that fail leak down tests that look like that. Also the side that is darker is usually a leaky area too.

#18

R

Rivets

R

Rivets

This is one time that Star and I agree, there is evidence of a blown gasket between the cylinder and valve train galley. I also see the dark surface of the gasket, opposite the valve galley, indicating leaking gasket.

#19

L

Legal v8

L

Legal v8

Thanks for your input. I have checked all of this - the muffler was the first thing to come off and get looked at. Definitely not plugged. Pics attached of the parts. The head gasket has a couple small chips out of the edge in the area where they burn through, but this happened when I pulled it off. That costing is super flaky around the edges it seems. I don’t see solid evidence of the gasket failing to the degree it would need to to cause this, but maybe the gasket is permeable between the layers...make sure the exhaust is open and free, and does not have any carbon build up on baffles or screens if there is a spark arrester on it. If the exhaust is slightly plugged it will raise combustion pressures and possibly cause blowby. You've checked the breather but check it again. If it is open to the air cleaner, which most dump into then pressure should not build up. Likewise, if there is too high an oil level or gasoline in the oil that can cause those symptoms too. A blown head gasket will show just a slight darkening in the affected area(s).

Fair enough! I’ll pass on the rings for now and just replace the head gasket. I’ll check the head for flatness.Those areas between the cylinder and push rod are normal blown head damage. And I replaced quite a few that fail leak down tests that look like that. Also the side that is darker is usually a leaky area too.

#20

L

Legal v8

L

Legal v8

I have a stupid question that I already know the answer to, but I’m going to ask it anyway.  . Is there any use/benefit in using a little gasket sealer between the bore and lifter valley to prolong the gasket from leaking there?

. Is there any use/benefit in using a little gasket sealer between the bore and lifter valley to prolong the gasket from leaking there?

#23

L

Legal v8

L

Legal v8

Alright. I followed the advice you guys gave me and I got it back together to spec, and it starts and runs really nice. Oil will still spray out of the dipstick tube when running, but not to the same intensity as before. I do not see any exhaust vapor/smoke coming from the tube after shutting it down, so I should be good, at least for now. The head was nowhere near as flat as I expected it would/should have been, so I worked it flat on a piece of glass and fine abrasive. As long as I didn’t goof up getting it flat, it should last awhile before needing another gasket job done.

Many thanks to everyone who contributed and offered help.

Many thanks to everyone who contributed and offered help.