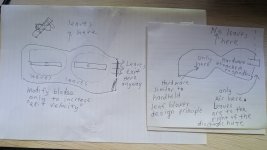

Interesting discussion, but I think putting paddles on the blades will try to send air, and therefore leaves off the tips of the blades, rather than out the chute. The two or three blades will fight each other rather than direct the flow out the chute. I think the typical blower is fully enclosed except for an inlet near the center, and an outlet at the edge, like a squirrel cage fan. It doesn't run leaves through it, it runs air through it and chases the leaves away. To approximate that with a mower deck, you'd need to enclose the bottom, and maybe only use one blade. And provide an air inlet. A better approach may be to just use your deck as is, but don't run over the leaves, just chase them with the discharge air. Like cleaning a sidewalk. At some point, you are still going to overwhelm the ability to chase leaves, and have to pick them up. At least I always did with a hand held blower. And with the mower deck you lose the ability to cycle the air flow up and down. I've never used one of those fancy walk behind blower, but I have to believe they work similarly. But what do I know. To settle this, somebody's going to have to build one! Not me, by the way.