You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Toro Timecutter (75742) G6 Gator Blade question

#1

A

apg1979

A

apg1979

I have a new Timecutter 75742 42" mower that will be used for the first time this spring.

42" TimeCutter® 22.5 HP Gas Zero-Turn Mower 75742 | Toro | Toro

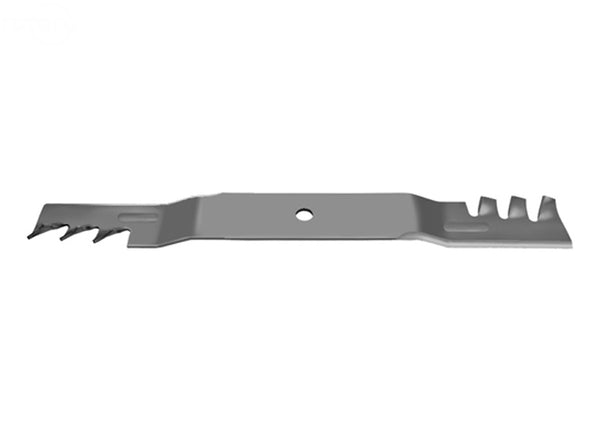

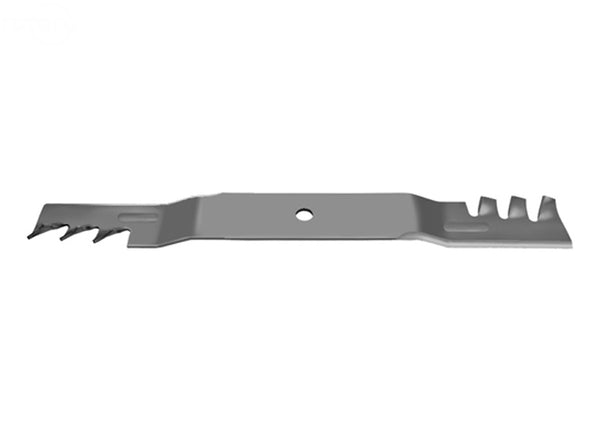

I picked up 2 G6 Gator blades to add in and they went on fine but curious if anyone has any advice if its not a good idea to use on this mower given they are wider and a decent amount heavier than the stock blades? I tested the PTO with them and it works fine but you can tell it takes a little more umph to get them going and a little louder when engaged

Mulching Blade, Gator® G6™, 21-9/16" | Oregon Products

Just wanted to get some smarter people than my opinions on this setup before i start using the new machine

thanks for your help!

42" TimeCutter® 22.5 HP Gas Zero-Turn Mower 75742 | Toro | Toro

I picked up 2 G6 Gator blades to add in and they went on fine but curious if anyone has any advice if its not a good idea to use on this mower given they are wider and a decent amount heavier than the stock blades? I tested the PTO with them and it works fine but you can tell it takes a little more umph to get them going and a little louder when engaged

Mulching Blade, Gator® G6™, 21-9/16" | Oregon Products

Just wanted to get some smarter people than my opinions on this setup before i start using the new machine

thanks for your help!

#2

B

bertsmobile1

B

bertsmobile1

Usually the results are good.

Got lots of time cutters running Gators of various styles.

If Oregon recommend them they will be fine .

The extra weight is a good thing for cutting rough & tuffted grass.

The only downside is it puts extra shock load on the clutch & belt so try to avoid turning the brakes on & off unless necessary.

Also note that they are designed to be able to throw so do not instal a mulching cover or the clippings will just build up under the deck till they overload the motor

By that time the grass clippings are a thick shake and when finally cleared out will not rot normally & can kill the grass where they land

Got lots of time cutters running Gators of various styles.

If Oregon recommend them they will be fine .

The extra weight is a good thing for cutting rough & tuffted grass.

The only downside is it puts extra shock load on the clutch & belt so try to avoid turning the brakes on & off unless necessary.

Also note that they are designed to be able to throw so do not instal a mulching cover or the clippings will just build up under the deck till they overload the motor

By that time the grass clippings are a thick shake and when finally cleared out will not rot normally & can kill the grass where they land

#3

A

apg1979

A

apg1979

thanks for the info! would that extra weight affect the spinning speed as well i'd imagine and impact the cutting performance when going full speed on my zero turn?

You mention the extra load on the clutch/belt and to avoid turn the brakes on/off.....excuse my inexperience since i'm new to zero turns but w/ that type of machine would that mean avoid going from forward motion to neutral w/ the levers more than you need to? (only brake that i know of other than the electronic brake when its in park w/ levers outward)

waffling if the risk of load on the clutch/belt is worth the benefits. i wonder if i could find some G5's for my size deck which i believe is lighter

You mention the extra load on the clutch/belt and to avoid turn the brakes on/off.....excuse my inexperience since i'm new to zero turns but w/ that type of machine would that mean avoid going from forward motion to neutral w/ the levers more than you need to? (only brake that i know of other than the electronic brake when its in park w/ levers outward)

waffling if the risk of load on the clutch/belt is worth the benefits. i wonder if i could find some G5's for my size deck which i believe is lighter

#4

A

apg1979

A

apg1979

i was looking what Oregon has for G3/5 for my model but they dont list anything. I did find G3 at the same 21-9/16th length and 5/8 center hole but the offset is 5/8 vs 5/16 which Oregon cautioned me against. think that difference is worth worrying about?

#5

M

MParr

M

MParr

I did some looking for you. There aren’t a lot of options for you. I found a couple of replacement blades. They aren’t Oregon brand. They are Rotary brand.

I would choose the Rotary brand. My reason? These blades are closest to the original thickness and length to the Toro blades. You certainly don’t need a G6 on your mower. Why? It’s a residential unit and isn’t designed to spin 3” wide x 1/4” thick metal blades at 18,000 RPMs.

#6

A

apg1979

A

apg1979

thank you for taking the time on this! appreciate the help! i ended up sending the g6 back today.....brand new mower i dont want to be worried about extra wear on it that isnt needed. I agree, not a lot of options for mine out there from what i see....i did find Oregon has a g3 which is identical to the g6 for what i'm supposed to have but its just that offset drops the blade about .3" lower. not sure if thats of any worry or not.... looking at that rotary option you sent that also looks promising but that also looks like it has a little bit of a drop compared to the stock blades (and the g6). Gator® G3™ Blade, 21-9/16" | Oregon Products

#7

M

MParr

Catalog pictures can be deceiving. Both of the Rotary blades are listed as replacements for the Toro blade part number. The G3 doesn’t show their blade being listed as a replacement for your Toro blade part number. That’s why I said to check the clearances.

M

MParr

The G3 that you linked to looks promising. They are close to the same thickness as your original Toro blade. The only thing that I would be concerned about is the blade length. After mounting them, you will need to check the clearance between the blades and between the blade and deck edge. You wouldn’t want to engage the PTO without confirming the clearance.thank you for taking the time on this! appreciate the help! i ended up sending the g6 back today.....brand new mower i dont want to be worried about extra wear on it that isnt needed. I agree, not a lot of options for mine out there from what i see....i did find Oregon has a g3 which is identical to the g6 for what i'm supposed to have but its just that offset drops the blade about .3" lower. not sure if thats of any worry or not.... looking at that rotary option you sent that also looks promising but that also looks like it has a little bit of a drop compared to the stock blades (and the g6). Gator® G3™ Blade, 21-9/16" | Oregon Products

Catalog pictures can be deceiving. Both of the Rotary blades are listed as replacements for the Toro blade part number. The G3 doesn’t show their blade being listed as a replacement for your Toro blade part number. That’s why I said to check the clearances.

#8

A

apg1979

A

apg1979

yup definitely smart thing to watch! so at least on the spec sheet, the g6 that i had and that g3 from the link above are identical on length (21-9/16) and the only thing different was the offset which is the part that would worry me that it would dip down too far and shoot the grass out of the bottom instead of towards the side discharge (or or course hit the bottom part of the deck metal that has a little lip on the bottom part. i'm gonna check more into those rotary ones ....the mulching blade looks like it has an offset similar to the g3 from what i can tell but it doesnt list the specs for that. do you have any experience w/ their blades? i was not familiar w/them

#9

B

bertsmobile1

No all blades will work with all decks due to the amount & direction of clipping throw.

Some times if using a wide blade they will just touch & need a little taken off the rear to avoid this & then of course rebalancing.

Now nothing is free so all that extra momentum in spinning the extra weight of the heavy blades will cause the throttle to be open a touch further to maintain the governed engine speed so You will use more fuel .

Engine is governed so the blades will spin at the same speed regardless of their weight because the engine always spins at the same speed ( or tries to )

Because the blades are heavier it will take a couple of extra seconds for the blades to attain full speed .

Listen to the sound when you turn the blades on.

After the screech of the belt & clutch engaging it take a couple of seconds before you get the sound of the blades spinning at their full speed.

Using heavier blades this will take a little longer because the blades require more energy to spin

The extra load on the belt & blade clutch is sort of like the difference between starting your car on the flat & starting going uphill .

We are talking about the BLADE clutch, there is no drive clutch as you have hydro drives .

Offset I believe you are talking about the step between the bolt hole & the cutting edge

Well here is the drum on that

This will change the volume of the air between the blades and the roof of the deck

This can have drastic effects and cause the clippings to get stuck under the deck & not discharge properly .

But exactly what the effects are will depend on so many variables it is not funny.

On some decks it does not matter as they come with spacers to alter the blade height , on others it can be a problem.

I have been supplying G3's for Time Cutters and the customers are very happy with them .

Only one customer is using the G5 and he loves them so much he now buys them from the USA & has them shipped to Australia because B & S are not going to import them any more ( B & S have a world wide Oregon distribution deal ) .

B

bertsmobile1

Specific blades are designed to work with specific decksthanks for the info! would that extra weight affect the spinning speed as well i'd imagine and impact the cutting performance when going full speed on my zero turn?

You mention the extra load on the clutch/belt and to avoid turn the brakes on/off.....excuse my inexperience since i'm new to zero turns but w/ that type of machine would that mean avoid going from forward motion to neutral w/ the levers more than you need to? (only brake that i know of other than the electronic brake when its in park w/ levers outward)

waffling if the risk of load on the clutch/belt is worth the benefits. i wonder if i could find some G5's for my size deck which i believe is lighter

No all blades will work with all decks due to the amount & direction of clipping throw.

Some times if using a wide blade they will just touch & need a little taken off the rear to avoid this & then of course rebalancing.

Now nothing is free so all that extra momentum in spinning the extra weight of the heavy blades will cause the throttle to be open a touch further to maintain the governed engine speed so You will use more fuel .

Engine is governed so the blades will spin at the same speed regardless of their weight because the engine always spins at the same speed ( or tries to )

Because the blades are heavier it will take a couple of extra seconds for the blades to attain full speed .

Listen to the sound when you turn the blades on.

After the screech of the belt & clutch engaging it take a couple of seconds before you get the sound of the blades spinning at their full speed.

Using heavier blades this will take a little longer because the blades require more energy to spin

The extra load on the belt & blade clutch is sort of like the difference between starting your car on the flat & starting going uphill .

We are talking about the BLADE clutch, there is no drive clutch as you have hydro drives .

Offset I believe you are talking about the step between the bolt hole & the cutting edge

Well here is the drum on that

This will change the volume of the air between the blades and the roof of the deck

This can have drastic effects and cause the clippings to get stuck under the deck & not discharge properly .

But exactly what the effects are will depend on so many variables it is not funny.

On some decks it does not matter as they come with spacers to alter the blade height , on others it can be a problem.

I have been supplying G3's for Time Cutters and the customers are very happy with them .

Only one customer is using the G5 and he loves them so much he now buys them from the USA & has them shipped to Australia because B & S are not going to import them any more ( B & S have a world wide Oregon distribution deal ) .

#10

A

apg1979

A

apg1979

thanks so much for all the great info here! i knew a lot went into the dynamics w/ the deck/blades which i wouldnt even try to pretend to know a sliver of so thats my hope to find the smart people here

On the timecutter g3/g5, would you happen to know if anyone w/ my specific 42" model was one you've supplied before and gotten feedback from? honestly i was hoping to find a g5 for my model but even talking to Oregon they had no ideas of any models that fit mine specifically. (https://www.toro.com/en/homeowner/riding-mowers/timecutter-75742)

Like i was saying before, the g3 theres one thats damn close but that offset (drop from the bolt to the blade) is what concerns me but i very well could be overthinking it all)

On the timecutter g3/g5, would you happen to know if anyone w/ my specific 42" model was one you've supplied before and gotten feedback from? honestly i was hoping to find a g5 for my model but even talking to Oregon they had no ideas of any models that fit mine specifically. (https://www.toro.com/en/homeowner/riding-mowers/timecutter-75742)

Like i was saying before, the g3 theres one thats damn close but that offset (drop from the bolt to the blade) is what concerns me but i very well could be overthinking it all)

#11

M

MParr

M

MParr

One more thing. Oregon lists those blades at 21 9/16” long. Rotary lists their blades at 21 5/8” long. The Rotary blades would be 1/16” longer. This may or may not be the case. I have used a lot of Rotary blades and they make their blades to OEM dimensions. If the Rotary part number lists the Toro blade part number, it will fit without problems.

You can go to Rotary, Stens, and Oregon websites and put in the Toro part number. If there is no match, don’t try to wing it.

Your Toro blade part number is 137-1999-03. If you do not see that number listed as a cross to an aftermarket blade, I would avoid it.

You can go to Rotary, Stens, and Oregon websites and put in the Toro part number. If there is no match, don’t try to wing it.

Your Toro blade part number is 137-1999-03. If you do not see that number listed as a cross to an aftermarket blade, I would avoid it.

#12

A

apg1979

A

apg1979

good to keep in mind! so for Oregon i put in the stock blade part # and nothing showed up but when i put in the model of the mower the G6 showed up (only one Oregon said they show compatible...mentioned that they are behind on updating w/ newer models). i did notice the slightly larger length on the Rotary one and was curious about that . I know the G6 that i had in there spun fine and did not collide w/ each other and had a very slight gap between when they'd pass but i didnt measure before i sent them back unfortunately. i do have my stock blades i can measure in the morning to make sure though what those measure out atOne more thing. Oregon lists those blades at 21 9/16” long. Rotary lists their blades at 21 5/8” long. The Rotary blades would be 1/16” longer. This may or may not be the case. I have used a lot of Rotary blades and they make their blades to OEM dimensions. If the Rotary part number lists the Toro blade part number, it will fit without problems.

You can go to Rotary, Stens, and Oregon websites and put in the Toro part number. If there is no match, don’t try to wing it.

#13

M

MParr

M

MParr

Mower companies can change the deck dimensions ever so slightly as model numbers change. So a 42” Toro deck may be slightly wider or more narrow when the model numbers change. The length of blades will have to change as well. But, they will continue to list it as a 42” cut. You can have a couple of things that can happen, as a result. You can get blades striking one another or the deck. Or, you can have enough gap between the blades to leave strips of uncut grass. I had a Toro MX5000 with the same problem. I could only use Toro OEM blades or Rotary blades.

#14

A

apg1979

A

apg1979

good point there! so local store here has what looks like those G3's in stock so i may get a specific measurement of my stock blades tomorrow and go check them out to see if they match up in length or not. that offset is my only concern but i could bring them home to see how they look in there before i decide. that gap between i had in mind as well. if that doesnt work i'm gonna check out the Rotary ones (dont think i can get those local)

#15

B

bertsmobile1

B

bertsmobile1

Also remember that there might be more than one part number for your blades

From Toro usually do a high lift & a low lift blade for just about every deck

And the blades for the fabricated deck may not be the same for the pressed deck

If you plug in the part number for a high lift blade then you will usually not get a Gator equivalent because the Gator is a mulching blade

I have been caught out before when just using the part numbers rather than the make & model number search

Now days I do a "blade by length" search to find blades of the same length then eliminate the ones with different mounting holes

For instance I fit Great Dane notched high lift blades to one of the Toro Z Masters and eXmark low lifts to the Great Dane.

In many cases it is trial & error to find which particular blade works best on your grass and in many cases you might need 2 different blades depending upon the season .

Right now I have just finished fitting the low lift ( Sand ) blades to the Cubs that we mow the pasture with as the grass is very stalky as it has gone to seed and the with the high lifts on the stalks just wrap around the spindle and wear out the bottom of the spindle housings .

Come spring ( I am in the souther hemisphere ) the high lifts will go back on again .

We wen through 17 different blades to work out what cuts best at which time of the year .

There is no such thing as a universal "best " blade it is a case of finding out what is the RIGHT blades for you .

Don't be afraid to experiment and if you get a really dud set , then put them aside for emergency use only .

After all they are only blades and blades are a service replacement part .

From Toro usually do a high lift & a low lift blade for just about every deck

And the blades for the fabricated deck may not be the same for the pressed deck

If you plug in the part number for a high lift blade then you will usually not get a Gator equivalent because the Gator is a mulching blade

I have been caught out before when just using the part numbers rather than the make & model number search

Now days I do a "blade by length" search to find blades of the same length then eliminate the ones with different mounting holes

For instance I fit Great Dane notched high lift blades to one of the Toro Z Masters and eXmark low lifts to the Great Dane.

In many cases it is trial & error to find which particular blade works best on your grass and in many cases you might need 2 different blades depending upon the season .

Right now I have just finished fitting the low lift ( Sand ) blades to the Cubs that we mow the pasture with as the grass is very stalky as it has gone to seed and the with the high lifts on the stalks just wrap around the spindle and wear out the bottom of the spindle housings .

Come spring ( I am in the souther hemisphere ) the high lifts will go back on again .

We wen through 17 different blades to work out what cuts best at which time of the year .

There is no such thing as a universal "best " blade it is a case of finding out what is the RIGHT blades for you .

Don't be afraid to experiment and if you get a really dud set , then put them aside for emergency use only .

After all they are only blades and blades are a service replacement part .

#16

A

andyboy

A

andyboy

I am heading into my fourth season using G3's on my 42" Timecutter. I have had no problems and am pleased with the improvement from the factory blades. I have them with mulching upgrades on the deck and I see some of the results mentioned here but I have no regrets.

#17

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

I agree, also if I recall, the timecutter blades are timed and driven by plastic cogged pulley that split in halve if you hit something, so do not hit an object!!!!!!!!!!!

#18

A

apg1979

A

apg1979

thanks everyone! good to remember on using the right blade/tool for the right situation so i was hoping to have a mulching blade along w/ the stock high lift ones to alternate if needed. as for hitting things, the only things i would really ever run into in my yard is small sticks (we pick up the big ones of course) or pine cones so hopefully thats ok. I have a coworker w/ a larger version of y timecutter and the g3's and also the mulch kit from toro and loves the results (mostly how they handle leaves) so i thought if i have luck w/ that blade i could add the plug and middle baffle to see how it does in the fall.....i think i prefer side discharge otherwise.

alright so i found HomeDepot had a pair of the g3's in stock so i picked them up tonight and loosely put them on to see how they work. below you can see the gap when they pass by each other (look to spin fine w/out any collision) and the offset/drop it has a 1/2 inch yet from the bottom of the blade to the little lip at the bottom of the deck so hoping thats sufficient. obviously i'll have to play around w/ deck height since its a little closer to the ground vs the stock ones. anything in these that look concerning ? (not the best photo's i got quickly.....only 2 quick mows w/ this new machine late fall looks like it did a number on the underdeck paint job already) . the g3's definitely are a lot lighter than the 6's so thats nice....they actually are a bit narrower vs the stock blades

alright so i found HomeDepot had a pair of the g3's in stock so i picked them up tonight and loosely put them on to see how they work. below you can see the gap when they pass by each other (look to spin fine w/out any collision) and the offset/drop it has a 1/2 inch yet from the bottom of the blade to the little lip at the bottom of the deck so hoping thats sufficient. obviously i'll have to play around w/ deck height since its a little closer to the ground vs the stock ones. anything in these that look concerning ? (not the best photo's i got quickly.....only 2 quick mows w/ this new machine late fall looks like it did a number on the underdeck paint job already) . the g3's definitely are a lot lighter than the 6's so thats nice....they actually are a bit narrower vs the stock blades

Attachments

#19

M

MParr

M

MParr

I see that your Toro blade part number is not listed on that G3 blade. It may work out though.

#20

A

apg1979

A

apg1979

thats just the sticker on the new g3's......the stock toro blades are not in any of those pictures. just wanted to post those to get an idea how the g3's fit in there (gap between the 2 when they pass in the middle and how the bottom of the blades hits on the bottom of the deck (oregon cautioned about it being a lower offset that it could sometimes shoot blades out of the bottomI see that your Toro blade part number is not listed on that G3 blade. It may work out though.

#21

M

MParr

M

MParr

There are Toro part numbers on those Oregon blades. Your Toro part number isn’t there. They may work out for you anyway. If the blades are slightly tucked inside of the deck, that’s a good thing. Toro blades will sit somewhere between 1/4” to 3/8” above the bottom deck lip. They may also be 1/16” shorter than your Toro blades. If that’s the case, you may notice an uncut strip of grass in the middle of the rows that you’re mowing. You won’t know, unless you try them.

#22

B

bertsmobile1

B

bertsmobile1

You are on the right course

Treat them as an experiment

Remember no two types of grass cut the same .

Way back there were dedicated decks for catching , mulching & throwing

These were replaced with the "universal" decks

Universal in such as bing mediocre to poor at doing any type of mowing .

But it cut the costs at the factory & at the dealership

Treat them as an experiment

Remember no two types of grass cut the same .

Way back there were dedicated decks for catching , mulching & throwing

These were replaced with the "universal" decks

Universal in such as bing mediocre to poor at doing any type of mowing .

But it cut the costs at the factory & at the dealership

#23

A

apg1979

A

apg1979

cool yup that all makes sense! thanks everyone for sticking with my probably over analyzing and obsessing about this haha

actually these are a tiny bit (about 1/16th) longer than the stock toro blades in my measurements or at the very least the same.

I see what you mean about the toro part #'s actually....misread that. I did notice mine is not on there but i remembered that Oregon told me that they are behind on the newer toro models so hopefully due to that. the blades come within 1/2" of the outter part of the deck and within each other which all is good i know....but the only thing i was concerned about is how close to that bottom lip that they come but as long as i keep them balanced and they dont hit that i'm sure i'll be good.

I agree though, wont really know until i try them out. once i can torque them on tomorrow and fire it up to see how they sound i wont know for sure (the stock blades spin up smooth and fast vs the g6's labored a bit and a bit louder so i expect the g3's to be closer to stock

actually these are a tiny bit (about 1/16th) longer than the stock toro blades in my measurements or at the very least the same.

I see what you mean about the toro part #'s actually....misread that. I did notice mine is not on there but i remembered that Oregon told me that they are behind on the newer toro models so hopefully due to that. the blades come within 1/2" of the outter part of the deck and within each other which all is good i know....but the only thing i was concerned about is how close to that bottom lip that they come but as long as i keep them balanced and they dont hit that i'm sure i'll be good.

I agree though, wont really know until i try them out. once i can torque them on tomorrow and fire it up to see how they sound i wont know for sure (the stock blades spin up smooth and fast vs the g6's labored a bit and a bit louder so i expect the g3's to be closer to stock

#24

B

bertsmobile1

B

bertsmobile1

The pros like them because they hold an edge for longer and more important don't bog down as much in thick grass so they can plough through at full speed .

For them the extra job they can finish in a day is worth the extra fuel consumption & wear

No such thing as a free lunch

For them the extra job they can finish in a day is worth the extra fuel consumption & wear

No such thing as a free lunch

#25

M

MParr

M

MParr

@apg1979

If they don’t work out for you, there’s always the Rotary Copperhead mulchers that I linked to. Amazon might have them.

This site has them at a reasonable price.

mowerblades.com

mowerblades.com

If they don’t work out for you, there’s always the Rotary Copperhead mulchers that I linked to. Amazon might have them.

This site has them at a reasonable price.

Rotary Copperhead Toothed Lawn Mower Blade 13129 -Toro Toothed Blades

Rotary 13129, Toro 106-2247-03,Toro 106-8744-03, 110-1857-03, Toro 110-6568-03 2 blades for a 42

#27

A

andyboy

A

andyboy

Regarding the chopping of leaves:

Despite having the mulching kit with Gator blades on my Toro timecutter I was frustrated with the leaves that escape out the right side beneath the deck. I made this rubber skirt to stop that. It hangs from the "tractor" frame and not the deck itself so it has a consistent height no matter the height to the deck. It works really well and I have fine tuned it with repeat prototypes. In addition to the lawn, I can chop leaves on an asphalt driveway with almost no leaves escaping the deck. I'll try to make before and after picks this fall of the mulching.

Despite having the mulching kit with Gator blades on my Toro timecutter I was frustrated with the leaves that escape out the right side beneath the deck. I made this rubber skirt to stop that. It hangs from the "tractor" frame and not the deck itself so it has a consistent height no matter the height to the deck. It works really well and I have fine tuned it with repeat prototypes. In addition to the lawn, I can chop leaves on an asphalt driveway with almost no leaves escaping the deck. I'll try to make before and after picks this fall of the mulching.

#29

A

andyboy

www.lawnmowerforum.com

www.lawnmowerforum.com

A

andyboy

It is an attempt to draw cleaner air from above the engine rather than around or below. As described here:andyboy- what are the 2 pipes sticking out the rear ? Exhaust stacks or what ?

Air source on my Toro Timecutter SS4235

I have a Kohler KT725 2 cyl. engine on my Toro Timecutter SS4235. I have an issue with where the air is drawn from for the engine. It seems to be kinda ducted up past the exhaust manifold before entering the air cleaner enclosure. I say kinda because this path is not airtight by any means...