You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Craftsman BackPack Leaf Blower No Spark

#1

W

welchs101

W

welchs101

Hi i have a craftsman backpack leaf blower model 316.794790 and my neighbor gave it to me. He said it has no spark.

I took off the pull chord housing hoping to see where the ignition coil is located........but for the life of me i cant see how to get to the iginition coil.

I can provide pics if this would help.......

I took off the pull chord housing hoping to see where the ignition coil is located........but for the life of me i cant see how to get to the iginition coil.

I can provide pics if this would help.......

#3

ILENGINE

ILENGINE

It would help us if we had the model number of the blower so we could see what it looks like. Trace the spark wire down into the housing to locate the ignition module. Most of those have the module on the same side of the engine as the fan, which will require a complete disassembly including removing the engine from the frame, separating the fan housing and remove the fan to get to the screws behind the fan to remove the housing from the engine.

Looks like you are mostly there. Just make sure you get the nut tight on the fan when you are done since that nut also is the nut that holds the flywheel tight to the crankshaft.

Looks like you are mostly there. Just make sure you get the nut tight on the fan when you are done since that nut also is the nut that holds the flywheel tight to the crankshaft.

#4

StarTech

StarTech

316.794790 (41AR2BPG799)

You got a lot more disassembly ahead as it is behind the blower assy.

You got a lot more disassembly ahead as it is behind the blower assy.

#5

W

welchs101

W

welchs101

How did you know it was behind the blower assembly? I believe you......this is what i was kinda thinking but how did you know? The blower assembly is the side of the blower that is closest to a persons back if they were wearing the blower is this right?316.794790 (41AR2BPG799)

You got a lot more disassembly ahead as it is behind the blower assy.

#8

W

welchs101

W

welchs101

what does IPL stand for? based on your diagram suggestion i was able to disassemble blower all the way to image between 19 and 23......see enclosed images.......i see the ignition coil. there are two wires connected to it i think.

?1: can the ignition coil spacing be too close........it does seem to rotate freely not touching but boy does it look close.

?2: how to tell if ignition coil is good.....i know i need to test resistance somewhere but where exactly?

?1: can the ignition coil spacing be too close........it does seem to rotate freely not touching but boy does it look close.

?2: how to tell if ignition coil is good.....i know i need to test resistance somewhere but where exactly?

Attachments

#9

ILENGINE

ILENGINE

It is actually very common for the flywheel and ignition module to be on the same side of the engine as the blower fan. And that is true for both backpack and handheld blowers. Which also explains why it is not economical to repair most of those units from a dealer standpoint. Labor will eat you alive even if parts are cheap.How did you know it was behind the blower assembly? I believe you......this is what i was kinda thinking but how did you know? The blower assembly is the side of the blower that is closest to a persons back if they were wearing the blower is this right?

#10

ILENGINE

ILENGINE

IPL is the abbreviation for the parts diagram or illustrated parts list. And .010 is a very common air gap clearance between the flywheel and the module legs. And basically the only way to test them is to make sure the kill switch is functioning and you crank it over with a good spark plug. No spark, faulty module. Most units don't have resistance readings for the modules, and in some cases an ohm meter can damage the modules electronics.what does IPL stand for? based on your diagram suggestion i was able to disassemble blower all the way to image between 19 and 23......see enclosed images.......i see the ignition coil. there are two wires connected to it i think.

?1: can the ignition coil spacing be too close........it does seem to rotate freely not touching but boy does it look close.

?2: how to tell if ignition coil is good.....i know i need to test resistance somewhere but where exactly?

#11

StarTech

StarTech

Then I do so much cheating I need to be arrested. 40 hrs of doing. Besides it is way my photographic mind works as I need an image to work from.Looking at the IPL is cheating ?

#12

W

welchs101

W

welchs101

how do you test "kill switch is functioning and you crank it over with a good spark plug" not sure i understand what this means. It kinda sounds like you want to try a new spark plug but if the ignition coil is bad a new spark plug wont help.....right? oh, wait i think i understand now.......try a new spark plug and if it still does not give a spark then its the module........but could it also be that the kill switch as you said is somehow causing the problem? How does measuring resistance cause ignition coil to go bad..........thanks for responding .......trying to learn a little about small engines........

#13

B

bertsmobile1

B

bertsmobile1

Down here you would be told Illustrated Parts list to indicated there was a diagram of some sort , not just a list of parts & numbers .

And yes, if the blower fan has to be removed then most are not an economical repair

Occasionally if I get a newish blower in so I can pull the fan & put some anti sieze on the keyed strait shaft ones they remain repairable.

Most of my customers use the big Stihl blowers & they have all been told unless they pull the fan off, don't bring them in because it can take the better part of a full day to get the fan off.

The shop I get most Stihl parts from smashes the fans &replaces them because that is cheaper than trying to remove them undamaged

And yes, if the blower fan has to be removed then most are not an economical repair

Occasionally if I get a newish blower in so I can pull the fan & put some anti sieze on the keyed strait shaft ones they remain repairable.

Most of my customers use the big Stihl blowers & they have all been told unless they pull the fan off, don't bring them in because it can take the better part of a full day to get the fan off.

The shop I get most Stihl parts from smashes the fans &replaces them because that is cheaper than trying to remove them undamaged

#14

Hammermechanicman

Hammermechanicman

I'm just jealous of all the documentation you have amassed and have access to.Then I do so much cheating I need to be arrested. 40 hrs of doing. Besides it is way my photographic mind works as I need an image to work from.

#15

W

welchs101

W

welchs101

if anyone knows how to test ignition coil let me know.

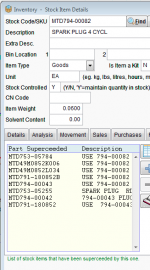

also, if i have to replace it any idea the model number. i looked up "mtd 7181B fl-56 201004" but nothing really came up.

I got "mtd 7181B fl-56 201004" from the picture i posted above.

also, if i have to replace it any idea the model number. i looked up "mtd 7181B fl-56 201004" but nothing really came up.

I got "mtd 7181B fl-56 201004" from the picture i posted above.

#16

B

bertsmobile1

B

bertsmobile1

for all practical purposes they are not testable other than the HT side

Ie plug cap to coil ground

However they are a non repairable part so they either work or they don't work .

You can use a variable gap spark tester to see just how good a working one is . but that is about the limit of it .

Ie plug cap to coil ground

However they are a non repairable part so they either work or they don't work .

You can use a variable gap spark tester to see just how good a working one is . but that is about the limit of it .

#17

StarTech

StarTech

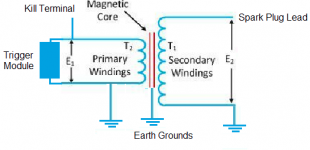

Basically it is a plug and play part. Disconnect the coil's kill terminal, the one that is the flat none bolted terminal. IF the coil is good the plug (used a known good plug) will spark (arc) when metal case is grounded while pulling the starter cord. IF not then the coil is bad provided your are checking with a known good plug. Now these little 10mm spark plugs are known to go bad quite often so that is another weak in the ignition system to check.

But according the model posted in post 1 the ignition coil part number is 753-04324. The spark plug is a Champion RDZ4H.

But according the model posted in post 1 the ignition coil part number is 753-04324. The spark plug is a Champion RDZ4H.

#18

W

welchs101

W

welchs101

where did you see the spark plug specification. note: the spark plug that is in the machine now is a firstfire FF-19 is that equivalent to the RDZ4H? Also, do they spec the resistance of spark plugs? i was curious because they tell you to measure the resistance of the plug to see if its any good..........i measure ~ 10k to 11k ohms on mine but i do not know if this is a good reading or a bad reading

#20

W

welchs101

W

welchs101

thanks.

Question: i was hoping someone knew how to measure the ignition coil to see if it is bad. i looked on line and i did some measurements but i have no way of knowing if based my values if its good or not.

i measured from iron core to post where kill switch goes and i got ~ 0.6kilo-ohms.

i measured from iron core to spark plug boot and i measured ~ 3kilo-ohms............

from what i have seen on others measurements the 3kilo ohms seems ok

but i am not sure about the 0.6kilo-ohms..........this could be good as well. i read somewhere on line that i should look up ignition coil specs

the coil i have on there now is an mtd 7181B........but i cant find the specs on it......does anyone know?

Question: i was hoping someone knew how to measure the ignition coil to see if it is bad. i looked on line and i did some measurements but i have no way of knowing if based my values if its good or not.

i measured from iron core to post where kill switch goes and i got ~ 0.6kilo-ohms.

i measured from iron core to spark plug boot and i measured ~ 3kilo-ohms............

from what i have seen on others measurements the 3kilo ohms seems ok

but i am not sure about the 0.6kilo-ohms..........this could be good as well. i read somewhere on line that i should look up ignition coil specs

the coil i have on there now is an mtd 7181B........but i cant find the specs on it......does anyone know?

#21

StarTech

StarTech

You must understand and accept due to the internal design with the electronic trigger, these coils can not be reliably be tested except with special test equipment. For us in the field [repair shops] they are tested as a plug and play item. Otherwords they are mounted and if they work great; if they don't then we replace them. The days of the externally triggered ignitions are now long gone. There a limited number engines still using the hybrid system and of course the antique engines with points and condenser system.

Ignition coils are basically a step up transformer. The testing problem rises because the electronic trigger is across the primary winding and due to the configuration any tests done on the primary side only shows the primary winding resistance. The trigger is higher resistance item but since it is mounted direct across the primary winding you only read the coil's primary resistance; therefore, there no reliable way to first these in the field other than plug and play. The kill tab is connected the floating end the primary so when you test from it to ground all are testing is primary transformer resistance.

Note after market coils for this engine are only around $20. and OEM coils are $70+.

Now there are couple other problems that will cause an engine not to hit on induce fuel mix. One is a sheared flywheel key throwing the ignition timing off and the other is low compression. Two cycles require at least 100 psi normally to even ignite the fuel mixture load. Now there are limited number of two cycle engines that I have seen that fire with as little as 90 psi compression but I use the 100 psi minimum as test rule here.

Ignition coils are basically a step up transformer. The testing problem rises because the electronic trigger is across the primary winding and due to the configuration any tests done on the primary side only shows the primary winding resistance. The trigger is higher resistance item but since it is mounted direct across the primary winding you only read the coil's primary resistance; therefore, there no reliable way to first these in the field other than plug and play. The kill tab is connected the floating end the primary so when you test from it to ground all are testing is primary transformer resistance.

Note after market coils for this engine are only around $20. and OEM coils are $70+.

Now there are couple other problems that will cause an engine not to hit on induce fuel mix. One is a sheared flywheel key throwing the ignition timing off and the other is low compression. Two cycles require at least 100 psi normally to even ignite the fuel mixture load. Now there are limited number of two cycle engines that I have seen that fire with as little as 90 psi compression but I use the 100 psi minimum as test rule here.

#23

upupandaway

upupandaway

Welchs101, Just for doo doo and giggles, did u try disconnecting the kill switch before taking the whole thing apart?

#24

M

mmoffitt

Happy New Year to all!

M

mmoffitt

I love it!... Seriously just reading all of these questions and answers, has given me so much usable knowledge ,but it would still take the 10,000 hrs plus another 10k of actual hands on to get good at this. A lot of these people here are some of the best of the best and thank you to everyone for sharing Their knowledge and wisdom!How did you know it was behind the blower assembly? I believe you......this is what i was kinda thinking but how did you know? The blower assembly is the side of the blower that is closest to a persons back if they were wearing the blower is this right?

Happy New Year to all!

#25

G

Gord Baker

G

Gord Baker

You should have first verified using a tester that there was indeed no current at the plug. Then Replace the plug with known or new good one. Simple stuff first.

#26

B

bertsmobile1

B

bertsmobile1

You have not been able to test small engine magneto coils with an ohm meter since 1994 when the patient for Atom Industries points eliminator expired and every manufacturers fitted coils with embedded Hall Effect Trigger circuits.

In fact some cheap ohm meters can fry the chip and as most work with negative voltages, touching the kill wire to any battery + will fry the circuits as well

The chip is hard wired into the primary windings of the coil so it is not repairable nor replaceable.

This is why there are no service details available

To test it you need a signal generator to stimulate the primary winding while simultaniously read the rising voltage in the primary coil which is in micro volts to see what voltage the trigger trips at when the entire coil is then in series for a micro second or so .

Unfortuneately the WWW is full of totally brain dead 1/2 witts whose mental capacity never progressed past that of a 4 year old .

So when faced with something they do not understand they make some thing up to explain it just like the fairies that we all knew lived in the bottom of the garden when we were 5.

Then these idiots go post a whole lot of twaddle often conflating things that have nothing to do with what they are posting about but seem to be connected in their overworked confused blubber pretending to be a mind to make them feel like they are important & not just oxygen thieves who the planet would be better off if they had been allowed to die at birth .

In fact some cheap ohm meters can fry the chip and as most work with negative voltages, touching the kill wire to any battery + will fry the circuits as well

The chip is hard wired into the primary windings of the coil so it is not repairable nor replaceable.

This is why there are no service details available

To test it you need a signal generator to stimulate the primary winding while simultaniously read the rising voltage in the primary coil which is in micro volts to see what voltage the trigger trips at when the entire coil is then in series for a micro second or so .

Unfortuneately the WWW is full of totally brain dead 1/2 witts whose mental capacity never progressed past that of a 4 year old .

So when faced with something they do not understand they make some thing up to explain it just like the fairies that we all knew lived in the bottom of the garden when we were 5.

Then these idiots go post a whole lot of twaddle often conflating things that have nothing to do with what they are posting about but seem to be connected in their overworked confused blubber pretending to be a mind to make them feel like they are important & not just oxygen thieves who the planet would be better off if they had been allowed to die at birth .

#27

B

bertsmobile1

B

bertsmobile1

Opps

Sorry I missed page 3 so I have just said the same as Star, in a different way.

Take home is , if you have access to the $ 30,000 worth of test gear then you can dry test the magnetos.

At the factory they simply run a magnet past the coil and measure the voltage generated and the time lapse from exitement to spark.

They do this over a variety of speeds and those that are perfect go into machine factory branded boxes or factory assembly trays.

And measure the number of sparks generated and compare them to the number that should have been generated .

From there on in they get dropped into "lesser" quality ( and price ) bins till eventually they are totally unuseable & they go into the scrap bin .

Now the QC lab might actually pull the odd one off the line and take measurements for the purpose of monitoring and comparing different components but the factory tests & sells them according to their output .

So basically it is the same as works or don't work .

Sorry I missed page 3 so I have just said the same as Star, in a different way.

Take home is , if you have access to the $ 30,000 worth of test gear then you can dry test the magnetos.

At the factory they simply run a magnet past the coil and measure the voltage generated and the time lapse from exitement to spark.

They do this over a variety of speeds and those that are perfect go into machine factory branded boxes or factory assembly trays.

And measure the number of sparks generated and compare them to the number that should have been generated .

From there on in they get dropped into "lesser" quality ( and price ) bins till eventually they are totally unuseable & they go into the scrap bin .

Now the QC lab might actually pull the odd one off the line and take measurements for the purpose of monitoring and comparing different components but the factory tests & sells them according to their output .

So basically it is the same as works or don't work .

#29

W

welchs101

W

welchs101

got new ignition coil............NOW I HAVE SPARK. So cool. Can you tell i am a newbie at this?

Ok, so i put some fuel in the spark plug hole and put spark plug back and put ignition coil back and tried to crank it........i guess it kinda turned over but did not run a lot.......i am going to say it ran for 1 sec maybe..........i tried connecting gas tank and priming bulb and starting it this way and it just wont start. So am guessing now it might be the carb? My carb i think has part number 753-05633.....anyone hve any videos on how to repair this one? or what ot look out for?

Ok, so i put some fuel in the spark plug hole and put spark plug back and put ignition coil back and tried to crank it........i guess it kinda turned over but did not run a lot.......i am going to say it ran for 1 sec maybe..........i tried connecting gas tank and priming bulb and starting it this way and it just wont start. So am guessing now it might be the carb? My carb i think has part number 753-05633.....anyone hve any videos on how to repair this one? or what ot look out for?

#30

W

welchs101

W

welchs101

ok, i took the carb apart and cleaned it with carb-spray.....put it back together and ........nothing still wont start up.

this 2 cycle carb has diaphrams and a few other things........not sure how to tell if the diaphram is good or bad..........i cleaned out spraying through all the holes but again not sure if the diaphrams are ok.......any idea on if they sell a carb kit? i have looked all over and cant find one....my carb model number is 753-05633

thoughts on what to do/try ?

this 2 cycle carb has diaphrams and a few other things........not sure how to tell if the diaphram is good or bad..........i cleaned out spraying through all the holes but again not sure if the diaphrams are ok.......any idea on if they sell a carb kit? i have looked all over and cant find one....my carb model number is 753-05633

thoughts on what to do/try ?

#31

Scrubcadet10

Scrubcadet10

Here lately i just replace 2 cycle carbs once they're confirmed they are the issue. The diaphragm should be very pliable, if it's stiff, its bad.

according to Sears parts direct the carb PN is 753-05633, like you said.

New are around $40 from the maker.

according to Sears parts direct the carb PN is 753-05633, like you said.

New are around $40 from the maker.

#32

Scrubcadet10

Scrubcadet10

it doesn't appear MTD sells a repair kit... If i can find out who made the carb (Walbro, Ruixing, KeHin, Zama) a rebuild kit could be found.

#33

B

bertsmobile1

B

bertsmobile1

Unless you used the really expensive Walbro carb cleaner o spray out your carb with, you have just destroyed it

Automotive carb cleaner destroys the seals in most check valves used in cube carbs

Despite what the experts on You tube say, if you pulled the carb apart then the gaskets need to be replaced because 90% of the time they will not be able to make a pressure tight seal again .

You can soften then by cooking them in warm oil , boiling in water or a variety of other bodges but they will dry out again and leak again.

That is why the wholesalers sell common gaskets in 10 & 20 packs

Automotive carb cleaner destroys the seals in most check valves used in cube carbs

Despite what the experts on You tube say, if you pulled the carb apart then the gaskets need to be replaced because 90% of the time they will not be able to make a pressure tight seal again .

You can soften then by cooking them in warm oil , boiling in water or a variety of other bodges but they will dry out again and leak again.

That is why the wholesalers sell common gaskets in 10 & 20 packs

#34

W

welchs101

W

welchs101

wanted to ask you all a question:

i am thinking i need to order a new carb i was thinking of getting this one

https://www.ebay.com/itm/273246767018?hash=item3f9ec6c7aa:g:5sAAAOSwyMVdnb0z

Thoughts?

i am thinking i need to order a new carb i was thinking of getting this one

https://www.ebay.com/itm/273246767018?hash=item3f9ec6c7aa:g:5sAAAOSwyMVdnb0z

Thoughts?

#36

Scrubcadet10

Scrubcadet10

really can't make any guarantee's on the aftermarket carbs. If it works proper, and you save money, good deal.

#37

W

welchs101

W

welchs101

would you do the $15 carb or would you do the more expensive one.......i just dont have a lot of experience replacing carbs so i dont know which i should do.........since i am trying to repair this mainly as a learning exercise i am leaning towards the cheaper one but am willing to pay more if there is a definite reason to

#38

W

welchs101

W

welchs101

how to identify who made the carb to see if we can get a repair kit......or shouldi just replace as one suggested.......thoughts?

#39

Scrubcadet10

Scrubcadet10

my policy is always Use OEM parts with 2 exceptions, The customer cant afford it, or the original part is no longer made.

#40

Scrubcadet10

Someone with more experience like Ilengine, Rivets or startech might know just by looking at it,

Scrubcadet10

generally the manufacturers name is stamped into the carburetor, location of it typically varies by carburetor.how to identify who made the carb to see if we can get a repair kit......or shouldi just replace as one suggested.......thoughts?

Someone with more experience like Ilengine, Rivets or startech might know just by looking at it,

#41

B

bertsmobile1

B

bertsmobile1

Rule of thumb with ebay is to right click on the "View other items " link

Now if the bulk of what comes up are carburettors & similar parts or all small engine / go cart / motorcycle type parts or all lawn & garden & landscaping parts then you might assume they know what they are doing & sell reasonable parts.

If they have a street address listed in the contacts section and you view it using one of the street view type apps and you see their company name on the side of the building then that is 2 runs on the board.

However if they are selling 22,795 different things from condoms to maternity bras then chances are they are selling any old junk they can lay their hands on cheap and by virtue they sell both condoms & maternity wear , obviously some of the stuff might not necessarily work as intended .

Now if the bulk of what comes up are carburettors & similar parts or all small engine / go cart / motorcycle type parts or all lawn & garden & landscaping parts then you might assume they know what they are doing & sell reasonable parts.

If they have a street address listed in the contacts section and you view it using one of the street view type apps and you see their company name on the side of the building then that is 2 runs on the board.

However if they are selling 22,795 different things from condoms to maternity bras then chances are they are selling any old junk they can lay their hands on cheap and by virtue they sell both condoms & maternity wear , obviously some of the stuff might not necessarily work as intended .

#42

StarTech

StarTech

The current 753-05633 is a Walbro WYJ-447-1 which uses the K20-WYJ carburetor repair kit.

Here is where the numbers are on the Walbro. If you look on your carburetor you find similar markings as MTD might used a slightly different version than the current part.

If you have a Ruixing carburetor then all bets are off as they are clones. And just have to be able recognize if it is a Walbro or Zama clone and get very lucky that one their repair kits will fit; otherwise, you have to replace it.

As for the flywheel to coil clearance I use a repair tag stock but a business also works. If the clearance is off a little 1 or 2 thousandths it only changes the timing a frog hair or so.

Here is where the numbers are on the Walbro. If you look on your carburetor you find similar markings as MTD might used a slightly different version than the current part.

If you have a Ruixing carburetor then all bets are off as they are clones. And just have to be able recognize if it is a Walbro or Zama clone and get very lucky that one their repair kits will fit; otherwise, you have to replace it.

As for the flywheel to coil clearance I use a repair tag stock but a business also works. If the clearance is off a little 1 or 2 thousandths it only changes the timing a frog hair or so.

#43

W

welchs101

W

welchs101

i am trying to look the WYJ-447-1 and/or the carb kit K20-WYJ.

For the part number WYJ-447-1.......when i go to the walbro website and type in a search of this part number nothing comes up. Am i doing something wrong?

When i look at the carb kit there are individual pieces that look like go to my carb (i think) but there are other pieces that i dont recall when i took it apart........could this mean mine is not a WYJ-447-1?

I will take the carb off in a little while and look for a part number.

For the part number WYJ-447-1.......when i go to the walbro website and type in a search of this part number nothing comes up. Am i doing something wrong?

When i look at the carb kit there are individual pieces that look like go to my carb (i think) but there are other pieces that i dont recall when i took it apart........could this mean mine is not a WYJ-447-1?

I will take the carb off in a little while and look for a part number.

#44

StarTech

StarTech

Heres what I get.

Link to parts page.

https://walbro.force.com/Store/ccrz__ProductDetails?sku=WYJ-447-1&cclcl=en_US

Link to parts page.

https://walbro.force.com/Store/ccrz__ProductDetails?sku=WYJ-447-1&cclcl=en_US

#45

W

welchs101

W

welchs101

huh, i tried to do that very thing.......i probably messed something up.......i will try it again. thanks.

oh, i forgot to ask , how on earth did you figure out that the carb model number was made by them?

oh, any comment on the "extra" stuff in the carb kit that i did not see when i took it apart?

oh, i forgot to ask , how on earth did you figure out that the carb model number was made by them?

oh, any comment on the "extra" stuff in the carb kit that i did not see when i took it apart?

#46

StarTech

StarTech

Their name is on the carburetor. Plus I have seen a lot of their carburetors over the last 13 yrs so I have learned how to id them.

It is because the kits covers multiple models and not all the parts are use on all models so you only used the matching parts you need the rest you throw away or save if in the repair business in case just need one of them.

It is because the kits covers multiple models and not all the parts are use on all models so you only used the matching parts you need the rest you throw away or save if in the repair business in case just need one of them.

#47

W

welchs101

W

welchs101

i looked at Carb again and there is a part number on it.

it is a Walbro..........447A-947

is this the same as the one you posted above?

it is a Walbro..........447A-947

is this the same as the one you posted above?

Attachments

#48

StarTech

StarTech

Yes it is same carburetor. Walbro just chose to use numbers for the letters use in suffix so "A" equals "1".

Also here is the service manual for the carburetor.

WYJ Service Manual

Also here is the service manual for the carburetor.

WYJ Service Manual

#49

W

welchs101

W

welchs101

i have a few questions. I took apart the carb again just to see if i missed anything and to try and verify the pieces/parts using the parts diagram from the Walbro diagram.

Q1: the walbro diagram has 4 pieces shown in the parts diagram where as my carb only has 2. How do i know what 2 pieces i have?

Q2: See my figures..._2......in this picture i am asking is the order of the pieces on my carb correct? or are they out of order...ie should the one that is currently on the bottom be on the top and the one on the top be on the bottom.

Q3: Would you order carb kit or a new carb? whats been your experience?

Q1: the walbro diagram has 4 pieces shown in the parts diagram where as my carb only has 2. How do i know what 2 pieces i have?

Q2: See my figures..._2......in this picture i am asking is the order of the pieces on my carb correct? or are they out of order...ie should the one that is currently on the bottom be on the top and the one on the top be on the bottom.

Q3: Would you order carb kit or a new carb? whats been your experience?

Attachments

#50

B

bertsmobile1

B

bertsmobile1

You should have 2

a pump diaphragm

a pump diaphragm gasket

There are 4 variations of the diaphragm

The gasket goes to the side that has the little ridge cast into it

The diaphragms are coded by the position of the tab that protrudes from the edge

They are different sizes , shapes & in different positions .

a pump diaphragm

a pump diaphragm gasket

There are 4 variations of the diaphragm

The gasket goes to the side that has the little ridge cast into it

The diaphragms are coded by the position of the tab that protrudes from the edge

They are different sizes , shapes & in different positions .

#51

W

welchs101

W

welchs101

from the picture i sent can you tell which variation i have? i mean which numbers 11,25,13,12.

Again from my picture, because i am trying to figure out if the gasket / diaphragm was flipped or something......in one of the pics i labeled the gasket and diaphragm...did i label them correctly?

in on eo the pics i showed the gasket/diaphragm sandwhiched between two metal plates. i dont know the techinical terms, but i am just trying to figure out which metal plate the gasket goes against and which the diaphram goes against. IN one pic you see a metal plate with two pegs sticking out.......is this the metal side that the gasket goes against?

Again from my picture, because i am trying to figure out if the gasket / diaphragm was flipped or something......in one of the pics i labeled the gasket and diaphragm...did i label them correctly?

in on eo the pics i showed the gasket/diaphragm sandwhiched between two metal plates. i dont know the techinical terms, but i am just trying to figure out which metal plate the gasket goes against and which the diaphram goes against. IN one pic you see a metal plate with two pegs sticking out.......is this the metal side that the gasket goes against?

#52

B

bertsmobile1

B

bertsmobile1

Look at what you have there.

The gasket which is soft will have a line impressed into it by the ridge cast into the surface

The other side is dead flat so the diaphragm goes against that because the little pump flaps have to seal against the hole .

Assuming that it had been working before you ripped it apart, you fir the same gasket & diaphragm from the kit as what was fitted in the first place

Different types of plastic are different colour

So if you had a blue diaphragm then you fit the blue one from the kit .

The gasket which is soft will have a line impressed into it by the ridge cast into the surface

The other side is dead flat so the diaphragm goes against that because the little pump flaps have to seal against the hole .

Assuming that it had been working before you ripped it apart, you fir the same gasket & diaphragm from the kit as what was fitted in the first place

Different types of plastic are different colour

So if you had a blue diaphragm then you fit the blue one from the kit .

#53

StarTech

StarTech

Just shaking my head now.

Bert you can't assume anything; unless, you know for sure no one else have been inside the carburetor after the factory assemble it. This is why I posted a link to the IPL. We got people working on these carburetors that has no idea how things goes together. I got local shop techs which should know what they are doing that should never touch a carburetor or anything else but I do make more money off their screw ups so I shouldn't complain. Although it does cost the customer more than it should.

I just did a WT on a Homelite saw where extra pump diaphragms were added. Made it so stiff that the carburetor could not even pump fuel mix after the repair got some age on it.

You must go by the IPL parts list (link posted) as I said before the kits contains parts for several versions of the WYJ carburetors. But I took the time to look it up again. The gasket is item 12. Items 11 and 25 are not used on the 447-1. Now item 13 is the pump diaphragm (must be used). The IPL also shows the order the gaskets and diaphragms goes in. On this carburetor the pump body (the one with the metering needle) is separate from the main body (the one with the rotary barrel). So your pump diaphragm/gasket setup is in the wrong order. It also tells me someone else has already been inside the carburetor.

Bert you can't assume anything; unless, you know for sure no one else have been inside the carburetor after the factory assemble it. This is why I posted a link to the IPL. We got people working on these carburetors that has no idea how things goes together. I got local shop techs which should know what they are doing that should never touch a carburetor or anything else but I do make more money off their screw ups so I shouldn't complain. Although it does cost the customer more than it should.

I just did a WT on a Homelite saw where extra pump diaphragms were added. Made it so stiff that the carburetor could not even pump fuel mix after the repair got some age on it.

You must go by the IPL parts list (link posted) as I said before the kits contains parts for several versions of the WYJ carburetors. But I took the time to look it up again. The gasket is item 12. Items 11 and 25 are not used on the 447-1. Now item 13 is the pump diaphragm (must be used). The IPL also shows the order the gaskets and diaphragms goes in. On this carburetor the pump body (the one with the metering needle) is separate from the main body (the one with the rotary barrel). So your pump diaphragm/gasket setup is in the wrong order. It also tells me someone else has already been inside the carburetor.

#54

Hammermechanicman

Hammermechanicman

How many times has a piece come in the shop and the gasket on metering side of the carb is on the wrong side of the diaphragm? Always lets you know Wilbur has worked on the carb.

#55

StarTech

Or when they take the short cut of not changing the metering needle. I replaced several last year where they were ringed that was causing flooding. Or those that do forget to set the metering lever thinking they right out of the kit but of even new carburetors needs to checked for this one.

StarTech

More times than I can count on my fingers and toes.How many times has a piece come in the shop and the gasket on metering side of the carb is on the wrong side of the diaphragm? Always lets you know Wilbur has worked on the carb.

Or when they take the short cut of not changing the metering needle. I replaced several last year where they were ringed that was causing flooding. Or those that do forget to set the metering lever thinking they right out of the kit but of even new carburetors needs to checked for this one.

#56

W

welchs101

W

welchs101

thanks. this is kinda what i thought after viewing the diagram you sent. i will reverse the two and let you know if it starts or any change at all.

#57

W

welchs101

W

welchs101

FYI: i think i mentioned in the first post that i got this from my neighbor...well neighbor down the street. A few days after i started this post i saw my neighbor and he asked how it was going with the blower. i said nothing new yet........i asked him if he had done anything to figure out the "spark" issue (because that was the issue i was facing at the time...trying to see if he had replaced the spark plug) and it was at this time he said all he did was "mess" with the carburetor. At the time i did not give it much thought but after someone's last post it was the first thing i thought of.

#58

StarTech

StarTech

That is why I said none of us can assume things when we receive equipment. We just don't all the specifics. As a small independent shop I get a lot things that have so called repaired. Some are simply rig jobs, others are done by other shops where the tech has no knowledge of what they are doing. Several years ago when I first moved my shop to where it is now had multiple people wanting me to hire them. After questioning them on things I could see they didn't know what were doing. I had one customer to try one these guys as he said said he knew it all because he was a diesel mechanic. Well the customer brought a couple hundred dollars in parts from me he finally had me to check out his mower. Boy what a mess that guy did to the deck. Six bearings where two were only needed and a missing spacer washer.FYI: i think i mentioned in the first post that i got this from my neighbor...well neighbor down the street. A few days after i started this post i saw my neighbor and he asked how it was going with the blower. i said nothing new yet........i asked him if he had done anything to figure out the "spark" issue (because that was the issue i was facing at the time...trying to see if he had replaced the spark plug) and it was at this time he said all he did was "mess" with the carburetor. At the time i did not give it much thought but after someone's last post it was the first thing i thought of.

#59

Hammermechanicman

Hammermechanicman

You can tell a tech that knows how to diagnose a problem vs one who guesses. For 40 years i had to walk up to machines, diagnose the problem, fix and smooze the customer and do it in a specific amount of time. Star knows the drill. Biggest problem was going behind another tech who half assed a fix or jacked a bunch of adjustments out of spec to compensate for worn parts or was too lazy to do real diagnostic work. Like star said, never assume something is correct. We had a name for those guys. Wilbur.

#60

W

welchs101

W

welchs101

i put the carburetor back together with the correct ordering of parts.......

I put a little gas/oil mixture in where the sparkplug goes and then put spark plug back

It ran for maybe 2 or 3 sec....but longer than before where it "tried" to run.....so i guess its progress.

I dont have much fuel in the tank but i thought i had enough to at least get it going.........

I plan on trying it again later tonight when i have more time but for now just kinda thinking about what my next steps should be

Anyone have any thoughts or suggestions?

I put a little gas/oil mixture in where the sparkplug goes and then put spark plug back

It ran for maybe 2 or 3 sec....but longer than before where it "tried" to run.....so i guess its progress.

I dont have much fuel in the tank but i thought i had enough to at least get it going.........

I plan on trying it again later tonight when i have more time but for now just kinda thinking about what my next steps should be

Anyone have any thoughts or suggestions?

#61

W

welchs101

W

welchs101

i am in no rush or anything using this as a learning exercise really. so i was thinking of ordering a carb kit and trying this out. but i kinda wondering if this is really going to work. when i took the carb apart the pieces looked ok to me.......the diaphragms looked ok....(as far as i could tell but my experience in these matters not good). gaskets looked ok not great but ok......just wondering if a kit is really going to help......i have a feeling i missed something.

#62

B

bertsmobile1

B

bertsmobile1

Cube carbs are pressure vessels

So "looks OK" does not cut the mustard

They must really be pressure tested & vacuum tested

The fuel tank & fuel cap and tank breather ( where fitted ) must also be tested.

If you don't know what new looks & feels like then you can not make a visual assesment of your old diaphragms & gaskets.

So you are just urinating into the wind .

If you really want to lear then search Joe Pace, two stroke carburettor diagnosis on you tube .

When I finally came across his series of tutorials it made a massive difference to my cube carb work.

I now only pull apart about 1/3 of the carbs that I used to because I find the faults are usually in the cap or tank and rarely in the carb itself.

The exception to thi is one where old fuel has been allowed to evaporate in the carb in which case it is a bin job .

Once opened it is nearly impossible to reseal them air tight using the old gaskets so it is SOP to fit new diaphragms & gaskets if a carb is opened .

Star has already sent yo a link to the service manual and on the same web site Walbro have about 1/2 dozen 3 minute service videos.

So "looks OK" does not cut the mustard

They must really be pressure tested & vacuum tested

The fuel tank & fuel cap and tank breather ( where fitted ) must also be tested.

If you don't know what new looks & feels like then you can not make a visual assesment of your old diaphragms & gaskets.

So you are just urinating into the wind .

If you really want to lear then search Joe Pace, two stroke carburettor diagnosis on you tube .

When I finally came across his series of tutorials it made a massive difference to my cube carb work.

I now only pull apart about 1/3 of the carbs that I used to because I find the faults are usually in the cap or tank and rarely in the carb itself.

The exception to thi is one where old fuel has been allowed to evaporate in the carb in which case it is a bin job .

Once opened it is nearly impossible to reseal them air tight using the old gaskets so it is SOP to fit new diaphragms & gaskets if a carb is opened .

Star has already sent yo a link to the service manual and on the same web site Walbro have about 1/2 dozen 3 minute service videos.

#63

StarTech

StarTech

My experiences are different as I seldom find tank venting to be the problem.

But from the previous images first I noticed a fuel pump diaphragm order problem. Second the fuel pump pumping flaps are deformed. And third the metering diaphragm looks like it is stiffen. On some engines it doesn't take whole lot of stiffening to cause problems.

As far as to kit or not it is gamble either way. Luckily these kits are fairly reasonable to try vs an OEM carburetor. I usually repair at least 98% of the ones I do. Of there will unrepairable carbs at times like the ready start versions.

But from the previous images first I noticed a fuel pump diaphragm order problem. Second the fuel pump pumping flaps are deformed. And third the metering diaphragm looks like it is stiffen. On some engines it doesn't take whole lot of stiffening to cause problems.

As far as to kit or not it is gamble either way. Luckily these kits are fairly reasonable to try vs an OEM carburetor. I usually repair at least 98% of the ones I do. Of there will unrepairable carbs at times like the ready start versions.

#64

B

bertsmobile1

B

bertsmobile1

When I did the months hand over from the previous owner I had little experience with cube carbs as I always tip the fuel out of my hand held devices and run them dry.

Thus my 30 year old gear was working perfectly ( or so I thought ) so I had no reason to pull them apart.

He showed me to clean down the engine pull the carbs off , replace the diaphragms & gaskets reassemble then do the checking that should have been done first if the tool did not run properly.

Now I work according to the proceedure shown by Joe Pace, starting with the cap & tank and many times all the tool really needed was the fuel line pulled 1/4 out further to re-establish the seal between the fuel line & tank on throw aways or a new grommet on quality tools or with the GX 25 /35's the cap vent cleaned

While it is nice to have a customer come back with a "thank you it runs better now than it did when new " in reality most just want it to start & run & the less that costs them the better

So $ 30 for replacing the old hard fuel line is better than $ 80 for a full rebuild & replacement of all service parts.

Thus my 30 year old gear was working perfectly ( or so I thought ) so I had no reason to pull them apart.

He showed me to clean down the engine pull the carbs off , replace the diaphragms & gaskets reassemble then do the checking that should have been done first if the tool did not run properly.

Now I work according to the proceedure shown by Joe Pace, starting with the cap & tank and many times all the tool really needed was the fuel line pulled 1/4 out further to re-establish the seal between the fuel line & tank on throw aways or a new grommet on quality tools or with the GX 25 /35's the cap vent cleaned

While it is nice to have a customer come back with a "thank you it runs better now than it did when new " in reality most just want it to start & run & the less that costs them the better

So $ 30 for replacing the old hard fuel line is better than $ 80 for a full rebuild & replacement of all service parts.

#65

StarTech

StarTech

Bert, this is where experience is key when working on these machines. An experienced person can easily diagnose a problem without tearing things apart indiscriminately looking for cause when it might simply be a broken fuel line. When I first started working on 2 cycle handhelds it would take most of a day to get them running where now it usually takes around an hour. I actually learn on a whole full size pickup truck bed full of another shop's discarded handhelds. I manage to get 3/4 of them working and sold.

#66

W

welchs101

W

welchs101

sorry for not replying sooner.........been sick with covid...actually still kinda sick. i just did not want you guys to think i had stopped reading or gave up on this blower......

#67

B

bertsmobile1

Then there are silly things I should have understood like the fuel pumps push fuel & air into the tank not suck fuel out of the tank as liquids push better than they pull .

However I can be just as lazy as the next man so doing what my predecessor showed me without thinking through what was happening was of course the easiest way to go .

As you know, once you know & understand how cube carbs work then you can fix just about any on them, if they are fixable

B

bertsmobile1

Nothing I like more than getting something I have never seen before & working out why it failed then how to fix it .Bert, this is where experience is key when working on these machines. An experienced person can easily diagnose a problem without tearing things apart indiscriminately looking for cause when it might simply be a broken fuel line. When I first started working on 2 cycle handhelds it would take most of a day to get them running where now it usually takes around an hour. I actually learn on a whole full size pickup truck bed full of another shop's discarded handhelds. I manage to get 3/4 of them working and sold.

Then there are silly things I should have understood like the fuel pumps push fuel & air into the tank not suck fuel out of the tank as liquids push better than they pull .

However I can be just as lazy as the next man so doing what my predecessor showed me without thinking through what was happening was of course the easiest way to go .

As you know, once you know & understand how cube carbs work then you can fix just about any on them, if they are fixable

#68

B

bertsmobile1

Nothing here is compulsory.

Sorry to hear you got the virus & hope you get a full recovery.

Some of my customers took month to get over the first variant and some are still not 100% more than a year latter.

Touch wood I have managed to avoid it so far but the way our government is managing ( or not rather not managing ) the outbreak it is just a matter of time.

Apparently the economy & dividends to shareholders is more important than peoples health .

B

bertsmobile1

No need for appologiessorry for not replying sooner.........been sick with covid...actually still kinda sick. i just did not want you guys to think i had stopped reading or gave up on this blower......

Nothing here is compulsory.

Sorry to hear you got the virus & hope you get a full recovery.

Some of my customers took month to get over the first variant and some are still not 100% more than a year latter.

Touch wood I have managed to avoid it so far but the way our government is managing ( or not rather not managing ) the outbreak it is just a matter of time.

Apparently the economy & dividends to shareholders is more important than peoples health .

#69

W

welchs101

W

welchs101

Hi all, well, its been a while since i have had time to work on this blower. I ordered a carb rebuild kit and well this did not seem to help..........so i then ordered a compression tester to see if the compression was ok. i am enclosing pics of what i measured which was ~ 65 psi......see enclosed picture. my question is......is this kinda low for unit to start? if so what should it be..........and does this mean there might be something wrong with valves..........if i chk the valves how do i know what they should be set to. so, many questions.

Attachments

#70

B

bertsmobile1

B

bertsmobile1

The numbers from that tester are meaningless

It is not suitable for small engines and to get a proper reading you will need to pull the starter around 100 times and even then it would be suspect.

For small engines ( 100cc or less ) you must use a tester with a solid connector or a very short connector with a valve at both ends .

Then you need the right adapter to screw into the head that has the exact same volume displacement as the spark plug.

OTOH it can be used for monitoring wear over time by noting how much the readings drop as a percentage of the new reading but absolute numbers are meaningless .

Now FWIW 65 psi, if that is real is right on the border line for 4 strokes and way too low for two strokes

It is not suitable for small engines and to get a proper reading you will need to pull the starter around 100 times and even then it would be suspect.

For small engines ( 100cc or less ) you must use a tester with a solid connector or a very short connector with a valve at both ends .

Then you need the right adapter to screw into the head that has the exact same volume displacement as the spark plug.

OTOH it can be used for monitoring wear over time by noting how much the readings drop as a percentage of the new reading but absolute numbers are meaningless .

Now FWIW 65 psi, if that is real is right on the border line for 4 strokes and way too low for two strokes

#71

W

welchs101

W

welchs101

if we assume it is low.........and we assume that the valves need adjusting.......what on earth would i adjust them too?

#72

StarTech

StarTech

I have to disagree with part of this. I use an Actron version with a very similar hose setup. The problem arises if the check valve is at the gauge end and not at the end of the hose. The Actron I use has the check valve (schrader valve) at the end of the hose right at the cylinder. With valve at the gauge the hose has to be fill on every stroke before the valve even attempts to open where as if at the cylinder end then valve opens right away and close holding the charge in the hose.The numbers from that tester are meaningless

It is not suitable for small engines and to get a proper reading you will need to pull the starter around 100 times and even then it would be suspect.

For small engines ( 100cc or less ) you must use a tester with a solid connector or a very short connector with a valve at both ends .

Then you need the right adapter to screw into the head that has the exact same volume displacement as the spark plug.

OTOH it can be used for monitoring wear over time by noting how much the readings drop as a percentage of the new reading but absolute numbers are meaningless .

Now FWIW 65 psi, if that is real is right on the border line for 4 strokes and way too low for two strokes

#74

W

welchs101

W

welchs101

in looking at the Craftsman backpack blower (Model number 316.794790) ....does this thing even have valves? If so i cant find them..........

Attachments

#75

W

welchs101

W

welchs101

so i was just reading........this 2 cycle engine may not have valves

so i guess i am back to the drawing board on this one.......i am not sure what to do to figure out why this thing wont start.

i checked spark using one of those spark checkers and the light comes on.....so i am assuming i have spark.

as i said earlier i rebuilt carb using parts from a carb kit...........thoughts on what do try?

fyi: as i said before i am just trying to learn a little here........i really dont care if if this back pack ever really runs again but i am just trying to learn a little.

so i guess i am back to the drawing board on this one.......i am not sure what to do to figure out why this thing wont start.

i checked spark using one of those spark checkers and the light comes on.....so i am assuming i have spark.

as i said earlier i rebuilt carb using parts from a carb kit...........thoughts on what do try?

fyi: as i said before i am just trying to learn a little here........i really dont care if if this back pack ever really runs again but i am just trying to learn a little.

#76

B

bertsmobile1

B

bertsmobile1

Well where to start .

SOP for non starters is to try some carb cleaner

That does not work the try a hot ( as in heated with a hot air gun ) plug to make sure the fuel is vapourised because only gases can burn.

Still no bang then it is off with the flywheel to check that the timing key ( usually cast into the flywheel ) is intact

Now I do this every day of the week so I can feel one that is too low on compression but in your case it would be off with the muffler and check the bore with a strong torch for scoring and that the piston ring is free and that the exhaust port is not clogged with carbon

If you have a compressor then you can slide the carb off , turn it sideways and with the fuel lines still connected turn it sideways and blow air through the carb to see if a strong stream of fuel droplets coms out of the carb.

After that there is not much you can do without proper tools

The crankcase seals really need to be pressure & vacuum tested but a very rough test is to pour some heavy oil down the induction port the pull the start rope slowly to distribute the oil over the seals a dozen or so times then pull it quick to expel the oil , replace the hot spark plug & see if it will go bang ..

SOP for non starters is to try some carb cleaner

That does not work the try a hot ( as in heated with a hot air gun ) plug to make sure the fuel is vapourised because only gases can burn.

Still no bang then it is off with the flywheel to check that the timing key ( usually cast into the flywheel ) is intact

Now I do this every day of the week so I can feel one that is too low on compression but in your case it would be off with the muffler and check the bore with a strong torch for scoring and that the piston ring is free and that the exhaust port is not clogged with carbon

If you have a compressor then you can slide the carb off , turn it sideways and with the fuel lines still connected turn it sideways and blow air through the carb to see if a strong stream of fuel droplets coms out of the carb.

After that there is not much you can do without proper tools

The crankcase seals really need to be pressure & vacuum tested but a very rough test is to pour some heavy oil down the induction port the pull the start rope slowly to distribute the oil over the seals a dozen or so times then pull it quick to expel the oil , replace the hot spark plug & see if it will go bang ..