Cusser

Well-Known Member

- Joined

- May 3, 2019

- Threads

- 16

- Messages

- 247

I have a Craftsman 42" lawn tractor, purchased new in 2005. Mine has a B&S engine though. I haven't had issues with removing the blade bolts, but then in Arizona we don't get rust.I bought a well-used Craftsman Riding Mower last year. It has it's share of problems for sure and no doubt any routine maintenance that ever needed to be done, needs done on this gem!

The blades obviously need sharpened, and I tried moving a couple of them with a ratchet + 9/16 socket. Wouldn't budge at all, so I put a cheater bar on them and pushed them about as far as I feel comfortable with at that moment.

I did a search here, and found a couple of you all could give me a 'good idea' on if the bolts are right-handed or left-handed, possibly.

Specifically the model number is: 917.273050, found it nice and clear on the plate under the seat.

(20 HP Kohler CV20S-65551 I'm pretty sure is what the faded tag for the engine says)

Best I can tell is right-handed from what I have found so far, but thought it wouldn't hurt to ask.

I think I might go get a Harbor Freight impact driver tomorrow as well. I have a good cheater bar, but I think my odds are better of not snapping a bolt with impact, correct?

They are on the second day of an ample PBlaster soak also.

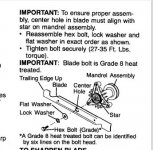

I use a 1/2" drive ratchet with a 9/16" socket (six-sided). Yes, these bolts are tight, and supposed to be tight, are fine thread and supposedly specially hardened, and are right hand thread. I disconnect the spark plug wire for safety, put on work gloves, and hold the blade with one gloved hand and the ratchet in the other, and pull the bade and ratchet towards each other. I have never needed to try a 1/2" breaker bar or my 1/2" drive electric impact wrench.

Nowadays, I do have a Harbor Freight lawn tractor jack, which I really like, so I can actually see what I'm doing, better than wedging a 2x4 under the deck to access the blade bolts.