You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Briggs 17.5 HP, OHC Engine Locks Up!

- Thread starter brchad

- Start date

More options

Export threadbertsmobile1

Lawn Royalty

- Joined

- Nov 29, 2014

- Threads

- 65

- Messages

- 24,995

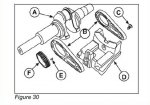

Check the counterweight and the counterweight con rod.

It is in 2 pieces with a single bolt that can shear or bend or come loose.

In fact I see more counter weight failures than crank failures

Also check there is not a little piece of the compression release stuck in the counterweight.

You also could have had a small piece of metal lodge in the gear teeth

It is in 2 pieces with a single bolt that can shear or bend or come loose.

In fact I see more counter weight failures than crank failures

Also check there is not a little piece of the compression release stuck in the counterweight.

You also could have had a small piece of metal lodge in the gear teeth

brchad

Member

- Joined

- Oct 26, 2017

- Threads

- 3

- Messages

- 34

That's fine.....so could a valve be open when the piston is at TDC..? (timing out)

EngineMan -

Not sure I understand the question. At this point....as I said .... the engine is almost totally apart. The head is off.... the rods are out .... the tappets are removed. Did I miss something?

Per your earlier suggestion.... I will be checking shortly to verify the position of the piston when it jams.

Thanks,

Bill

brchad

Member

- Joined

- Oct 26, 2017

- Threads

- 3

- Messages

- 34

Check the counterweight and the counterweight con rod.

It is in 2 pieces with a single bolt that can shear or bend or come loose.

In fact I see more counter weight failures than crank failures

Also check there is not a little piece of the compression release stuck in the counterweight.

You also could have had a small piece of metal lodge in the gear teeth

berts -

Thank you. I had briefly "studied" the counterweight early on... but it certainly could be one of those faulty presumptions I mentioned earlier. That also applies to the potential of a counterweight piece stuck in the counterweight. If there's a small piece lodged in the gear teeth.... it would have to be microscopic .... I checked and cleaned it. (I will still be getting the new one tomorrow, just to be sure.)

I'll be getting back to you shortly on the first two points.

Bill

brchad

Member

- Joined

- Oct 26, 2017

- Threads

- 3

- Messages

- 34

Well guys.... it's NOT the crank gear. Installed the new one.... still locking up.

Looks like the next step is bertsmobile1's suggestion to check the counterweight system.

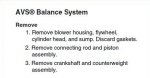

Unfortunately, my engine has the AVS Balance System.... so that means the counterweight bolt is located on the flywheel end. That means I'll have to pull the flywheel in order to access the bolt.

Tomorrow morning I am scheduled to have some pretty extensive oral surgery. (6-8 teeth pulled) Yuck!! So.... I have no idea how long it will be until I am able to get back into the engine.

In the meantime.... I want to thank everyone again for all of your suggestions and assistance. I'll be back to you as soon as I can eat Ice-cream!

Bill

Looks like the next step is bertsmobile1's suggestion to check the counterweight system.

Unfortunately, my engine has the AVS Balance System.... so that means the counterweight bolt is located on the flywheel end. That means I'll have to pull the flywheel in order to access the bolt.

Tomorrow morning I am scheduled to have some pretty extensive oral surgery. (6-8 teeth pulled) Yuck!! So.... I have no idea how long it will be until I am able to get back into the engine.

In the meantime.... I want to thank everyone again for all of your suggestions and assistance. I'll be back to you as soon as I can eat Ice-cream!

Bill

brchad

Member

- Joined

- Oct 26, 2017

- Threads

- 3

- Messages

- 34

UPDATE: Re: Briggs 17.5 HP, OHC Engine Locks Up!

Well, I survived my "Death by Dentist" experience and I was able to continue this "Engine Locks Up" adventure today.

Here is where I stand at this point:

As I mentioned earlier, I do believe that bertmobile1's suggestion to remove and inspect the counterbalance system (along with piston/rod in the process.)

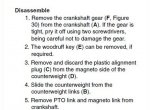

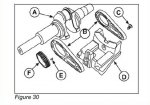

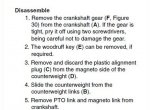

There are two different types of counterbalance systems for the 31C707 series. Earlier models use what B&S calls the "Synchro-Balance System" which is accessible by merely removing the bolt from the sump end. Later models utilize what B&S calls the "AVS System" which is somewhat more involved, since it requires removal of the flywheel. Of course.... my engine has the "AVS System!"

(Click thumbnail to enlarge)

The flywheel was a challenge (most are) but using a combination of different "tricks" I was able to pop it up and off without too much trouble. The next step was removal of the Connecting Rod bolts and cap. This is where I ran into a real challenge. I quickly realized that the bolts, with a round head, were torque bolts .... a T-40. I didn't have a decent T-40, so bought a new, good quality, 3/8"-T40. I noted that the torque spec for the bolt is 150 lb-in, so didn't expect it to be too difficult. WRONG!!! The first one was a real surprise. I started with a long handle ratchet ... and quickly saw that it was fruitless! I changed to a long pull bar and after a real struggle.... managed to crack it loose. The second one was even worse. I tried every trick in my bag to get that sucker off and nothing worked. I've worked on every size of engine... up to big block V-8's .... and NEVER ran across a bolt that tight.

I'm betting most of you can guess the outcome. Yep..... ace mechanic here, eventually, succeeded in buggering up the bolt head to the point where NO wrench is going to loosen it now!

So.... here I am ... back for more advice, suggestions, etc. I thought about vise grips... real tight .... pop with a mall. Alas, not able to get a firm grip with the vise grips. All I've been able to come up with is perhaps grinding off the bolt head.... sacrificing the rod, etc.

Any other ideas anyone? Again.... thanks for your help thus far!

Bill

Well, I survived my "Death by Dentist" experience and I was able to continue this "Engine Locks Up" adventure today.

Here is where I stand at this point:

As I mentioned earlier, I do believe that bertmobile1's suggestion to remove and inspect the counterbalance system (along with piston/rod in the process.)

There are two different types of counterbalance systems for the 31C707 series. Earlier models use what B&S calls the "Synchro-Balance System" which is accessible by merely removing the bolt from the sump end. Later models utilize what B&S calls the "AVS System" which is somewhat more involved, since it requires removal of the flywheel. Of course.... my engine has the "AVS System!"

(Click thumbnail to enlarge)

The flywheel was a challenge (most are) but using a combination of different "tricks" I was able to pop it up and off without too much trouble. The next step was removal of the Connecting Rod bolts and cap. This is where I ran into a real challenge. I quickly realized that the bolts, with a round head, were torque bolts .... a T-40. I didn't have a decent T-40, so bought a new, good quality, 3/8"-T40. I noted that the torque spec for the bolt is 150 lb-in, so didn't expect it to be too difficult. WRONG!!! The first one was a real surprise. I started with a long handle ratchet ... and quickly saw that it was fruitless! I changed to a long pull bar and after a real struggle.... managed to crack it loose. The second one was even worse. I tried every trick in my bag to get that sucker off and nothing worked. I've worked on every size of engine... up to big block V-8's .... and NEVER ran across a bolt that tight.

I'm betting most of you can guess the outcome. Yep..... ace mechanic here, eventually, succeeded in buggering up the bolt head to the point where NO wrench is going to loosen it now!

So.... here I am ... back for more advice, suggestions, etc. I thought about vise grips... real tight .... pop with a mall. Alas, not able to get a firm grip with the vise grips. All I've been able to come up with is perhaps grinding off the bolt head.... sacrificing the rod, etc.

Any other ideas anyone? Again.... thanks for your help thus far!

Bill

ILENGINE

Lawn Royalty

- Joined

- May 6, 2010

- Threads

- 51

- Messages

- 11,426

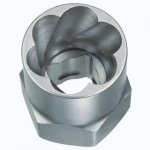

Had one in the shop several years ago that did the exact same thing. Had to grind the head of the bolt off to get it apart. I now have some of those twisted spline looking bolt extractors, so maybe something like that would grip the rounded head and get it free.

brchad

Member

- Joined

- Oct 26, 2017

- Threads

- 3

- Messages

- 34

Had one in the shop several years ago that did the exact same thing. Had to grind the head of the bolt off to get it apart. I now have some of those twisted spline looking bolt extractors, so maybe something like that would grip the rounded head and get it free.

Checked on Google.... made a 5 minute drive to Advanced Auto and purchased the kit for $17.00:

https://shop.advanceautoparts.com/p/irwin-bolt-out-with-case-394001/9010233-P?searchTerm=bolt+extractor

Here's what the actual extractor looks like:

Attached the 1/2" extractor to my pull bar.... snugged it into place on the connector bolt.... a TAH DAH!! Popped loose with about a quarter turn!

Kudos to you ILENGINE!! Just goes to show you.... us old farts need to stay informed on new technology! LOL!!

Thanks a ton for the tip! Now.... back to work to see what else I can try to break! Ha!

Bill

ILENGINE

Lawn Royalty

- Joined

- May 6, 2010

- Threads

- 51

- Messages

- 11,426

That is the tool I was thinking of. Comes in handy when you need them. I have used my set to remove more than one allen head bolt on the camshaft cover of yamaha atv's and the lug nuts on an arctic cat atv. Seems like there has been other uses that I can't think of right now.

brchad

Member

- Joined

- Oct 26, 2017

- Threads

- 3

- Messages

- 34

UPDATE - Re: Briggs 17.5 HP, OHC Engine Locks Up!

Well... I now have the entire engine in parts!

I was pleasantly surprised at what I found. The piston/rings/rod were all in excellent shape. More importantly.... the crankshaft journals, throughout, were like new... no discoloration.... nice and smooth with minimal detectable wear.

Here's the good news.... arising from the bad. Inspection of the AVS counterbalance assembly was a different story. At first glance, I couldn't imagine that anything was wrong. WRONG! Upon closer inspection, the PTO side Counterweight Link appeared loose... and when I tried to rotate it on the crank, it would gall up in places. The one on the Flywheel end turned freely. When I removed the one on the PTO side, I immediately noted that the pin was discolored (black burn/wear marks) while the other side was nice and clean. My assumption at this point is that the pin and the link are both bad. This could certainly account for the "lock up" that brought me this far!

I ordered new Counterweight Links and Pins for both sides.... along with the two Connecting Rod bolts that were ruined... seals, gaskets, etc.

Thanks again to all who have helped me here. I really appreciate it.

The parts arrive on Thursday. I'll be back with the news sometime soon after.

Bill

Well... I now have the entire engine in parts!

I was pleasantly surprised at what I found. The piston/rings/rod were all in excellent shape. More importantly.... the crankshaft journals, throughout, were like new... no discoloration.... nice and smooth with minimal detectable wear.

Here's the good news.... arising from the bad. Inspection of the AVS counterbalance assembly was a different story. At first glance, I couldn't imagine that anything was wrong. WRONG! Upon closer inspection, the PTO side Counterweight Link appeared loose... and when I tried to rotate it on the crank, it would gall up in places. The one on the Flywheel end turned freely. When I removed the one on the PTO side, I immediately noted that the pin was discolored (black burn/wear marks) while the other side was nice and clean. My assumption at this point is that the pin and the link are both bad. This could certainly account for the "lock up" that brought me this far!

I ordered new Counterweight Links and Pins for both sides.... along with the two Connecting Rod bolts that were ruined... seals, gaskets, etc.

Thanks again to all who have helped me here. I really appreciate it.

The parts arrive on Thursday. I'll be back with the news sometime soon after.

Bill