You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Correct connector for fuel shutoff solenoid

#1

E

Elkins45

E

Elkins45

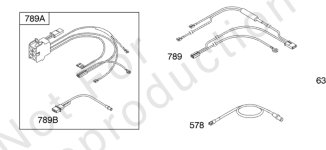

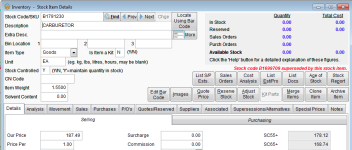

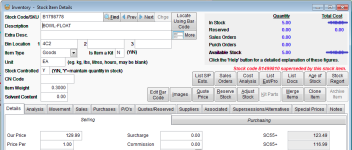

I picked up a used parts mower last week and the guy said it just needed a carb cleaning (ha) and it did fire when he shot it full of ether. When I started removing the carb I discovered the wiring connector to the carb solenoid was mangled and one of the wires is broken off. I downloaded the parts diagram and I can’t figure out what I need to replace. Which of these contains the carb connector?

Better yet, is there a way to just buy a new connector and splice it in? That’s bound to be cheaper. Or maybe just delete the solenoid and splice in a manual fuel shutoff? The engine is a 407677-0229E1. The manual specifies two different solenoids and this is the earlier one.

Better yet, is there a way to just buy a new connector and splice it in? That’s bound to be cheaper. Or maybe just delete the solenoid and splice in a manual fuel shutoff? The engine is a 407677-0229E1. The manual specifies two different solenoids and this is the earlier one.

#2

B

bertsmobile1

B

bertsmobile1

789 is the solenoid wire

The plug with the ground wire ( eye terminal ) on it is the solenoid plug

Star & a private group of techs have been compiling a list of the connectors & plugs but the down side is few places stock them and direct from the factory / wholesalers have minimum wholesale sized orders

The plug with the ground wire ( eye terminal ) on it is the solenoid plug

Star & a private group of techs have been compiling a list of the connectors & plugs but the down side is few places stock them and direct from the factory / wholesalers have minimum wholesale sized orders

#3

StarTech

StarTech

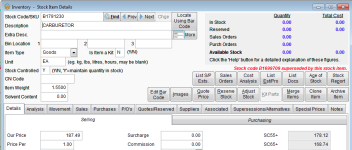

The two wire connector housing and terminals is what I replace here.

This is cheapest way to go.

One Molex 03-06-1023 Receptacle

Two Molex 02-06-1103 Pins

You also will need one Molex 02-08-1002 Socket for the 6 position Molex Receptacle along with tool to remove the old socket terminal. 5

These are available from Mouser, Inc. or at they are for me as I have an account with them. And I do buy enough to make several sets at a time.

Now of course you would a open barrel terminal crimper to professionally crimp the pins so they will fit the receptacle and some 18 ga wire.

But for a layman you are better buying the pre-made harness. As for us in a shop setting we can just the cost of the tools to do this but the parts excluding is all of two dollars for my customers. For one of the tools cost me $70 five years ago.

This is cheapest way to go.

One Molex 03-06-1023 Receptacle

Two Molex 02-06-1103 Pins

You also will need one Molex 02-08-1002 Socket for the 6 position Molex Receptacle along with tool to remove the old socket terminal. 5

These are available from Mouser, Inc. or at they are for me as I have an account with them. And I do buy enough to make several sets at a time.

Now of course you would a open barrel terminal crimper to professionally crimp the pins so they will fit the receptacle and some 18 ga wire.

But for a layman you are better buying the pre-made harness. As for us in a shop setting we can just the cost of the tools to do this but the parts excluding is all of two dollars for my customers. For one of the tools cost me $70 five years ago.

#4

E

Elkins45

E

Elkins45

The harness is $30 the cheapest I can find it. Crazy! Given that I have no idea if this engine will ever work I may just disable the solenoid and install a manual shutoff.The two wire connector housing and terminals is what I replace here.

This is cheapest way to go.

One Molex 03-06-1023 Receptacle

Two Molex 02-06-1103 Pins

You also will need one Molex 02-08-1002 Socket for the 6 position Molex Receptacle along with tool to remove the old socket terminal. 5

These are available from Mouser, Inc. or at they are for me as I have an account with them. And I do buy enough to make several sets at a time.

Now of course you would a open barrel terminal crimper to professionally crimp the pins so they will fit the receptacle and some 18 ga wire.

But for a layman you are better buying the pre-made harness. As for us in a shop setting we can just the cost of the tools to do this but the parts excluding is all of two dollars for my customers. For one of the tools cost me $70 five years ago.

#5

StarTech

StarTech

Just be aware the fuel solenoid on the carburetor only blocks the main nozzle/jet. It is not a fuel shut off device like the manual or vacuum shut off valve. It only mention to prevent the after fire (fuel detonation) in the exhaust system.

Instead destroying an expensive solenoid just replace it an appropriate screw as a temporary bypass.

Instead destroying an expensive solenoid just replace it an appropriate screw as a temporary bypass.

#6

E

Elkins45

E

Elkins45

Yeah, I’ve done a bunch of learning about them today. Frankly given the condition of the float bowl I would be amazed if the solenoid is functional. I really should replace the bowl too but I don’t want to throw money at an engine that may have other problems as well.Just be aware the fuel solenoid on the carburetor only blocks the main nozzle/jet. It is not a fuel shut off device like the manual or vacuum shut off valve. It only mention to prevent the after fire (fuel detonation) in the exhaust system.

Instead destroying an expensive solenoid just replace it an appropriate screw as a temporary bypass.

#7

StarTech

StarTech

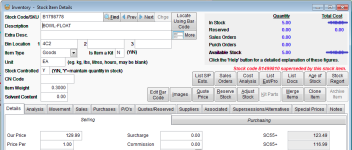

That 499810 fuel is NLA and replaced by 798778 with 841653 O-ring added. But there is one heck a sticker shock with it. I brought 6 of the fuel bowl before the major price hike.Currently the fuel bowl lists for $134.99 with my cost being around $122. But the ones I got on the shelf only cost $30.

#8

E

Elkins45

I can buy a complete Chinesium replacement carb for less than $30: https://www.ebay.com/itm/1446257038...DtHb3zdi8xOEI5IdTopfruXQxtbg-2UUaAmanEALw_wcB

E

Elkins45

I only paid $125 for the whole mower. I’m pretty sure I could pull a whole carb off a dead engine for less. As I said the main reason I bought the mower was for the deck and transmission. If I can get the mower running in the cheap then I will, but I’m not going to pour money into something that might never run.That 499810 fuel is NLA and replaced by 798778 with 841653 O-ring added. But there is one heck a sticker shock with it. I brought 6 of the fuel bowl before the major price hike.Currently the fuel bowl lists for $134.99 with my cost being around $122. But the ones I got on the shelf only cost $30.

I can buy a complete Chinesium replacement carb for less than $30: https://www.ebay.com/itm/1446257038...DtHb3zdi8xOEI5IdTopfruXQxtbg-2UUaAmanEALw_wcB

#9

O

OldDiyer

O

OldDiyer

The only problem is you buy the whole carb assy. but then you still need that harness or connectors to get it set up. Good Luck !!

#10

E

Elkins45

E

Elkins45

I’m 99% sure it won’t run 5 minutes before it throws off some scale from the bowl and clogs again even after aI sanded and flushed it with solvent. The most cost effective thing for me to do is disable the solenoid on the old carb and see if it will start and run. If it does then I’ll run It until it clogs, then buy the replacement carb and disable the solenoid on it. I’ll just use the manual shutoff to run the engine dry to stop it.The only problem is you buy the whole carb assy. but then you still need that harness or connectors to get it set up. Good Luck !!

#11

StarTech

StarTech

Some people think they can get something for basically nothing, patch it up, and resell it to someone else just to pass the problems along. I just repaired one mower this rigged up mowers and currently fighting with a 3010 UTV where the previous so called repairman rigged nearly everything up just to sell it to an unsuspecting person. I am already $2000 into the repairs but I thought I was about until I found that he glued the carburetor together.

Btw to clean a steel only bowl use Muriatic Acid or use electrolysis with white vinegar solution. First one is fast although it can produce toxic fumes and the second is slower but less dangerous.

Btw to clean a steel only bowl use Muriatic Acid or use electrolysis with white vinegar solution. First one is fast although it can produce toxic fumes and the second is slower but less dangerous.

#12

E

Elkins45

E

Elkins45

Not planning on selling it. I bought it for the deck and transmission. Getting the engine running would just be a bonus because I could use the mower itself rather than stripping it to fix my other one. I’m all for the option that means less work for me.Some people think they can get something for basically nothing, patch it up, and resell it to someone else just to pass the problems along. I just repaired one mower this rigged up mowers and currently fighting with a 3010 UTV where the previous so called repairman rigged nearly everything up just to sell it to an unsuspecting person. I am already $2000 into the repairs but I thought I was about until I found that he glued the carburetor together.

Btw to clean a steel only bowl use Muriatic Acid or use electrolysis with white vinegar solution. First one is fast although it can produce toxic fumes and the second is slower but less dangerous.

#13

B

bertsmobile1

Works a treat and of course washes off in water, better in hot water .

B

bertsmobile1

I use soda blaster on bowls.Some people think they can get something for basically nothing, patch it up, and resell it to someone else just to pass the problems along. I just repaired one mower this rigged up mowers and currently fighting with a 3010 UTV where the previous so called repairman rigged nearly everything up just to sell it to an unsuspecting person. I am already $2000 into the repairs but I thought I was about until I found that he glued the carburetor together.

Btw to clean a steel only bowl use Muriatic Acid or use electrolysis with white vinegar solution. First one is fast although it can produce toxic fumes and the second is slower but less dangerous.

Works a treat and of course washes off in water, better in hot water .

#14

B

bertsmobile1

IF yes then stuff an oily rag down the inlet manifold and either sell the engine as "has been run" or shove it in the back of your shed.

The solenoid can be replaced with a carb bowl bolt if it is used to hold the bowl on or a dob of silicon if it is a side mount one.

You can chop the plunger off but that destroys a $ 50 part or you can activate it with a square transistor battery

I test them with one of those 9 Volt batteries and it will hold it open for a couple of days .

TO connect it to the solenoid you can just use a pair of small aligator clips. bare wires & some heat shrink

I use some of those thin patch leads with an aligator clip on both ends for testing

B

bertsmobile1

Simple solution is to swap your carb for this one and see if the engine runsNot planning on selling it. I bought it for the deck and transmission. Getting the engine running would just be a bonus because I could use the mower itself rather than stripping it to fix my other one. I’m all for the option that means less work for me.

IF yes then stuff an oily rag down the inlet manifold and either sell the engine as "has been run" or shove it in the back of your shed.

The solenoid can be replaced with a carb bowl bolt if it is used to hold the bowl on or a dob of silicon if it is a side mount one.

You can chop the plunger off but that destroys a $ 50 part or you can activate it with a square transistor battery

I test them with one of those 9 Volt batteries and it will hold it open for a couple of days .

TO connect it to the solenoid you can just use a pair of small aligator clips. bare wires & some heat shrink

I use some of those thin patch leads with an aligator clip on both ends for testing

#15

StarTech

Fuel bowl kit came with the solenoid the last time I brought them.

StarTech

Kinda wish the solenoid was only $50 as Briggs no longer has the solenoid available and their solution is replace the whole carburetor assembly; although, there is a fuel bowl kit available although not noted in the IPL.Simple solution is to swap your carb for this one and see if the engine runs

IF yes then stuff an oily rag down the inlet manifold and either sell the engine as "has been run" or shove it in the back of your shed.

The solenoid can be replaced with a carb bowl bolt if it is used to hold the bowl on or a dob of silicon if it is a side mount one.

You can chop the plunger off but that destroys a $ 50 part or you can activate it with a square transistor battery

I test them with one of those 9 Volt batteries and it will hold it open for a couple of days .

TO connect it to the solenoid you can just use a pair of small aligator clips. bare wires & some heat shrink

I use some of those thin patch leads with an aligator clip on both ends for testing

Fuel bowl kit came with the solenoid the last time I brought them.

#16

S

slomo

S

slomo

Solder the wires on for free. Not puppy dog surgery here guys. No need for special connectors. Just a lawn mower....

Better yet, snip the solenoid plunger and use a fuel shut off valve. Never mess with this again. Another free tech tip Friday.

Better yet, snip the solenoid plunger and use a fuel shut off valve. Never mess with this again. Another free tech tip Friday.

#17

E

Elkins45

I‘m assuming the engine doesn’t run when the solenoid isn’t energized, right? Otherwise why have it?

E

Elkins45

I can’t just swap carbs because of the mangled connector. I’m either going to have to repair or hard wire the solenoid or I‘m going to have to disable it. I’m on the lookout for a short bolt with the correct threads just as soon as I find or grind down a thin wrench to turn off the solenoid.Simple solution is to swap your carb for this one and see if the engine runs

IF yes then stuff an oily rag down the inlet manifold and either sell the engine as "has been run" or shove it in the back of your shed.

The solenoid can be replaced with a carb bowl bolt if it is used to hold the bowl on or a dob of silicon if it is a side mount one.

You can chop the plunger off but that destroys a $ 50 part or you can activate it with a square transistor battery

I test them with one of those 9 Volt batteries and it will hold it open for a couple of days .

TO connect it to the solenoid you can just use a pair of small aligator clips. bare wires & some heat shrink

I use some of those thin patch leads with an aligator clip on both ends for testing

I‘m assuming the engine doesn’t run when the solenoid isn’t energized, right? Otherwise why have it?

#18

B

bertsmobile1

B

bertsmobile1

Yes the plunger is spring loaded out & the power pulls it back in .

The need for a thin wrench tells me your solenoid holds the bowl on the carb in which case you use a carb nut from an earlier non solenoid model .

As you are just testing the engine , the mangled connetor does not matter I mentioned two methods to make a temporary connection for testing purposes.

The need for a thin wrench tells me your solenoid holds the bowl on the carb in which case you use a carb nut from an earlier non solenoid model .

As you are just testing the engine , the mangled connetor does not matter I mentioned two methods to make a temporary connection for testing purposes.

#19

E

Elkins45

E

Elkins45

I managed to remove the solenoid and it turned out to be a moot point. The plunger was so rusted it wouldn’t move even with pliers and a dose of PB Blaster so I replaced it with a bolt. I’m going to reinstall the carb tomorrow morning and see what happens. Thanks for all the assistance.Yes the plunger is spring loaded out & the power pulls it back in .

The need for a thin wrench tells me your solenoid holds the bowl on the carb in which case you use a carb nut from an earlier non solenoid model .

As you are just testing the engine , the mangled connetor does not matter I mentioned two methods to make a temporary connection for testing purposes.

#21

S

slomo

S

slomo

What bone yards are you speaking about? Nothing around where I live. Would love a list of mower grave yards.find another carb in a bone yard