You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Bolt Threading for Blade Removal

#1

O

Overcast451

O

Overcast451

I bought a well-used Craftsman Riding Mower last year. It has it's share of problems for sure and no doubt any routine maintenance that ever needed to be done, needs done on this gem!

The blades obviously need sharpened, and I tried moving a couple of them with a ratchet + 9/16 socket. Wouldn't budge at all, so I put a cheater bar on them and pushed them about as far as I feel comfortable with at that moment.

I did a search here, and found a couple of you all could give me a 'good idea' on if the bolts are right-handed or left-handed, possibly.

Specifically the model number is: 917.273050, found it nice and clear on the plate under the seat.

(20 HP Kohler CV20S-65551 I'm pretty sure is what the faded tag for the engine says)

Best I can tell is right-handed from what I have found so far, but thought it wouldn't hurt to ask.

I think I might go get a Harbor Freight impact driver tomorrow as well. I have a good cheater bar, but I think my odds are better of not snapping a bolt with impact, correct?

They are on the second day of an ample PBlaster soak also.

The blades obviously need sharpened, and I tried moving a couple of them with a ratchet + 9/16 socket. Wouldn't budge at all, so I put a cheater bar on them and pushed them about as far as I feel comfortable with at that moment.

I did a search here, and found a couple of you all could give me a 'good idea' on if the bolts are right-handed or left-handed, possibly.

Specifically the model number is: 917.273050, found it nice and clear on the plate under the seat.

(20 HP Kohler CV20S-65551 I'm pretty sure is what the faded tag for the engine says)

Best I can tell is right-handed from what I have found so far, but thought it wouldn't hurt to ask.

I think I might go get a Harbor Freight impact driver tomorrow as well. I have a good cheater bar, but I think my odds are better of not snapping a bolt with impact, correct?

They are on the second day of an ample PBlaster soak also.

#2

B

bertsmobile1

B

bertsmobile1

all right hand cut blades have right hand threads

All left hand cut blades have left hand thread

There will probably be an exception, but not on a craftsman

All left hand cut blades have left hand thread

There will probably be an exception, but not on a craftsman

#3

7394

7394

Spray some good penetration oil around the bolts first,.................. then go get yer impact @ Harbor (giving time to hopefully help things),.

#4

sgkent

sgkent

penetrating oil and stop as the bolt seizes up then go back the other way a little and slowly work it out.

#6

ILENGINE

ILENGINE

Sometimes OEM's put loctite is the strangest and most inconvenient places. Worked on a brand of chainsaws a few years back that used red heat release loctite on the threads of the clutch that you had to remove to replace the sprocket.Bolt (3/8-24 x 1.25) right hand threading. Image of bolt show is shows it to have a Loctite patch. Why the OEM started using a Loctite patch is not known here.

View attachment 60115

#7

StarTech

Its like the Homelite chainsaw I had to replace the ignition coil on back before 2015 where they use red Loctitle on the screws. I most didn't get the screw out. I had broke off the head of the screw.

StarTech

Agree.Sometimes OEM's put loctite is the strangest and most inconvenient places. Worked on a brand of chainsaws a few years back that used red heat release loctite on the threads of the clutch that you had to remove to replace the sprocket.

Its like the Homelite chainsaw I had to replace the ignition coil on back before 2015 where they use red Loctitle on the screws. I most didn't get the screw out. I had broke off the head of the screw.

#8

ILENGINE

ILENGINE

@StarTech Nothing like red loctite on screws that are secured into aluminum. Can't get it hot enough to release it without damaging other components due to heat sink, or you destroy the fastener trying to remove it, or just pull the threads out of the aluminum case.

#9

StarTech

StarTech

Or like the red loctite that Cat wants you to use on their pressure washer pump heads. I had one that I was rebuilding when one of the caps locked in place before I even got it torqued. I ended up destroying the cap to get it off even with me using heat sparely due plastic check valves. And that all brass threads. Ever since I switched to blue Loctite for those caps. Maybe I shouldn't used the surface prep spray with the Loctite.

#10

O

Overcast451

Awesome, thanks for all the input all! Yeah, they have been soaking in PBlaster for a couple days now. Assuming I can get them to budge at all, I will do that.

O

Overcast451

penetrating oil and stop as the bolt seizes up then go back the other way a little and slowly work it out.

Awesome, thanks for all the input all! Yeah, they have been soaking in PBlaster for a couple days now. Assuming I can get them to budge at all, I will do that.

#11

Cusser

I use a 1/2" drive ratchet with a 9/16" socket (six-sided). Yes, these bolts are tight, and supposed to be tight, are fine thread and supposedly specially hardened, and are right hand thread. I disconnect the spark plug wire for safety, put on work gloves, and hold the blade with one gloved hand and the ratchet in the other, and pull the bade and ratchet towards each other. I have never needed to try a 1/2" breaker bar or my 1/2" drive electric impact wrench.

Nowadays, I do have a Harbor Freight lawn tractor jack, which I really like, so I can actually see what I'm doing, better than wedging a 2x4 under the deck to access the blade bolts.

Cusser

I have a Craftsman 42" lawn tractor, purchased new in 2005. Mine has a B&S engine though. I haven't had issues with removing the blade bolts, but then in Arizona we don't get rust.I bought a well-used Craftsman Riding Mower last year. It has it's share of problems for sure and no doubt any routine maintenance that ever needed to be done, needs done on this gem!

The blades obviously need sharpened, and I tried moving a couple of them with a ratchet + 9/16 socket. Wouldn't budge at all, so I put a cheater bar on them and pushed them about as far as I feel comfortable with at that moment.

I did a search here, and found a couple of you all could give me a 'good idea' on if the bolts are right-handed or left-handed, possibly.

Specifically the model number is: 917.273050, found it nice and clear on the plate under the seat.

(20 HP Kohler CV20S-65551 I'm pretty sure is what the faded tag for the engine says)

Best I can tell is right-handed from what I have found so far, but thought it wouldn't hurt to ask.

I think I might go get a Harbor Freight impact driver tomorrow as well. I have a good cheater bar, but I think my odds are better of not snapping a bolt with impact, correct?

They are on the second day of an ample PBlaster soak also.

I use a 1/2" drive ratchet with a 9/16" socket (six-sided). Yes, these bolts are tight, and supposed to be tight, are fine thread and supposedly specially hardened, and are right hand thread. I disconnect the spark plug wire for safety, put on work gloves, and hold the blade with one gloved hand and the ratchet in the other, and pull the bade and ratchet towards each other. I have never needed to try a 1/2" breaker bar or my 1/2" drive electric impact wrench.

Nowadays, I do have a Harbor Freight lawn tractor jack, which I really like, so I can actually see what I'm doing, better than wedging a 2x4 under the deck to access the blade bolts.

#12

StarTech

StarTech

My HFT mower jack is modified now as that ATV saddle just kept getting in the way. Plus on CC ZTRs I have to use 2x8s so the deck can clear the jack foot. Besides try getting the jack under a broke down ATV, very hard to slide under one without the jack having spring loaded dolly wheels.

Oh on that Craftsman the blade bolts are only torqued to 55 ft/lbs.

Oh on that Craftsman the blade bolts are only torqued to 55 ft/lbs.

#13

O

Overcast451

Well for this one, I removed the deck entirely to give it a good cleaning and all the belts need replaced anyway. Last season they jumped off and I put them back on - was enough to finish up the last cut of the year at least. I bought a new spring for the pulley that keeps tension on the belts, along with new belts.

They really don't look too awful rusted, but I'm sure that's a bit of a factor - being in Indiana.

O

Overcast451

I have a Craftsman 42" lawn tractor, purchased new in 2005. Mine has a B&S engine though. I haven't had issues with removing the blade bolts, but then in Arizona we don't get rust.

I use a 1/2" drive ratchet with a 9/16" socket (six-sided). Yes, these bolts are tight, and supposed to be tight, are fine thread and supposedly specially hardened, and are right hand thread. I disconnect the spark plug wire for safety, put on work gloves, and hold the blade with one gloved hand and the ratchet in the other, and pull the bade and ratchet towards each other. I have never needed to try a 1/2" breaker bar or my 1/2" drive electric impact wrench.

Nowadays, I do have a Harbor Freight lawn tractor jack, which I really like, so I can actually see what I'm doing, better than wedging a 2x4 under the deck to access the blade bolts.

Well for this one, I removed the deck entirely to give it a good cleaning and all the belts need replaced anyway. Last season they jumped off and I put them back on - was enough to finish up the last cut of the year at least. I bought a new spring for the pulley that keeps tension on the belts, along with new belts.

They really don't look too awful rusted, but I'm sure that's a bit of a factor - being in Indiana.

#14

7394

7394

IIRC Craftsman blade bolts torque to 50 ft lbs..

Scag is between 75 ft lbs & 100 ft lbs. Never used any thread locker on either of these.

Scag is between 75 ft lbs & 100 ft lbs. Never used any thread locker on either of these.

#15

O

Overcast451

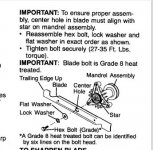

The manual actually lists 27-35 ft lbs. Seems a bit light though, really. I wouldn't use thread locker in most cases, unless it's something I don't plan on removing for a very long time again. I will probably give the bolts a good scrub with a wire brush for good measure either way, if and when I get them out.

This should be the right manual also, found it using the specific model number on the Sears parts site.

O

Overcast451

IIRC Craftsman blade bolts torque to 50 ft lbs..

Scag is between 75 ft lbs & 100 ft lbs. Never used any thread locker on either of these.

The manual actually lists 27-35 ft lbs. Seems a bit light though, really. I wouldn't use thread locker in most cases, unless it's something I don't plan on removing for a very long time again. I will probably give the bolts a good scrub with a wire brush for good measure either way, if and when I get them out.

This should be the right manual also, found it using the specific model number on the Sears parts site.

#16

7394

7394

Good info, but back about 15 yrs or so, I had a craftsman rider & the book listed blade torque to 50 ft lbs.. 27 -35 ft lb does seem light.. But maybe I don't remember that one so well.

Now my current Scag® cutter does spec the cutter blade bolts to 75 ft lbs. But if using hi-lift blades, torque to 100 ft lbs. I just double checked,..

Now my current Scag® cutter does spec the cutter blade bolts to 75 ft lbs. But if using hi-lift blades, torque to 100 ft lbs. I just double checked,..

#17

Cusser

27-35 ft lbs is also listed in the owner's manual for my 2005-purchased LT1000. I do admit that even though I have a torque wrench, I have never used it for the bolt/blade install.

Cusser

The manual actually lists 27-35 ft lbs.

View attachment 60130

27-35 ft lbs is also listed in the owner's manual for my 2005-purchased LT1000. I do admit that even though I have a torque wrench, I have never used it for the bolt/blade install.

#19

oldlawnguy

oldlawnguy

Maybe you have already done this since you stated this mower needs some maintenance.

Have you dropped the deck from the mower to get at the blades? It is much easier to flip the deck over, use about 6" of a 2x4 to wedge blade against deck wall as you use 1 hand on bolt socket and other hand on wrench to loosen bolt.

You will also be able to inspect/clean deck assembly for other issues and easily look at the belts, idler pullies etc.

Have you dropped the deck from the mower to get at the blades? It is much easier to flip the deck over, use about 6" of a 2x4 to wedge blade against deck wall as you use 1 hand on bolt socket and other hand on wrench to loosen bolt.

You will also be able to inspect/clean deck assembly for other issues and easily look at the belts, idler pullies etc.

#20

B

BTBO

B

BTBO

If you haven't been able to loosen the bolt yet, try heating the housing slightly to expand it with a propane torch, moving it around to spread the heat evenly. Then whack it (the bolt head) a few times with a hammer to help the process. If that works, apply some NevrSieze or similar product to the bolt threads----guaranteed not to ever have problems removing the bolt again.I bought a well-used Craftsman Riding Mower last year. It has it's share of problems for sure and no doubt any routine maintenance that ever needed to be done, needs done on this gem!

The blades obviously need sharpened, and I tried moving a couple of them with a ratchet + 9/16 socket. Wouldn't budge at all, so I put a cheater bar on them and pushed them about as far as I feel comfortable with at that moment.

I did a search here, and found a couple of you all could give me a 'good idea' on if the bolts are right-handed or left-handed, possibly.

Specifically the model number is: 917.273050, found it nice and clear on the plate under the seat.

(20 HP Kohler CV20S-65551 I'm pretty sure is what the faded tag for the engine says)

Best I can tell is right-handed from what I have found so far, but thought it wouldn't hurt to ask.

I think I might go get a Harbor Freight impact driver tomorrow as well. I have a good cheater bar, but I think my odds are better of not snapping a bolt with impact, correct?

They are on the second day of an ample PBlaster soak also.

#21

7394

7394

That would be hard on the grease seal.. I wouldn't advise heat. But that's me..try heating the housing slightly to expand it with a propane torch, moving it around to spread the heat evenly.

#22

R

RayMcD

R

RayMcD

I bought a well-used Craftsman Riding Mower last year. It has it's share of problems for sure and no doubt any routine maintenance that ever needed to be done, needs done on this gem!

The blades obviously need sharpened, and I tried moving a couple of them with a ratchet + 9/16 socket. Wouldn't budge at all, so I put a cheater bar on them and pushed them about as far as I feel comfortable with at that moment.

I did a search here, and found a couple of you all could give me a 'good idea' on if the bolts are right-handed or left-handed, possibly.

Specifically the model number is: 917.273050, found it nice and clear on the plate under the seat.

(20 HP Kohler CV20S-65551 I'm pretty sure is what the faded tag for the engine says)

Best I can tell is right-handed from what I have found so far, but thought it wouldn't hurt to ask.

I think I might go get a Harbor Freight impact driver tomorrow as well. I have a good cheater bar, but I think my odds are better of not snapping a bolt with impact, correct?

They are on the second day of an ample PBlaster soak also.

#23

R

RayMcD

Best penetrating oil on the planet, r

R

RayMcD

I bought a well-used Craftsman Riding Mower last year. It has it's share of problems for sure and no doubt any routine maintenance that ever needed to be done, needs done on this gem!

The blades obviously need sharpened, and I tried moving a couple of them with a ratchet + 9/16 socket. Wouldn't budge at all, so I put a cheater bar on them and pushed them about as far as I feel comfortable with at that moment.

I did a search here, and found a couple of you all could give me a 'good idea' on if the bolts are right-handed or left-handed, possibly.

Specifically the model number is: 917.273050, found it nice and clear on the plate under the seat.

(20 HP Kohler CV20S-65551 I'm pretty sure is what the faded tag for the engine says)

Best I can tell is right-handed from what I have found so far, but thought it wouldn't hurt to ask.

I think I might go get a Harbor Freight impact driver tomorrow as well. I have a good cheater bar, but I think my odds are better of not snapping a bolt with impact, correct?

They are on the second day of an ample PBlaster soak also.

Best penetrating oil on the planet, r