I've had this machine since new. I've done some major things to keep 'er running like replace transmission, weld up rust holes in the deck, numerous jackshaft replacements, switch to Kevlar belts which are near bulletproof, change over to solid state ignition, rebuild carb, replace seat with one from Northern Tool, weld up cracks in the chassis, complete redesign and rebuild of vibration isolation engine mount bolts using rubber stoppers from Home Depot and Grade 8 bolts, replace leaking crankcase gasket. Today right as I finished mowing, the steering wheel got sloppy and didn't turn the wheels. In an instant I realized the drag link spherical joint at the steering arm had come apart.

I have checked carefully and cannot find the part. P/N from my original owner's manual is 1640J. Google, Amazon, eBay, you name it. Discontinued, part not available.

My question is this. Has anyone managed to repair this type spherical joint? The ball is still fine, from wear it just slipped out of the socket. My first thought is to lube with moly grease and re-insert and then carefully hammer on the rod end with spherical cavity enough to retain the ball. Would have to be careful not to deform the darn thing too much. Delicate touch with heavy hammer not an easy thing.

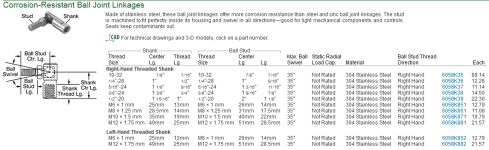

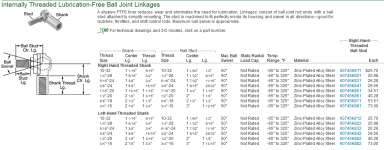

If that won't work, I'm thinking I could buy another drag link with same size threaded fitting (3/8" x 24 NF), cut it off and weld onto original drag link after cutting the bad end off. .

Has anyone out there run into this problem and what would be your advice?

I have checked carefully and cannot find the part. P/N from my original owner's manual is 1640J. Google, Amazon, eBay, you name it. Discontinued, part not available.

My question is this. Has anyone managed to repair this type spherical joint? The ball is still fine, from wear it just slipped out of the socket. My first thought is to lube with moly grease and re-insert and then carefully hammer on the rod end with spherical cavity enough to retain the ball. Would have to be careful not to deform the darn thing too much. Delicate touch with heavy hammer not an easy thing.

If that won't work, I'm thinking I could buy another drag link with same size threaded fitting (3/8" x 24 NF), cut it off and weld onto original drag link after cutting the bad end off. .

Has anyone out there run into this problem and what would be your advice?