You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

YTA24V48 - Clutch Anti-Rotation Pin keeps snapping!

#1

S

shas595

S

shas595

Hello all

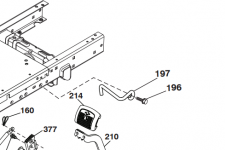

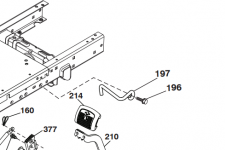

I have a YTA24V48 - Somehow the link that bolts to the frame to keep the clutch from spinning upon blade engagement keeps snapping. Mind you, its a 5/16" steel link (Item 197), pretty heavy duty.

It will run, then somehow it gets snapped, the clutch then is free to spin and rips the wires. This is the 4th pin I've replaced. Clutch works fine, its spinning freely when 12V Applied. I just cannot figure out how its getting broken.

You can see the top slot getting abused. What could possible cause the clutch to keep slamming into this pin and snap it.

I have notice the mower does rev up and down occasionally , but if the clutch is working then I don't see how that could affect it. Its driving me nuts!!

I have a YTA24V48 - Somehow the link that bolts to the frame to keep the clutch from spinning upon blade engagement keeps snapping. Mind you, its a 5/16" steel link (Item 197), pretty heavy duty.

It will run, then somehow it gets snapped, the clutch then is free to spin and rips the wires. This is the 4th pin I've replaced. Clutch works fine, its spinning freely when 12V Applied. I just cannot figure out how its getting broken.

You can see the top slot getting abused. What could possible cause the clutch to keep slamming into this pin and snap it.

I have notice the mower does rev up and down occasionally , but if the clutch is working then I don't see how that could affect it. Its driving me nuts!!

#2

sgkent

sgkent

I don't know your mower, and you probably see the same thing I do in the photo, but something like the blade or another pulley seems to be hitting that clutch or whatever it is, and that may be shearing your link. The steel is worn and peeled back. Also you can see where the rivets look worn by something hitting it. Is the blade loose, or does it have enough freeplay in it to hit that part? Can it or the spindle rise up to where it comes closer to the part? Are any bolts missing from the transmission or blade pulley system that allow excess movement? Just suggestions until someone comes by who has seen this before. Try to figure out what is hitting it first and that may lead you to the cause. The yellow box is where the wear arc is, and the arrow points to how hard what ever is hitting it is gouging into the part. That whatever is probably also shearing the pin.

Attachments

#3

B

bertsmobile1

B

bertsmobile1

I think you are confusing effect damage with cause damage .

When the retaining pin sheared the clutch would have spun & that would have caused the damage in the photos

That clutch has been hammering the retaining pin far too much so something is causing the clutch to slam into the pin, back off & slam into the pin again.

Loose engine mounting bolts will do this

Failed belt tensioner will do this

Running a belt that is too tight & mowing thick tufted grasses ( or hitting a lot of tree roots or scaopling the ground a lot ) will do this

Running with a bent blade will do this

Failed spindle bearings will do this

A bent PTO shaft will do this

Running a deck that is too heavy for the clutch will do this .

A broken wire is the clutch coil that is consistantly making & breaking contact will do this

If that was in my workshop I would file that slot true then weld in a thrust plate so the pin only has about 0.030" of clearance .

Before that I would have run the engine for a few seconds to check the PTO shaft is not bent and of course given the engine a good shove to make sure it is tight in the frame .

This is going to be a difficult problem to diagnose because there are so many causes that could be the problem either by themselves or in addition to each other .

When the retaining pin sheared the clutch would have spun & that would have caused the damage in the photos

That clutch has been hammering the retaining pin far too much so something is causing the clutch to slam into the pin, back off & slam into the pin again.

Loose engine mounting bolts will do this

Failed belt tensioner will do this

Running a belt that is too tight & mowing thick tufted grasses ( or hitting a lot of tree roots or scaopling the ground a lot ) will do this

Running with a bent blade will do this

Failed spindle bearings will do this

A bent PTO shaft will do this

Running a deck that is too heavy for the clutch will do this .

A broken wire is the clutch coil that is consistantly making & breaking contact will do this

If that was in my workshop I would file that slot true then weld in a thrust plate so the pin only has about 0.030" of clearance .

Before that I would have run the engine for a few seconds to check the PTO shaft is not bent and of course given the engine a good shove to make sure it is tight in the frame .

This is going to be a difficult problem to diagnose because there are so many causes that could be the problem either by themselves or in addition to each other .

#4

sgkent

sgkent

so when it spins what SPECIFIC part is it hitting that is gouging it so much?I think you are confusing effect damage with cause damage .

When the retaining pin sheared the clutch would have spun & that would have caused the damage in the photos

That clutch has been hammering the retaining pin far too much so something is causing the clutch to slam into the pin, back off & slam into the pin again.

Loose engine mounting bolts will do this

Failed belt tensioner will do this

Running a belt that is too tight & mowing thick tufted grasses ( or hitting a lot of tree roots or scaopling the ground a lot ) will do this

Running with a bent blade will do this

Failed spindle bearings will do this

A bent PTO shaft will do this

Running a deck that is too heavy for the clutch will do this .

A broken wire is the clutch coil that is consistantly making & breaking contact will do this

If that was in my workshop I would file that slot true then weld in a thrust plate so the pin only has about 0.030" of clearance .

Before that I would have run the engine for a few seconds to check the PTO shaft is not bent and of course given the engine a good shove to make sure it is tight in the frame .

This is going to be a difficult problem to diagnose because there are so many causes that could be the problem either by themselves or in addition to each other .

#5

S

shas595

The last time I replaced it, I didn't even cut grass, had the deck all the way up and was just picking up what little leaves were left after fall cleanup, so no work really on the blades.

I have to say, this thing does shake pretty well; I mean its a mower, but it seems to shake more than it should.

My plan is to fix the clutch wiring, put it back in without the deck and run it and check on the pin after a while. If its damaged its outside the deck, if not then my issue is like you said, bad pulley or bend blades. I appreciate the input, Ill keep you all posted.

S

shas595

You are definitely on the right track. My first thought was, it would have to be hammering that pin repeatedly for the pin to break before the sheet metal on the clutch. The mower does surge, do you think that could be part of it? I *think* when the blades are engaged they are always engaged (not the clutch turning on and off repeatedly), but its hard to be certain; however the clutch itself looks OK, the contacting surfaces are not that scored, so I can't imagine that its turning on and off in the middle of mowing otherwise the contacting plated would be really worn in.I think you are confusing effect damage with cause damage .

When the retaining pin sheared the clutch would have spun & that would have caused the damage in the photos

That clutch has been hammering the retaining pin far too much so something is causing the clutch to slam into the pin, back off & slam into the pin again.

Loose engine mounting bolts will do this

Failed belt tensioner will do this

Running a belt that is too tight & mowing thick tufted grasses ( or hitting a lot of tree roots or scaopling the ground a lot ) will do this

Running with a bent blade will do this

Failed spindle bearings will do this

A bent PTO shaft will do this

Running a deck that is too heavy for the clutch will do this .

A broken wire is the clutch coil that is consistantly making & breaking contact will do this

If that was in my workshop I would file that slot true then weld in a thrust plate so the pin only has about 0.030" of clearance .

Before that I would have run the engine for a few seconds to check the PTO shaft is not bent and of course given the engine a good shove to make sure it is tight in the frame .

This is going to be a difficult problem to diagnose because there are so many causes that could be the problem either by themselves or in addition to each other .

The last time I replaced it, I didn't even cut grass, had the deck all the way up and was just picking up what little leaves were left after fall cleanup, so no work really on the blades.

I have to say, this thing does shake pretty well; I mean its a mower, but it seems to shake more than it should.

My plan is to fix the clutch wiring, put it back in without the deck and run it and check on the pin after a while. If its damaged its outside the deck, if not then my issue is like you said, bad pulley or bend blades. I appreciate the input, Ill keep you all posted.

#6

sgkent

sgkent

Trying to get my head around that arrangement.

The pictorial shows that part #13 and the pulley above it #12 go onto the crank. When you apply voltage the magnetism which then causes the clutch to grab and apply power. The coil and bracket is held from spinning by maybe the two pins, (#9 and your #197). https://www.jackssmallengines.com/j...de-mowers/yta24v48-96045005400-2015-07/engine

What part is causing the wear pattern? If it is the pulley #12 why does it have so much play like that to allow it and the clutch to rub? Bent crank or worn thrust? I dunno. But looking at #12 online it appears to have too much clearance between it and the clutch by design so that should not be the part that rubs. Is the belt coming off and grabbing everything as it wears and shears the pin? Is this model capable of having the belt hop on and off the pulley in between the pulley and clutch where it still drives the mower but causes it to shake? I dunno. Maybe StarTech or Bert will know the cause.

I would check to see if anything was loose, engine or the transmission mount bolts loose front or rear. I would also want to check the clutch bearing to be sure it wasn't gritty or worn out because if the bearing is grabbing that would put a lot of pressure on the link.

Most of all I would want to understand the wear pattern and what is causing it. I guess as Bert suggested it could be anything in its path when it spins, maybe a bolt or even the broken pin I guess etc.. When the bearing is working right there should not be that much pressure on it unless other stresses are involved like a loose mount etc.. The engineers would not have designed it as a high failure item, and if it was an engineering mistake Google would have brought up a lot of others with the same issue. Bert or StarTech will figure it out.

The pictorial shows that part #13 and the pulley above it #12 go onto the crank. When you apply voltage the magnetism which then causes the clutch to grab and apply power. The coil and bracket is held from spinning by maybe the two pins, (#9 and your #197). https://www.jackssmallengines.com/j...de-mowers/yta24v48-96045005400-2015-07/engine

What part is causing the wear pattern? If it is the pulley #12 why does it have so much play like that to allow it and the clutch to rub? Bent crank or worn thrust? I dunno. But looking at #12 online it appears to have too much clearance between it and the clutch by design so that should not be the part that rubs. Is the belt coming off and grabbing everything as it wears and shears the pin? Is this model capable of having the belt hop on and off the pulley in between the pulley and clutch where it still drives the mower but causes it to shake? I dunno. Maybe StarTech or Bert will know the cause.

I would check to see if anything was loose, engine or the transmission mount bolts loose front or rear. I would also want to check the clutch bearing to be sure it wasn't gritty or worn out because if the bearing is grabbing that would put a lot of pressure on the link.

Most of all I would want to understand the wear pattern and what is causing it. I guess as Bert suggested it could be anything in its path when it spins, maybe a bolt or even the broken pin I guess etc.. When the bearing is working right there should not be that much pressure on it unless other stresses are involved like a loose mount etc.. The engineers would not have designed it as a high failure item, and if it was an engineering mistake Google would have brought up a lot of others with the same issue. Bert or StarTech will figure it out.

Attachments

#7

ILENGINE

ILENGINE

Either that clutch is shaking really bad due to the crankshaft wobbling, or there is a bearing failing within the clutch causing it to hammer that hard. You should be able to hang onto the clutch with your fingers and keep it from rotating. There shouldn't be any pressure on the anti rotation pin

#8

sgkent

sgkent

could the belt hop with loose mounts in a way that would load and unload it over and over?Either that clutch is shaking really bad due to the crankshaft wobbling, or there is a bearing failing within the clutch causing it to hammer that hard. You should be able to hang onto the clutch with your fingers and keep it from rotating. There shouldn't be any pressure on the anti rotation pin

#9

Hammermechanicman

Hammermechanicman

I would remove the deck and check all the bearings and inspect the belt for damage. A belt with a bad spot can cause the problem you are seeing.

#10

B

bertsmobile1

B

bertsmobile1

Surging should not be enough to shear the pin unless it is chronic enough to make the mower jump sideways

Surging can loosen the engine mounting bolts .

Surging can loosen the engine mounting bolts .

#11

ILENGINE

ILENGINE

could the belt hop with loose mounts in a way that would load and unload it over and over?

A bad spot in the belt would be more noticeable in the deck idler tension arm. The kind of force to damage the engine pulleys would be hammering the idler arm on the deck. Loose engine mounting bolts could cause issues because the damage is more relevant to a wobbling clutch pulley than a deck belt issue,I would remove the deck and check all the bearings and inspect the belt for damage. A belt with a bad spot can cause the problem you are seeing.

#12

M

MParr

M

MParr

I see some damage to the wiring insulation close to the clutch. I see oil on the engine side of the clutch. Time to remove the deck and check the torque on all of the fasteners on the bottom of your mower. Pay particular attention to the bolts holding down the engine. Check all of the pulleys on the deck. The clutch bracket is shot.

#13

Hammermechanicman

Hammermechanicman

Had a cust with a simplicity broadmoor that had a spindle seize and locked up the deck so the belt slipped on the clutch and burned the width to about half. Cust replaced the spindle but not he belt. The foot long narrow spot in the belt made the clutch hammer back and forth and the tension idler arm jump like crazy. Strange thing was there was no abnormal sound.A bad spot in the belt would be more noticeable in the deck idler tension arm. The kind of force to damage the engine pulleys would be hammering the idler arm on the deck. Loose engine mounting bolts could cause issues because the damage is more relevant to a wobbling clutch pulley than a deck belt issue,

#14

S

shas595

S

shas595

All

just inspected the deck. All blades are even (not bent), and they spin freely and without and slop so spindles seem to be OK. All pulleys are tight, the one on the deck (not tensioner) has a very tiny amount of play, not enough to be concerned about in my opinion. Belt looks good, no worn spots or uneven areas. Going to check out the engine and frame shortly

just inspected the deck. All blades are even (not bent), and they spin freely and without and slop so spindles seem to be OK. All pulleys are tight, the one on the deck (not tensioner) has a very tiny amount of play, not enough to be concerned about in my opinion. Belt looks good, no worn spots or uneven areas. Going to check out the engine and frame shortly

#15

G

Gord Baker

G

Gord Baker

Excellent advice. A NEW anchor plate should be attached first. Present one has cracks and is distorted. If you have clearance, get a 1/8" plate cut, formed and drilled to cover the existing plate and seal well it all around the perimiter.I think you are confusing effect damage with cause damage .

When the retaining pin sheared the clutch would have spun & that would have caused the damage in the photos

That clutch has been hammering the retaining pin far too much so something is causing the clutch to slam into the pin, back off & slam into the pin again.

Loose engine mounting bolts will do this

Failed belt tensioner will do this

Running a belt that is too tight & mowing thick tufted grasses ( or hitting a lot of tree roots or scaopling the ground a lot ) will do this

Running with a bent blade will do this

Failed spindle bearings will do this

A bent PTO shaft will do this

Running a deck that is too heavy for the clutch will do this .

A broken wire is the clutch coil that is consistantly making & breaking contact will do this

If that was in my workshop I would file that slot true then weld in a thrust plate so the pin only has about 0.030" of clearance .

Before that I would have run the engine for a few seconds to check the PTO shaft is not bent and of course given the engine a good shove to make sure it is tight in the frame .

This is going to be a difficult problem to diagnose because there are so many causes that could be the problem either by themselves or in addition to each other .

#16

R

Ranamow

R

Ranamow

If the engine bolts are loose, when you disengaged the mower you will hear a hammering noise for a few seconds.

#17

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

This reply in on point but did not list that the engine rpm is not steady, thus another back and forth against the pin. The pin and the hole in the clutch must be similar sized and the deck belt and engine rpm must not aggravate the pair.I think you are confusing effect damage with cause damage .

When the retaining pin sheared the clutch would have spun & that would have caused the damage in the photos

That clutch has been hammering the retaining pin far too much so something is causing the clutch to slam into the pin, back off & slam into the pin again.

Loose engine mounting bolts will do this

Failed belt tensioner will do this

Running a belt that is too tight & mowing thick tufted grasses ( or hitting a lot of tree roots or scaopling the ground a lot ) will do this

Running with a bent blade will do this

Failed spindle bearings will do this

A bent PTO shaft will do this

Running a deck that is too heavy for the clutch will do this .

A broken wire is the clutch coil that is consistantly making & breaking contact will do this

If that was in my workshop I would file that slot true then weld in a thrust plate so the pin only has about 0.030" of clearance .

Before that I would have run the engine for a few seconds to check the PTO shaft is not bent and of course given the engine a good shove to make sure it is tight in the frame .

This is going to be a difficult problem to diagnose because there are so many causes that could be the problem either by themselves or in addition to each other .

#18

B

bertsmobile1

Except that the engine rpm changes need to be fairly drastic .

In most cases it is just varying the pressure on the retaining pin rather than backing off and hammering the pin except when there is little to no load on the blades .

I think it was the Xmarks that I had to fit a rubber damper to the pin to stop it ratteling because it was so loud the customers kept bringing the mowers back for services .

B

bertsmobile1

No arguement about thatThis reply in on point but did not list that the engine rpm is not steady, thus another back and forth against the pin. The pin and the hole in the clutch must be similar sized and the deck belt and engine rpm must not aggravate the pair.

Except that the engine rpm changes need to be fairly drastic .

In most cases it is just varying the pressure on the retaining pin rather than backing off and hammering the pin except when there is little to no load on the blades .

I think it was the Xmarks that I had to fit a rubber damper to the pin to stop it ratteling because it was so loud the customers kept bringing the mowers back for services .

#19

S

shas595

S

shas595

Another update.

I noticed when I put the clutch back on, without the deck, and tightened it up, it instantly seized. As in even the loose ring up top was no longer moving. I am fairly certian thats not right.

I am noticing when I search for the clutch that matches my mower, it shows the clutch having what looks like a 1/4" rise above the bearing / face plate (see pic) where as mine (pic in original post) is flush. I am not sure which is correct, but that would make sense that its seizing up upon tightening. I need to get a definitive answer on what clutch I should have and what it looks like. Maybe this is the root of the issue?

I noticed when I put the clutch back on, without the deck, and tightened it up, it instantly seized. As in even the loose ring up top was no longer moving. I am fairly certian thats not right.

I am noticing when I search for the clutch that matches my mower, it shows the clutch having what looks like a 1/4" rise above the bearing / face plate (see pic) where as mine (pic in original post) is flush. I am not sure which is correct, but that would make sense that its seizing up upon tightening. I need to get a definitive answer on what clutch I should have and what it looks like. Maybe this is the root of the issue?

#20

sgkent

it sounds like your bearing has failed, and no longer spins properly. I'd replace it. You might be able to look at the other side and see if the bearing has moved, and left a witness mark where it was pressed into originally. The witness mark would be about the amount it used to be above the other side.

sgkent

I noticed when I put the clutch back on, without the deck, and tightened it up, it instantly seized.

it sounds like your bearing has failed, and no longer spins properly. I'd replace it. You might be able to look at the other side and see if the bearing has moved, and left a witness mark where it was pressed into originally. The witness mark would be about the amount it used to be above the other side.

#21

M

MParr

saffordequipment.com

saffordequipment.com

M

MParr

Husqvarna 5.0 Ogura Electric Clutch OEM #587241601 | Safford Equipment Company

Husqvarna 5.0 Ogura Electric Clutch OEM #587241601 This is a Genuine OEM Part. Find this and other great parts at Safford Equipment.

#22

S

shas595

S

shas595

Another (Possible solution) Update!

So I noticed, the crankshaft is 1.000": Dia, but the bore on my clutch is 1-1/8".

I can put the clutch on any way wityout having to line up the keyway as there is 1/8" of play. If thats the case, its going to be off center and whipping like crazy, which would explain my issue??? I hope.

I am waiting back to hear from my local Husq dealer to get the info on which is the correct clutch for my mower, but I think I'm on the right track!!

So I noticed, the crankshaft is 1.000": Dia, but the bore on my clutch is 1-1/8".

I can put the clutch on any way wityout having to line up the keyway as there is 1/8" of play. If thats the case, its going to be off center and whipping like crazy, which would explain my issue??? I hope.

I am waiting back to hear from my local Husq dealer to get the info on which is the correct clutch for my mower, but I think I'm on the right track!!

#24

Scrubcadet10

Scrubcadet10

What engine is on this unit? from what I've found it should be a briggs V-Twin. 44_______