You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Tiger Cat 2 - Starting Issue (since new)

#1

W

Wendol

W

Wendol

Since day one, when endeavoring to start the mower, on first try I get only a click, and on second try turns over and starts immediately. I installed a relay per the dealers instructions, but nothing changed.

Any thoughts on how to correct this would be greatly appreciated.

Any thoughts on how to correct this would be greatly appreciated.

#2

R

Rivets

R

Rivets

Our crystal balls have become very cloudy, due to the recent elections. You are not giving us much info to help you. We have no idea how old this unit is, which engine it has, or if you have done anything to solve the problem besides changing the relay? With out unit model and serial numbers, plus all engine numbers everyone here will just be guessing. My first guess is that there Is a loose or dirty connection. My second guess is that you don’t have the proper size battery. If it is a single cylinder engine, the battery should have a minimum of 300 CCA. If you have a twin, the battery should have a minimum of 350 CCA. If you want more help please provide more info.

#3

W

Wendol

W

Wendol

Sorry about the lack of info.

Mower: TIGER CAT II STCII-61V-32BV Serial # 8000092

Engine: Vanguard ModelNo./Mfg No. 543777-3222-J1 Serial# 2110138781751

This was purchased a year ago, currently has 27 hours on it (medical issues have limited my mowing)

As stated earlier, the cranking issue has been there since day1, after dealing with it for a couple of months, removed the battery, had the dealer test it, and he said it tested "marginal".

At that time the battery was replaced with the Interstate SP-40 (350 CCA).

Any additional thoughts would be greatly appreciated.

Mower: TIGER CAT II STCII-61V-32BV Serial # 8000092

Engine: Vanguard ModelNo./Mfg No. 543777-3222-J1 Serial# 2110138781751

This was purchased a year ago, currently has 27 hours on it (medical issues have limited my mowing)

As stated earlier, the cranking issue has been there since day1, after dealing with it for a couple of months, removed the battery, had the dealer test it, and he said it tested "marginal".

At that time the battery was replaced with the Interstate SP-40 (350 CCA).

Any additional thoughts would be greatly appreciated.

#4

ILENGINE

ILENGINE

The click maybe the starter solenoid not completely pulling in the bendix to engage the flywheel. My nephews starter on his 35 Vanguard on his stump grinder does the same thing on occasion since new and he is pushing 700 hours. The first start attempt doesn't allow the starter to fully engage the flywheel and energize the solenoid contacts to spin the starter. Has been an on going issue with that engine and starter setup with no known cure but various shops and Briggs tech support have tried different things over the years without complete success.

#5

Tiger Small Engine

Tiger Small Engine

If

it is under warranty, take it to the dealer.Sorry about the lack of info.

Mower: TIGER CAT II STCII-61V-32BV Serial # 8000092

Engine: Vanguard ModelNo./Mfg No. 543777-3222-J1 Serial# 2110138781751

This was purchased a year ago, currently has 27 hours on it (medical issues have limited my mowing)

As stated earlier, the cranking issue has been there since day1, after dealing with it for a couple of months, removed the battery, had the dealer test it, and he said it tested "marginal".

At that time the battery was replaced with the Interstate SP-40 (350 CCA).

Any additional thoughts would be greatly appreciated.

#6

StarTech

StarTech

Strange the engine was made in 2021 so up to dealer if they want to cover an out of base warranty engine. A gray area. Only the dealer knows if the mower has been sitting for two years unused.

#7

D

Douglas Lee

D

Douglas Lee

Wendol,

You stated the dealer suggested an additional relay. "I installed a relay per the dealers instructions"

Can you provide us with details on that?

Just curious!

Doug Lee

*

You stated the dealer suggested an additional relay. "I installed a relay per the dealers instructions"

Can you provide us with details on that?

Just curious!

Doug Lee

*

#8

StarTech

StarTech

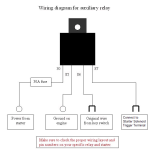

That should be like the helper relay that JD used on the Kohler engines that had the solenoid shift starters. Basically it is wired as to provide much shorter trigger wire circuit.Wendol,

You stated the dealer suggested an additional relay. "I installed a relay per the dealers instructions"

Can you provide us with details on that?

Just curious!

Doug Lee

*

#9

W

Wendol

W

Wendol

Yes helper/assist relay as StarTech describes.Wendol,

You stated the dealer suggested an additional relay. "I installed a relay per the dealers instructions"

Can you provide us with details on that?

Just curious!

Doug Lee

*

#10

S

S854

S

S854

Since your issue started “on day one” it may be something as simple as a faulty ground.

I am unfamiliar with Tiger Cat, however, I’ve corrected several “no-start” situations by following the battery ground wire to where it connects to the frame/chassis.

I have a motorcycle that came from the factory where the ground wire connected to the frame through the paint! Cleaned the paint off, cleaned the ground lug and put it back together… even the headlight was brighter after that…

I am unfamiliar with Tiger Cat, however, I’ve corrected several “no-start” situations by following the battery ground wire to where it connects to the frame/chassis.

I have a motorcycle that came from the factory where the ground wire connected to the frame through the paint! Cleaned the paint off, cleaned the ground lug and put it back together… even the headlight was brighter after that…

#12

H

hlw49

H

hlw49

The people of America have spoken.Our crystal balls have become very cloudy, due to the recent elections. You are not giving us much info to help you. We have no idea how old this unit is, which engine it has, or if you have done anything to solve the problem besides changing the relay? With out unit model and serial numbers, plus all engine numbers everyone here will just be guessing. My first guess is that there Is a loose or dirty connection. My second guess is that you don’t have the proper size battery. If it is a single cylinder engine, the battery should have a minimum of 300 CCA. If you have a twin, the battery should have a minimum of 350 CCA. If you want more help please provide more info.

The American people have spoken.Our crystal balls have become very cloudy, due to the recent elections. You are not giving us much info to help you. We have no idea how old this unit is, which engine it has, or if you have done anything to solve the problem besides changing the relay? With out unit model and serial numbers, plus all engine numbers everyone here will just be guessing. My first guess is that there Is a loose or dirty connection. My second guess is that you don’t have the proper size battery. If it is a single cylinder engine, the battery should have a minimum of 300 CCA. If you have a twin, the battery should have a minimum of 350 CCA. If you want more help please provide more info.

#14

D

Douglas Lee

D

Douglas Lee

StarTech,

Thanks for the diagram.

Does the extra relay just parallel the original wiring

to trigger the starter relay when the starter switch is turned?

Thanks . . .

Doug Lee

*

Thanks for the diagram.

Does the extra relay just parallel the original wiring

to trigger the starter relay when the starter switch is turned?

Thanks . . .

Doug Lee

*

#15

H

hlw49

H

hlw49

I have used a solenoid for an inerta drive starter and wire it basically the same way. I use 10 ga wire from the engine starter solenoid and back to the exciter terminal on the engine starter. You don't have to run a ground wire from the solenoid since the solenoid grounds to the frame when you bolt it down.

#16

StarTech

StarTech

What it does is to reduce the voltage drop at the starter solenoid. This why it is installed as close the starter as possible. What JD found was that the long trigger wire paths was causing large voltage drops due wiring resistance; therefore, the solenoid did not have current to fully pull in to engage the starter switch inside the solenoid. Instead of several feet of wiring wiring now there is just a few inches. Also the relay requires a lot less current so the voltage drop in the current wiring is reduce to the relay.

Another term I seen used is "helper relay". Basically comes down to you installing a switch at the solenoid to connect to battery cable at the starter instead going thru all the wiring harness. You could do the same using a screwdriver but this a lot easier. This way you can be seated ready to use the mower instead ruining your screwdriver tips.

One side note here is that the relay must be a water proof version as it is exposed to outdoor weather conditions so not just any old cheap relay can be use.

Another term I seen used is "helper relay". Basically comes down to you installing a switch at the solenoid to connect to battery cable at the starter instead going thru all the wiring harness. You could do the same using a screwdriver but this a lot easier. This way you can be seated ready to use the mower instead ruining your screwdriver tips.

One side note here is that the relay must be a water proof version as it is exposed to outdoor weather conditions so not just any old cheap relay can be use.

#18

G

Gym123

Where did you add the relay- show photos and a diagram. Is it activated by the crank wire and bypassing that wire, with tab 87 connected to the battery and tab 30 connected to the solenoid?

Adding a relay strikes me as similar to adding a fuel filter when the original one becomes clogged.

Has anyone ever lubricated the Bendix on the starter?

G

Gym123

Since day one, when endeavoring to start the mower, on first try I get only a click, and on second try turns over and starts immediately. I installed a relay per the dealers instructions, but nothing changed.

Any thoughts on how to correct this would be greatly appreciated.

Where did you add the relay- show photos and a diagram. Is it activated by the crank wire and bypassing that wire, with tab 87 connected to the battery and tab 30 connected to the solenoid?

Adding a relay strikes me as similar to adding a fuel filter when the original one becomes clogged.

Has anyone ever lubricated the Bendix on the starter?

#19

jes_in_sac

jes_in_sac

To eliminate all extraneous wiring and issues, use a good voltmeter and check the cranking voltage right at the starter, and then moving both the positive and negative probes to various spots to find where you lose starting voltage. If you have full voltage at the starter [with your - probe on the starter case] during the first crank attempt, then you are losing the voltage inside the starter contact or motor brushes. If you don't have a meter, use a set of jumper cables and go from a good car battery. Attach the negative somewhere on the starter itself, then touch the positive directly to the starter positive post. That will tell you for sure if the internal starter solenoid is not making good contact until it first "loosens up" with the first start attempt. If it starts good the first time, then start going back and trying to figure out where you are losing the available start current.

#20

W

Wendol

W

Wendol

I have recently removed the relay (was wired as in Star Tech's diagram), gave the ground wires a good cleaning and unit appears to start better, (just not consistently) at this point and time.Where did you add the relay- show photos and a diagram. Is it activated by the crank wire and bypassing that wire, with tab 87 connected to the battery and tab 30 connected to the solenoid?

Adding a relay strikes me as similar to adding a fuel filter when the original one becomes clogged.

Has anyone ever lubricated the Bendix on the starter?

#21

H

hlw49

H

hlw49

Not so I have seen starters not work just click and not turm the engine over. What people don't realize is the manufactures use the smallest wire they can get by with. Over time they can build up a resistance and not work any more. As well the contacts in the solenoid can oxidize and cause the same porblem. I have use solenoids for a inertia drive starter wired in and make it work this way. Just did my first one with the relay and it works as well.Where did you add the relay- show photos and a diagram. Is it activated by the crank wire and bypassing that wire, with tab 87 connected to the battery and tab 30 connected to the solenoid?

Adding a relay strikes me as similar to adding a fuel filter when the original one becomes clogged.

Has anyone ever lubricated the Bendix on the starter?

#22

R

rhkraft

R

rhkraft

Battery is weak. You said it was marginal. I think the new battery fixed it!Since day one, when endeavoring to start the mower, on first try I get only a click, and on second try turns over and starts immediately. I installed a relay per the dealers instructions, but nothing changed.

Any thoughts on how to correct this would be greatly appreciated.

#23

G

Gym123

I can't imagine designing something like these and using unsealed wire terminals/Molex plugs, knowing that they're used outdoors, often in bad weather and left outdoors, even if in a garage. They could have put dielectric grease on the terminals, a plastic cover on the plugs or used silicone rubber seals to keep moisture out. It's not that much more expensive! They probably paid more in warranty claims than these upgrades would have cost.

G

Gym123

I looking at/working on the Ariens, I was a bit surprised to see unsealed Molex connectors, thin wire, bad head bolt distribution (the cause of the head gasket failures) and then, there's the headlights being fed AC Voltage because the alternator can't deliver enough to power them with DC. That just tells me the MBAs were in control and engineering had to deliver these at the lowest possible cost, which is made worse by competition from foreign competitors (China). The headlights didn't work, so I disconnected the wires at the hinge for the shroud, tested them and found that the contacts were corroded, so I cleaned them. After disconnecting the plugs enough times, they began to work.Not so I have seen starters not work just click and not turm the engine over. What people don't realize is the manufactures use the smallest wire they can get by with. Over time they can build up a resistance and not work any more. As well the contacts in the solenoid can oxidize and cause the same porblem. I have use solenoids for a inertia drive starter wired in and make it work this way. Just did my first one with the relay and it works as well.

I can't imagine designing something like these and using unsealed wire terminals/Molex plugs, knowing that they're used outdoors, often in bad weather and left outdoors, even if in a garage. They could have put dielectric grease on the terminals, a plastic cover on the plugs or used silicone rubber seals to keep moisture out. It's not that much more expensive! They probably paid more in warranty claims than these upgrades would have cost.

#24

StarTech

StarTech

Well I can tell you that the so-called sealed Molex MX150 connectors are not as water proof as they claim. I have replaced several of the Toro electric brake.control modules and the connectors with new terminals because water got in and corroded things.

Most mower connectors and terminal don't usually corrode. Now there are times they get loose and then things happen afterwards.

Most mower connectors and terminal don't usually corrode. Now there are times they get loose and then things happen afterwards.

#25

G

Gym123

G

Gym123

I was thinking of the Packard/Weatherpack connectors used by GM- you can spray water directly onto them from any angle but the terminals were definitely not making good contact. The wires are still flexible, so I doubt the strands have broken and the lights still work. The main Molex is completely exposed, at the bottom of the engine, with nothing to protect it. I'm not a fan of spraying water, soapy or not, on engines. I know, they have gaskets and should survive it, I just don't like it.Well I can tell you that the so-called sealed Molex MX150 connectors are not as water proof as they claim. I have replaced several of the Toro electric brake.control modules and the connectors with new terminals because water got in and corroded things.

Most mower connectors and terminal don't usually corrode. Now there are times they get loose and then things happen afterwards.

#26

StarTech

StarTech

Even those are not as waterproof as they advertise. I have water damage even in them.

But most lawn equipment connectors are not weather proof types.

I currently working on a mower with Delphi (Aptiv) terminals and connector housings which is definitely not of the sealed type. I have more problems with the F56 style female terminals with the spring hinges breaking over time creating loose connections which the problem with this mower. Fairly easy to get and replace when you have the right tools. The Gravely dealer told the customer he had to replace the complete wiring harness as the terminal weren't available which is BS.

But having the right tools is important with any terminal replacement. Just can't use just any old tool to do this work.

But most lawn equipment connectors are not weather proof types.

I currently working on a mower with Delphi (Aptiv) terminals and connector housings which is definitely not of the sealed type. I have more problems with the F56 style female terminals with the spring hinges breaking over time creating loose connections which the problem with this mower. Fairly easy to get and replace when you have the right tools. The Gravely dealer told the customer he had to replace the complete wiring harness as the terminal weren't available which is BS.

But having the right tools is important with any terminal replacement. Just can't use just any old tool to do this work.

#27

Dadah

My suggestion: check, clean and tighten “all” electrical connections including those at the switch. A lot of time is the most simple thing!!!

Dadah

Wendol: Experienced a start problem on my 329BB Grasshopper years ago when new. They replaced the battery, new starter but still didn’t want to easily start every time. The dealers son took a look at it and found a bad connection at the starter or solenoid. He stated he had seen this several times over the years.Since day one, when endeavoring to start the mower, on first try I get only a click, and on second try turns over and starts immediately. I installed a relay per the dealers instructions, but nothing changed.

Any thoughts on how to correct this would be greatly appreciated.

My suggestion: check, clean and tighten “all” electrical connections including those at the switch. A lot of time is the most simple thing!!!

#28

W

Wendol

Solenoid/Starter is in the shop right now, the gentleman gave it a quick check and said he believes it's a solenoid issue, but will also check into the starter as well.

W

Wendol

Thanks, I'll double check the connections.Wendol: Experienced a start problem on my 329BB Grasshopper years ago when new. They replaced the battery, new starter but still didn’t want to easily start every time. The dealers son took a look at it and found a bad connection at the starter or solenoid. He stated he had seen this several times over the years.

My suggestion: check, clean and tighten “all” electrical connections including those at the switch. A lot of time is the most simple thing!!!

Solenoid/Starter is in the shop right now, the gentleman gave it a quick check and said he believes it's a solenoid issue, but will also check into the starter as well.

#29

G

Gym123

One thing I hate- being lied to. If that person thought it was true, they need to learn that everything is available and that the manufacturers don't make their own small parts in most cases. The reason GM owned parts manufacturers is because they were so huge and it was cheaper to buy small parts companies than to buy from outside.

This stuff isn't weatherproof and that makes no sense to me but the application that makes even less sense is in boats- many brands still use regular butt splices, etc on harnesses and to me, using sealed should be a no-brainer.

G

Gym123

The dealer obviously wants NOBODY to go back to them, since they're lying to customers. EVERYTHING is available, if someone knows where to look. For almost any terminals, Del City is one distributor that sells them- I found out about them when I went to MasterCraft boat service training- someone asked the instructor where to buy the terminals for GM fuel injected engines and he mentioned this company. The trick is in using the correct crimper, as you mentioned, with the correct pressure- some companies crimp with far more pressure than hands can provide but for a small number of terminals, soldering each one makes reliability better.Even those are not as waterproof as they advertise. I have water damage even in them.

But most lawn equipment connectors are not weather proof types.

I currently working on a mower with Delphi (Aptiv) terminals and connector housings which is definitely not of the sealed type. I have more problems with the F56 style female terminals with the spring hinges breaking over time creating loose connections which the problem with this mower. Fairly easy to get and replace when you have the right tools. The Gravely dealer told the customer he had to replace the complete wiring harness as the terminal weren't available which is BS.

But having the right tools is important with any terminal replacement. Just can't use just any old tool to do this work.

One thing I hate- being lied to. If that person thought it was true, they need to learn that everything is available and that the manufacturers don't make their own small parts in most cases. The reason GM owned parts manufacturers is because they were so huge and it was cheaper to buy small parts companies than to buy from outside.

This stuff isn't weatherproof and that makes no sense to me but the application that makes even less sense is in boats- many brands still use regular butt splices, etc on harnesses and to me, using sealed should be a no-brainer.

#30

W

Wendol

W

Wendol

Just a quick update.......took starter/solenoid into speciality shop for this type of issue, and it was determined the solenoid was most likely the problem.

Replaced the solenoid, and problem solved!! No more clicks, just starts instantly.

Replaced the solenoid, and problem solved!! No more clicks, just starts instantly.

#31

G

Gym123

G

Gym123

It's great, having specialty shops.Just a quick update.......took starter/solenoid into speciality shop for this type of issue, and it was determined the solenoid was most likely the problem.

Replaced the solenoid, and problem solved!! No more clicks, just starts instantly.