You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Used tractor nightmare

#1

Demonseed

Demonseed

Hello all, while I hate to meet new folks under stressful times, I'm certainly glad you've stopped in to hear just how bad of an experience buying a used tractor could be.

So I guess I begin with the machine which is a MTD Yard-Man Model 13AC762F755 DOM 4/2007 and I don't know if these next are relevant but their located just under the model so I'll include them too, 1602944.

So now that we all know "what" machine we're talking about, let's move right into the "why" we're talking about it.

As mentioned, this tractor was bought used. Supposedly in perfect operating condition. Well as I'm sure you've guessed by now, that wasn't exactly truthful.

When I went to pick it up from the guy, he was already outside with it and jumping it off. So ok, bad battery, not so bad. He gets it started with ease, turned over one time and fired right up, cool, so far so good. He then proceeded to demo it cutting capabilities, and right away it was obvious something wasn't quite right, and It was making noises it had no business making. And the blades weren't engaging correctly. He tinkered a bit but ultimately placed the blame on a spring that was damaged or missing. And like a fool I believed him, and didn't inspect it for my self. But honestly I don't know it would of done any good, because I wasn't familiar with the machine and wouldn't have caught the slew of problems it really had.

It wasn't untill I got it home, took it apart, then looked up it's breakdown manual that it became painfully clear that this deck was missing a lot of it's parts. Not only that but the parts that were on it didn't belong to it.

So thinking this was the extent of my troubles, I proceeded to examine the parts manual, and begin the painful experience of looking up and procuring every single part that bolted to the deck so I could rebuild it entirely with new OEM parts.

After jumping into all sorts of discontinued part number rabbit holes, and locating every piece I could identify from the exploded view of the deck, I then put it all together. That bit went fairly smoothly, and thinking I had this thing handled, I proceeded to remounting the deck to the machine.

Ok, I should of mentioned already, while researching all the parts I kept running into parts that were exclusively intended for a 46 inch deck, and what I have is a 38 inch. Now up to now I've been only referencing the deck portion of the parts manual thinking that covered all parts deck related.

So now I'm trying to reinstall the deck with all the bogus parts and deck mods reverted to their original manufacturer condition, and it's a fight. Like almost impossible, can't win kind of fight. And for the life of me I can't figure out what in the world is so wrong that the hangers absolutely will not reach all their intended mounting locations. Like, as far as I could tell by going over the manuals, and having only now ventured onto a new page, going over what I saw vs what the manual showed it appeared everything was in its place, present and accounted for except one oblong bracket that on the webpage I was referencing was identified as "unknown (discontinued)" with nothing more. And to further compound my confusion the exploded view is a multi model breakdown and so has parts shown that don't necessarily apply to everyone.

So after combing through all the parts several times, I finally noticed a detail that I've been over looking, and it was a sub-exploded view of all my lift hangers and hardware (meaning these were the parts I can see are actually on this machine) and they were circled with a footnote "46 inch deck hangers"

So once I got the world to quit spinning, I went back to the manual trying to understand how these could only be for a 46 inch when I clearly had a 38 inch machine and nothing so far as I could tell from the manual showed what was meant to hang the smaller decks. That is untill I noticed that one oblong bar shown again,. But there's only one shown so there isn't any way that could be a hanger bracket right?

Fast forward, I downloaded the parts pdf from MTD and printed it, then located the mystery bracket known up to now as part 41 "unknown (discontinued)" and then hopped over to the reference page and... Low and behold there it was, 41 Lift arm, Deck-RH. Followed up by a ghost part with no reference number for the exploded view, named, you guessed it, Lift arm, Deck-LH.

Neither of which were present on my machine, but also weren't shown with any sort of context by the manual, so as far as I knew they were actually an old and discontinued part no longer used but still referenced for the sake of historical purposes.

The hunt continued then for undisputable proof that I either did or didn't have parts intended for a bigger deck, and that's when I saw it, among all the other part names on the index page, (Deck lift lever [46 inch decks only]) so I jumped back to the exploded view and there it was right in front of me the entire time. Two completely different lifting levers that I could easily tell for sure now which I infact had. F-my life. It's the 46 lever.

So now I sit here, licking my wounds, pondering what kind of jacka** would hack up a machine so completely. Then I started to wonder if it's time to start counting my losses and throw in the towel, or dig-in and find out just how many more curveballs these pricks had left for me to discover.

I'm currently sitting somewhere around 500ish dollars with the machine and all parts purchased, with no clue how much a new complete 38 inch deck hanger system will cost, or even how involved it is to actually change all those parts.

I'm beat up. This damn thing has beat me down. I don't know enough about these things (but I'm quickly learning) to know what my best move from here is.

If any of you out there have an opinion on the matter, I sure would love to hear it. If y'all say that the worst is over and the remaining repairs aren't stupid to achieve, I guess I'll keep going, but I'm at a loss.

Everyone's welcome to point out exactly how many times I had to jump ship, before I crossed that point of no return.

I leave my future in you guys hands, don't let me down!

So I guess I begin with the machine which is a MTD Yard-Man Model 13AC762F755 DOM 4/2007 and I don't know if these next are relevant but their located just under the model so I'll include them too, 1602944.

So now that we all know "what" machine we're talking about, let's move right into the "why" we're talking about it.

As mentioned, this tractor was bought used. Supposedly in perfect operating condition. Well as I'm sure you've guessed by now, that wasn't exactly truthful.

When I went to pick it up from the guy, he was already outside with it and jumping it off. So ok, bad battery, not so bad. He gets it started with ease, turned over one time and fired right up, cool, so far so good. He then proceeded to demo it cutting capabilities, and right away it was obvious something wasn't quite right, and It was making noises it had no business making. And the blades weren't engaging correctly. He tinkered a bit but ultimately placed the blame on a spring that was damaged or missing. And like a fool I believed him, and didn't inspect it for my self. But honestly I don't know it would of done any good, because I wasn't familiar with the machine and wouldn't have caught the slew of problems it really had.

It wasn't untill I got it home, took it apart, then looked up it's breakdown manual that it became painfully clear that this deck was missing a lot of it's parts. Not only that but the parts that were on it didn't belong to it.

So thinking this was the extent of my troubles, I proceeded to examine the parts manual, and begin the painful experience of looking up and procuring every single part that bolted to the deck so I could rebuild it entirely with new OEM parts.

After jumping into all sorts of discontinued part number rabbit holes, and locating every piece I could identify from the exploded view of the deck, I then put it all together. That bit went fairly smoothly, and thinking I had this thing handled, I proceeded to remounting the deck to the machine.

Ok, I should of mentioned already, while researching all the parts I kept running into parts that were exclusively intended for a 46 inch deck, and what I have is a 38 inch. Now up to now I've been only referencing the deck portion of the parts manual thinking that covered all parts deck related.

So now I'm trying to reinstall the deck with all the bogus parts and deck mods reverted to their original manufacturer condition, and it's a fight. Like almost impossible, can't win kind of fight. And for the life of me I can't figure out what in the world is so wrong that the hangers absolutely will not reach all their intended mounting locations. Like, as far as I could tell by going over the manuals, and having only now ventured onto a new page, going over what I saw vs what the manual showed it appeared everything was in its place, present and accounted for except one oblong bracket that on the webpage I was referencing was identified as "unknown (discontinued)" with nothing more. And to further compound my confusion the exploded view is a multi model breakdown and so has parts shown that don't necessarily apply to everyone.

So after combing through all the parts several times, I finally noticed a detail that I've been over looking, and it was a sub-exploded view of all my lift hangers and hardware (meaning these were the parts I can see are actually on this machine) and they were circled with a footnote "46 inch deck hangers"

So once I got the world to quit spinning, I went back to the manual trying to understand how these could only be for a 46 inch when I clearly had a 38 inch machine and nothing so far as I could tell from the manual showed what was meant to hang the smaller decks. That is untill I noticed that one oblong bar shown again,. But there's only one shown so there isn't any way that could be a hanger bracket right?

Fast forward, I downloaded the parts pdf from MTD and printed it, then located the mystery bracket known up to now as part 41 "unknown (discontinued)" and then hopped over to the reference page and... Low and behold there it was, 41 Lift arm, Deck-RH. Followed up by a ghost part with no reference number for the exploded view, named, you guessed it, Lift arm, Deck-LH.

Neither of which were present on my machine, but also weren't shown with any sort of context by the manual, so as far as I knew they were actually an old and discontinued part no longer used but still referenced for the sake of historical purposes.

The hunt continued then for undisputable proof that I either did or didn't have parts intended for a bigger deck, and that's when I saw it, among all the other part names on the index page, (Deck lift lever [46 inch decks only]) so I jumped back to the exploded view and there it was right in front of me the entire time. Two completely different lifting levers that I could easily tell for sure now which I infact had. F-my life. It's the 46 lever.

So now I sit here, licking my wounds, pondering what kind of jacka** would hack up a machine so completely. Then I started to wonder if it's time to start counting my losses and throw in the towel, or dig-in and find out just how many more curveballs these pricks had left for me to discover.

I'm currently sitting somewhere around 500ish dollars with the machine and all parts purchased, with no clue how much a new complete 38 inch deck hanger system will cost, or even how involved it is to actually change all those parts.

I'm beat up. This damn thing has beat me down. I don't know enough about these things (but I'm quickly learning) to know what my best move from here is.

If any of you out there have an opinion on the matter, I sure would love to hear it. If y'all say that the worst is over and the remaining repairs aren't stupid to achieve, I guess I'll keep going, but I'm at a loss.

Everyone's welcome to point out exactly how many times I had to jump ship, before I crossed that point of no return.

I leave my future in you guys hands, don't let me down!

#2

sgkent

sgkent

but you got a good deal right? Maybe somewhere between the jump start and weird noises I would have hidden my wallet from him.. Given time, almost anything can be sorted out. Good luck.

#3

Demonseed

I'm not even counting the many countless hours I've lost trying to brute force problem solve my way through this mess. Three times now I thought I had it licked, and every time I walked away defeated, realizing each time the problems I just discovered were twice as involved and required twice as many parts as the time before it. Not even kidding, if I have that repeat just once more I'll have had to rebuild the entire machine from the frame up. /face-palm

Don't think I'll ever buy from facebook market again, that's for sure. Garbage platform doesn't even have a way that I can see to report the seller for making false claims, to warn any future unsuspecting would be buyer of the guys tendency of being less than truthful. I even tried contacting him again through the platform to reason with him to tell me what else I may encounter but not surprisingly I've yet to hear back. Shocker I know.

I'm just afraid all these new parts are going to add another two or three hundred to this nightmare. I could of bought one a hell of a lot newer and nicer then this POS for that kind of capitol had I known what I was getting myself into.

Sorry for being so talkative on the subject. This has been almost two months in the making and I haven't had a soul to talk to about it all. lol So what does one do in those situations but grab the first stranger that walks by and unload on the poor guy. Unfortunately you just happened to be him.

Demonseed

Ha, well I suppose it all depends on how you would classify "good deal". Did I initially pay a lot, no. I gave him three of the four hundred he was first asking. But did I get it patched up for the cost of a spring? Again, no. After digging through all the purchases, turns out I was off quite a bit before saying I was only five hundred into this thing, the real number shocked even me once I added it all up. As of right now I'm closer to eight hundred than I'd like to admit. So, maybe it's just me being salty, but no, I do not think I got a good deal at all.but you got a good deal right?

I'm not even counting the many countless hours I've lost trying to brute force problem solve my way through this mess. Three times now I thought I had it licked, and every time I walked away defeated, realizing each time the problems I just discovered were twice as involved and required twice as many parts as the time before it. Not even kidding, if I have that repeat just once more I'll have had to rebuild the entire machine from the frame up. /face-palm

Don't think I'll ever buy from facebook market again, that's for sure. Garbage platform doesn't even have a way that I can see to report the seller for making false claims, to warn any future unsuspecting would be buyer of the guys tendency of being less than truthful. I even tried contacting him again through the platform to reason with him to tell me what else I may encounter but not surprisingly I've yet to hear back. Shocker I know.

I'm just afraid all these new parts are going to add another two or three hundred to this nightmare. I could of bought one a hell of a lot newer and nicer then this POS for that kind of capitol had I known what I was getting myself into.

Sorry for being so talkative on the subject. This has been almost two months in the making and I haven't had a soul to talk to about it all. lol So what does one do in those situations but grab the first stranger that walks by and unload on the poor guy. Unfortunately you just happened to be him.

#4

StarTech

StarTech

I as a repair shop owner have seen a lot this DIYer stuff. Enough to drive me crazy at times. I know most of the costs involved in straightening out a F'd up machine but customer still go out and buy a cobble up machine and expect me to straighten it out for parts only. When those customers come in I just send them on to another shop that is will to do patch work.

#5

B

bertsmobile1

B

bertsmobile1

There is nothing on a deck that can not be fabricated with a bit scrap steel a welder a file & a drill .

I make or repair deck hangers out of old blades all the time , mostly because they are stupid prices down here or the franchise holder is not importing that part any more .

New MTD stuff all use the Cub Cadet fast connect system , since around 2000 and the old ones are mostly plain flat straps pins & bushes

As yours is a 2007 model & has the Cub mounts

That model number should bring up the 38" deck as the F in the model is the 38" deck so it was originally 38" so should have the 38" parts on it unless some one tried to do an "upgrade " to 46" which since the original engine can not drive any deck over 42" would not go down well .

The only difference between the 46 & 38 hangers is the actual length of the arms, the 46 are longer because it is a 3 blade deck so is longer front to back

On the same tack, the drag link for the 46 is shorter .

So if your lift arm are too long then get ( or make ) a longer drag link and if they are too short then get a shorter front drag link

You can use a turnbuckle with a bolt through the deck mount if you want .

Did you buy this to use or to repair & flip ?

The part # 41 is the lift arm stabilizer and there are 2 of them one each side .

The are held into the lift arm , # 1 in the diagram by a pin

Now what we need to know is why does the deck not fit

Belt too short ?

Front drag link too short "

lift arms too short

The larger decks had smaller blades so they use a bigger engine pulley

A common ruse is to use the bigger pulley with the smaller deck to increase the blade speed in the incorrect belief that the faster blades will make the mower cut faster or throw further ( it does not )

Some photos would help a lot to visualize your dilema

I make or repair deck hangers out of old blades all the time , mostly because they are stupid prices down here or the franchise holder is not importing that part any more .

New MTD stuff all use the Cub Cadet fast connect system , since around 2000 and the old ones are mostly plain flat straps pins & bushes

As yours is a 2007 model & has the Cub mounts

That model number should bring up the 38" deck as the F in the model is the 38" deck so it was originally 38" so should have the 38" parts on it unless some one tried to do an "upgrade " to 46" which since the original engine can not drive any deck over 42" would not go down well .

The only difference between the 46 & 38 hangers is the actual length of the arms, the 46 are longer because it is a 3 blade deck so is longer front to back

On the same tack, the drag link for the 46 is shorter .

So if your lift arm are too long then get ( or make ) a longer drag link and if they are too short then get a shorter front drag link

You can use a turnbuckle with a bolt through the deck mount if you want .

Did you buy this to use or to repair & flip ?

The part # 41 is the lift arm stabilizer and there are 2 of them one each side .

The are held into the lift arm , # 1 in the diagram by a pin

Now what we need to know is why does the deck not fit

Belt too short ?

Front drag link too short "

lift arms too short

The larger decks had smaller blades so they use a bigger engine pulley

A common ruse is to use the bigger pulley with the smaller deck to increase the blade speed in the incorrect belief that the faster blades will make the mower cut faster or throw further ( it does not )

Some photos would help a lot to visualize your dilema

#6

Demonseed

When I first set out to fix the deck I thought I could get away with only changing the blades, blade spindles, and idler along with a new belt. So I proceeded to getting the right parts and replacing all of them. But once I had done that, I found I could no longer get the drive belt around all the pulleys. Which led to discovering the idler that was on it wasnt the right swingarm nor was the same diameter of the original. So I fixed the arm, and the belt became even more impossible to get around the pulleys. So I dug in deeper.

All the while, I had been seeing that they had also modified were the drag link mounted to the deck with a very poorly welded a chunk of flat metal extending forward, with a hole in the end that the link was connected to. So I incorrectly assumed that this must be why the belt would no longer fit. I then proceeded to cutting off the chunk of flat metal, locating the right drag link and trying again. Only now that I've done that, I'm finding the drag link is not long enough to reach it's frame mounting hole so each time I restore something I get even further away from my goal of hanging the deck and fitting the drive belt. So again, I dug in deeper, and finally I found the root of all my suffering, and that was all the hangers were also wrong.

So apparently everything I had "fixed" so far on the deck, was only ever tampered with in the first place because of them having changed the hanger system out for one off a 46" decked machine. I'm unraveling this mess exactly opposite of how I imagine they butchered it. Them chasing deck and belt fitment after the hangers were changed by removing parts then me seeing all the wrong parts restoring things, then hitting the same roadblocks they encountered with the belt and deck attachment. Only I didn't have the advantage of knowing why nothing was working, and seemingly getting worse with every part I put back to original.

Hopefully you can make out what's going on. But basically here I've dropped the lifting linkage from the carriage arms while the machine is lifted up so the deck would come forward enough to just barely get the drag link to thread on it's nut. But now that the link is connected, it will no longer go up and back enough to re-engage the lifting linkage.

This is some of the garbage I've pulled off it already.

I've attached the parts page and it's corresponding lookup page.

Shown outside that circle, above and to the right, is were part #41 is illustrated with a C next to it indicating where the lift linkage rod (part #39) connects. Which you'll notice is not the same linkage rod illustrated inside the circle connecting to part #1. Although oddly enough the linkage shown to connect to #1 isn't even given a part number inside that circle. But it's clearly different from the one above #39 in shape so I assume is not the same rod.

But again, this page is very confusing to look at. This particular page of the manual does a very poor job of conveying that you're seeing more than one configuration for the lifting assembly.

There seem to be two linkage rods for the 46" decks that pull up on both the bars labeled #1, and only one for the smaller decks that connect to part #41, with the other lift arm (not shown in the illustration, but is referenced on the next page as "Deck lift arm-LH) I think is the stabilizer you mentioned.

Or there's the possibility I'm still misinterpreting this manual and nothing I said is right. IDK anymore.

Demonseed

Agreed, but I dont currently own a welder, so fabing my own parts isnt as easy as it could be. But regardless it would be like trying to find a switch in the pitch black dark in a room you've never been in before, because I have never seen the part that actually fits outside of the manual.There is nothing on a deck that can not be fabricated with a bit scrap steel a welder a file & a drill .

I make or repair deck hangers out of old blades all the time

Correct, it is and always was a 38" deck on the machine. I can only guess at why they initially did what they did to this thing, but I'm fairly sure I understand the alterations now that I have the full picture of what they did.bertsmobile1 said:That model number should bring up the 38" deck as the F in the model is the 38" deck so it was originally 38" so should have the 38" parts on it unless some one tried to do an "upgrade " to 46" which since the original engine can not drive any deck over 42" would not go down well .

When I first set out to fix the deck I thought I could get away with only changing the blades, blade spindles, and idler along with a new belt. So I proceeded to getting the right parts and replacing all of them. But once I had done that, I found I could no longer get the drive belt around all the pulleys. Which led to discovering the idler that was on it wasnt the right swingarm nor was the same diameter of the original. So I fixed the arm, and the belt became even more impossible to get around the pulleys. So I dug in deeper.

All the while, I had been seeing that they had also modified were the drag link mounted to the deck with a very poorly welded a chunk of flat metal extending forward, with a hole in the end that the link was connected to. So I incorrectly assumed that this must be why the belt would no longer fit. I then proceeded to cutting off the chunk of flat metal, locating the right drag link and trying again. Only now that I've done that, I'm finding the drag link is not long enough to reach it's frame mounting hole so each time I restore something I get even further away from my goal of hanging the deck and fitting the drive belt. So again, I dug in deeper, and finally I found the root of all my suffering, and that was all the hangers were also wrong.

So apparently everything I had "fixed" so far on the deck, was only ever tampered with in the first place because of them having changed the hanger system out for one off a 46" decked machine. I'm unraveling this mess exactly opposite of how I imagine they butchered it. Them chasing deck and belt fitment after the hangers were changed by removing parts then me seeing all the wrong parts restoring things, then hitting the same roadblocks they encountered with the belt and deck attachment. Only I didn't have the advantage of knowing why nothing was working, and seemingly getting worse with every part I put back to original.

This is what I've discovered. The arms installed are far to long.bertsmobile1 said:The only difference between the 46 & 38 hangers is the actual length of the arms, the 46 are longer because it is a 3 blade deck so is longer front to back

Hopefully you can make out what's going on. But basically here I've dropped the lifting linkage from the carriage arms while the machine is lifted up so the deck would come forward enough to just barely get the drag link to thread on it's nut. But now that the link is connected, it will no longer go up and back enough to re-engage the lifting linkage.

That sort of thinking is exactly what led to this mess I'm dealing with right now. I'm intent on putting it back right, not shadetree hacking it together.bertsmobile1 said:On the same tack, the drag link for the 46 is shorter .

So if your lift arm are too long then get ( or make ) a longer drag link and if they are too short then get a shorter front drag link

You can use a turnbuckle with a bolt through the deck mount if you want .

This is some of the garbage I've pulled off it already.

Bought it to use and hopefully for a very long time, after how much trouble it's turned into before I can ever see it cut it's first blade of grass.bertsmobile1 said:Did you buy this to use or to repair & flip ?

Not saying you're wrong anything, but you're definitely not right either. You've clearly pulled up the manual and looked but take another look. I think you made the same oversight I did at first and looked at the lift assembly in the lower left of the diagram as though it was the only one shown. Which it is not. part #1 shown in that circled section of the diagram is only for the larger 46" deck. And infact part #41 is not a stabilizer at all, nor does it attach to part #1. It is infact the 38" deck equivalent of part #1 that is, as you mentioned, infact shorter than part #1bertsmobile1 said:The part # 41 is the lift arm stabilizer and there are 2 of them one each side .

The are held into the lift arm , # 1 in the diagram by a pin

I've attached the parts page and it's corresponding lookup page.

Shown outside that circle, above and to the right, is were part #41 is illustrated with a C next to it indicating where the lift linkage rod (part #39) connects. Which you'll notice is not the same linkage rod illustrated inside the circle connecting to part #1. Although oddly enough the linkage shown to connect to #1 isn't even given a part number inside that circle. But it's clearly different from the one above #39 in shape so I assume is not the same rod.

But again, this page is very confusing to look at. This particular page of the manual does a very poor job of conveying that you're seeing more than one configuration for the lifting assembly.

There seem to be two linkage rods for the 46" decks that pull up on both the bars labeled #1, and only one for the smaller decks that connect to part #41, with the other lift arm (not shown in the illustration, but is referenced on the next page as "Deck lift arm-LH) I think is the stabilizer you mentioned.

Or there's the possibility I'm still misinterpreting this manual and nothing I said is right. IDK anymore.

Pretty sure my previous answers covered all that.burtsmobile1 said:Now what we need to know is why does the deck not fit

Belt too short ?

Front drag link too short "

lift arms too short

Doneburtsmobile1 said:Some photos would help a lot to visualize your dilemma

Attachments

#7

Demonseed

Demonseed

Well I tracked down the other two lift bars and ordered them, and ordered new drive line belts because at this point what the hell right? Tacking another hundred onto my ever growing total. But fingers crossed I'm wrong about the lifting linkage being different between the various decks, and what I have will simply work once the new bars arrive. I so want this to be over already. All I wanted to do was cut my grass, and very much need to at this point because I've neglected it since I first got this thing and it's very much gone wild in the meantime.

So wish me luck.

Hopefully the next you'll hear from me is my declaration of victory over this nightmare, and not the other way around.

So wish me luck.

Hopefully the next you'll hear from me is my declaration of victory over this nightmare, and not the other way around.

#8

Demonseed

Demonseed

Oh I do have one more question for you guys before I take off and it's about the belts.

I noticed the original drive line belts rub against the decks lifting linkage and possibly other spots as well. Is that normal for these machines to have such tight tolerance for the belts that they rub other components or is that yet another symptom of something else I haven't discovered either being worn out or missing?

Can't lie I'm a little befuddled by just how many springs were used in the designing of these things. Those are certainly something I need to inventory and make sure there aren't any missing or wrong before I wrap this project up.

I noticed the original drive line belts rub against the decks lifting linkage and possibly other spots as well. Is that normal for these machines to have such tight tolerance for the belts that they rub other components or is that yet another symptom of something else I haven't discovered either being worn out or missing?

Can't lie I'm a little befuddled by just how many springs were used in the designing of these things. Those are certainly something I need to inventory and make sure there aren't any missing or wrong before I wrap this project up.

#9

B

bertsmobile1

B

bertsmobile1

From the top.

1) the modifications done were done to raise the maximum deck cutting height.

Despite what is printed these mowers can barely get to 3.5" let alone the 4.5 they are supposed to cut.

2) in hind sight all that was really needed was a non standard sized belt

3) you have the lift arms fitted wrong and the connecting pins are in the wrong holes

The arms go to the inside of the U shaped bracket in the slot

The pins are also U shaped and spring loaded with the spring sitting where you currently have the arm fitted

The pins go in one of the 3 holes on the lift arm depending upon the deck so it overhangs the back of the deck

This effectively shortens the length of the lift arm

The extra holes are for different sized & styles of decks

Now if you intend to keep this mower you need to do another modification.

A the front, the plastic hood sits on the edge of the front frame rail

The plastic tab where the bolt goes through will break off , I am amazed that it had not done so already .

You need to make a brace bar to span the front frame rails and go far enough forward for the middle of the hood to sit on it so it take the weight of the hood .

1) the modifications done were done to raise the maximum deck cutting height.

Despite what is printed these mowers can barely get to 3.5" let alone the 4.5 they are supposed to cut.

2) in hind sight all that was really needed was a non standard sized belt

3) you have the lift arms fitted wrong and the connecting pins are in the wrong holes

The arms go to the inside of the U shaped bracket in the slot

The pins are also U shaped and spring loaded with the spring sitting where you currently have the arm fitted

The pins go in one of the 3 holes on the lift arm depending upon the deck so it overhangs the back of the deck

This effectively shortens the length of the lift arm

The extra holes are for different sized & styles of decks

Now if you intend to keep this mower you need to do another modification.

A the front, the plastic hood sits on the edge of the front frame rail

The plastic tab where the bolt goes through will break off , I am amazed that it had not done so already .

You need to make a brace bar to span the front frame rails and go far enough forward for the middle of the hood to sit on it so it take the weight of the hood .

#10

Demonseed

But honestly I fail to understand how longer arms could increase the cutting height, seems to me it would decrease it. But I'm not disagreeing, because I've already proven I fail to understand a lot.

.

So if I'm understanding you correctly, basically a smi-permanently attached quick release pull pin then yeah? But how would that apply to the left side as it doesnt have the same sort of C shaped bracketry as the right side does, nor does it show any signs of something being cut off. Is there only one quick release pin (pulled from the right side) that's long enough to catch both the hanger holes simultaneously?

I can't find anything like that in the illustrations, or any reference whatsoever to what belonged in that bracket.

Wouldn't by any chance have a picture so I could see it would you? Or even better a part number so I can get me one.

So if I move to a more forward hole, will I then be able to fit the correct sized belt on the pulleys or would that only land me closer but still in a place I'd need that longer belt you mentioned?

Demonseed

Somehow I feel like you're giving these guys far to much credit with their intent. But even if you're not wrong, stripping the deck of all its safety features ie.breaks, pulley guards etc certainly was not the right way to achieve that goal.From the top.

1) the modifications done were done to raise the maximum deck cutting height.

Despite what is printed these mowers can barely get to 3.5" let alone the 4.5 they are supposed to cut.

But honestly I fail to understand how longer arms could increase the cutting height, seems to me it would decrease it. But I'm not disagreeing, because I've already proven I fail to understand a lot.

Maybe, but it sat under the tractor so cockeyed and crooked to start with, because of their jacked up methods of making alterations that I don't regret removing every trace of them having ever been there.bertsmobile1 then said:2) in hindsight all that was really needed was a non standard sized belt

Really? That's something I haven't even considered. I will absolutely be testing that theory at first light tomorrow. I'd be ecstatic if it will actually go back together.bertsmobile1 followed up and said:3) you have the lift arms fitted wrong and the connecting pins are in the wrong holes

I suspected that was the case but wasn't sure, I had the right side in its correct location to start off then, but I didn't have a carriage pin long enough to reach through that bracket with the added thickness of the arm on the outside of the boxbertsmobile1 also said:The arms go to the inside of the U shaped bracket in the slot

The pins are also U shaped and spring loaded with the spring sitting where you currently have the arm fitted

.

So if I'm understanding you correctly, basically a smi-permanently attached quick release pull pin then yeah? But how would that apply to the left side as it doesnt have the same sort of C shaped bracketry as the right side does, nor does it show any signs of something being cut off. Is there only one quick release pin (pulled from the right side) that's long enough to catch both the hanger holes simultaneously?

I can't find anything like that in the illustrations, or any reference whatsoever to what belonged in that bracket.

Wouldn't by any chance have a picture so I could see it would you? Or even better a part number so I can get me one.

So if I move to a more forward hole, will I then be able to fit the correct sized belt on the pulleys or would that only land me closer but still in a place I'd need that longer belt you mentioned?

Good to know. I had already noticed exactly that, and thought it looked pretty spindly. So thanks for that heads up, I'll definitely take that tip and put it to good use.bertsmobile1 concluded and said:Now if you intend to keep this mower you need to do another modification.

At the front, the plastic hood sits on the edge of the front frame rail

The plastic tab where the bolt goes through will break off, I am amazed that it had not done so already .

You need to make a brace bar to span the front frame rails and go far enough forward for the middle of the hood to sit on it so it take the weight of the hood.

#11

B

bertsmobile1

B

bertsmobile1

They are shown in the parts book

Two U pins with a long leg to go through the bracket & into the arm and a short one that when turned strait down holds the pin back so you can drop the arm in to position

A quick release mechanism .

Should be the same both sides of the deck but the left has the height adjustment on it for leveling the deck

Two U pins with a long leg to go through the bracket & into the arm and a short one that when turned strait down holds the pin back so you can drop the arm in to position

A quick release mechanism .

Should be the same both sides of the deck but the left has the height adjustment on it for leveling the deck

#12

Demonseed

Demonseed

I believe that's what is meant to be there, but I'll be damned if I can locate them in the parts manual, and a search of the entire document for Quick yields 0 return found so without part numbers I'm afraid cotter pins are the best I can do. Not sure where in the book you saw them but a page number would go a long way in helping me locate them.

#13

StarTech

StarTech

Boy is this stupid as I don't see them on any of the MTD diagrams but they are available. Had go through CC to find the PNs.

Two each are require.

747-1116 Rod, Handle, Deck Rel .375 Dia

Two each are require.

747-1116 Rod, Handle, Deck Rel .375 Dia

732-04652 Compression Spring, .535" X 1.75"

914-0470 Cotter Pin, 1/8 X 1.25 (of course you can use just cotter pin that is correct size beside MTD wants a ridiculous price for one.)

#14

B

bertsmobile1

B

bertsmobile1

Sorry

I saw they were shown in the diagram but did not check the parts list proper

As Star mentioned they are listed in the Cub Cadel perts lists

You also need a washer to go between the spring & split pin to take the spring force .

The left one has the height adjuster with it so the entire housing moves up & down rather than moving the lift arm

Sounds like your mower is missing that part as well

It is good system when set up properly and is probably the easiest hook up aside from what Toro use on the Timecutters

I saw they were shown in the diagram but did not check the parts list proper

As Star mentioned they are listed in the Cub Cadel perts lists

You also need a washer to go between the spring & split pin to take the spring force .

The left one has the height adjuster with it so the entire housing moves up & down rather than moving the lift arm

Sounds like your mower is missing that part as well

It is good system when set up properly and is probably the easiest hook up aside from what Toro use on the Timecutters

#15

StarTech

StarTech

I do forget those items that I provide in house like the washer as those are common hardware items.

#16

Demonseed

Demonseed

I appreciate all the help guys, but I think I'm done spending money on this thing, at least for the time being, well almost.

Now that I finally have it reassembled and basically fully functional, (oh yeah, right. Didn't tell you yet. Surprise! I fixed it!) All I want now is to just use it so I can feel like it was all justified.

Believe it or not that damn thing had one last zinger of a curve ball to throw at me, one last challenge if you will, in the form of the PTO engaging lever barely putting any tension on the deck belt. After I stripped it down of its fenders and seat so I could get a good look at it, I noticed the bracket the cable attached to didn't appear to be the same shape as the one I was seeing in the diagram. Pulled it off, went and looked up a proper image online and sure enough, someone had wrenched that poor handle so hard they twisted the tab on the end everything connects to about 45 degrees out of its original position. So I broke out the Oxy/Map torch and got her glowing nice and red then proceeded to easing it on back where it was meant to be, and somehow managed not to break it in the process.

Got it reinstalled, and while the finders were off did the two transmission belts before finally reassembling it, then gave it the long overdue test cut. And it did awesome, except the one spot it scalped the ground, but we'll just pretend that didn't happen and say it was ultimately a complete success!

The only real issue I saw while driving it for the first time was the breaks. They aren't awesome, and upon examination I've concluded I don't have the first clue how that thing stops. So it stands to reason I also don't know how difficult it will be to fix. Enter you guys to save my *** again. Someone please clue me in. Is it easy, hard, quick and easy or super involved? Once this bit is as it should be, this little machine has its work cut out for it to pay back it's recent debts. Only thin will I consider giving it the cosmedics it has been begging for, new headlight valence, tires, quick release deck, you know,the stuff it wants but doesn't really need. It has got to prove itself worthy first. Then the fun stuff can be considered.

But it's cutting grass, so finally something went my way. Yeay me, woohoo!

ok celebration over, back to work...

Now that I finally have it reassembled and basically fully functional, (oh yeah, right. Didn't tell you yet. Surprise! I fixed it!) All I want now is to just use it so I can feel like it was all justified.

Believe it or not that damn thing had one last zinger of a curve ball to throw at me, one last challenge if you will, in the form of the PTO engaging lever barely putting any tension on the deck belt. After I stripped it down of its fenders and seat so I could get a good look at it, I noticed the bracket the cable attached to didn't appear to be the same shape as the one I was seeing in the diagram. Pulled it off, went and looked up a proper image online and sure enough, someone had wrenched that poor handle so hard they twisted the tab on the end everything connects to about 45 degrees out of its original position. So I broke out the Oxy/Map torch and got her glowing nice and red then proceeded to easing it on back where it was meant to be, and somehow managed not to break it in the process.

Got it reinstalled, and while the finders were off did the two transmission belts before finally reassembling it, then gave it the long overdue test cut. And it did awesome, except the one spot it scalped the ground, but we'll just pretend that didn't happen and say it was ultimately a complete success!

The only real issue I saw while driving it for the first time was the breaks. They aren't awesome, and upon examination I've concluded I don't have the first clue how that thing stops. So it stands to reason I also don't know how difficult it will be to fix. Enter you guys to save my *** again. Someone please clue me in. Is it easy, hard, quick and easy or super involved? Once this bit is as it should be, this little machine has its work cut out for it to pay back it's recent debts. Only thin will I consider giving it the cosmedics it has been begging for, new headlight valence, tires, quick release deck, you know,the stuff it wants but doesn't really need. It has got to prove itself worthy first. Then the fun stuff can be considered.

But it's cutting grass, so finally something went my way. Yeay me, woohoo!

ok celebration over, back to work...

#18

B

bertsmobile1

B

bertsmobile1

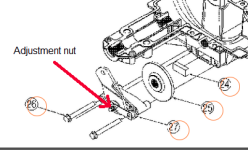

Not shown in the diagram Star posted is the pins

the lever is bent & pushes two small pins agains a shim behind a tiny brake block that pushes against the disc.

The disc is floating an a spline so it can move and bear against the second brake pad that sits in a recess in the housing ( part # 24 )

So the disc must be free to slide on the splined shaft or the brake becomes one sided & does not work.

The brake locks the layshaft inside the transmission which it turn locks the diff, exactly the same as the Park position on a car auto box.

This means that the wheels have to turn in opposite directions so you stop quick

As such the brake is not progressive it is all on or not on

The nut in the above diagram adjusts the brakes to accomodate wear on the pads

The rod that pulls the brake on will have an adjuster at the other end to balance the clutching & braking

Remember only 1 pedal for both so the adjustment has to be made such that the brake dissengages just before the clutch starts to spin the drive belts If it is over adjusted , the belt will burn because it will not be able to run on the drive pulley.

IT takes a bit of fiddleing to get it just right

If you take your foot off the clutch / brake pedal & the mower tosses a wheelie then the brakes are too late dissengaging.

I usually pop an old carton under the brake when I pull one apart because one of the parts always tries to run away & hide ( usually the shim ).

To remove & clean the brake, take the 2 long bolts out of the caliper & do one touch the center adjustment bolt till it is reassembled and you are setting it .

And no grease, it goes together dry

the lever is bent & pushes two small pins agains a shim behind a tiny brake block that pushes against the disc.

The disc is floating an a spline so it can move and bear against the second brake pad that sits in a recess in the housing ( part # 24 )

So the disc must be free to slide on the splined shaft or the brake becomes one sided & does not work.

The brake locks the layshaft inside the transmission which it turn locks the diff, exactly the same as the Park position on a car auto box.

This means that the wheels have to turn in opposite directions so you stop quick

As such the brake is not progressive it is all on or not on

The nut in the above diagram adjusts the brakes to accomodate wear on the pads

The rod that pulls the brake on will have an adjuster at the other end to balance the clutching & braking

Remember only 1 pedal for both so the adjustment has to be made such that the brake dissengages just before the clutch starts to spin the drive belts If it is over adjusted , the belt will burn because it will not be able to run on the drive pulley.

IT takes a bit of fiddleing to get it just right

If you take your foot off the clutch / brake pedal & the mower tosses a wheelie then the brakes are too late dissengaging.

I usually pop an old carton under the brake when I pull one apart because one of the parts always tries to run away & hide ( usually the shim ).

To remove & clean the brake, take the 2 long bolts out of the caliper & do one touch the center adjustment bolt till it is reassembled and you are setting it .

And no grease, it goes together dry

#19

Demonseed

Demonseed

That seems doable. Nothing there sounds to hard, just fidgety. So you say parts run away when pulling it apart? So no clips or retainers on the pads for assembly? Sounds fun. I'll for sure be attempting the adjustment first in hopes that the pads still have some life left in them.

Topic change once more, the scalping I briefly mentioned, you guys wouldn't happen to have any recommendations for some aftermarket anti scalping wheels that include bracketry that I could get for this thing? Ideally ones that won't break the bank.

I found some on amazon but they're listed as MTD 2009 and newer for like 55 bucks and I swear the price jumped to 64 bucks while I was looking at them! But they were listed to be for 36 inch and 42 inch decks, and every other one I've found (not necessarily for MTD) all were for 42 inch. I'm not unwilling to get creative and do whatever is needed to add some, because damn this things blades hit the dirt FAR to much. My yard is all sorts of wavy and full of holes and ruts, to the point I'm not even sure just rear mounted wheels are going to be enough, I think I may need some or at least one centered in the front as well.

Just thought you guys having far more experience with these machines might just have some you have used or seen used that you could recommend and possibly save me from having to take this thing to my buddy's welding shop to fab up custom brackets.

The most affordable ones I've located so far were 35 dollars for a Husqvarna which seems more reasonable to me than that jacked up price of 64

Topic change once more, the scalping I briefly mentioned, you guys wouldn't happen to have any recommendations for some aftermarket anti scalping wheels that include bracketry that I could get for this thing? Ideally ones that won't break the bank.

I found some on amazon but they're listed as MTD 2009 and newer for like 55 bucks and I swear the price jumped to 64 bucks while I was looking at them! But they were listed to be for 36 inch and 42 inch decks, and every other one I've found (not necessarily for MTD) all were for 42 inch. I'm not unwilling to get creative and do whatever is needed to add some, because damn this things blades hit the dirt FAR to much. My yard is all sorts of wavy and full of holes and ruts, to the point I'm not even sure just rear mounted wheels are going to be enough, I think I may need some or at least one centered in the front as well.

Just thought you guys having far more experience with these machines might just have some you have used or seen used that you could recommend and possibly save me from having to take this thing to my buddy's welding shop to fab up custom brackets.

The most affordable ones I've located so far were 35 dollars for a Husqvarna which seems more reasonable to me than that jacked up price of 64

#20

B

bertsmobile1

B

bertsmobile1

Wheels & axels are easy, Oregon, Prime Line , Stens , Rotary all do wheels & rollers

Brackets to fit onto the mower are another story as most OEM ones are welded to the deck and they need to be substantial

Some 3" wide flat strap at least 1/8" thick will be needed to fabricate them

Brackets to fit onto the mower are another story as most OEM ones are welded to the deck and they need to be substantial

Some 3" wide flat strap at least 1/8" thick will be needed to fabricate them