You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Troy Built 2010 bronco riding mower Problem with speed pedal not disengaging.

#1

C

Curtisun

C

Curtisun

I have a 2010 Bronco model 13WX78KS066.

What has been done since it came in.

1. Lower and upper drive belts replaced.

2. Deck belt, Spindles and blades replaced.

3 Ignition switch replaced.

The problem is when you place it in gear Foward or reverse it goes in low speed and will speed up when speed control pedal is pressed and will not stop it until you put it in neutral. I have found no adjustments for the tension on the lower drive belt which controls the speed. It works sometimes if you mess with pressing brake and speed pedals but it always goes back to not working. Does anyone know what to do about it or had this problem?

What has been done since it came in.

1. Lower and upper drive belts replaced.

2. Deck belt, Spindles and blades replaced.

3 Ignition switch replaced.

The problem is when you place it in gear Foward or reverse it goes in low speed and will speed up when speed control pedal is pressed and will not stop it until you put it in neutral. I have found no adjustments for the tension on the lower drive belt which controls the speed. It works sometimes if you mess with pressing brake and speed pedals but it always goes back to not working. Does anyone know what to do about it or had this problem?

#2

ILENGINE

ILENGINE

First question? Did you use OEM belts when you replaced them. If not that is a most likely the cause of your issue. Second question is the return spring connected so that it brings the go pedal back to the neutral position.

#3

C

Curtisun

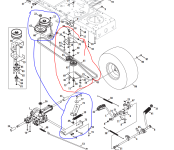

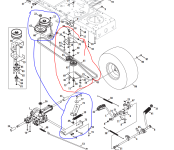

be below is a parts breakdown. The circled blue is the variable speed and upper belt tensioner spring. The circled red is the lower belt tensioner that has no spring.

C

Curtisun

This was supposed to be a OEM belt. But bought on Amazon. It measured out correct to the specs because I thought the same thing after I got it in. The go pedal has only the return spring going to the pedal that returns the pedal to it's up position. This pedal has turtle and rabbit marked on it. The belt should slip with the pedal up. It has no spring on the belt tensioner. This sort of floats when the speed pedal is up.First question? Did you use OEM belts when you replaced them. If not that is a most likely the cause of your issue. Second question is the return spring connected so that it brings the go pedal back to the neutral position.

be below is a parts breakdown. The circled blue is the variable speed and upper belt tensioner spring. The circled red is the lower belt tensioner that has no spring.

#4

C

Curtisun

Also is that variable speed pully supposed to be spring loaded or is it supposed to be just one side free floating because when I put the belt on I had to raise the one side with my finger and it had no spring loaded pully.

C

Curtisun

The slotted arm in part 69 and rod 56 that attaches to the brake pedal does not make contact with either end of the slot with the pedal up or down, so it does not force it to neutral when you press the brake. It seems there is something not right in that area. The Speed pedal does force contact and move part 69 to speed it up but does not contact the other end when the pedal is up.First question? Did you use OEM belts when you replaced them. If not that is a most likely the cause of your issue. Second question is the return spring connected so that it brings the go pedal back to the neutral position.

Also is that variable speed pully supposed to be spring loaded or is it supposed to be just one side free floating because when I put the belt on I had to raise the one side with my finger and it had no spring loaded pully.

#5

ILENGINE

ILENGINE

The center section of the variable pulley is free floating. Also it looks like item 55 which is the idler tension arm may have a threaded end with a ball joint and lock nut at the pulley end. Is it possible that this has had incorrect belts installed in the past and somebody has adjusted that rod to compensate for incorrect belts.

#6

StarTech

StarTech

It wouldn't be the first time someone Amazon claimed the belts are MTD when they are not.

Belt specs

954-04208A 2/3 x 40-9/10-in

954-0467A 2/3 x 90-4/5-in

Many places will try to pass off a 5/8 (.625) belt in place of the .656 belt plus those 5/8 have a different height profile which sits deeper in the pulleys causing the belt grab the v quicker. If you work on enough MTD CVT drives you will quickly learn that only MTD OEM belts works; all others will give various problems.

Belt specs

954-04208A 2/3 x 40-9/10-in

954-0467A 2/3 x 90-4/5-in

Many places will try to pass off a 5/8 (.625) belt in place of the .656 belt plus those 5/8 have a different height profile which sits deeper in the pulleys causing the belt grab the v quicker. If you work on enough MTD CVT drives you will quickly learn that only MTD OEM belts works; all others will give various problems.

#7

B

bertsmobile1

B

bertsmobile1

From the top

What was it doing before you changed the belts ?

Next what did you undo / remove & replace in order to replace the belts ?

does the plate # 69 move freely back & forward with nothing connected to it ?

Is spring # 38 back in the correct place "

Has spring # 38 chopped a long slot in the frame where it anchors to ?

Can the tension arm # 72 swing freely with the spring removed ?

Are both the belts wrapped ?

I have had customers come in with what they thought was the right belt only to see they had fitted a plain belt which is uncovered so becomes sticky when hot .

What was it doing before you changed the belts ?

Next what did you undo / remove & replace in order to replace the belts ?

does the plate # 69 move freely back & forward with nothing connected to it ?

Is spring # 38 back in the correct place "

Has spring # 38 chopped a long slot in the frame where it anchors to ?

Can the tension arm # 72 swing freely with the spring removed ?

Are both the belts wrapped ?

I have had customers come in with what they thought was the right belt only to see they had fitted a plain belt which is uncovered so becomes sticky when hot .

#8

C

Curtisun

. Not sure what change may have been just needed running some.

. Not sure what change may have been just needed running some.

C

Curtisun

It started working on its onThe center section of the variable pulley is free floating. Also it looks like item 55 which is the idler tension arm may have a threaded end with a ball joint and lock nut at the pulley end. Is it possible that this has had incorrect belts installed in the past and somebody has adjusted that rod to compensate for incorrect belts.

#9

C

Curtisun

It seems to be ok now. It is working properly. The belts were not OEM as stated because I do not think OEM supplies a Kevlar belt. I would not look forward to another 3 hrs. work to replace it again. Worst belt I have ever replaced. No room anywhere it goes over a pully. About 1/8 inch clearance on the centrifugal pulleys and it does not have a bolt bolting the pully on shaft like shown in the parts. I had to remove bolts out of bracket and pry the bracket back away enough to force the belt on pully. It has a shaft that is a washer is welded on the pully side and it is factory welded. It is bolted on from the bottom next to the rear axle housing could not get to it to remove would have had to pull rear end completely out. This one has been a pain.

Since it is working, and I give a warranty on anything I work on I will redo the job if I have too.

C

Curtisun

The belts were worn so bad it would not move.From the top

What was it doing before you changed the belts ?

Next what did you undo / remove & replace in order to replace the belts ?

does the plate # 69 move freely back & forward with nothing connected to it ?

Is spring # 38 back in the correct place "

Has spring # 38 chopped a long slot in the frame where it anchors to ?

Can the tension arm # 72 swing freely with the spring removed ?

Are both the belts wrapped ?

I have had customers come in with what they thought was the right belt only to see they had fitted a plain belt which is uncovered so becomes sticky when hot .

It seems to be ok now. It is working properly. The belts were not OEM as stated because I do not think OEM supplies a Kevlar belt. I would not look forward to another 3 hrs. work to replace it again. Worst belt I have ever replaced. No room anywhere it goes over a pully. About 1/8 inch clearance on the centrifugal pulleys and it does not have a bolt bolting the pully on shaft like shown in the parts. I had to remove bolts out of bracket and pry the bracket back away enough to force the belt on pully. It has a shaft that is a washer is welded on the pully side and it is factory welded. It is bolted on from the bottom next to the rear axle housing could not get to it to remove would have had to pull rear end completely out. This one has been a pain.

Since it is working, and I give a warranty on anything I work on I will redo the job if I have too.

#10

C

Curtisun

C

Curtisun

This belt measured .654 using my calipers. Length was 90 3/4 inches so it was Very close to the (954-0467A) and I agree with you about the OEM belts but when a customer says use aftermarket because of price you either lose the job or use aftermarket. I am not a full shop I do this just to earn some extra to help because I am SS and it does not provide the funds for everything. I am 72 and was forced to retire. I lost all my IRA funds in the 2009 crash so have no choice but to take in work I can get.It wouldn't be the first time someone Amazon claimed the belts are MTD when they are not.

Belt specs

954-04208A 2/3 x 40-9/10-in

954-0467A 2/3 x 90-4/5-in

Many places will try to pass off a 5/8 (.625) belt in place of the .656 belt plus those 5/8 have a different height profile which sits deeper in the pulleys causing the belt grab the v quicker. If you work on enough MTD CVT drives you will quickly learn that only MTD OEM belts works; all others will give various problems.

#11

B

bertsmobile1

B

bertsmobile1

OK

If you are trying to turn a dollar then search the web for the MTD "Must have manual of outdoor power Equipment"

There are 4 volumes and ride ons are covered in volume 2 "Rear Engine Riders & Lawn Tractors

Vol 1,2 & 4 can be found at K & T's web page plus a lot of IPL's and their parts prices are reasonable

Usually with a vari drive system, you start by setting the parking brake

Next is flipping the belt off the rear tensioning pulley # 64

The remove the large drive pulley # 62 as most use the rear frame as belt keepers

Then the top belt usually can be slipped off

Following that you slip the front belt off the variable pulley

Then undo / loosen the 2 clutch pulleys so they will drop far enough to get the belt off them

Last bit is to undo the engine pulley and slide it down as most MTD's use tangs in the frame as keepers for the front belt

Replacing is as they say the reverse of removing

On some the variable pulley mounting has to be loosened so it moves a bit ( not needed to be removed ) as again it runs near the frame to use the frame as a belt keeper

If you are trying to turn a dollar then search the web for the MTD "Must have manual of outdoor power Equipment"

There are 4 volumes and ride ons are covered in volume 2 "Rear Engine Riders & Lawn Tractors

Vol 1,2 & 4 can be found at K & T's web page plus a lot of IPL's and their parts prices are reasonable

Usually with a vari drive system, you start by setting the parking brake

Next is flipping the belt off the rear tensioning pulley # 64

The remove the large drive pulley # 62 as most use the rear frame as belt keepers

Then the top belt usually can be slipped off

Following that you slip the front belt off the variable pulley

Then undo / loosen the 2 clutch pulleys so they will drop far enough to get the belt off them

Last bit is to undo the engine pulley and slide it down as most MTD's use tangs in the frame as keepers for the front belt

Replacing is as they say the reverse of removing

On some the variable pulley mounting has to be loosened so it moves a bit ( not needed to be removed ) as again it runs near the frame to use the frame as a belt keeper

#12

Tiger Small Engine

Tiger Small Engine

The belts were worn so bad it would not move.

It seems to be ok now. It is working properly. The belts were not OEM as stated because I do not think OEM supplies a Kevlar belt. I would not look forward to another 3 hrs. work to replace it again. Worst belt I have ever replaced. No room anywhere it goes over a pully. About 1/8 inch clearance on the centrifugal pulleys and it does not have a bolt bolting the pully on shaft like shown in the parts. I had to remove bolts out of bracket and pry the bracket back away enough to force the belt on pully. It has a shaft that is a washer is welded on the pully side and it is factory welded. It is bolted on from the bottom next to the rear axle housing could not get to it to remove would have had to pull rear end completely out. This one has been a pain.

Since it is working, and I give a warranty on anything I work on I will redo the job if I have too.

#13

Tiger Small Engine

Tiger Small Engine

How long does your warranty typically last on work you perform for customers? If you are forced to take on most jobs due to tight finances, doesn’t that sort of put you in a compromising position? I make good on the few comebacks I get when it is my fault, but never give a warranty. Just asking. Some of these repair jobs can be a real pain in the butt.This belt measured .654 using my calipers. Length was 90 3/4 inches so it was Very close to the (954-0467A) and I agree with you about the OEM belts but when a customer says use aftermarket because of price you either lose the job or use aftermarket. I am not a full shop I do this just to earn some extra to help because I am SS and it does not provide the funds for everything. I am 72 and was forced to retire. I lost all my IRA funds in the 2009 crash so have no choice but to take in work I can get.

#14

B

bertsmobile1

B

bertsmobile1

I guarantee MY WORK for 12 months which is the same warranty period on the parts I use

To do this the customer gets an invoice with the WORK I DID clearly described and on the bottom I add the caveats

ie ;- the D130 I have just replaced the trans belt on has the following at the bottom

"steering fan gear worn excessively, gear , pinion & bushes all require replacing , LH front wheel both bushes worn beyond safe limit & will damage wheel , deck cracked - requires welding with brace plates "

The owner is thinking about replacing it with a ZTR so does not want to spend money on it .

This mower was last serviced in 2016 ( I date the filers with a paint pen ) and when I checked the previous invoice it had the same disclaimers on the bottom.

A service is a service, not a repair so when I do one if the owner does not want repairs done I list all that I did not do at the bottom to cover my backside .

IT has served me well over the years .

To do this the customer gets an invoice with the WORK I DID clearly described and on the bottom I add the caveats

ie ;- the D130 I have just replaced the trans belt on has the following at the bottom

"steering fan gear worn excessively, gear , pinion & bushes all require replacing , LH front wheel both bushes worn beyond safe limit & will damage wheel , deck cracked - requires welding with brace plates "

The owner is thinking about replacing it with a ZTR so does not want to spend money on it .

This mower was last serviced in 2016 ( I date the filers with a paint pen ) and when I checked the previous invoice it had the same disclaimers on the bottom.

A service is a service, not a repair so when I do one if the owner does not want repairs done I list all that I did not do at the bottom to cover my backside .

IT has served me well over the years .