You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

TS148X Seat Switch Issue

#1

C

c1916

C

c1916

Newbie here...appreciate anyone that's looking at my post.

Brand new (and I mean, just off the skid) TS148X. Bought to replace my YTH, which was a workhorse but died in the fall, and I was told the TS148X is on the same frame so I can reuse the snow thrower and all my accessories. Anyway....

Roll it off the pallet into the garage, add fuel, connect the battery, align the seat, go through the checklist and fire it up. Cranks easily first try, release the brake and...uh oh...engine kills. I have a pretty good idea what that means.

Sure enough, bypass the seat switch, recrank, and everything works as expected.

Get Husqy on the phone and say, I've got a brand new unit with a bad seat switch, I'd like this corrected. (I know some people like the safety mech bypassed for convenience, but I figure it's there for a reason and if it works correctly, it just may save me one day)

She reads my local service centers (Chicago burbs) from the Husqy website, but I know how this is going to go. I call them one by one (while still in the chat with her), and each one tells me, they're not affiliated with Husqy, never have been an authorized service center, don't sell Husqy....whatever. Zero hits whatsoever. So, I pull the grenade pin and quote from their return policy and say I want a replacement or refund because what was sent is not operable out of the box, and if they choose the third option (service center) I want them to find me one so I don't waste my time making calls based on their out of date service site links (one shop told me they used to service Husqy, but they've been unaffiliated for 6 years...so, good on ya for keeping the website up to date ). The agent said she needed to escalate and would call me in a couple of minutes. Suffice it to say I'm no longer holding my breath waiting for the call.

). The agent said she needed to escalate and would call me in a couple of minutes. Suffice it to say I'm no longer holding my breath waiting for the call.

Anyway, I figure I can fix the damn thing with a 532192749 replacement switch. And, if they won't send me one, I can get one for $15 off Amazon.

But, what I can't figure out is the new seat cover. It looks like the switch has to come in from the "top" (meaning under the seat cover). The switch doesn't look able to be pried out from the underside where the harness sits.

So...

A) Does it make sense that the switch is the culprit if bypassing it makes the mower run?

B) What is the proper path to force Husqy to take some responsibility for actually shipping me something that doesn't work out of the box?

C) If I choose the path of least resistance and fix it myself, is there a tutorial somewhere on removing the seat cover so as to gain access to the switch?

D) Am I gonna be unpleasantly surprised when I try to mount the snow thrower from the YTH on this thing (Husqy says no, and my retailer says no, but call me skeptical)?

Once again, thanks for considering my problems.

All the best.

Brand new (and I mean, just off the skid) TS148X. Bought to replace my YTH, which was a workhorse but died in the fall, and I was told the TS148X is on the same frame so I can reuse the snow thrower and all my accessories. Anyway....

Roll it off the pallet into the garage, add fuel, connect the battery, align the seat, go through the checklist and fire it up. Cranks easily first try, release the brake and...uh oh...engine kills. I have a pretty good idea what that means.

Sure enough, bypass the seat switch, recrank, and everything works as expected.

Get Husqy on the phone and say, I've got a brand new unit with a bad seat switch, I'd like this corrected. (I know some people like the safety mech bypassed for convenience, but I figure it's there for a reason and if it works correctly, it just may save me one day)

She reads my local service centers (Chicago burbs) from the Husqy website, but I know how this is going to go. I call them one by one (while still in the chat with her), and each one tells me, they're not affiliated with Husqy, never have been an authorized service center, don't sell Husqy....whatever. Zero hits whatsoever. So, I pull the grenade pin and quote from their return policy and say I want a replacement or refund because what was sent is not operable out of the box, and if they choose the third option (service center) I want them to find me one so I don't waste my time making calls based on their out of date service site links (one shop told me they used to service Husqy, but they've been unaffiliated for 6 years...so, good on ya for keeping the website up to date

Anyway, I figure I can fix the damn thing with a 532192749 replacement switch. And, if they won't send me one, I can get one for $15 off Amazon.

But, what I can't figure out is the new seat cover. It looks like the switch has to come in from the "top" (meaning under the seat cover). The switch doesn't look able to be pried out from the underside where the harness sits.

So...

A) Does it make sense that the switch is the culprit if bypassing it makes the mower run?

B) What is the proper path to force Husqy to take some responsibility for actually shipping me something that doesn't work out of the box?

C) If I choose the path of least resistance and fix it myself, is there a tutorial somewhere on removing the seat cover so as to gain access to the switch?

D) Am I gonna be unpleasantly surprised when I try to mount the snow thrower from the YTH on this thing (Husqy says no, and my retailer says no, but call me skeptical)?

Once again, thanks for considering my problems.

All the best.

#2

StarTech

StarTech

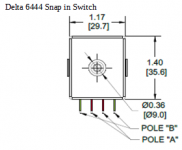

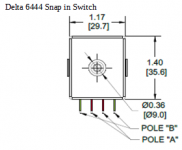

First I would verify it is actually a bad seat switch. According the schematic the switch is a dual pole NC/NC Delta 9444 switch.

So when the switch is not depress there will be continuity for each pole. When depress no continuity for each pole. You problem may that the seat connector is not functioning as it should because either it is not fully seated or the built-in shorting strip is defective. The 9444 tabs are really too short to disengage the shorting strip; unless, the connector is fully seated and latched.

One option is to remove the shorting strip and then when the switch is plug in you still normal seat switch operation. I just ran into a similar problem with an older unit where the locking was broken off.

In order to remove the shorting strip the Delphi 12066214 terminals must be removed, noting the installed order.

This reference to the 532192749 [Stens 430-420, Delta 9444-82] switch.

Can't answer on the seat cover removal as I haven't done one yet.

So when the switch is not depress there will be continuity for each pole. When depress no continuity for each pole. You problem may that the seat connector is not functioning as it should because either it is not fully seated or the built-in shorting strip is defective. The 9444 tabs are really too short to disengage the shorting strip; unless, the connector is fully seated and latched.

One option is to remove the shorting strip and then when the switch is plug in you still normal seat switch operation. I just ran into a similar problem with an older unit where the locking was broken off.

In order to remove the shorting strip the Delphi 12066214 terminals must be removed, noting the installed order.

This reference to the 532192749 [Stens 430-420, Delta 9444-82] switch.

Can't answer on the seat cover removal as I haven't done one yet.

#3

C

c1916

C

c1916

Thanks for the quick and thoughtful reply.

When I indicated that I bypassed the sensor, I did so via the "Toothpick" method (using small pieces of wood to prevent the shorting strip from making contact). It is my understanding that this gives the same result as removing the shorting strip. Am I correct in that assumption?

If my assumption is correct, the Toothpick method ensures that I don't void any warranty since one may have difficulty returning the shorting strip to the plug if it is removed entirely.

The difference being that I cannot reconnect the plug and the sensor with toothpicks in place to test out whether the depressor switch is bad or not (which I gather was your first suggestion).

When I indicated that I bypassed the sensor, I did so via the "Toothpick" method (using small pieces of wood to prevent the shorting strip from making contact). It is my understanding that this gives the same result as removing the shorting strip. Am I correct in that assumption?

If my assumption is correct, the Toothpick method ensures that I don't void any warranty since one may have difficulty returning the shorting strip to the plug if it is removed entirely.

The difference being that I cannot reconnect the plug and the sensor with toothpicks in place to test out whether the depressor switch is bad or not (which I gather was your first suggestion).

#4

StarTech

StarTech

Correct as long the toothpicks are in place you can't attach the switch. You need a cheap ohms meter the check the switch. Getting it depress might be hard since it take weight on the seat, though, if you have test leads with insulted clips you extend the leads out to where you can test the switch operation by sitting on and off the seat. While sitting on the this way both poles should register as open circuits. Most likely you are having problem with pole "B". since it will have the Gray lead. The lead next to it maybe Green instead of Black it is like the Craftsman sitting on the yard.

#6

StarTech

StarTech

If OP luck is like mine he is wasting his time trying to get Husqvarna off their duffs. Most OEM will just the dealers to avoid doing anything to support their products. The only ones that support is the dealer that actually sold the unit and they usually get stuck with having to make on the warranty out their own pockets.

#7

C

c1916

C

c1916

I guess I've been lucky with my YTH, I never needed manufacturer's service. Over the life of that tractor, I only called on my local small engine guy twice.

That's the reason I went with Husqy again. My retailer is out of state, but will be my next call. While I might feel bad for them having to clean up the manufacturer's mess, I have to remind myself that I'm the guy that paid for the new mower.

Thanks for everyone's comments.

All the best.

That's the reason I went with Husqy again. My retailer is out of state, but will be my next call. While I might feel bad for them having to clean up the manufacturer's mess, I have to remind myself that I'm the guy that paid for the new mower.

Thanks for everyone's comments.

All the best.

#8

B

bertsmobile1

B

bertsmobile1

One of the reasons why mowers bought off line or from big box stores are cheaper is because you get them in a crate so you have to do the predelivery work.

While it does save the owner money , there are pitfalls as c1916 has found because if there is a problem then getting it rectified is a big headache.

for obvious reasons no factory will believe that their mower will not work without getting it independently verified .

Now the dealers will not be in a hurry because it is YOUR problem not their problem because they dd not sell you the mower so there is no PROFIT POOL to cover their costs .

What most do not understand is warranty work is always done at a loss.

The money ( usually paid as a purchase credit ) does not come anywhere near the actual labour cost of testing the mower and submitting the warranty claim let alone actually fixing the mower .

For most good mower shops the only benefit of running a warranty claim is they get your bum into their shop and then have the chance to sell you something ar add you to their data base for latter marketing .

The rest will see you as the enemy , too cheap for your own good so will do the least possible to help you in the hope of the bad experience will convince you ( and your fiends ) that they are better off buying from the dealer & paying for some one else to do the predelivery.

One of the local shops does free pick up & delivery for their own work but charges external warranty claims $ 100 each way for delivery & Pick up .

While it does save the owner money , there are pitfalls as c1916 has found because if there is a problem then getting it rectified is a big headache.

for obvious reasons no factory will believe that their mower will not work without getting it independently verified .

Now the dealers will not be in a hurry because it is YOUR problem not their problem because they dd not sell you the mower so there is no PROFIT POOL to cover their costs .

What most do not understand is warranty work is always done at a loss.

The money ( usually paid as a purchase credit ) does not come anywhere near the actual labour cost of testing the mower and submitting the warranty claim let alone actually fixing the mower .

For most good mower shops the only benefit of running a warranty claim is they get your bum into their shop and then have the chance to sell you something ar add you to their data base for latter marketing .

The rest will see you as the enemy , too cheap for your own good so will do the least possible to help you in the hope of the bad experience will convince you ( and your fiends ) that they are better off buying from the dealer & paying for some one else to do the predelivery.

One of the local shops does free pick up & delivery for their own work but charges external warranty claims $ 100 each way for delivery & Pick up .

#9

StarTech

StarTech

Bert, I have learned most OEMs will do everything they can to avoid admitting it is their fault even when it is. They even run their dealers through the wringers taking over a half year to pay even what few warranty claims they approve. Meanwhile the dealer is out the money that they could be using to build their business and to pay other bills.

And they wonder why I refuse to become a dealer when offer the opportunity. I just not going to be their patsy. I warranty what I sell out my own pocket and forget the headaches of trying to do warranty claims.

And they wonder why I refuse to become a dealer when offer the opportunity. I just not going to be their patsy. I warranty what I sell out my own pocket and forget the headaches of trying to do warranty claims.

#10

B

bertsmobile1

B

bertsmobile1

I do the same

Just sold a 40 series B &S left over from a batch I bought in 2017

Gave a 3 year warranty on the engine on a back to base basis.

Had to be like that because with a 58" deck I can not tow back here

Customer was not sure if the 40 would be powerful to replace the 44

Checked back yesterday & he said the wife never noticed any difference.

He does notice it was down on power but then again they are trying to cut 18" off the grass with mulching blades fitted .

Kawakasi have been goo with warranty work and they will accept a warranty claim through me but again it is just parts and credits not cash.

Hard to pay the power bill with kawakasi purchase credits .

Just sold a 40 series B &S left over from a batch I bought in 2017

Gave a 3 year warranty on the engine on a back to base basis.

Had to be like that because with a 58" deck I can not tow back here

Customer was not sure if the 40 would be powerful to replace the 44

Checked back yesterday & he said the wife never noticed any difference.

He does notice it was down on power but then again they are trying to cut 18" off the grass with mulching blades fitted .

Kawakasi have been goo with warranty work and they will accept a warranty claim through me but again it is just parts and credits not cash.

Hard to pay the power bill with kawakasi purchase credits .

#11

StarTech

StarTech

I would be just happy if Briggs and Kohler would just had replace the defective parts. I can't even get Briggs to replace defective new out of the packaging parts. Luckily I only lost a couple hundred dollars last year but that may be only as I cut way back on part purchases from them too.

Now I have already order $200 in parts from them with half of them being back ordered. Dang I glad it is the off season here. Grass don't really grow when it is 20F overnight.

It was strange yesterday I was laying on my back on the asphalt installing a failed transaxle when it was 35F and it didn't feel cold. Maybe my fat insulation has move around into to right places. Even my fingers didn't hurt. The customer came in and cancelled the repair job after I had already gotten the parts in. He thinks I can just return the parts and get my money back. Yes I can if I want to pay return shipping and take a 20% restocking fee on top of the already paid inbound shipping charge.

Is the problem of towing just because you don't have trailer wide enough or is it some stupid government rule? Like here where you must have brakes on trailer it is a tandem axle even you don't pull heavy loads. I had pull mine for 20 yrs fully loaded without them but of course I use my head on braking.

Yes it would be noticeable when they are trying to use a mower as bush hog rotary mower. Now I have seen a few new mowers where the engine were way under power that they couldn't take off a couple inches of grass. On those I recommend a larger engine or if just purchase return it due lack performance. A 10.5 hp with a 42" deck just don't it literately. It takes at 17.5 hp and that is pushing it depending the type grass being cut. Here my current mower came with a 16.5 (31) hp engine with restrictor plate and it could barely cut a slightly overgrown yard. I did upgrade the engine to a 21hp (33 CI) and now I cut whatever I want to although I need slow down on the extra tall stuff.

Now I have already order $200 in parts from them with half of them being back ordered. Dang I glad it is the off season here. Grass don't really grow when it is 20F overnight.

It was strange yesterday I was laying on my back on the asphalt installing a failed transaxle when it was 35F and it didn't feel cold. Maybe my fat insulation has move around into to right places. Even my fingers didn't hurt. The customer came in and cancelled the repair job after I had already gotten the parts in. He thinks I can just return the parts and get my money back. Yes I can if I want to pay return shipping and take a 20% restocking fee on top of the already paid inbound shipping charge.

Is the problem of towing just because you don't have trailer wide enough or is it some stupid government rule? Like here where you must have brakes on trailer it is a tandem axle even you don't pull heavy loads. I had pull mine for 20 yrs fully loaded without them but of course I use my head on braking.

Yes it would be noticeable when they are trying to use a mower as bush hog rotary mower. Now I have seen a few new mowers where the engine were way under power that they couldn't take off a couple inches of grass. On those I recommend a larger engine or if just purchase return it due lack performance. A 10.5 hp with a 42" deck just don't it literately. It takes at 17.5 hp and that is pushing it depending the type grass being cut. Here my current mower came with a 16.5 (31) hp engine with restrictor plate and it could barely cut a slightly overgrown yard. I did upgrade the engine to a 21hp (33 CI) and now I cut whatever I want to although I need slow down on the extra tall stuff.

#12

B

bertsmobile1

A customer of mine bought when we was made redundant and became a grass cutter ( now a full on lawn & garden maintenance operator )

It was widened to take the Great Dane so 44" is all the width I have to play with.

And yes down here anything bigger than a 6 x 4 box must be braked & all new ones the brakes must be electric .

I am working on a 6 x 10 conversion of an old tray top but it is one of those roundtuit jobs as I want it to be low & tilting so I can drive or winch mowers into it without using ramps

Trailer I got was modified to sit level behind his 4 ton flat top so it sits very much nose down behind my 1 ton van.

The most common size domestic ride on down here is 42" for blocks 0.5 to 10 acres.

And of course commercial customers have their own trailers so they deliver the mower to me .

Domestice customers with big mowers by & large bought them second hand from a commercial contractor & have done nothing in the way of maintenance to them other than changing the oil so it being "too big" for my trailer often works in my favour .

In a pinch I can get a 60" ztr on the motorcycle trailer, but it is a big job to do it .

So 46" & 48" get the decks pulled and towed that way but after that most tracks are too wide to go in .

I am set up for air & have a petrol compressor for on site work if I really want to but for most of those big commercials I leave it to the dealers unless it is a good friend or commercial customer .

B

bertsmobile1

Trailer is a tilt trailer custom built for a 42" Cub Cadet 2000 series back in the 90'sI would be just happy if Briggs and Kohler would just had replace the defective parts. I can't even get Briggs to replace defective new out of the packaging parts. Luckily I only lost a couple hundred dollars last year but that may be only as I cut way back on part purchases from them too.

Now I have already order $200 in parts from them with half of them being back ordered. Dang I glad it is the off season here. Grass don't really grow when it is 20F overnight.

It was strange yesterday I was laying on my back on the asphalt installing a failed transaxle when it was 35F and it didn't feel cold. Maybe my fat insulation has move around into to right places. Even my fingers didn't hurt. The customer came in and cancelled the repair job after I had already gotten the parts in. He thinks I can just return the parts and get my money back. Yes I can if I want to pay return shipping and take a 20% restocking fee on top of the already paid inbound shipping charge.

Is the problem of towing just because you don't have trailer wide enough or is it some stupid government rule? Like here where you must have brakes on trailer it is a tandem axle even you don't pull heavy loads. I had pull mine for 20 yrs fully loaded without them but of course I use my head on braking.

Yes it would be noticeable when they are trying to use a mower as bush hog rotary mower. Now I have seen a few new mowers where the engine were way under power that they couldn't take off a couple inches of grass. On those I recommend a larger engine or if just purchase return it due lack performance. A 10.5 hp with a 42" deck just don't it literately. It takes at 17.5 hp and that is pushing it depending the type grass being cut. Here my current mower came with a 16.5 (31) hp engine with restrictor plate and it could barely cut a slightly overgrown yard. I did upgrade the engine to a 21hp (33 CI) and now I cut whatever I want to although I need slow down on the extra tall stuff.

A customer of mine bought when we was made redundant and became a grass cutter ( now a full on lawn & garden maintenance operator )

It was widened to take the Great Dane so 44" is all the width I have to play with.

And yes down here anything bigger than a 6 x 4 box must be braked & all new ones the brakes must be electric .

I am working on a 6 x 10 conversion of an old tray top but it is one of those roundtuit jobs as I want it to be low & tilting so I can drive or winch mowers into it without using ramps

Trailer I got was modified to sit level behind his 4 ton flat top so it sits very much nose down behind my 1 ton van.

The most common size domestic ride on down here is 42" for blocks 0.5 to 10 acres.

And of course commercial customers have their own trailers so they deliver the mower to me .

Domestice customers with big mowers by & large bought them second hand from a commercial contractor & have done nothing in the way of maintenance to them other than changing the oil so it being "too big" for my trailer often works in my favour .

In a pinch I can get a 60" ztr on the motorcycle trailer, but it is a big job to do it .

So 46" & 48" get the decks pulled and towed that way but after that most tracks are too wide to go in .

I am set up for air & have a petrol compressor for on site work if I really want to but for most of those big commercials I leave it to the dealers unless it is a good friend or commercial customer .

#13

StarTech

StarTech

That why I brought a 6.5 x 16 tandem trailer. I didn't want to be limited to only small equipment. I also need to move vehicle at times or need to haul a couple pallets of concrete blocks.

#14

B

bertsmobile1

B

bertsmobile1

Trouble with big car moving trailers is they are hard to manouver in the hilly yards around here, you have to use loading ramps and I am pulling it with 2.4L LPG powered 4 cylinder Mitsubishi long wheel base van not a USA style 10L V8 Pick Up .

Even with my fairly light set up there are times I have ripped up a customers lawn trying to retrieve their mower which always seem to die with locked transmissions in the far back down hill corner and of course that is not good for business.

The "new" trailer is all aluminium apart from the single draw bar & axels .

Axels are rubber bushed cantilevered type so no springs and the trailer will be around 10" off the ground at the back so the body will touch the ground even when empty .

I am putting some arms on it (actually done that bit ) so the drop sides can be locked strait down allowing the decks to overhang and the combing will be replaced with locking channel that takes drop in tie down rings as used in aircraft cargo space .

However I really don't want to work on anything with a deck much over 48" as I am here by myself and big decks get very heavy very quickly so not having a big enough trailer ican be convienant at times .

Even with my fairly light set up there are times I have ripped up a customers lawn trying to retrieve their mower which always seem to die with locked transmissions in the far back down hill corner and of course that is not good for business.

The "new" trailer is all aluminium apart from the single draw bar & axels .

Axels are rubber bushed cantilevered type so no springs and the trailer will be around 10" off the ground at the back so the body will touch the ground even when empty .

I am putting some arms on it (actually done that bit ) so the drop sides can be locked strait down allowing the decks to overhang and the combing will be replaced with locking channel that takes drop in tie down rings as used in aircraft cargo space .

However I really don't want to work on anything with a deck much over 48" as I am here by myself and big decks get very heavy very quickly so not having a big enough trailer ican be convienant at times .

#15

StarTech

StarTech

It one of the reason I have an engine crane and think about a gantry type crane. Even some the 48" Cub Cadet fabricated decks are well over 100 lbs.

As for lock up transaxles I usually pull the wheel keys so they can roll. It is those 60+ inch ZTR that I must use an electric winch to load them. If the equipment is in a muddy area either the customer waits until it is dry enough for me to get to machine or they out someone else that willing to get stuck.

As for lock up transaxles I usually pull the wheel keys so they can roll. It is those 60+ inch ZTR that I must use an electric winch to load them. If the equipment is in a muddy area either the customer waits until it is dry enough for me to get to machine or they out someone else that willing to get stuck.