You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

422707-121401 sump gasket

#1

McTurff

McTurff

I have to put a new sump gasket and governor in my 422707-121401 Briggs

Engine is off machine and on bench 6 bolts removed from sump!

This thing is on tight rubber mallet not working don't want to damage anything any ideas

Afraid to keep beating on it!

Engine is off machine and on bench 6 bolts removed from sump!

This thing is on tight rubber mallet not working don't want to damage anything any ideas

Afraid to keep beating on it!

Attachments

#2

S

SeniorCitizen

S

SeniorCitizen

You take the wife's best big sharpest kitchen knife and place the sharp edge on which side of the gasket you like . Then you use the hammer to tap -tap - tap the back edge of the blade . If necessary work around .

#3

R

Rivets

R

Rivets

Before doing anything more remove the key and bolt. Then take some medium/fine abrasive paper and polish the crankshaft until it is smooth and shiny. Wipe clean with an oily rag and the sump cover should slide right off.

#4

ILENGINE

ILENGINE

there should be a total of 7 bolts/studs holding the sump on. Check down those deep hole above and below the crankshaft. I think you are missing a fastener which is holding the sump on.

#5

McTurff

I keep all knifes away from my wife!

Thanks

The reason I'm took motor out is because I belive the governor arm is shot and small gasket leak!

I have adjusted and set governor arm every which way and the engine just goes wide open throttle

I can choke it to control rpms and manually adjust throttle but can't get it to smooth out!

So I decided to put motor back on to go over everything again!

McTurff

Yup had the knife outYou take the wife's best big sharpest kitchen knife and place the sharp edge on which side of the gasket you like . Then you use the hammer to tap -tap - tap the back edge of the blade . If necessary work around .

I keep all knifes away from my wife!

Thanks

I'm taking a step back and can use some help!Before doing anything more remove the key and bolt. Then take some medium/fine abrasive paper and polish the crankshaft until it is smooth and shiny. Wipe clean with an oily rag and the sump cover should slide right off.

The reason I'm took motor out is because I belive the governor arm is shot and small gasket leak!

I have adjusted and set governor arm every which way and the engine just goes wide open throttle

I can choke it to control rpms and manually adjust throttle but can't get it to smooth out!

So I decided to put motor back on to go over everything again!

Thanks wasn't sure that one in the hole was a fastener!there should be a total of 7 bolts/studs holding the sump on. Check down those deep hole above and below the crankshaft. I think you are missing a fastener which is holding the sump on.

#6

Tiger Small Engine

Tiger Small Engine

Take a heat gun and run it around the two halves of engine case where gasket is.Yup had the knife out

I keep all knifes away from my wife!

Thanks

I'm taking a step back and can use some help!

The reason I'm took motor out is because I belive the governor arm is shot and small gasket leak!

I have adjusted and set governor arm every which way and the engine just goes wide open throttle

I can choke it to control rpms and manually adjust throttle but can't get it to smooth out!

So I decided to put motor back on to go over everything again!

Thanks wasn't sure that one in the hole was a fastener!

#7

A

Auto Doc's

A

Auto Doc's

Check the throttle plate and make sure a screw has not come loose. I've seen it happen a couple of times. The throttle blade gets wedged in the bore. The screw likely got sucked into the engine and rattled around between the piston and the head.

#8

McTurff

But dose not move with Throttle control

Will only stay at WOT

should the Throttle plate open and close with Throttle control when engine off?

Or is it controlled by the govenor?

Meaning say on my OHV engines the Throttle control opens and closes the throttle plate or butterfly freely!

This is my first opposed twin so its messing with my head but just working through best I can!

McTurff

Throttle plate functions and good!Check the throttle plate and make sure a screw has not come loose. I've seen it happen a couple of times. The throttle blade gets wedged in the bore. The screw likely got sucked into the engine and rattled around between the piston and the head.

But dose not move with Throttle control

Will only stay at WOT

should the Throttle plate open and close with Throttle control when engine off?

Or is it controlled by the govenor?

Meaning say on my OHV engines the Throttle control opens and closes the throttle plate or butterfly freely!

This is my first opposed twin so its messing with my head but just working through best I can!

#10

McTurff

McTurff

Yes all springs in place and correct i have looked at every picture on net and manuals looked at every video I can find and tried everything that's why I'm still thinking its the governor?Is the governor arm pull back spring in place?

#11

F

Forest#2

F

Forest#2

Step back and look before you break it.

Most likely another fastener. If you beat on it or use knives with force you will find out why AFTER IT'S WARPED OR BROKEN.

If you see any bolt heads in the deep holes they need to come out also.

Most likely another fastener. If you beat on it or use knives with force you will find out why AFTER IT'S WARPED OR BROKEN.

If you see any bolt heads in the deep holes they need to come out also.

#12

A

Auto Doc's

A

Auto Doc's

Check this out:

www.partstree.com

www.partstree.com

PartsTree - Home of OEM Parts for Outdoor Power Equipment

We are committed to providing you with the largest selection of OEM parts from the best brands, the best diagrams and part search tools anywhere.

www.partstree.com

www.partstree.com

#13

McTurff

Thanks

McTurff

Got it i found the fastenerStep back and look before you break it.

Most likely another fastener. If you beat on it or use knives with force you will find out why AFTER IT'S WARPED OR BROKEN.

If you see any bolt heads in the deep holes they need to come out also.

Thanks

#14

McTurff

I have New Governor gear crankcase gasket and oil seal ready to go!

McTurff

Thanks Auto Doc'sCheck this out:

PartsTree - Home of OEM Parts for Outdoor Power Equipment

We are committed to providing you with the largest selection of OEM parts from the best brands, the best diagrams and part search tools anywhere.www.partstree.com

I have New Governor gear crankcase gasket and oil seal ready to go!

#15

McTurff

No change!

Opened engine and Governor is fine everything inside good so new gasket fixed small leak so I'm in better shape there!

I had a new carb and put it on adjusted governor and no change engine racing so I'm still stumped or doing something wrong all linkages the same!

Engine fires right up but no control of throttle!

I can only choke to get it to slow down but that's not going to work!

I have not found a video on tuning one of these engines unless I'm missing something!

McTurff

Ok here is where I'm at!Check this out:

PartsTree - Home of OEM Parts for Outdoor Power Equipment

We are committed to providing you with the largest selection of OEM parts from the best brands, the best diagrams and part search tools anywhere.www.partstree.com

No change!

Opened engine and Governor is fine everything inside good so new gasket fixed small leak so I'm in better shape there!

I had a new carb and put it on adjusted governor and no change engine racing so I'm still stumped or doing something wrong all linkages the same!

Engine fires right up but no control of throttle!

I can only choke to get it to slow down but that's not going to work!

I have not found a video on tuning one of these engines unless I'm missing something!

#16

A

Auto Doc's

A

Auto Doc's

Have you actually looked at the carburetor throttle plate? I have seen them come off and get trapped in the intake port before. That is all that is left.

#17

McTurff

Could it Be sucking air someplace??

Would that cause it to run WOT?

McTurff

Plate is fineHave you actually looked at the carburetor throttle plate? I have seen them come off and get trapped in the intake port before. That is all that is left.

Could it Be sucking air someplace??

Would that cause it to run WOT?

#18

A

Auto Doc's

A

Auto Doc's

Is the governor link hooked to the throttle? An engine cannot run wide open with a closed throttle. Are you sure the governor adjustment is correct?

#19

McTurff

Govenor adjustment is a basic setting and pretty hard to get it wrong

Only one way to do it!

If its wrong nothing moves??

Anyway I have adjusted the governor many times to see if it changes anything

Nope

McTurff

The governor holds the throttle plate wide open i thought and will pull it closed as motor runs??Is the governor link hooked to the throttle? An engine cannot run wide open with a closed throttle. Are you sure the governor adjustment is correct?

Govenor adjustment is a basic setting and pretty hard to get it wrong

Only one way to do it!

If its wrong nothing moves??

Anyway I have adjusted the governor many times to see if it changes anything

Nope

#20

B

bentrim

B

bentrim

The engine speed is controlled by a balancing act between the governor and the governor spring. When the engine is running the governor should pull the carburetor closed, when you start the engine is there any force opposing the sparing? Trying to close the throttle?

Can you hold the governor linkage to idle and does the engine idle down? If so the governor is not working or the wrong spring is on the governor arm.

How are you adjusting the governor (or syching it to the carb)? With the control wide open, the carburetor should be wide open. Note which way the governor shaft turns to open the then throttle. Turn the shaft that direction as far as it will go, now tighten the pinch bolt Governor is now adjusted. Try to move the linkage to idle if it does not move you turned the shaft the wrong way. The linkage should move freely with no rough spots or hang ups.

NOTES. Aproperly adjusted governor should not cause surging. A lean mixture will cause surging. A carburetor cleaning may be needed.

If after properly adjusting the carb and even moving the linkage to idle does not controll the engine speed check the carbfor a loose throttle plate or a broken throttle shaft, or even the control lever loose on the shaft.

When the engine shuts off the governor naturally stops functioning and the arm will pulled to wide open by the spring, on starting the governor starts "working" and overcomes the spring closing the throttle plate to maintain set speed.

Can you hold the governor linkage to idle and does the engine idle down? If so the governor is not working or the wrong spring is on the governor arm.

How are you adjusting the governor (or syching it to the carb)? With the control wide open, the carburetor should be wide open. Note which way the governor shaft turns to open the then throttle. Turn the shaft that direction as far as it will go, now tighten the pinch bolt Governor is now adjusted. Try to move the linkage to idle if it does not move you turned the shaft the wrong way. The linkage should move freely with no rough spots or hang ups.

NOTES. Aproperly adjusted governor should not cause surging. A lean mixture will cause surging. A carburetor cleaning may be needed.

If after properly adjusting the carb and even moving the linkage to idle does not controll the engine speed check the carbfor a loose throttle plate or a broken throttle shaft, or even the control lever loose on the shaft.

When the engine shuts off the governor naturally stops functioning and the arm will pulled to wide open by the spring, on starting the governor starts "working" and overcomes the spring closing the throttle plate to maintain set speed.

#21

F

Forest#2

F

Forest#2

Have you looked at the Briggs and Stratton L-Head OPPOSED TWIN service manual 271172?

You can find one on-line to review the Governor settings and look at carb/gov linkages, adjustments, pg 54-69

You can find one on-line to review the Governor settings and look at carb/gov linkages, adjustments, pg 54-69

#22

McTurff

Has to be something in the linkages

Hopefully can figure this out!

McTurff

Thanks will be going through it again todayThe engine speed is controlled by a balancing act between the governor and the governor spring. When the engine is running the governor should pull the carburetor closed, when you start the engine is there any force opposing the sparing? Trying to close the throttle?

Can you hold the governor linkage to idle and does the engine idle down? If so the governor is not working or the wrong spring is on the governor arm.

How are you adjusting the governor (or syching it to the carb)? With the control wide open, the carburetor should be wide open. Note which way the governor shaft turns to open the then throttle. Turn the shaft that direction as far as it will go, now tighten the pinch bolt Governor is now adjusted. Try to move the linkage to idle if it does not move you turned the shaft the wrong way. The linkage should move freely with no rough spots or hang ups.

NOTES. Aproperly adjusted governor should not cause surging. A lean mixture will cause surging. A carburetor cleaning may be needed.

If after properly adjusting the carb and even moving the linkage to idle does not controll the engine speed check the carbfor a loose throttle plate or a broken throttle shaft, or even the control lever loose on the shaft.

When the engine shuts off the governor naturally stops functioning and the arm will pulled to wide open by the spring, on starting the governor starts "working" and overcomes the spring closing the throttle plate to maintain set speed.

Has to be something in the linkages

Hopefully can figure this out!

#23

McTurff

McTurff

Thanks will review againHave you looked at the Briggs and Stratton L-Head OPPOSED TWIN service manual 271172?

You can find one on-line to review the Governor settings and look at carb/gov linkages, adjustments, pg 54-69

#24

McTurff

All springs in place ect

The original carb is fine and put new one on to test that way!

The engine was opened as my earlier post indicated to find governor in tact!

The governor spring pulls trottle plate to wide open!

Today I put a wire on governor arm to control it and bring it to idle

And I can so I'm stumped because when I opened engine as stated in earlier post the governor gear inside was in perfect condition???

I did not touch gear or move anything inside engine when opened so I'm wondering is something with governor still has a problem inside!

McTurff

Everything you mentioned i have doneThe engine speed is controlled by a balancing act between the governor and the governor spring. When the engine is running the governor should pull the carburetor closed, when you start the engine is there any force opposing the sparing? Trying to close the throttle?

Can you hold the governor linkage to idle and does the engine idle down? If so the governor is not working or the wrong spring is on the governor arm.

How are you adjusting the governor (or syching it to the carb)? With the control wide open, the carburetor should be wide open. Note which way the governor shaft turns to open the then throttle. Turn the shaft that direction as far as it will go, now tighten the pinch bolt Governor is now adjusted. Try to move the linkage to idle if it does not move you turned the shaft the wrong way. The linkage should move freely with no rough spots or hang ups.

NOTES. Aproperly adjusted governor should not cause surging. A lean mixture will cause surging. A carburetor cleaning may be needed.

If after properly adjusting the carb and even moving the linkage to idle does not controll the engine speed check the carbfor a loose throttle plate or a broken throttle shaft, or even the control lever loose on the shaft.

When the engine shuts off the governor naturally stops functioning and the arm will pulled to wide open by the spring, on starting the governor starts "working" and overcomes the spring closing the throttle plate to maintain set speed.

All springs in place ect

The original carb is fine and put new one on to test that way!

The engine was opened as my earlier post indicated to find governor in tact!

The governor spring pulls trottle plate to wide open!

Today I put a wire on governor arm to control it and bring it to idle

And I can so I'm stumped because when I opened engine as stated in earlier post the governor gear inside was in perfect condition???

I did not touch gear or move anything inside engine when opened so I'm wondering is something with governor still has a problem inside!

#25

B

bentrim

B

bentrim

You stated you were able to bring it back to idle by using a wire -- does the governor are try to pull it back to idle? If not there could be one of two issues. Governor not adjusted properly which you said you did, or the internal governor has a problem which could be 1. the flyweights weights are missing or not moving properly 2. the thimble is worn or stuck on the shaft possiblely it is worn where the weights push against it not allowing it to function properly. 3. The shaft has pulled out of the case and will not allow the weights/thimble to collapse fully. 4 The governor arm is bent and not contacting the thimlbe.

If the governor arm has force trying to pull it back. then check the governor spring is it or they hooked up correctly.

To check for this issue remove the springs from the governor arm and start engine it shoul immediately go to idle and you would have to force the lever to speed up engine, just as the spring would do. If you have no force trying to move the lever back to idle ---- well just may be time for surgery -- again.

If the governor arm has force trying to pull it back. then check the governor spring is it or they hooked up correctly.

To check for this issue remove the springs from the governor arm and start engine it shoul immediately go to idle and you would have to force the lever to speed up engine, just as the spring would do. If you have no force trying to move the lever back to idle ---- well just may be time for surgery -- again.

#26

McTurff

Ok all good suggestions

Can't be adjustment I've tried every which way to Sunday!

Will try the spring removal test!

McTurff

So i was using wire to pull governor arm to idle so I guess I was doing what governor is supposed to do?You stated you were able to bring it back to idle by using a wire -- does the governor are try to pull it back to idle? If not there could be one of two issues. Governor not adjusted properly which you said you did, or the internal governor has a problem which could be 1. the flyweights weights are missing or not moving properly 2. the thimble is worn or stuck on the shaft possiblely it is worn where the weights push against it not allowing it to function properly. 3. The shaft has pulled out of the case and will not allow the weights/thimble to collapse fully. 4 The governor arm is bent and not contacting the thimlbe.

If the governor arm has force trying to pull it back. then check the governor spring is it or they hooked up correctly.

To check for this issue remove the springs from the governor arm and start engine it shoul immediately go to idle and you would have to force the lever to speed up engine, just as the spring would do. If you have no force trying to move the lever back to idle ---- well just may be time for surgery -- again.

Ok all good suggestions

Can't be adjustment I've tried every which way to Sunday!

Will try the spring removal test!

#27

McTurff

Should the manual throttle control from dash or console move the throttle plate from closed to open

I asked this question before my OHV engines do this one is not?

Or is the throttle plate always held open by governor arm and spring weather in Turtle or rabbit

or rabbit  ???

???

This one is not functioning correctly if that's the case and would be linkage??

McTurff

One more thingOk all good suggestions

Can't be adjustment I've tried every which way to Sunday!

Will try the spring removal test!

Should the manual throttle control from dash or console move the throttle plate from closed to open

I asked this question before my OHV engines do this one is not?

Or is the throttle plate always held open by governor arm and spring weather in Turtle

This one is not functioning correctly if that's the case and would be linkage??

#28

B

bentrim

B

bentrim

Some engines do this but I am not familiar (don't remember really) it has been a while since I have worked at one of the opposed flat head twins.

The best would be to follow the linkage and see if there is a link or lever to do so. Even the service manual has no clear picture of the control.

If interested in the repair manual it is PN 271172 printed 4/99 -- The black book the early manual was red.

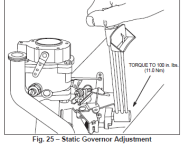

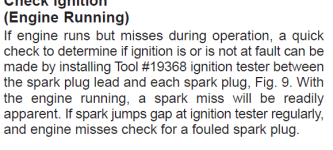

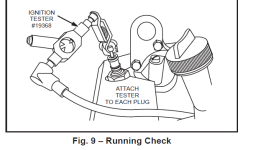

WARNING: BEFORE STARTING or running

engine, static adjustment of the governor must

be completed! Failure to make the static

adjustments first could result in engine overspeeding

which may result in engine damage,

property damage or personal injury.

STATIC GOVERNOR ADJUSTMENT

1. With governor lever nut loose, push governor lever

counter-clockwise as far as it will go (wide open

throttle) and hold in this position.

2. Rotate governor shaft counter-clockwise as far it

will go, Fig. 25.

Torque governor nut to 100 in. lbs. (11.0 Nm). A 7/16”

crowfoot socket may be required on ducted engines.

See procedure below for dual speed or 1800 RPM

generators. Fig. 25 – Static Governor Adjustment

Governor Gear

1. Check gear for damaged or worn teeth, Fig. 11.

2. Check thrust washer, governor weights and hinge

pins for wear and burrs.

3. Check governor cup for wear and burrs.

Replace as required.

Governed Idle

All Twin II twin cylinder engines equipped for remote control are equipped with governed idle. A detent in the equipment

control provides governed idle when the equipment control is moved to the full slow position.

Pre-Twin II, twin cylinder engines equipped for remote control have provision for governed idle. Equipment manufacturer’s

control may or may not provide a detent for governed idle. Controls with detents permit the governor to maintain

engine speeds under light loads with control in the detent position. Moving the remote control beyond the detent to the

full slow position overrides the governed idle and closes the throttle to the fully closed position to prevent engine overspeeding,

in the event of governor failure.

Remote controls without detents will provide governor control, depending on control setting, at all positions except full

slow position.

General Information

The purpose of the governor is to maintain, within certain limits, a desired engine speed, even though loads may vary.

The governor spring tends to pull the throttle open. The force of the counterweights, which are operated by centrifugal

force, tends to close the throttle. The engine speed at which these two forces balance is called the governed speed.

To comply with specific top governed speed limits, Briggs & Stratton supplies manufacturers with engines having an

adjustable top speed limit, which is set to equipment manufacturers’ specifications.

If a governor spring must be replaced, consult the appropriate Illustrated Parts Lists. Choose the proper governor springs

by engine type number.

The best would be to follow the linkage and see if there is a link or lever to do so. Even the service manual has no clear picture of the control.

If interested in the repair manual it is PN 271172 printed 4/99 -- The black book the early manual was red.

WARNING: BEFORE STARTING or running

engine, static adjustment of the governor must

be completed! Failure to make the static

adjustments first could result in engine overspeeding

which may result in engine damage,

property damage or personal injury.

STATIC GOVERNOR ADJUSTMENT

1. With governor lever nut loose, push governor lever

counter-clockwise as far as it will go (wide open

throttle) and hold in this position.

2. Rotate governor shaft counter-clockwise as far it

will go, Fig. 25.

Torque governor nut to 100 in. lbs. (11.0 Nm). A 7/16”

crowfoot socket may be required on ducted engines.

See procedure below for dual speed or 1800 RPM

generators. Fig. 25 – Static Governor Adjustment

Governor Gear

1. Check gear for damaged or worn teeth, Fig. 11.

2. Check thrust washer, governor weights and hinge

pins for wear and burrs.

3. Check governor cup for wear and burrs.

Replace as required.

Governed Idle

All Twin II twin cylinder engines equipped for remote control are equipped with governed idle. A detent in the equipment

control provides governed idle when the equipment control is moved to the full slow position.

Pre-Twin II, twin cylinder engines equipped for remote control have provision for governed idle. Equipment manufacturer’s

control may or may not provide a detent for governed idle. Controls with detents permit the governor to maintain

engine speeds under light loads with control in the detent position. Moving the remote control beyond the detent to the

full slow position overrides the governed idle and closes the throttle to the fully closed position to prevent engine overspeeding,

in the event of governor failure.

Remote controls without detents will provide governor control, depending on control setting, at all positions except full

slow position.

General Information

The purpose of the governor is to maintain, within certain limits, a desired engine speed, even though loads may vary.

The governor spring tends to pull the throttle open. The force of the counterweights, which are operated by centrifugal

force, tends to close the throttle. The engine speed at which these two forces balance is called the governed speed.

To comply with specific top governed speed limits, Briggs & Stratton supplies manufacturers with engines having an

adjustable top speed limit, which is set to equipment manufacturers’ specifications.

If a governor spring must be replaced, consult the appropriate Illustrated Parts Lists. Choose the proper governor springs

by engine type number.

#29

McTurff

McTurff

I hope someone that has this engine chimes in on this before I open this thing up again!

Manual doesn't explain this and I can't find a video showing the console movement in relation to throttle control opening and closing throttle plate

I can see how it would work but just seems that its not designed to function this way and that the throttle plate is always WOT plate unit engine starts and governor closes it???

Manual doesn't explain this and I can't find a video showing the console movement in relation to throttle control opening and closing throttle plate

I can see how it would work but just seems that its not designed to function this way and that the throttle plate is always WOT plate unit engine starts and governor closes it???

#30

F

Forest#2

F

Forest#2

With the engine not running.

I looked a couple of my opposed twins full open throttle and full closed throttle.

full open throttle on the dash = (can feel the throttle lever shaft at the carb slightly forceful spring loaded to full open and some force required to force it too go to the idle position and will spring back full open when not held at idle.

As the throttle on the dash is moved from full open to full closed towards idle the carb shaft moves less than half way closed towards idle and is only slightly (very weak) spring loaded when at idle position.

Carb shaft just very slightly spring loaded. (not hardly any governor spring tension felt with throttle on dash at idle)

I suspect your throttle control plate or governor springs are not connected correctly or someone has installed wrong length connecting links.

You might have to remove the throttle plate from the engine and look behind at the springs or go to ebay and search opposed twin throttle plate and linkages, look at some pictures. I think maybe you could completely remove the little governor spring and your dash throttle would then without the engine running move towards idle. The holes in the governor spring linkages is too adjust the governor sensitivity so as the engine does not hunt and surge at governor speeds. (the stronger the spring force the more forceful the governor) The governor springs are also color coded per engine codes but I've never seen them very critical of operation by color when I'm making Frankenstein engines. (taking several opposed twins engines and throttle plates and making one)

I looked a couple of my opposed twins full open throttle and full closed throttle.

full open throttle on the dash = (can feel the throttle lever shaft at the carb slightly forceful spring loaded to full open and some force required to force it too go to the idle position and will spring back full open when not held at idle.

As the throttle on the dash is moved from full open to full closed towards idle the carb shaft moves less than half way closed towards idle and is only slightly (very weak) spring loaded when at idle position.

Carb shaft just very slightly spring loaded. (not hardly any governor spring tension felt with throttle on dash at idle)

I suspect your throttle control plate or governor springs are not connected correctly or someone has installed wrong length connecting links.

You might have to remove the throttle plate from the engine and look behind at the springs or go to ebay and search opposed twin throttle plate and linkages, look at some pictures. I think maybe you could completely remove the little governor spring and your dash throttle would then without the engine running move towards idle. The holes in the governor spring linkages is too adjust the governor sensitivity so as the engine does not hunt and surge at governor speeds. (the stronger the spring force the more forceful the governor) The governor springs are also color coded per engine codes but I've never seen them very critical of operation by color when I'm making Frankenstein engines. (taking several opposed twins engines and throttle plates and making one)

#31

McTurff

I just have to keep searching for answers !

McTurff

Thanks all useful infoWith the engine not running.

I looked a couple of my opposed twins full open throttle and full closed throttle.

full open throttle on the dash = (can feel the throttle lever shaft at the carb slightly forceful spring loaded to full open and some force required to force it too go to the idle position and will spring back full open when not held at idle.

As the throttle on the dash is moved from full open to full closed towards idle the carb shaft moves less than half way closed towards idle and is only slightly (very weak) spring loaded when at idle position.

Carb shaft just very slightly spring loaded. (not hardly any governor spring tension felt with throttle on dash at idle)

I suspect your throttle control plate or governor springs are not connected correctly or someone has installed wrong length connecting links.

You might have to remove the throttle plate from the engine and look behind at the springs or go to ebay and search opposed twin throttle plate and linkages, look at some pictures. I think maybe you could completely remove the little governor spring and your dash throttle would then without the engine running move towards idle. The holes in the governor spring linkages is too adjust the governor sensitivity so as the engine does not hunt and surge at governor speeds. (the stronger the spring force the more forceful the governor) The governor springs are also color coded per engine codes but I've never seen them very critical of operation by color when I'm making Frankenstein engines. (taking several opposed twins engines and throttle plates and making one)

I just have to keep searching for answers !

#32

B

bentrim

B

bentrim

Just a quick question. Was the governor lever turned the right way when you put the sump back on?

#33

F

Forest#2

F

Forest#2

A hint that yours will not idle with the engine running is you say the carb throttle shaft still feels strong spring pressure even with the engine not running and the on dash speed control set to low idle.

#34

B

bentrim

B

bentrim

With the engine not running there should be spring force trying to pull the throttle open. Yours according to the service manual has a "governed Idle" which does not allow the carburetor to close and touch the speed adjustment screw on the carb. It is designed to allow the operator to idle the engine and apply a load without the engine stalling. That is the second smaller, shorter spring that pulls on the governor arm.

Just another thought is you might remove the governor spring ( the one controlled by the dash lever) and see if it will idle then. You might also remove the governered idle spring and the lever should move freely and go immediately to idle when the engine starts. If that works you either have the wrong governor spring or it is hooked in wrong. If the engine still runs away -- time for surgery.

Just another thought is you might remove the governor spring ( the one controlled by the dash lever) and see if it will idle then. You might also remove the governered idle spring and the lever should move freely and go immediately to idle when the engine starts. If that works you either have the wrong governor spring or it is hooked in wrong. If the engine still runs away -- time for surgery.

#35

A

Auto Doc's

A

Auto Doc's

Unhook the throttle cable and move it by hand to see if it will pull it down to idle.

#36

McTurff

McTurff

Thanks everyone for all the great ideas!

I will continue to try all these suggestions and put them to practice hopefully don't have to open her up again but that's not to difficult!

If i do I put a new sump gasket in literally a week ago when I had it opened up!

Should I get a new gasket or would I be lucky enough to reuse that one??

No biggie just need to know if I have to go back down that road!

Thanks

I will continue to try all these suggestions and put them to practice hopefully don't have to open her up again but that's not to difficult!

If i do I put a new sump gasket in literally a week ago when I had it opened up!

Should I get a new gasket or would I be lucky enough to reuse that one??

No biggie just need to know if I have to go back down that road!

Thanks

#37

McTurff

So hopefully it was right

McTurff

I never changed or moved anythingJust a quick question. Was the governor lever turned the right way when you put the sump back on?

So hopefully it was right

#38

McTurff

McTurff

Ok after further review

I have to take engine off and dive back in I have exhausted all tests!

So when I open it up again unless anything changed I will see what was an intact govenor

So what should I look for beyond everyone's suggestions?

Maybe governor arm is not in the right place or bent, thimble stuck ect!

The weights were all in place and pins the governor seemed to look correct!!

I have a new Governor should I just install it regardless of the old one looking good?

Anyway when I go in this time want to check everything so hopefully don't have to pull for 4th time!!

I have to take engine off and dive back in I have exhausted all tests!

So when I open it up again unless anything changed I will see what was an intact govenor

So what should I look for beyond everyone's suggestions?

Maybe governor arm is not in the right place or bent, thimble stuck ect!

The weights were all in place and pins the governor seemed to look correct!!

I have a new Governor should I just install it regardless of the old one looking good?

Anyway when I go in this time want to check everything so hopefully don't have to pull for 4th time!!

#39

McTurff

McTurff

Well im totally lost

New Governor in everything looked fine no bent arm the governor did come loose and keeper ring had come off so I don't know if that happened when I put back together last time

But there was absolutely nothing wrong with original governor

But put new one on to try it

Made sure it stayed on rotated engine slightly so camshaft and governor gear were good!

Put all back together

Same thing

WOT

ONLY way I can slow it down is to put a makeshift wire to governor arm and pull it to idle!

Very disappointed or im just completely missing something

It just seems like governor is not working and yes I reset it!

New Governor in everything looked fine no bent arm the governor did come loose and keeper ring had come off so I don't know if that happened when I put back together last time

But there was absolutely nothing wrong with original governor

But put new one on to try it

Made sure it stayed on rotated engine slightly so camshaft and governor gear were good!

Put all back together

Same thing

WOT

ONLY way I can slow it down is to put a makeshift wire to governor arm and pull it to idle!

Very disappointed or im just completely missing something

It just seems like governor is not working and yes I reset it!

#40

McTurff

I'm going to have to take pictures because everything looks good inside!

Now ready to pull for 4th time!

I don't know what else can be causing my problem!

Edit i did reply to your post but i guess I just assumed everything was correct inside !

is there anything else i can look for when I open the engine up again??

And which way should governor arm be facing?

I will try and find pic of orientation!

McTurff

This maybe my problem but I missed your reply before doing work on my engine!Just a quick question. Was the governor lever turned the right way when you put the sump back on?

I'm going to have to take pictures because everything looks good inside!

Now ready to pull for 4th time!

I don't know what else can be causing my problem!

Edit i did reply to your post but i guess I just assumed everything was correct inside !

is there anything else i can look for when I open the engine up again??

And which way should governor arm be facing?

I will try and find pic of orientation!

#41

F

Forest#2

F

Forest#2

Take a look at this video for a engine model same as yours.

This guy is making the static governor adjustment. (opposite of the recommended procedure)

422707-1275-1

Setting governor for Briggs L Head opposed twin 18hp

Keep in mind that the governor shaft only moves approx 90 degrees or less full travel.

After making a static governor adjust if the engine is overspeeding I do as this guy and adjust the governor just the opposite.

I've seen some Briggs engines that the governor shaft had to be adjusted completely backwards of what the service manual indicates to keep from overspeeding and to get lower rpms per the throttle.

With the engine not running and the throttle set to idle manually turning the governor shaft through it complete range should move the carb throttle shaft towards idle. If not the springs and or linkages on the throttle plate is binding or wrong.

This guy is making the static governor adjustment. (opposite of the recommended procedure)

422707-1275-1

Setting governor for Briggs L Head opposed twin 18hp

Keep in mind that the governor shaft only moves approx 90 degrees or less full travel.

After making a static governor adjust if the engine is overspeeding I do as this guy and adjust the governor just the opposite.

I've seen some Briggs engines that the governor shaft had to be adjusted completely backwards of what the service manual indicates to keep from overspeeding and to get lower rpms per the throttle.

With the engine not running and the throttle set to idle manually turning the governor shaft through it complete range should move the carb throttle shaft towards idle. If not the springs and or linkages on the throttle plate is binding or wrong.

#42

McTurff

My Govenor arm moves throttle plate as it should open an closed with engine at idle!

The other thing is if you turn the governor shaft the opposite direction the arm locks up so you know it won't work that direction it only goes one way or works one way or direction!

McTurff

Take a look at this video for a engine model same as yours.

This guy is making the static governor adjustment. (opposite of the recommended procedure)

422707-1275-1

Setting governor for Briggs L Head opposed twin 18hp

Keep in mind that the governor shaft only moves approx 90 degrees or less full travel.

After making a static governor adjust if the engine is overspeeding I do as this guy and adjust the governor just the opposite.

I've seen some Briggs engines that the governor shaft had to be adjusted completely backwards of what the service manual indicates to keep from overspeeding and to get lower rpms per the throttle.

With the engine not running and the throttle set to idle manually turning the governor shaft through it complete range should move the carb throttle shaft towards idle. If not the springs and or linkages on the throttle plate is binding or wrong.

Take a look at this video for a engine model same as yours.

This guy is making the static governor adjustment. (opposite of the recommended procedure)

422707-1275-1

Setting governor for Briggs L Head opposed twin 18hp

Keep in mind that the governor shaft only moves approx 90 degrees or less full travel.

After making a static governor adjust if the engine is overspeeding I do as this guy and adjust the governor just the opposite.

I've seen some Briggs engines that the governor shaft had to be adjusted completely backwards of what the service manual indicates to keep from overspeeding and to get lower rpms per the throttle.

With the engine not running and the throttle set to idle manually turning the governor shaft through it complete range should move the carb throttle shaft towards idle. If not the springs and or linkages on the throttle plate is binding or wrong.

I have watched that video and every video on static adjustment tried to adjust both ways!Take a look at this video for a engine model same as yours.

This guy is making the static governor adjustment. (opposite of the recommended procedure)

422707-1275-1

Setting governor for Briggs L Head opposed twin 18hp

Keep in mind that the governor shaft only moves approx 90 degrees or less full travel.

After making a static governor adjust if the engine is overspeeding I do as this guy and adjust the governor just the opposite.

I've seen some Briggs engines that the governor shaft had to be adjusted completely backwards of what the service manual indicates to keep from overspeeding and to get lower rpms per the throttle.

With the engine not running and the throttle set to idle manually turning the governor shaft through it complete range should move the carb throttle shaft towards idle. If not the springs and or linkages on the throttle plate is binding or wrong.

My Govenor arm moves throttle plate as it should open an closed with engine at idle!

The other thing is if you turn the governor shaft the opposite direction the arm locks up so you know it won't work that direction it only goes one way or works one way or direction!

#43

McTurff

McTurff

Ok went through more tests and all suggestions for my problem!

No change

Just to clarify when I remove springs from governor arm the engine should go to idle??

Mine dose not !

I am going to open the engine up again this weekend and see if governor came off when reinstalling or the governor arm is flipped which i don't think it did!

But other than that unless someone has any other ideas I don't know what else to do!

I can't find anything on the internet and beyond that someone has had the issue im having!

The only other thing i can think of is the governor cap or weights that hit the governor arm flap are not connecting??

If that's the case something could be bent but I just did not see that was the case when I opened the engine up last time!

No change

Just to clarify when I remove springs from governor arm the engine should go to idle??

Mine dose not !

I am going to open the engine up again this weekend and see if governor came off when reinstalling or the governor arm is flipped which i don't think it did!

But other than that unless someone has any other ideas I don't know what else to do!

I can't find anything on the internet and beyond that someone has had the issue im having!

The only other thing i can think of is the governor cap or weights that hit the governor arm flap are not connecting??

If that's the case something could be bent but I just did not see that was the case when I opened the engine up last time!

#44

B

bentrim

B

bentrim

How about a lesson on how a governor works??

The governor contained in the crankcase has two flyweights on it and the lever on the flyweight forces the thimble away from the gear.

The thimble applies force to the lever on the end of the shaft that passes thru the case and has the arm mounted on it. When everything is functioning properly, The weights "fly" out pushing the thimble apply force to the flat spot on the end of the shaft that pass to the outside.

If every thing is adjusted properly, and every thing functions, you start the engine and at any speed even idle and the arm WILL be forced to close the throttle plate.

A governor controls the speed by balancing the force from the flyweights against the pull of the governor spring. So with no spring hooked up the engine should go right to idle.

While you have the pan off spin the governor gear, checking that the weights "fly" out and the gear spins freely, and the thimble is free to move on the shaft and is against the levers of the flyweights. Be sure the governor arm is turned so it is over the governor before closing the crankcase.

To properly adjust a governor move the throttle to wide open. Note which way the governor shaft turns to open the carburetor. Loosen the pinch bolt and continue to turn the shaft so it would open the throttle (same direction as the shaft moves when opening the throttle), Tighten pinch bolt. This adjustment collapses the thimble into the weights and syncronizes the carb to the governor.

Just to clarify when I remove springs from governor arm the engine should go to idle?? YES

As bfore be sure 1. the shaft is turned so it can contact the governor when the pan is reinstalled. 2. Before closing the case observe governor weights should be fully retracted and the thimble colapsed into the weights. 3 Be sure all linkage moves freely and nothing hangs up.

Governors can be used on carburetored engines from less the 1 horsepower to large engine of over 1000 horsepower and all mechanical governors function the same and need syncronized to the carburetor by using the same procedure.

The governor contained in the crankcase has two flyweights on it and the lever on the flyweight forces the thimble away from the gear.

The thimble applies force to the lever on the end of the shaft that passes thru the case and has the arm mounted on it. When everything is functioning properly, The weights "fly" out pushing the thimble apply force to the flat spot on the end of the shaft that pass to the outside.

If every thing is adjusted properly, and every thing functions, you start the engine and at any speed even idle and the arm WILL be forced to close the throttle plate.

A governor controls the speed by balancing the force from the flyweights against the pull of the governor spring. So with no spring hooked up the engine should go right to idle.

While you have the pan off spin the governor gear, checking that the weights "fly" out and the gear spins freely, and the thimble is free to move on the shaft and is against the levers of the flyweights. Be sure the governor arm is turned so it is over the governor before closing the crankcase.

To properly adjust a governor move the throttle to wide open. Note which way the governor shaft turns to open the carburetor. Loosen the pinch bolt and continue to turn the shaft so it would open the throttle (same direction as the shaft moves when opening the throttle), Tighten pinch bolt. This adjustment collapses the thimble into the weights and syncronizes the carb to the governor.

Just to clarify when I remove springs from governor arm the engine should go to idle?? YES

As bfore be sure 1. the shaft is turned so it can contact the governor when the pan is reinstalled. 2. Before closing the case observe governor weights should be fully retracted and the thimble colapsed into the weights. 3 Be sure all linkage moves freely and nothing hangs up.

Governors can be used on carburetored engines from less the 1 horsepower to large engine of over 1000 horsepower and all mechanical governors function the same and need syncronized to the carburetor by using the same procedure.

#45

McTurff

More now than ever

I have read and watched more videos than I could imagine

I will be going back in and paying more attention to detail!

This will be my 3rd time inside this engine so hopefully it is a charm!

Thank You for taking time for the detailed replies really appreciate it!

McTurff

Thanks I know how the governor operates!How about a lesson on how a governor works??

The governor contained in the crankcase has two flyweights on it and the lever on the flyweight forces the thimble away from the gear.

The thimble applies force to the lever on the end of the shaft that passes thru the case and has the arm mounted on it. When everything is functioning properly, The weights "fly" out pushing the thimble apply force to the flat spot on the end of the shaft that pass to the outside.

If every thing is adjusted properly, and every thing functions, you start the engine and at any speed even idle and the arm WILL be forced to close the throttle plate.

A governor controls the speed by balancing the force from the flyweights against the pull of the governor spring. So with no spring hooked up the engine should go right to idle.

While you have the pan off spin the governor gear, checking that the weights "fly" out and the gear spins freely, and the thimble is free to move on the shaft and is against the levers of the flyweights. Be sure the governor arm is turned so it is over the governor before closing the crankcase.

To properly adjust a governor move the throttle to wide open. Note which way the governor shaft turns to open the carburetor. Loosen the pinch bolt and continue to turn the shaft so it would open the throttle (same direction as the shaft moves when opening the throttle), Tighten pinch bolt. This adjustment collapses the thimble into the weights and syncronizes the carb to the governor.

Just to clarify when I remove springs from governor arm the engine should go to idle?? YES

As bfore be sure 1. the shaft is turned so it can contact the governor when the pan is reinstalled. 2. Before closing the case observe governor weights should be fully retracted and the thimble colapsed into the weights. 3 Be sure all linkage moves freely and nothing hangs up.

Governors can be used on carburetored engines from less the 1 horsepower to large engine of over 1000 horsepower and all mechanical governors function the same and need syncronized to the carburetor by using the same procedure.

More now than ever

I have read and watched more videos than I could imagine

I will be going back in and paying more attention to detail!

This will be my 3rd time inside this engine so hopefully it is a charm!

Thank You for taking time for the detailed replies really appreciate it!

#46

F

Forest#2

F

Forest#2

Just to clarify when I remove springs from governor arm the engine should go to idle?? YES

Just to clairfy.

If it will not go to idle (or slower RPM's) with the governor spring removed or the governor disabled, this throttle control problem lower rpm needs to be repaired BEFORE addressing the governor.

(because the external mechanical throttle control is not allowing the governor to operate correctly)

Just to clairfy.

If it will not go to idle (or slower RPM's) with the governor spring removed or the governor disabled, this throttle control problem lower rpm needs to be repaired BEFORE addressing the governor.

(because the external mechanical throttle control is not allowing the governor to operate correctly)

#47

B

bentrim

B

bentrim

Does moving the governor arm to the slow position control the engine speed? without the engine running?

From all that you have posted I question if the lever of the governor arm is. turned properly and the governor is pushing against it -- because you have no force moving the arm toward idle speed. Even seasoned mechanics have made that mistake.

Without the governor spring hooked up there should be force trying to push the throttle plate closed --- engine running

The spring is supposed to oppose the governor, and the governor should oppose the spring, so the engine runs at the desired speed. More spring pull equals more governor resistance.

From all that you have posted I question if the lever of the governor arm is. turned properly and the governor is pushing against it -- because you have no force moving the arm toward idle speed. Even seasoned mechanics have made that mistake.

Without the governor spring hooked up there should be force trying to push the throttle plate closed --- engine running

The spring is supposed to oppose the governor, and the governor should oppose the spring, so the engine runs at the desired speed. More spring pull equals more governor resistance.

#48

McTurff

McTurff

Does moving the governor arm to the slow position control the engine speed? without the engine running?

From all that you have posted I question if the lever of the governor arm is. turned properly and the governor is pushing against it -- because you have no force moving the arm toward idle speed. Even seasoned mechanics have made that mistake.

Without the governor spring hooked up there should be force trying to push the throttle plate closed --- engine running

The spring is supposed to oppose the governor, and the governor should oppose the spring, so the engine runs at the desired speed. More spring pull equals more governor resistance.

Attachments

#49

McTurff

McTurff

Got it apart and this is how the arm tab has looked each time!

And first time I opened engine governor was in place and arm the same!

When I removed springs it was still wide open!

Have tried adjustment on governor every which way

I'm trying to stay persistent the motor fires right up so its something that has to be fixable

Its really a pretty clean tractor I don't think anyone dis anything other than mess with carburetor but that's not the issue

And first time I opened engine governor was in place and arm the same!

When I removed springs it was still wide open!

Have tried adjustment on governor every which way

I'm trying to stay persistent the motor fires right up so its something that has to be fixable

Its really a pretty clean tractor I don't think anyone dis anything other than mess with carburetor but that's not the issue

#50

McTurff

I can take more if it helps

McTurff

Added a picture of arm and tabDoes moving the governor arm to the slow position control the engine speed? without the engine running?

From all that you have posted I question if the lever of the governor arm is. turned properly and the governor is pushing against it -- because you have no force moving the arm toward idle speed. Even seasoned mechanics have made that mistake.

Without the governor spring hooked up there should be force trying to push the throttle plate closed --- engine running

The spring is supposed to oppose the governor, and the governor should oppose the spring, so the engine runs at the desired speed. More spring pull equals more governor resistance.

I can take more if it helps

Does moving the governor arm to the slow position control the engine speed? without the engine running?

From all that you have posted I question if the lever of the governor arm is. turned properly and the governor is pushing against it -- because you have no force moving the arm toward idle speed. Even seasoned mechanics have made that mistake.

Without the governor spring hooked up there should be force trying to push the throttle plate closed --- engine running

The spring is supposed to oppose the governor, and the governor should oppose the spring, so the engine runs at the desired speed. More spring pull equals more governor resistance.

Does moving the governor arm to the slow position control the engine speed? without the engine running?

From all that you have posted I question if the lever of the governor arm is. turned properly and the governor is pushing against it -- because you have no force moving the arm toward idle speed. Even seasoned mechanics have made that mistake.

Without the governor spring hooked up there should be force trying to push the throttle plate closed --- engine running

The spring is supposed to oppose the governor, and the governor should oppose the spring, so the engine runs at the desired speed. More spring pull equals more governor resistance.

#52

McTurff

Just found this video

End of video this guy shows camshaft side of engine and tab looks just like mine same orientation!

Now im confused

McTurff

Just found this video

End of video this guy shows camshaft side of engine and tab looks just like mine same orientation!

Now im confused

#53

B

bentrim

B

bentrim

Looks like you have the shaft/lever turned the right way Notice the little shiny spot on the lever that is where the thimble is contacting the lever. While it is apart spin the governor and see if the flyweights and thimble move properly. As you are reinstalling the pan check to be sure the governor is engaging the cam, a small wire or thin flat plate can go between the housings. One more question does the governor shaft appear installed correctly? Can the thimble fully retract into the weights? If so the only thing left is the external adustment.

#54

McTurff

Not sure what you mean by the thin wire?

To probe or feel for gears properly meshing between cam and governor gear!

Anyway again thanks to your help and explanation I think im in the right track

Hopefully it works this time around!!

McTurff

Yes shaft looks good and thimble and weights spin free !Looks like you have the shaft/lever turned the right way Notice the little shiny spot on the lever that is where the thimble is contacting the lever. While it is apart spin the governor and see if the flyweights and thimble move properly. As you are reinstalling the pan check to be sure the governor is engaging the cam, a small wire or thin flat plate can go between the housings. One more question does the governor shaft appear installed correctly? Can the thimble fully retract into the weights? If so the only thing left is the external adustment.

Not sure what you mean by the thin wire?

To probe or feel for gears properly meshing between cam and governor gear!

Anyway again thanks to your help and explanation I think im in the right track

Hopefully it works this time around!!

#55

B

bentrim

B

bentrim

By a thin wire I just meant something that would go between the block and sump to be sure the governor is engaging the cam.

Somewhere you've got to win!! Just trying to share what I have learned over the years, as I know governor are a a mystery to most people.

Somewhere you've got to win!! Just trying to share what I have learned over the years, as I know governor are a a mystery to most people.

#56

McTurff

Anyway

Got it back together same thing!!

Adjusted governor

Running wild i videoed my whole reinstall hoping it could help someone and maybe it still will

How to or not how to video but I can't see how it could be done any other way!

I don't know what else to do!

Everything lined up perfect not hard to see

I may make the video available it came out good maybe someone can see something i did wrong not afraid of criticism but I just can't see any other way to do it!

I seem to always get head scratcher projects!!

McTurff

Yes I understood after reading againBy a thin wire I just meant something that would go between the block and sump to be sure the governor is engaging the cam.

Somewhere you've got to win!! Just trying to share what I have learned over the years, as I know governor are a a mystery to most people.

Anyway

Got it back together same thing!!

Adjusted governor

Running wild i videoed my whole reinstall hoping it could help someone and maybe it still will

How to or not how to video but I can't see how it could be done any other way!

I don't know what else to do!

Everything lined up perfect not hard to see

I may make the video available it came out good maybe someone can see something i did wrong not afraid of criticism but I just can't see any other way to do it!

I seem to always get head scratcher projects!!

#57

McTurff

At least it shows some detail of this engine opened that i haven't seen!

Now have to figure what to do next!

McTurff

Here is my video I feel kinda defeated but maybe still be some good info for someone!By a thin wire I just meant something that would go between the block and sump to be sure the governor is engaging the cam.

Somewhere you've got to win!! Just trying to share what I have learned over the years, as I know governor are a a mystery to most people.

At least it shows some detail of this engine opened that i haven't seen!

Now have to figure what to do next!

#58

B

bentrim

B

bentrim

By the video you have everthing correct on the inside.

Not that you do not know what youi are doing, you seem quite knowlegable. But I question the external adjustment. I you turn the shaft correctly remember you are moving the lever against the thimble, so when the engine starts the weights fly out, push the thimble up moving the lever turning the shaft and closing the carburetor plate. By the video you would turn the shaft anti-clockwise until it stops (touches the thimble) with the throttle wide open, tighten bolt and all should be well. If adjusted the wrong way the governor arm will not move.

Here s the procedure from Breaks & Scapem.

Hope all works out and you are back in the saddle and don't need to continue getting frustrated at this issue.

STATIC GOVERNOR ADJUSTMENT

1. With governor lever nut loose, push governor lever

counter-clockwise as far as it will go (wide open

throttle) and hold in this position.

2. Rotate governor shaft counter-clockwise as far it

will go, Fig. 25.

Torque governor nut to 100 in. lbs. (11.0 Nm). A 7/16”

crowfoot socket may be required on ducted engines.

See procedure below for dual speed or 1800 RPM

generators. Fig. 25 – Static Governor Adjustment

Not that you do not know what youi are doing, you seem quite knowlegable. But I question the external adjustment. I you turn the shaft correctly remember you are moving the lever against the thimble, so when the engine starts the weights fly out, push the thimble up moving the lever turning the shaft and closing the carburetor plate. By the video you would turn the shaft anti-clockwise until it stops (touches the thimble) with the throttle wide open, tighten bolt and all should be well. If adjusted the wrong way the governor arm will not move.

Here s the procedure from Breaks & Scapem.

Hope all works out and you are back in the saddle and don't need to continue getting frustrated at this issue.

STATIC GOVERNOR ADJUSTMENT

1. With governor lever nut loose, push governor lever

counter-clockwise as far as it will go (wide open

throttle) and hold in this position.

2. Rotate governor shaft counter-clockwise as far it

will go, Fig. 25.

Torque governor nut to 100 in. lbs. (11.0 Nm). A 7/16”

crowfoot socket may be required on ducted engines.

See procedure below for dual speed or 1800 RPM

generators. Fig. 25 – Static Governor Adjustment

#59

McTurff

All I can do is keep trying

And my knowledge comes from just tinkering, sometimes you get lucky, but most of my info has come from people like you.So I thank you for that!!

McTurff

I have adjusted it so many times each way. That it's driving me crazy. There's no way that I could have got it wrong after doing it. So many times testing it each time, it's very frustrating, but I just don't think it's working right!!By the video you have everthing correct on the inside.

Not that you do not know what youi are doing, you seem quite knowlegable. But I question the external adjustment. I you turn the shaft correctly remember you are moving the lever against the thimble, so when the engine starts the weights fly out, push the thimble up moving the lever turning the shaft and closing the carburetor plate. By the video you would turn the shaft anti-clockwise until it stops (touches the thimble) with the throttle wide open, tighten bolt and all should be well. If adjusted the wrong way the governor arm will not move.

Here s the procedure from Breaks & Scapem.

Hope all works out and you are back in the saddle and don't need to continue getting frustrated at this issue.

STATIC GOVERNOR ADJUSTMENT

1. With governor lever nut loose, push governor lever

counter-clockwise as far as it will go (wide open

throttle) and hold in this position.

2. Rotate governor shaft counter-clockwise as far it

will go, Fig. 25.

Torque governor nut to 100 in. lbs. (11.0 Nm). A 7/16”

crowfoot socket may be required on ducted engines.

See procedure below for dual speed or 1800 RPM

generators. Fig. 25 – Static Governor Adjustment

View attachment 71430

View attachment 71431

All I can do is keep trying

And my knowledge comes from just tinkering, sometimes you get lucky, but most of my info has come from people like you.So I thank you for that!!

#60

F

Forest#2

F

Forest#2

Couple questions:

Can you hold the carb linkage at idle and get a slow idle? (I'm talking about holding the carb shaft against the idle set screw)

Next: You mention that yours runs at high rpm even with the dash control set at slow. If so you have a throttle plate control problem instead of a governor problem.

In post #31 and 33 I posted that I my opposed twins will slow idle with the dash control set at slow and the governor not even needed. The governor arm is actually locked out mechanically and not even used at slow idle on mine,(cannot even move the governor arm with hand because it's locked mechanically at low idle) but does have a governored idle part way up on the dash throttle.

My engine model types and codes are as follows 422707 1263 01, code 9403105A and 42E707 2631 E1 code 9811235B and both use the same governor arm and throttle plate and springs.

Your engine shows on parts lists that it uses the same governor arm and throttle plate as my engines. (but Briggs does have other type throttle plates and governor arms for the opposed twins and they must be kept matched for correct mechanical governor/throttle operation)

Post up some good pictures of your governor arm and throttle plate. I see that Briggs has different type throttle plates and governor arms for the opposed twins is why I ask about pictures of yours.

Also post up close up pictures of yours throttle plate when at idle and also a full throttle.

Can you hold the carb linkage at idle and get a slow idle? (I'm talking about holding the carb shaft against the idle set screw)

Next: You mention that yours runs at high rpm even with the dash control set at slow. If so you have a throttle plate control problem instead of a governor problem.

In post #31 and 33 I posted that I my opposed twins will slow idle with the dash control set at slow and the governor not even needed. The governor arm is actually locked out mechanically and not even used at slow idle on mine,(cannot even move the governor arm with hand because it's locked mechanically at low idle) but does have a governored idle part way up on the dash throttle.

My engine model types and codes are as follows 422707 1263 01, code 9403105A and 42E707 2631 E1 code 9811235B and both use the same governor arm and throttle plate and springs.

Your engine shows on parts lists that it uses the same governor arm and throttle plate as my engines. (but Briggs does have other type throttle plates and governor arms for the opposed twins and they must be kept matched for correct mechanical governor/throttle operation)

Post up some good pictures of your governor arm and throttle plate. I see that Briggs has different type throttle plates and governor arms for the opposed twins is why I ask about pictures of yours.

Also post up close up pictures of yours throttle plate when at idle and also a full throttle.

#61

McTurff

CHINA

I will take a look at it tomorrow I cleaned up the original carb to put back on i don't know if it is actually the right carb??

Anyway i will get some pics!

I do have another Briggs carburetor looks like it could work it is from a twin engine pretty sure it was an opposed twin!

It has #s on it so I should look and see if it will work on my engine!

I keep posting this

The engine runs wild with no springs or tension on governor

And I thought that would mean it is not functioning???

Should come to idle??

Thanks for more info and I will report!

McTurff

I had the original carb on it when I first got it running but put another carb onCouple questions:

Can you hold the carb linkage at idle and get a slow idle? (I'm talking about holding the carb shaft against the idle set screw)

Next: You mention that yours runs at high rpm even with the dash control set at slow. If so you have a throttle plate control problem instead of a governor problem.

In post #31 and 33 I posted that I my opposed twins will slow idle with the dash control set at slow and the governor not even needed. The governor arm is actually locked out mechanically and not even used at slow idle on mine,(cannot even move the governor arm with hand because it's locked mechanically at low idle) but does have a governored idle part way up on the dash throttle.

My engine model types and codes are as follows 422707 1263 01, code 9403105A and 42E707 2631 E1 code 9811235B and both use the same governor arm and throttle plate and springs.

Your engine shows on parts lists that it uses the same governor arm and throttle plate as my engines. (but Briggs does have other type throttle plates and governor arms for the opposed twins and they must be kept matched for correct mechanical governor/throttle operation)

Post up some good pictures of your governor arm and throttle plate. I see that Briggs has different type throttle plates and governor arms for the opposed twins is why I ask about pictures of yours.

Also post up close up pictures of yours throttle plate when at idle and also a full throttle.

CHINA

I will take a look at it tomorrow I cleaned up the original carb to put back on i don't know if it is actually the right carb??

Anyway i will get some pics!

I do have another Briggs carburetor looks like it could work it is from a twin engine pretty sure it was an opposed twin!

It has #s on it so I should look and see if it will work on my engine!

I keep posting this

The engine runs wild with no springs or tension on governor

And I thought that would mean it is not functioning???

Should come to idle??

Thanks for more info and I will report!

#62

F

Forest#2

F

Forest#2

You mentioned changing the carb. Not likely the carb with the symptoms you said.

Them Briggs twins only used two types of carbs a 3 screw and a 4 screw and this referred to the fuel pump on the front of the carb. Kit for the carb same for both, just had to get correct kit for the fuel pump. Not likely it's a carb issue because you say you changed carb's and symptoms same. Them carbs usually very reliable except the pump can become erratic from not being used and ethanol gas. Make sure the little dog leg linkage swivel connection behind the carb is allowing the linkages to swivel freely for the carb throttle plate carb shaft control.

My point being:

At first You are going to have to get the engine to idle slow without the governor control. You will never get governor speed control if the engine cannot be slow idled without the governor.

The first test is making sure it idles holding the carb shaft at idle against the idle set screw while the engine is running. This test is confirming that the throttle butterfly in the carb throat is closing or you do not have a bad air leak causing a high rpm and neither one is likely. (but this needs to be confirmed first)

Next is seeing that the on dash throttle lever brings the engine to idle with the engine not running. This can be see by watching the carb shaft going to or towards idle. (Without the governor arm even connected, just leave the governor arm completely loose on the shaft)

I suspect your engine speed issue is with the mechanical operation of the throttle plate not allowing lower rpm idle operation and the spring loaded governor lever arm cannot over ride such trying to slow the engine speed.

Them Briggs twins only used two types of carbs a 3 screw and a 4 screw and this referred to the fuel pump on the front of the carb. Kit for the carb same for both, just had to get correct kit for the fuel pump. Not likely it's a carb issue because you say you changed carb's and symptoms same. Them carbs usually very reliable except the pump can become erratic from not being used and ethanol gas. Make sure the little dog leg linkage swivel connection behind the carb is allowing the linkages to swivel freely for the carb throttle plate carb shaft control.

My point being:

At first You are going to have to get the engine to idle slow without the governor control. You will never get governor speed control if the engine cannot be slow idled without the governor.

The first test is making sure it idles holding the carb shaft at idle against the idle set screw while the engine is running. This test is confirming that the throttle butterfly in the carb throat is closing or you do not have a bad air leak causing a high rpm and neither one is likely. (but this needs to be confirmed first)

Next is seeing that the on dash throttle lever brings the engine to idle with the engine not running. This can be see by watching the carb shaft going to or towards idle. (Without the governor arm even connected, just leave the governor arm completely loose on the shaft)

I suspect your engine speed issue is with the mechanical operation of the throttle plate not allowing lower rpm idle operation and the spring loaded governor lever arm cannot over ride such trying to slow the engine speed.

#63

B

bentrim

B

bentrim

If you can control the speed by moving the carb lever to touch the idle speed screw, you don't have a carb problem.