You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Troy Bilt bronco 17.5 hp mower is slow

#1

E

Endless Summer

E

Endless Summer

I just bought a used Troy Bilt bronco riding mower. Even without the blades running, it will only run at about a maximum of 2 mph on flat ground.

I’m wondering if anyone can give me some advice as to why it doesn’t move faster?

I’m wondering if anyone can give me some advice as to why it doesn’t move faster?

#2

B

bertsmobile1

B

bertsmobile1

With vari speed mowers slow running is usually due to a stuck variable pulley or worn out belt.

Try pulling the brake pedal up.

If that makes it go faster then the clutch needs attention.

Do you have the owners manual for this mower ?

Some of them have fixed speed ratios which limit the travel of the GO pedal

Because these transmission work on balancing spring pressures, a misplaced tension spring on either the upper or lower belt will also cause it to run slow.

Try pulling the brake pedal up.

If that makes it go faster then the clutch needs attention.

Do you have the owners manual for this mower ?

Some of them have fixed speed ratios which limit the travel of the GO pedal

Because these transmission work on balancing spring pressures, a misplaced tension spring on either the upper or lower belt will also cause it to run slow.

#3

E

Endless Summer

Thanks!

Pulling the break pedal up didn’t do anything.

I did find the manual online.

the upper drive belt looks pretty worn so I guess I start by replacing the belt and see what happens.

E

Endless Summer

With vari speed mowers slow running is usually due to a stuck variable pulley or worn out belt.

Try pulling the brake pedal up.

If that makes it go faster then the clutch needs attention.

Do you have the owners manual for this mower ?

Some of them have fixed speed ratios which limit the travel of the GO pedal

Because these transmission work on balancing spring pressures, a misplaced tension spring on either the upper or lower belt will also cause it to run slow.

Thanks!

Pulling the break pedal up didn’t do anything.

I did find the manual online.

the upper drive belt looks pretty worn so I guess I start by replacing the belt and see what happens.

#4

B

bertsmobile1

B

bertsmobile1

Belts.

They must be replaced as a set

Buy original MTD belts or OEM spec belts from a mower store, not generic belts from NAPA

These belts are a different shape to standard V belts.

When the belts are off check that the sliding sheave can move freely up & down to vary the pulley ratios.

They must be replaced as a set

Buy original MTD belts or OEM spec belts from a mower store, not generic belts from NAPA

These belts are a different shape to standard V belts.

When the belts are off check that the sliding sheave can move freely up & down to vary the pulley ratios.

#5

E

Endless Summer

E

Endless Summer

I don’t have experience with riding lawn mowers but I would expect most would run at least 4mph right?

#6

E

Endless Summer

E

Endless Summer

Also, I found the belt that runs the mower deck comes off of the front pulley. Can this be tightened or does that belt need to be replaced as well?

#7

tom3

tom3

Take a look at that manual, usually some sort of retainer on that belt so it won't come off. Maybe just a rod located close to the pulley on each side.

#8

R

Rivets

R

Rivets

If it were me I would be replacing all three belts, as you must remove the deck to replace the drive belts. A couple of suggestions if you decide to do this yourself. Removing the battery and case will help. There are two bolts on the outside of the chassis which you need to loosen, do not remove, which will make it easier to remove the drive belts. Get the rear end as high off the ground as possible to crawl underneath. I like about 8-10”. Get an assistant if possible, these can be a real bugger when you are doing it the first time. Patience will be your friend, so go slow. There are a couple of videos out there which may help you understand how to do it.

#9

B

bertsmobile1

With the former the belt is always tight and the latter the belt has to go loose to allow the blades to stop spinning.

In any case changing all of the belts is always a good idea as suggested check the old drive belt against the new one for shape, cracks & wear.

Note V belts wear thin across the V.

While it is off spin all of the small pulleys, they should be smooth & QUIET, if not replace them as well.

So it would be a good idea to schedule the work over 2 weekends.

The most important tool in your tool chest is YOUR CAMERA take lots of photos ,

Belt run, Spring anchor points and note the clutch spring is handed & must go back on the same way

Also note the position of the tension spring on the top pulley ( big one ) under the seat.

The whole system is reliant upon this spring.

On some the big pulley needs to be loosened ( or removed ) because it uses the sides of the mower as belt retainers so the belt can not come off.

This is best done with a rattle gun.

We are here to help so if you post a few pictures of the set up we can can direct you through the process step by step and the best place to start is the ID tag under the seat.

The videos from "Taryl Fixes All" & "Donnyboy" tend to ne the most accurate & easy to follow.

When searching use both Troy Built and also MTD as MTD made the mower and the exact same mower is sold under a dozen different names .

B

bertsmobile1

This will depend upon weather you have an electric PTO ( pull a button ) or manual PTO swing a lever.Also, I found the belt that runs the mower deck comes off of the front pulley. Can this be tightened or does that belt need to be replaced as well?

With the former the belt is always tight and the latter the belt has to go loose to allow the blades to stop spinning.

In any case changing all of the belts is always a good idea as suggested check the old drive belt against the new one for shape, cracks & wear.

Note V belts wear thin across the V.

While it is off spin all of the small pulleys, they should be smooth & QUIET, if not replace them as well.

So it would be a good idea to schedule the work over 2 weekends.

The most important tool in your tool chest is YOUR CAMERA take lots of photos ,

Belt run, Spring anchor points and note the clutch spring is handed & must go back on the same way

Also note the position of the tension spring on the top pulley ( big one ) under the seat.

The whole system is reliant upon this spring.

On some the big pulley needs to be loosened ( or removed ) because it uses the sides of the mower as belt retainers so the belt can not come off.

This is best done with a rattle gun.

We are here to help so if you post a few pictures of the set up we can can direct you through the process step by step and the best place to start is the ID tag under the seat.

The videos from "Taryl Fixes All" & "Donnyboy" tend to ne the most accurate & easy to follow.

When searching use both Troy Built and also MTD as MTD made the mower and the exact same mower is sold under a dozen different names .

#10

E

Endless Summer

E

Endless Summer

Thanks for all the replies!

I changed the drive belt, but I haven’t noticed any improvement in speed. It tops out at around 2-3 mph.

is that normal?

I changed the drive belt, but I haven’t noticed any improvement in speed. It tops out at around 2-3 mph.

is that normal?

#11

R

Rivets

R

Rivets

Did you only replace one drive belt? With a variable speed drive system you should have two belts and they should be replaced as a set, which Bert stated earlier.

#14

StarTech

Troy Bilt riding mowers

StarTech

Okay which one these 347 models is it?I replaced both the upper and lower belts.

serial number: 1E130B10144

Troy Bilt riding mowers

#16

StarTech

StarTech

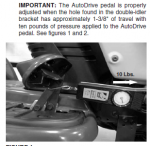

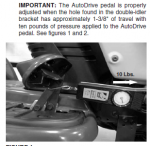

Okay it is an auto drive version. Hopeful you used OEM belts. PTO to variable 5Lx 90.8" and Variable to Transmission 5L x 40.9". A couple thing you can try to increase the speed. One is the Auto drive linkage at the twin idlers. It has an adjustable tie rod end and the other is to try either a 5/8 x 41.5" or 5/8 x 42" Variable to transmission belts. Just got make sure the tension pulley doesn't hit the frame. Also check the front double stack pulley for excessive wear and that the belts are actually the correct lengths.

One last thing to check which I have seen but not too common is that engine mounting hole are worn allowing the engine to slide back. I got one MTD here with a P90 engine that the owner let the motor to stay loose until the mower quit pulling all together. He won't spend the money on the repairs so it is now being parted out.

One last thing to check which I have seen but not too common is that engine mounting hole are worn allowing the engine to slide back. I got one MTD here with a P90 engine that the owner let the motor to stay loose until the mower quit pulling all together. He won't spend the money on the repairs so it is now being parted out.

#17

E

Endless Summer

E

Endless Summer

Appreciate the advice!

Unfortunately, you’re a little too advanced for me. I don’t even know what the auto drive linkage is or where to find it.

Unfortunately, you’re a little too advanced for me. I don’t even know what the auto drive linkage is or where to find it.

#19

StarTech

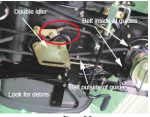

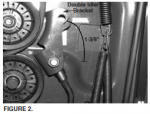

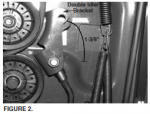

Just you are interested the circle is the where the adjustment is. Even I admit it is not the easiest adjustment to get to or to adjust.

StarTech

No harm in admitting you are over your head. I wish a lot my customers would, it save me a lot of undo their attempts.Appreciate the advice!

Unfortunately, you’re a little too advanced for me. I don’t even know what the auto drive linkage is or where to find it.

Just you are interested the circle is the where the adjustment is. Even I admit it is not the easiest adjustment to get to or to adjust.

#20

B

bertsmobile1

B

bertsmobile1

Looks like Star beat me to posting the parts break down .

To understand why your mower is slow you have to understand how it works.

And it all comes down to spring tension .

When you changed the belts did you check that the sliding element in the sheave # 78 moved fully from top to bottom ?

People who use the cruise control for hours & hours will end up wearing a little notch in the sheave which stops the sliding element moving all the way up or down.

No solution for that apart from replacement $$$$$$$$ .

In the diagram, spring # 39 is connected to pulley # 64 and over time it wears a groove where either end is anchored.

This drops the tension in the upper belt # 60 which usually stops the mower going slow, if it has been put back into the wrong hole so it is too tight then the sheave will not be able to get to the top and the mower will go too slow .

The same thing happens to either end of spring # 20 in fact I have had a couple in where the spring cut right through the speed controler # 5 and fell off.

If the controller can not put more tension in the lower belt # 61 than is in the upper belt #60 then the controller will not be able to force the sliding element to move up & down.

The sliding element moving up & down is what changes the speed just the same as a pair of stacked pulleys on a bench drill except there is an infinate number of combinations of pulley sizes.

Tightening the control rod # 55 will mean that there is more tension on the lower belt # 61 at every position of the speed control pedal # 42.

While this is a bog simple system there are a lot of places where small amounts of wear will create a bit difference to the speed attainable.

Parts to look at are the bushes # 51 ( 2 of them )

Pivot holes in # 72 & # 69 & # 70

And lastly the idler pulleys # 63 ( 2 ) & # 64 .

As a rule they rarely outlast 2 sets of belts.

They must be in good condition externally with no groves or flat spots and spine both freely & quietly.

To understand why your mower is slow you have to understand how it works.

And it all comes down to spring tension .

When you changed the belts did you check that the sliding element in the sheave # 78 moved fully from top to bottom ?

People who use the cruise control for hours & hours will end up wearing a little notch in the sheave which stops the sliding element moving all the way up or down.

No solution for that apart from replacement $$$$$$$$ .

In the diagram, spring # 39 is connected to pulley # 64 and over time it wears a groove where either end is anchored.

This drops the tension in the upper belt # 60 which usually stops the mower going slow, if it has been put back into the wrong hole so it is too tight then the sheave will not be able to get to the top and the mower will go too slow .

The same thing happens to either end of spring # 20 in fact I have had a couple in where the spring cut right through the speed controler # 5 and fell off.

If the controller can not put more tension in the lower belt # 61 than is in the upper belt #60 then the controller will not be able to force the sliding element to move up & down.

The sliding element moving up & down is what changes the speed just the same as a pair of stacked pulleys on a bench drill except there is an infinate number of combinations of pulley sizes.

Tightening the control rod # 55 will mean that there is more tension on the lower belt # 61 at every position of the speed control pedal # 42.

While this is a bog simple system there are a lot of places where small amounts of wear will create a bit difference to the speed attainable.

Parts to look at are the bushes # 51 ( 2 of them )

Pivot holes in # 72 & # 69 & # 70

And lastly the idler pulleys # 63 ( 2 ) & # 64 .

As a rule they rarely outlast 2 sets of belts.

They must be in good condition externally with no groves or flat spots and spine both freely & quietly.

#21

E

Endless Summer

Yes. Thanks. It does move freely.

E

Endless Summer

Did you pay any attention to the last sentence in reply #4 ?

Yes. Thanks. It does move freely.

#22

S

SeniorCitizen

S

SeniorCitizen

The only time the clutch should be used is to stop and or stop to shift to reverse. To keep the variable sheave active occasionally shift the lever completely through the speed range 1-7 or whatever is indicated on your selector.

#23

E

Endless Summer

Not sure if it’s something I can handle but I’ll look into it.

E

Endless Summer

Thanks!No harm in admitting you are over your head. I wish a lot my customers would, it save me a lot of undo their attempts.

Just you are interested the circle is the where the adjustment is. Even I admit it is not the easiest adjustment to get to or to adjust.

View attachment 50971

Not sure if it’s something I can handle but I’ll look into it.

#24

E

Endless Summer

wow. Thanks for all the info!

I’ll have to look into it on my next day off.

E

Endless Summer

Looks like Star beat me to posting the parts break down .

To understand why your mower is slow you have to understand how it works.

And it all comes down to spring tension .

When you changed the belts did you check that the sliding element in the sheave # 78 moved fully from top to bottom ?

People who use the cruise control for hours & hours will end up wearing a little notch in the sheave which stops the sliding element moving all the way up or down.

No solution for that apart from replacement $$$$$$$$ .

In the diagram, spring # 39 is connected to pulley # 64 and over time it wears a groove where either end is anchored.

This drops the tension in the upper belt # 60 which usually stops the mower going slow, if it has been put back into the wrong hole so it is too tight then the sheave will not be able to get to the top and the mower will go too slow .

The same thing happens to either end of spring # 20 in fact I have had a couple in where the spring cut right through the speed controler # 5 and fell off.

If the controller can not put more tension in the lower belt # 61 than is in the upper belt #60 then the controller will not be able to force the sliding element to move up & down.

The sliding element moving up & down is what changes the speed just the same as a pair of stacked pulleys on a bench drill except there is an infinate number of combinations of pulley sizes.

Tightening the control rod # 55 will mean that there is more tension on the lower belt # 61 at every position of the speed control pedal # 42.

While this is a bog simple system there are a lot of places where small amounts of wear will create a bit difference to the speed attainable.

Parts to look at are the bushes # 51 ( 2 of them )

Pivot holes in # 72 & # 69 & # 70

And lastly the idler pulleys # 63 ( 2 ) & # 64 .

As a rule they rarely outlast 2 sets of belts.

They must be in good condition externally with no groves or flat spots and spine both freely & quietly.

wow. Thanks for all the info!

I’ll have to look into it on my next day off.

#25

B

bertsmobile1

B

bertsmobile1

IT is quite simple in theory which ever belt is tighter will cause the pulley to spread so have an effective smaller diameter causing the pulley to spin faster for a given engne speed.

It might also be worth checking your engine speed..

It should be around 3600 but if it is down to 3400 for instance the mower will be slow.

Very few people can actually pick engine speeds because what we hear is mostly exhaust noise.

It might also be worth checking your engine speed..

It should be around 3600 but if it is down to 3400 for instance the mower will be slow.

Very few people can actually pick engine speeds because what we hear is mostly exhaust noise.

#26

StarTech

StarTech

As Bert said it is a simple system on the surface but just like a two cycle engine everything got to be right and working together for things to work correctly. This is where an experience mechanic has an advantage just a trained tech. We run so many different problems with a system like the CVT system that we check things out a nature troubleshooting skill. With a system this it is a lot easier for me to actually put my hands on it.

Also here some additional info that might help. It is assumed you have the correct PTO (engine pulley) to Variable pulley installed.

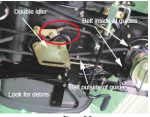

Actual under carriage location of adjustment. Note some layout different layouts had been seen as actual pull off springs can be positioned differently for an example..

factory setting of auto drive linkage

Also here some additional info that might help. It is assumed you have the correct PTO (engine pulley) to Variable pulley installed.

Actual under carriage location of adjustment. Note some layout different layouts had been seen as actual pull off springs can be positioned differently for an example..

factory setting of auto drive linkage

#27

E

Endless Summer

Does tightening the nut on the tie rod adjust the auto drive linkage?

I did that but I’m not seeing it change anything whether I loosen or tighten it?

E

Endless Summer

Thanks for all the pics/diagrams!As Bert said it is a simple system on the surface but just like a two cycle engine everything got to be right and working together for things to work correctly. This is where an experience mechanic has an advantage just a trained tech. We run so many different problems with a system like the CVT system that we check things out a nature troubleshooting skill. With a system this it is a lot easier for me to actually put my hands on it.

Also here some additional info that might help. It is assumed you have the correct PTO (engine pulley) to Variable pulley installed.

Actual under carriage location of adjustment. Note some layout different layouts had been seen as actual pull off springs can be positioned differently for an example..

View attachment 50978

factory setting of auto drive linkage

View attachment 50979

View attachment 50980

View attachment 50981

Does tightening the nut on the tie rod adjust the auto drive linkage?

I did that but I’m not seeing it change anything whether I loosen or tighten it?

Attachments

#28

R

Rivets

R

Rivets

The nut on the linkage rod is a lock nut. You must remove the nut holding the linkage rod to the plate. This will allow you to remove the rod, back the tie rod end out one full revolution and re install. This will allow for more tension on the belt and reduce slippage, allowing the unit to move faster. Might have to do this a couple of times. To me that belt looks worn and if so I would replace it first.

#29

E

Endless Summer

The belt on there is an OEM brand new belt.

I tightened the tie rod all the way. Still have noticed much change.

I have appreciated your feedback. Do you know what the average top speed of this mower would be?

E

Endless Summer

Thanks.The nut on the linkage rod is a lock nut. You must remove the nut holding the linkage rod to the plate. This will allow you to remove the rod, back the tie rod end out one full revolution and re install. This will allow for more tension on the belt and reduce slippage, allowing the unit to move faster. Might have to do this a couple of times. To me that belt looks worn and if so I would replace it first.

The belt on there is an OEM brand new belt.

I tightened the tie rod all the way. Still have noticed much change.

I have appreciated your feedback. Do you know what the average top speed of this mower would be?

#30

E

Endless Summer

I put spring #39 back in the same spot where it was when I started. I’m thinking it’s in the right place since I don’t really see any other good options where it could go.

E

Endless Summer

Looks like Star beat me to posting the parts break down .

To understand why your mower is slow you have to understand how it works.

And it all comes down to spring tension .

When you changed the belts did you check that the sliding element in the sheave # 78 moved fully from top to bottom ?

People who use the cruise control for hours & hours will end up wearing a little notch in the sheave which stops the sliding element moving all the way up or down.

No solution for that apart from replacement $$$$$$$$ .

In the diagram, spring # 39 is connected to pulley # 64 and over time it wears a groove where either end is anchored.

This drops the tension in the upper belt # 60 which usually stops the mower going slow, if it has been put back into the wrong hole so it is too tight then the sheave will not be able to get to the top and the mower will go too slow .

The same thing happens to either end of spring # 20 in fact I have had a couple in where the spring cut right through the speed controler # 5 and fell off.

If the controller can not put more tension in the lower belt # 61 than is in the upper belt #60 then the controller will not be able to force the sliding element to move up & down.

The sliding element moving up & down is what changes the speed just the same as a pair of stacked pulleys on a bench drill except there is an infinate number of combinations of pulley sizes.

Tightening the control rod # 55 will mean that there is more tension on the lower belt # 61 at every position of the speed control pedal # 42.

While this is a bog simple system there are a lot of places where small amounts of wear will create a bit difference to the speed attainable.

Parts to look at are the bushes # 51 ( 2 of them )

Pivot holes in # 72 & # 69 & # 70

And lastly the idler pulleys # 63 ( 2 ) & # 64 .

As a rule they rarely outlast 2 sets of belts.

They must be in good condition externally with no groves or flat spots and spine both freely & quietly.

I put spring #39 back in the same spot where it was when I started. I’m thinking it’s in the right place since I don’t really see any other good options where it could go.

Attachments

#32

E

Endless Summer

E

Endless Summer

What do you think may be not threaded correctly?Something doesn't appear to be threaded right.

#33

B

bertsmobile1

B

bertsmobile1

The springs should not cross over each other.

Spring 38 should be connected to the pedal then travel above the top belt to a hole in the mower chassis.

A strong flash light will show with some keyhole wear , it is a return spring to make the belt go slack.

Spring 39 looks right.

And if that is the new belt in the photo it is showing bare rubber which means that excessive wear has worn the cover off .

Check that it is not rubbing on something .

If it does not have enough slack then the engine pulley will wear the cover off & start burning the belt.

Spring 38 should be connected to the pedal then travel above the top belt to a hole in the mower chassis.

A strong flash light will show with some keyhole wear , it is a return spring to make the belt go slack.

Spring 39 looks right.

And if that is the new belt in the photo it is showing bare rubber which means that excessive wear has worn the cover off .

Check that it is not rubbing on something .

If it does not have enough slack then the engine pulley will wear the cover off & start burning the belt.

#34

R

Rivets

R

Rivets

To me the belt is routed wrong. If you look at the pics Star posted and your pic, the belts are routed differently. I may be wrong, as I can’t see the entire adjuster arm.

#35

B

bertsmobile1

I think the bottom of the phots is the front & the top is the back.

B

bertsmobile1

I thought that when I first looked at it but the rod pulls so when it comes back the rear pulley should come forward .To me the belt is routed wrong. If you look at the pics Star posted and your pic, the belts are routed differently. I may be wrong, as I can’t see the entire adjuster arm.

I think the bottom of the phots is the front & the top is the back.