Hi all, very frustrated/tired after two days off of fighting with this. Hope I can get some help!

Seems like I'm just missing something.

I had to change the deck belt (42" deck", I have the correct belt (number on belt and package is what it should be. Blades were disengaged before starting this.

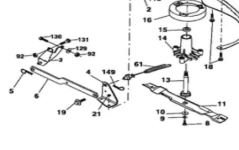

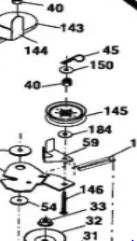

I dropped the deck, followed the diagrams and such. Belt is installed correctly BUT WILL NOT FIT around the front pulley.

I followed the instructions in the manual to the letter but there just isn't enough slack. The only way to make enough slack is to take the "spring Ext Elect Clutch" off (makes more slack in the belt) but then there is no way to reattach that when everything else is attached. Or if I get that (spring) back on, the deck support arms and such will NOT line up.

This is very hard to explain and just baffles me, this should not be a huge deal. I have had the thing on and off so many times it's just nuts, but I just can't figure it out.

I hope someone can tell me it's something really dumb that I'm missing. I really need to get this done so I can use it....

Thanks in Advance!!!

I tried to attach some photos but it says they are too Large?

Seems like I'm just missing something.

I had to change the deck belt (42" deck", I have the correct belt (number on belt and package is what it should be. Blades were disengaged before starting this.

I dropped the deck, followed the diagrams and such. Belt is installed correctly BUT WILL NOT FIT around the front pulley.

I followed the instructions in the manual to the letter but there just isn't enough slack. The only way to make enough slack is to take the "spring Ext Elect Clutch" off (makes more slack in the belt) but then there is no way to reattach that when everything else is attached. Or if I get that (spring) back on, the deck support arms and such will NOT line up.

This is very hard to explain and just baffles me, this should not be a huge deal. I have had the thing on and off so many times it's just nuts, but I just can't figure it out.

I hope someone can tell me it's something really dumb that I'm missing. I really need to get this done so I can use it....

Thanks in Advance!!!

I tried to attach some photos but it says they are too Large?