You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Vanguard 7.5 ignition coil help

#1

B

Blownvette

B

Blownvette

Have a near new (very low hours) 1997 Vanguard 7.5 in a Ryan Lawnaire 28 aerator.

Starts early on first pull. Dies when hot.

Replaced all fuel lines, fuel line cutoff valve, new Briggs and Stratton carb, new spark plug, changed oil, new Briggs pre filter and air filter. Think it’s the ignition coil but can’t fine a new one other than the cheap eBay types…

Any one have any ideas or sources for a Briggs coil? 715982 is the part number of the coil. All the places listing it as available don’t have it in stock and Briggs is sold out. Thanks

Starts early on first pull. Dies when hot.

Replaced all fuel lines, fuel line cutoff valve, new Briggs and Stratton carb, new spark plug, changed oil, new Briggs pre filter and air filter. Think it’s the ignition coil but can’t fine a new one other than the cheap eBay types…

Any one have any ideas or sources for a Briggs coil? 715982 is the part number of the coil. All the places listing it as available don’t have it in stock and Briggs is sold out. Thanks

#3

B

Blownvette

B

Blownvette

Thanks for pointing that out. Really want to avoid non Briggs parts if possible. I searched on the forum and it was mentioned about sanding the coil and it being a problem on the Vanguard engines? Has anyone had any experience with the grounding issue and sanding to clear the warm engine cutoff issue?

#4

StarTech

StarTech

I too prefer to stick with OEM most times but Briggs is really dragging their feet on parts lately. We have been fighting for the last two years with one particular camshaft delivery issue it taking up to 6 month or better just to get them.

I even got an under one year Poulan Pole saw that I can't even get a throttle cable until after maybe March 2023. Doesn't do any good when the customer needs the saw now.

I even got an under one year Poulan Pole saw that I can't even get a throttle cable until after maybe March 2023. Doesn't do any good when the customer needs the saw now.

#5

B

bertsmobile1

B

bertsmobile1

Firstly B & S make absolutely nothing

like most modern companies run by MBA's they sold off all of the manufacturing divisions in favour of buying in everything and just assembling engines. Thus they can drive down the cost of each item by competative tenders .

The reason why there are so many Chinese B & S parts is because just about all of the parts are made in China

The only benefit of purchasing B & S branded parts is you can be 90% sure the parts have been through a thorough QC regeime so they should be good .

I buy parts directly from the manufacturers in China via "made in china" and am yet to get a dud part out of well over a thousand parts purchased .

The demand for old parts is very low and from an accounting point of view, buying a minimum economic orders worth of your magnetos knowing that the demand is less than 100 / year and the minimum economic quantity is 1000 means it is considered bad use of capital so B & S will not do it when the same money spent on new engine parts will yield a better return in a shorter time .

B & S are not alone in this

a lot of brand names will not order old parts till they have accumulated 30% to 50% of a minimum economic order quantity on back order thus if they order 1000 of your magnetos they can be sure that 500 will sell in the first week which would just about return the cost .

Again a management theory out of Princeton University taught to all MBA graduates world wide ( yes Aust companies do the same thing too ).

So don't expect the new mean, lean & financially prudent B & S to carry parts for engines that are older than the previous series ie, current model & it's predessor only after that they want you to buy a new engine.

Remember B & S make their money from selling new engines to mower manufacturers not from selling retail customers engines or parts , that division looses money which is why you can not get much in the way of parts for any cheap import from any country because supplying service & repair parts LOOSES money despite what all the braindead morons on Face Ache , Twatter & You Boob espouse .

Finally rust on a coils laminations has zero effect on it unless it is between the laminations & the ground contact or it gets thick enough to bridge the gap between the laminations & the magnet.

The use of any mechanical device to clean the surface of a magnet actually decreases the strength of the magnet so wire brushes are a no no

like most modern companies run by MBA's they sold off all of the manufacturing divisions in favour of buying in everything and just assembling engines. Thus they can drive down the cost of each item by competative tenders .

The reason why there are so many Chinese B & S parts is because just about all of the parts are made in China

The only benefit of purchasing B & S branded parts is you can be 90% sure the parts have been through a thorough QC regeime so they should be good .

I buy parts directly from the manufacturers in China via "made in china" and am yet to get a dud part out of well over a thousand parts purchased .

The demand for old parts is very low and from an accounting point of view, buying a minimum economic orders worth of your magnetos knowing that the demand is less than 100 / year and the minimum economic quantity is 1000 means it is considered bad use of capital so B & S will not do it when the same money spent on new engine parts will yield a better return in a shorter time .

B & S are not alone in this

a lot of brand names will not order old parts till they have accumulated 30% to 50% of a minimum economic order quantity on back order thus if they order 1000 of your magnetos they can be sure that 500 will sell in the first week which would just about return the cost .

Again a management theory out of Princeton University taught to all MBA graduates world wide ( yes Aust companies do the same thing too ).

So don't expect the new mean, lean & financially prudent B & S to carry parts for engines that are older than the previous series ie, current model & it's predessor only after that they want you to buy a new engine.

Remember B & S make their money from selling new engines to mower manufacturers not from selling retail customers engines or parts , that division looses money which is why you can not get much in the way of parts for any cheap import from any country because supplying service & repair parts LOOSES money despite what all the braindead morons on Face Ache , Twatter & You Boob espouse .

Finally rust on a coils laminations has zero effect on it unless it is between the laminations & the ground contact or it gets thick enough to bridge the gap between the laminations & the magnet.

The use of any mechanical device to clean the surface of a magnet actually decreases the strength of the magnet so wire brushes are a no no

#6

StarTech

StarTech

Bert, you pretty got it. The problem with Briggs right is that they had file bankruptcy and was snatched up by a financial investment group that only cares about making top dollar on everything thing. Customer loyalty went right out the door when they took over Briggs.

I got Nikki fuel bowls here that was sold for under $30 to dealers before all this happen and they now cost around $120 ea and for a while they were the same price as a complete carburetor. Nearly everything Briggs sales now is over priced. I am having to buy Briggs after market parts now because the OEM parts are out sight price wise.

On top this it is becoming impossible to get parts most of the imported stuff as the factories in China tends to disappear after a major run of making an item.

Plus I have lost two Briggs distributors as they demand more in sales than I could per because of the over priced parts and engines.

I am even name brand OEM equipment becoming throw a way lately too I got current a Poulan polesaw in the shop now that is less one year and can't even get a throttle cable for it. It is about the same with a Stihl brush cutter that I need a drive cable for. It has been on back order for now 8 months. I finally cancelled the order Friday as I found an used Stihl with the right cable that has a bad engine. I also had Chinese kids ATV in the shop back in the Spring that was 6 months old that I could not get parts for yet the local dealer was still selling new ones.

I got Nikki fuel bowls here that was sold for under $30 to dealers before all this happen and they now cost around $120 ea and for a while they were the same price as a complete carburetor. Nearly everything Briggs sales now is over priced. I am having to buy Briggs after market parts now because the OEM parts are out sight price wise.

On top this it is becoming impossible to get parts most of the imported stuff as the factories in China tends to disappear after a major run of making an item.

Plus I have lost two Briggs distributors as they demand more in sales than I could per because of the over priced parts and engines.

I am even name brand OEM equipment becoming throw a way lately too I got current a Poulan polesaw in the shop now that is less one year and can't even get a throttle cable for it. It is about the same with a Stihl brush cutter that I need a drive cable for. It has been on back order for now 8 months. I finally cancelled the order Friday as I found an used Stihl with the right cable that has a bad engine. I also had Chinese kids ATV in the shop back in the Spring that was 6 months old that I could not get parts for yet the local dealer was still selling new ones.

#7

B

bertsmobile1

B

bertsmobile1

This management philosophy was in place well before the B & S bankruptcy & is the norm for most large public companies .

B & S engine parts have been underpriced for decades Kawasaki & Kohler prices are actually reasonable but people call them expensive because they get compared to the very cheap B & S parts.

Back when B & S had better than 1/2 of the market there was probably enough profits from new engine sales to subsidize spare parts and cheaper spares was a selling point so there was strong demand for mowers that had the B & S engines fitted .

Now B &S are a small bit player and their volumes are reducing every year

Remember no sales at all to MTD almost non to Toro & the bottom end cheap engine in the Husqvarna range replacing Tecumseh .

Their big mistake was being out foxed by MTD when they took over Murray to abandoned mower manufacture which increased the volumes and power of AYP & MTD , had they kept Murray production going then their would have been a big enough volume to maintain profitable levels of production but without Murray & MTD B& S is doomed to become a low volume small bit player supplying engines only to their own brands and a small number to other makers who want to wave the Stars & Stripes by selling an "All American" to that small percentage of the population that have a flagpole in their front yard

The dominant management plan in Western businesses is to flog off flashy looking low service life products with as little after sales support as possible and governments have been encouraging this for decades

The EU tried to bring in manditory service life and the result was locally made products being abandoned in favour of imports that did not have the same provisions applied to them .

This is the 2nd big reason why the planet is in the situation we are in now .

There needs to be a lot less manufacture for replacement os short life products if we want to survive but that is a hard message to sell a product by.

Purchase our new 20 year service life lawnmower so the planet will survive for your great grandchildren

or

Purchase this wizz bang new mower for 30% less than those 20 year mowers

We all know what wins

B & S engine parts have been underpriced for decades Kawasaki & Kohler prices are actually reasonable but people call them expensive because they get compared to the very cheap B & S parts.

Back when B & S had better than 1/2 of the market there was probably enough profits from new engine sales to subsidize spare parts and cheaper spares was a selling point so there was strong demand for mowers that had the B & S engines fitted .

Now B &S are a small bit player and their volumes are reducing every year

Remember no sales at all to MTD almost non to Toro & the bottom end cheap engine in the Husqvarna range replacing Tecumseh .

Their big mistake was being out foxed by MTD when they took over Murray to abandoned mower manufacture which increased the volumes and power of AYP & MTD , had they kept Murray production going then their would have been a big enough volume to maintain profitable levels of production but without Murray & MTD B& S is doomed to become a low volume small bit player supplying engines only to their own brands and a small number to other makers who want to wave the Stars & Stripes by selling an "All American" to that small percentage of the population that have a flagpole in their front yard

The dominant management plan in Western businesses is to flog off flashy looking low service life products with as little after sales support as possible and governments have been encouraging this for decades

The EU tried to bring in manditory service life and the result was locally made products being abandoned in favour of imports that did not have the same provisions applied to them .

This is the 2nd big reason why the planet is in the situation we are in now .

There needs to be a lot less manufacture for replacement os short life products if we want to survive but that is a hard message to sell a product by.

Purchase our new 20 year service life lawnmower so the planet will survive for your great grandchildren

or

Purchase this wizz bang new mower for 30% less than those 20 year mowers

We all know what wins

#8

ILENGINE

Murray was a slightly larger company than MTD which both of them combined wasn't even a spot on the radar for AYP. Back when MTD, Murray, and AYP were servicing Walmart. MTD and Murray has basically 13 states each east of the Mississippi River. AYP had the other 24 states West of the Mississippi(numbers not exact) and that was only 5% of AYP annual production. A much larger portion of AYP production went to Craftsman and we all know how that ended.

ILENGINE

The Murray thing was complicated. It wasn't by choice to stop production of Murray. Briggs was barred from using the Murray name for 5 years as part of the bankruptcy agreement. Production of the Murray products became Brute Power Products and was still continuing under that same until recently. One of the big mistakes Briggs made was farming out those brand names to other companies for productions. In 2010 with Murray name back on the market they were manufactured by MTD and AYP using Briggs engines by contract agreement and later to a Chinese company with no product support. What really put Briggs in the doghouse was MTD stopped using Briggs engines for a period after the Murray bankruptcy. and started their own import branded engine that same year.Remember no sales at all to MTD almost non to Toro & the bottom end cheap engine in the Husqvarna range replacing Tecumseh .

Their big mistake was being out foxed by MTD when they took over Murray to abandoned mower manufacture which increased the volumes and power of AYP & MTD , had they kept Murray production going then their would have been a big enough volume to maintain profitable levels of production but without Murray & MTD B& S is doomed to become a low volume small bit player supplying engines only to their own brands and a small number to other makers who want to wave the Stars & Stripes by selling an "All American" to that small percentage of the population that have a flagpole in their front yard

Murray was a slightly larger company than MTD which both of them combined wasn't even a spot on the radar for AYP. Back when MTD, Murray, and AYP were servicing Walmart. MTD and Murray has basically 13 states each east of the Mississippi River. AYP had the other 24 states West of the Mississippi(numbers not exact) and that was only 5% of AYP annual production. A much larger portion of AYP production went to Craftsman and we all know how that ended.

#9

B

bertsmobile1

B

bertsmobile1

While the Murray branded products were banned Murray made a lot of other brands

Down here Murray made the ride ons for Victa , Rover, Pace , Parklander , Stihl and several local store brands .

Murray also made a lot of brands sold in the EU some of which are also imported into Australia & of course some of the Craftsman branded mowers.

And Sentinal was also supposedly an independent brand made for Sentinal by Murray and we got a lot of Murray Sentinals ( painted black ) and almost identical Sentinals by Murray painted red

Most of these brands continued by sourcing mowers from China , while Stihl seemed to drop the mower line all together.

What my rep told me was MTD told B &S that they would stop using any B & S engine if they continued running the Murray factory which was of course was in direct competition to MTD particular for manufacture of other branded mowers.

Weather that was the absolute truth is another question but that is what I was told

Down here Murray made the ride ons for Victa , Rover, Pace , Parklander , Stihl and several local store brands .

Murray also made a lot of brands sold in the EU some of which are also imported into Australia & of course some of the Craftsman branded mowers.

And Sentinal was also supposedly an independent brand made for Sentinal by Murray and we got a lot of Murray Sentinals ( painted black ) and almost identical Sentinals by Murray painted red

Most of these brands continued by sourcing mowers from China , while Stihl seemed to drop the mower line all together.

What my rep told me was MTD told B &S that they would stop using any B & S engine if they continued running the Murray factory which was of course was in direct competition to MTD particular for manufacture of other branded mowers.

Weather that was the absolute truth is another question but that is what I was told

#10

ILENGINE

ILENGINE

The only true statement that can be confirmed is MTD did stop using Briggs engines on their products for a period of time. There have been so many shutdowns and sales of so many mower and mower parts manufacturers the last few years it is hard to keep them all straight.

#11

StarTech

StarTech

And it is a nightmare to figure who made what at times. It is like the new Snapper mowers that are under Briggs wings that are actually using Husqvarna parts. A few that have been in my shop I discovered that the Husqvarna part numbers are on many of the parts; although, when you look up the parts they have Briggs part number on the IPLs. Now some of the Husqvarna are customize for the Snappers and Husqvarna will not list those part numbers openly.

This hiding of the true manufacture is done so the equipment OEM can make more money on the parts as they know very well people like me do buy at the best price from our distributors. The internet has caused these companies headaches as we find way around their pricing schemes.

As we all should know by now OEMs are switching to selling assemblies only now which something the auto industry did decades ago. I remember when I could rebuild starters, alternators, wheel cylinders, brake master cylinders, and power rack and pinion assemblies. Now all we can get is either new or factory rebuilt units. A real irritate to someone that knows how to it but can't get the parts.

And we must be willing to retrain ourselves as the industry changes as it the case with lawn care here in the USA as we are being force into battery powered equipment to supposedly save our planet. But the manufactures must be willing to part with the info to service these unit. We must be supplied with things like wiring schematics and decent IPLs.

Our reduce, reuse, and recycle program has been a major failure now as more and more items are being throw away because the lack of parts and service info. Many of our younger techs don't even have the knowledge to do anything other than part swap, guessing at the causes. Many don't even an idea of how to troubleshoot problems.

I had one in the area that claim him knew everything about mowers because he was a diesel mechanic. Well he didn't as he screwed up several my customers mowers. I had go behind him remove his screw ups and fix the equipment correctly. I afraid the next generation will be a bunch of college educated dummies. What I mean they will be book smart but have no practical knowledge or abilities Most now can't even change out a light switch.

When I retire from this work who know if anyone will even be able or willing to do the things that I can.

This hiding of the true manufacture is done so the equipment OEM can make more money on the parts as they know very well people like me do buy at the best price from our distributors. The internet has caused these companies headaches as we find way around their pricing schemes.

As we all should know by now OEMs are switching to selling assemblies only now which something the auto industry did decades ago. I remember when I could rebuild starters, alternators, wheel cylinders, brake master cylinders, and power rack and pinion assemblies. Now all we can get is either new or factory rebuilt units. A real irritate to someone that knows how to it but can't get the parts.

And we must be willing to retrain ourselves as the industry changes as it the case with lawn care here in the USA as we are being force into battery powered equipment to supposedly save our planet. But the manufactures must be willing to part with the info to service these unit. We must be supplied with things like wiring schematics and decent IPLs.

Our reduce, reuse, and recycle program has been a major failure now as more and more items are being throw away because the lack of parts and service info. Many of our younger techs don't even have the knowledge to do anything other than part swap, guessing at the causes. Many don't even an idea of how to troubleshoot problems.

I had one in the area that claim him knew everything about mowers because he was a diesel mechanic. Well he didn't as he screwed up several my customers mowers. I had go behind him remove his screw ups and fix the equipment correctly. I afraid the next generation will be a bunch of college educated dummies. What I mean they will be book smart but have no practical knowledge or abilities Most now can't even change out a light switch.

When I retire from this work who know if anyone will even be able or willing to do the things that I can.

#12

ILENGINE

ILENGINE

The problem Star is the OEM's have no plans to make the battery equipment repairable or even serviceable. When it dies it will go straight to the landfill and get replaced. No replacement parts, no replacement batteries. and if your 48v trimmer quits with a faulty battery under warranty the OEM will just cut the customer a check and then the customer can go buy the newest 49v trimmer because the 48v battery is no longer available. The push has been in the works for years to make the service centers, and the techs NLA.

#13

StarTech

StarTech

This has been my impression for years from what I have been seeing over the years. For it has been getting harder and harder to just get the parts I need to do repairs. When the world come to realization as to what we doing to planet it probably be too late but most likely I won't be around then. I already got one foot on the banana peel and going downhill.The problem Star is the OEM's have no plans to make the battery equipment repairable or even serviceable. When it dies it will go straight to the landfill and get replaced. No replacement parts, no replacement batteries. and if your 48v trimmer quits with a faulty battery under warranty the OEM will just cut the customer a check and then the customer can go buy the newest 49v trimmer because the 48v battery is no longer available. The push has been in the works for years to make the service centers, and the techs NLA.

#14

ILENGINE

ILENGINE

Star I am on the banana peel myself. 3 weeks and still don't have an ortho consult appointment. So this arm injury has the potential of leading to life changing events.

#15

B

Blownvette

B

Blownvette

Thank you to everyone for the insight. At this point even the aftermarket ones do not appear to be proper. The one on Amazon does not match what is in the aerator. If anyone has, or knows a source for an aftermarket part it would be greatly appreciated if you were able to share it.

Attachments

#17

ILENGINE

ILENGINE

I don't know what difference you are looking at. But Briggs went from a induction ignition system to a CDI ignition on most of their replacement coils. so you can no longer compare the old coil shape to the new coil shape. The old induction systems were more of a round center winding looking coil, were as the new CDI ignition coils are more box rectangular shaped if that is what you are comparing.Thank you to everyone for the insight. At this point even the aftermarket ones do not appear to be proper. The one on Amazon does not match what is in the aerator. If anyone has, or knows a source for an aftermarket part it would be greatly appreciated if you were able to share it.

#18

StarTech

StarTech

Kinda what I am thinking too; unless, someone changed the engine shroud and didn't transfer the engine info from the old shroud.

#19

B

Blownvette

B

Blownvette

I believe the engine matches the cover picture I posted as the replacement carburetor was correct for the engine. below is the photos of the coil I need to replace. Really need a source for a correct replacement as the aftermarket do not seem to match the external wires that the original has. Thanks for all that help. Really appreciate your replies.

Attachments

#22

ILENGINE

ILENGINE

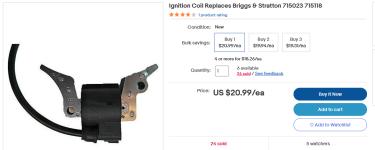

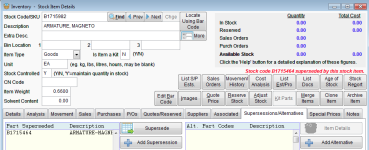

Look at the 715023 coil It appears there are three very similar ignition modules used on similar engines. the 715023 is used on the 6.5 hp engine the 715982 is used on the 7.5 hp and the 715118 is used on the 9 hp engine. I found a listing on amazon that says replaced 715023, 715118. and 715464 which is the predecessor to the 715982. So the choices could be the module on your engine is incorrect. Or try Star's option of inverting the module.

#23

StarTech

StarTech

Good Catch there IL. The new coil pack does appears to be the Briggs 715023.

And the 715023 is not a direct replacement for the 715982 but the Chinese apparently are saying it will work anyways when installed. Drop the B1 prefix I use in house.

Sometimes it is only the tension lead length and termination that are the main differences. But IL probably remember those coils on v-twin that Briggs had us modifying the cylinder mounting with a die grinder so the new replacement coils would fit several years ago.

And the 715023 is not a direct replacement for the 715982 but the Chinese apparently are saying it will work anyways when installed. Drop the B1 prefix I use in house.

Sometimes it is only the tension lead length and termination that are the main differences. But IL probably remember those coils on v-twin that Briggs had us modifying the cylinder mounting with a die grinder so the new replacement coils would fit several years ago.

#24

ILENGINE

It also looks like they use the 915023 the 715464 and the 715982 on the 138432 engine depending on type number.

ILENGINE

Remember grinding them to fit the square peg in the round hole. Or for the unknowing, we has to grind down the webbing between the module mounting pegs to make clearance for the new CDI square body of the modules.Good Catch there IL. The new coil pack does appears to be the Briggs 715023.

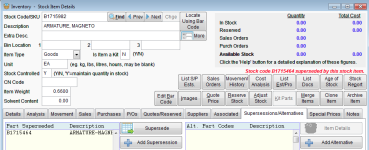

View attachment 62875

And the 715023 is not a direct replacement for the 715982 but the Chinese apparently are saying it will work anyways when installed. Drop the B1 prefix I use in house.

View attachment 62876

Sometimes it is only the tension lead length and termination that are the main differences. But IL probably remember those coils on v-twin that Briggs had us modifying the cylinder mounting with a die grinder so the new replacement coils would fit several years ago.

It also looks like they use the 915023 the 715464 and the 715982 on the 138432 engine depending on type number.