You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

STIHL hedgetrimmer HS82 T and R : carburator "H" screw setting???

#1

F

Flatsix

F

Flatsix

Hello,

I bought last year 2 hedgetrimmers STIHL HS82 - the "T" and the "R" version. They do good, only I see and hear that 1 of them, the "R" is running too rich because fumes , sound and more oil coming out of the exhaust.

I went to 2 Stihl-dealers here, but both don't seem to be able to adjust the machine as I wish.

I checked how many turns the "H"-sscrew was screwed out on both machines. The "R" had 2.5 turns out and the "T" had 2.1/8" turns out.

I have set the H also at 2.1/8" on my "R"-type and thought that then they would be the same, but I see that the "R" is still running too rich.

Then I asked STIHL-Belgium what the factory settings are for the hedgetrimmer HS82, they replied: turn H and L-screw both 1.1/2 turn out. Then turn the rpm on the L-screw as low as possible and the H-screw as high rpm as possible.

I know that the HS82 has a speed-limiter (9300 rpm) - so when I turn the H-screw it is difficult to hear because of that speedlimiter. I have also a tachometer.

Can somebody explain to me HOW I CAN SET THE H-screw CORRECTLY ON MY 2 HEDGETRIMMERS HS82. Both machines are the same when you only compare the motor. I can use my tachometer eventually.

HOW TO DO IT ??

Thanks for your technical advise.

I bought last year 2 hedgetrimmers STIHL HS82 - the "T" and the "R" version. They do good, only I see and hear that 1 of them, the "R" is running too rich because fumes , sound and more oil coming out of the exhaust.

I went to 2 Stihl-dealers here, but both don't seem to be able to adjust the machine as I wish.

I checked how many turns the "H"-sscrew was screwed out on both machines. The "R" had 2.5 turns out and the "T" had 2.1/8" turns out.

I have set the H also at 2.1/8" on my "R"-type and thought that then they would be the same, but I see that the "R" is still running too rich.

Then I asked STIHL-Belgium what the factory settings are for the hedgetrimmer HS82, they replied: turn H and L-screw both 1.1/2 turn out. Then turn the rpm on the L-screw as low as possible and the H-screw as high rpm as possible.

I know that the HS82 has a speed-limiter (9300 rpm) - so when I turn the H-screw it is difficult to hear because of that speedlimiter. I have also a tachometer.

Can somebody explain to me HOW I CAN SET THE H-screw CORRECTLY ON MY 2 HEDGETRIMMERS HS82. Both machines are the same when you only compare the motor. I can use my tachometer eventually.

HOW TO DO IT ??

Thanks for your technical advise.

#2

M

mechanic mark

M

mechanic mark

Read Operators Manual thoroughly, should be under warranty take to reputable Stihl Dealer. Use 90 octane gasoline minimum plus Stihl 2-cycle oil.

#3

F

Flatsix

I do not know any "reputable dealer" - there are already 2 of those stihl-dealers that played with the settings, but none of them are good. That is why I wanted to do it myself instead of letting it do by another dealer.

I have 6 Stihl-machines and they all get the best : 98 Octane and the Stihl full synthetic 2-cycle oil (HP ULTRA).

Can anyone tell me exactly how to make the fuel/air mixture like it should (H-screw).??

F

Flatsix

Operators Manual does not mention anything about the settings of the "H" screw. It says only that the machine is set in the factory for optimal results.Read Operators Manual thoroughly, should be under warranty take to reputable Stihl Dealer. Use 90 octane gasoline minimum plus Stihl 2-cycle oil.

I do not know any "reputable dealer" - there are already 2 of those stihl-dealers that played with the settings, but none of them are good. That is why I wanted to do it myself instead of letting it do by another dealer.

I have 6 Stihl-machines and they all get the best : 98 Octane and the Stihl full synthetic 2-cycle oil (HP ULTRA).

Can anyone tell me exactly how to make the fuel/air mixture like it should (H-screw).??

#4

Fish

Fish

The unit is newer, so I don't have any service manual.

But in general, just as a test, take off the air filter and start. See if the performance changes any.

If so, was the air filter if it is washable, or get a new one.

I have seen folks pull their hair out, and their trouble was a dirty air filter.

As far as any help on adjustment, I would need to see a pic of it, the side with the adjustments.

If it has limiter caps, there is very little range you can adjust it.

But do the air filter test first, see if the trimmer runs differently.

But in general, just as a test, take off the air filter and start. See if the performance changes any.

If so, was the air filter if it is washable, or get a new one.

I have seen folks pull their hair out, and their trouble was a dirty air filter.

As far as any help on adjustment, I would need to see a pic of it, the side with the adjustments.

If it has limiter caps, there is very little range you can adjust it.

But do the air filter test first, see if the trimmer runs differently.

#7

F

Flatsix

F

Flatsix

Thanks Fish for the pages you showed. I do not have limiter caps on the machines - the airfilter is clean and as new and nice as a brandnew machine.

The STANDARDSETTING of the "H"-screw is 1.1/2 turn OPENED; this is the same as the people of STIHL-Belgium wrote.

But from 1.1/2 turns out to the optimal setting to have the right mix air/fuel : that is my question. HOW TO DO THIS TO OBTAIN THE RIGHT MIX AIR/FUEL by adjusting the H-screw.

At present both machines their "H" screw have I set to 2.1/8 turns out. I did so because my T-version was set on 2.1/8 out. The other was set at 2,5 turns out and I changed it to 2.1/8 - but for me still to rich....

HOW TO ??

The STANDARDSETTING of the "H"-screw is 1.1/2 turn OPENED; this is the same as the people of STIHL-Belgium wrote.

But from 1.1/2 turns out to the optimal setting to have the right mix air/fuel : that is my question. HOW TO DO THIS TO OBTAIN THE RIGHT MIX AIR/FUEL by adjusting the H-screw.

At present both machines their "H" screw have I set to 2.1/8 turns out. I did so because my T-version was set on 2.1/8 out. The other was set at 2,5 turns out and I changed it to 2.1/8 - but for me still to rich....

HOW TO ??

#8

F

Flatsix

F

Flatsix

At the end both of my machines HS82 work fine , the T-version sounds a little leaner and the exhaust is less greasy (or oily...) and produces less fumes when full throttle. The other one , the R-version works great but a little more oil at the exhaust + more fumes, but it sounds and works great.

If only I got to know from one of your specialists how to fine-tune that H-screw on each machine individually so that at full throttle I would have exactly the good mixture air/fuel then I would be happy. If not then I leave it like it is because I have no intention at screwing up my machines by turning without any procedure.

Can anyone tell me how the fine-tuning is done : I have no limiter caps on it, I have the special Stihl octogonal screwdriver and I have a tachomter in my possession, so with these I should be able to finetune if I get a procedure or a way to do it from you folks.

If only I got to know from one of your specialists how to fine-tune that H-screw on each machine individually so that at full throttle I would have exactly the good mixture air/fuel then I would be happy. If not then I leave it like it is because I have no intention at screwing up my machines by turning without any procedure.

Can anyone tell me how the fine-tuning is done : I have no limiter caps on it, I have the special Stihl octogonal screwdriver and I have a tachomter in my possession, so with these I should be able to finetune if I get a procedure or a way to do it from you folks.

#10

Tiger Small Engine

Tiger Small Engine

It takes years to be able to tune handheld 2-stroke equipment efficiently and effectively by ear and using a tachometer. Not something you can read and just turn a screw. Some are easier than others.Okay you do need the Tach as going by ear just don't cut it.

Both the T and R are adjusted the same; unless, you have a Brazil setup which is slightly different on the R.

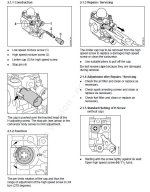

View attachment 66914

And I assuming the throttle cable has not been removed and reinstalled or otherwise messed with.

#11

StarTech

StarTech

Personally even after 15 yrs I still can't tell when RPMs change by 50 rpm on the Echo line besides I do wear ear plugs most times to save my hearing.

#12

Fish

Fish

If you have 2 units with the same carb, and 1 doesn't run right, swap the carbs and see which one runs right.

#13

StarTech

StarTech

IF doing try this be aware the air filter cover setup maybe different as two different setups was used on these hedgers depending on which choke lever was used.

#14

F

Flatsix

I know that it is not easy to adjust the H-screw for an unexperienced fellow like me, but I am sure that when I get a good description of what to hear and see on the tach I will be able to have the good result. I have a very big garden and work a lot with 2-stroke machines, so I am aware of the difficulties in hearing, but am not new to it.

The 2.1/2 turns out for the H seems too rich for my machines. So need a procedure to be able to set it better with my ears + tachometer. It is a pity that the machine has an rpm-limiter that kicks in at 9300 rpm, otherwhise it would be much mure easier : I just turn the H till machine reaches max. 9300 rpm and that was it, but now with the rev.limiter it is not evident.

Do you think there is a way to help me with that adjusting of my "H"-screw, or do I leave it at 2.1/8 turns out like it is now??

F

Flatsix

Startech : many thanks for the papers you sent - with that I can do the adjustment of the L-screw and I know the basic for the "H"-screw. It is a pity that there is not much said or written about the "H"screw that for me is the most important adjustion that is to make on my machines. Then only write : turn H-screw 2.1/2 turns out and that is it...It takes years to be able to tune handheld 2-stroke equipment efficiently and effectively by ear and using a tachometer. Not something you can read and just turn a screw. Some are easier than others.

I know that it is not easy to adjust the H-screw for an unexperienced fellow like me, but I am sure that when I get a good description of what to hear and see on the tach I will be able to have the good result. I have a very big garden and work a lot with 2-stroke machines, so I am aware of the difficulties in hearing, but am not new to it.

The 2.1/2 turns out for the H seems too rich for my machines. So need a procedure to be able to set it better with my ears + tachometer. It is a pity that the machine has an rpm-limiter that kicks in at 9300 rpm, otherwhise it would be much mure easier : I just turn the H till machine reaches max. 9300 rpm and that was it, but now with the rev.limiter it is not evident.

Do you think there is a way to help me with that adjusting of my "H"-screw, or do I leave it at 2.1/8 turns out like it is now??

#15

F

Flatsix

That is why I wanted to tune each machine individually with a procedure as I have a tachometer, so I can read the rpm - if I can get a plan how to do then it will be possible to finetune each of them for optimum mixture air/fuel.

Now I think the R runs too rich although it has the same setting as the T (2.1/8 turns out).

F

Flatsix

My 2 machines "R" and "T" are both identical - they both run great but the "R" runs richer then the "T", although both have the same "turning out of the H-screw", namely both 2.1/8" out. They should do the same, both they don't.IF doing try this be aware the air filter cover setup maybe different as two different setups was used on these hedgers depending on which choke lever was used.

That is why I wanted to tune each machine individually with a procedure as I have a tachometer, so I can read the rpm - if I can get a plan how to do then it will be possible to finetune each of them for optimum mixture air/fuel.

Now I think the R runs too rich although it has the same setting as the T (2.1/8 turns out).

#16

StarTech

StarTech

There is a note in the service manual about the Brazilian 82R being set at 2 turns. They run these rich is to keep them cooler as they can overheat if too lean. Especially they are tuned for high altitude and then used at sea level.

These service manual setting are probably for sea level to 2500 ft.

Also if you are at higher altitude a leaner mixture would be needed.

I usually tune to basic settings for most Stihl with limiters and finally touch up the H to where the limiter just start kicking in. This way it is still on the rich side but not excessively rich. This is because L setting does affect the H setting but H does not affect L setting.

These service manual setting are probably for sea level to 2500 ft.

Also if you are at higher altitude a leaner mixture would be needed.

I usually tune to basic settings for most Stihl with limiters and finally touch up the H to where the limiter just start kicking in. This way it is still on the rich side but not excessively rich. This is because L setting does affect the H setting but H does not affect L setting.

#17

F

Flatsix

F

Flatsix

I do not understand this StarTech. Normally they set the H at 2.1/2 turns out. The Brazilian 82R is set at 2 turns out to run them rich. But 2 turns out is leaner then 2 1/2 turns out, isn't it? I thougt that screwing in (clockwise) makes the mixture leaner - mine sits now at 2.1/8 turn in instead of 2.5 turns in - so mine is now set leaner than the standard? Please conform because now i am getting a little confused.There is a note in the service manual about the Brazilian 82R being set at 2 turns. They run these rich is to keep them cooler as they can overheat if too lean. Especially they are tuned for high altitude and then used at sea level.

These service manual setting are probably for sea level to 2500 ft.

Also if you are at higher altitude a leaner mixture would be needed.

I usually tune to basic settings for most Stihl with limiters and finally touch up the H to where the limiter just start kicking in. This way it is still on the rich side but not excessively rich. This is because L setting does affect the H setting but H does not affect L setting.

#18

StarTech

StarTech

Yes turning the screws CW does lean out the mixture. Just the nature RH threaded screws.

As for why the Brazilian units are tuned differently I don't know unless they changed the mixture screws somehow or it is some government reg.

As for why the Brazilian units are tuned differently I don't know unless they changed the mixture screws somehow or it is some government reg.

#19

F

Flatsix

then instead of putting them on 2.1/8 I better put the screw on 2.5/8 as that would be leaner then the original 2.5 turns that they set as standard?

F

Flatsix

Startech, are you shure? So 2.1/2 turns out is leaner then 2.1/8 turns out? I thought that screwing tem IN (counterwhise) would make the mixture with less fuel - so leaner.Yes turning the screws CW does lean out the mixture. Just the nature RH threaded screws.

As for why the Brazilian units are tuned differently I don't know unless they changed the mixture screws somehow or it is some government reg.

then instead of putting them on 2.1/8 I better put the screw on 2.5/8 as that would be leaner then the original 2.5 turns that they set as standard?

#20

F

Flatsix

F

Flatsix

I will definitely continue doing it my way - screwing IN (clockwise) = leaner and screwing OUT (counterclockwise) = richer mixture. Thanks for your help with the papers you have sent .

#21

Fish

Fish

Yes, cw goes more lean.

I suggested that you swap the carbs so you can know for sure that the problem is the carb.

One carb make have a leaky needle, or incorrect lever height, making it perform differently.

I suggested that you swap the carbs so you can know for sure that the problem is the carb.

One carb make have a leaky needle, or incorrect lever height, making it perform differently.

#22

F

Flatsix

F

Flatsix

Hallo again

Sorry but I misunderstood the meaning of CW - I thought it ment counterclockwise, but it means CLOCKWISE.... my mistake (but I have problems with the language English - I am a dutch speaking fellow)

Swapping carburators is not in my skills.

Both machines are brandnew - only used a couple of hours.

The problem here in Belgium is that you find many "specialists" - but very few people really now their thing. The man where a bought the machines knows very good how to adjust Stihl, only the problem is that he has another function now and does not longer do the work in the garage. The one that replaces him is not customerfriendly : he said to me that he had adjusted my "R" rich because that period it was 30°C outside and he would not set it back to normal.

That is why I wanted to adjust it myself, but that seems also not so evident.

Sorry but I misunderstood the meaning of CW - I thought it ment counterclockwise, but it means CLOCKWISE.... my mistake (but I have problems with the language English - I am a dutch speaking fellow)

Swapping carburators is not in my skills.

Both machines are brandnew - only used a couple of hours.

The problem here in Belgium is that you find many "specialists" - but very few people really now their thing. The man where a bought the machines knows very good how to adjust Stihl, only the problem is that he has another function now and does not longer do the work in the garage. The one that replaces him is not customerfriendly : he said to me that he had adjusted my "R" rich because that period it was 30°C outside and he would not set it back to normal.

That is why I wanted to adjust it myself, but that seems also not so evident.

#23

Fish

Fish

Turning the high speed screw to the right makes the mixture more lean {less fuel}, and the 2 cycle engines will run faster the farther you lean it out, to a point.

You will reach a point that the rpms stop going higher, and that is getting into the danger area, as running too lean for very long will damage/melt the piston, so the safe range is on the rich side of that adjustment. The use of an rpm meter is advisable.

Then as you go richer the engine will start slowing, and that is where you want to be.

But doing the adjustment on the high screw, you likely will need to adjust the low and idle screws. It should idle well, and have fast response when you hit the accelerator, and not die when it comes back down to idle.

After tweaking that, then go back and fine tune the high screw.

But the high speed screw is extremely critical, and adjusting it to lean will damage the engine. If you cannot adjust it out, then the problem is somewhere.

Which is why I suggested swapping carbs. If the other saw runs too rich, and the other saw runs good, then you know that the problem is in the carb. And can confidently go from there.

You will reach a point that the rpms stop going higher, and that is getting into the danger area, as running too lean for very long will damage/melt the piston, so the safe range is on the rich side of that adjustment. The use of an rpm meter is advisable.

Then as you go richer the engine will start slowing, and that is where you want to be.

But doing the adjustment on the high screw, you likely will need to adjust the low and idle screws. It should idle well, and have fast response when you hit the accelerator, and not die when it comes back down to idle.

After tweaking that, then go back and fine tune the high screw.

But the high speed screw is extremely critical, and adjusting it to lean will damage the engine. If you cannot adjust it out, then the problem is somewhere.

Which is why I suggested swapping carbs. If the other saw runs too rich, and the other saw runs good, then you know that the problem is in the carb. And can confidently go from there.

#24

F

Flatsix

F

Flatsix

Oké Fish, I understand and know all this, but the main problem on these engines is that there is a rev-limiter that kicks-in. So when you open the throttle you hear the motor going into the rpm-limiter. At 9300 rpm it will be finished and you hear it also that the sound is in the rev-limiter. So not easy to adjust that H-screw.

#25

R

RevB

If you mix the fuel yourself, use only

STIHL two-stroke engine oil or another

high-performance engine oil in

accordance with JASO FB, JASO FC,

JASO FD, ISO-L-EGB, ISO-L-EGC or

ISO-L-EGD"

Stihl oil not required.

R

RevB

Read Operators Manual thoroughly, should be under warranty take to reputable Stihl Dealer. Use 90 octane gasoline minimum plus Stihl 2-cycle o ini

It's a two stroke. Effective compression ratio is at best 7:1, no 90 octane required. Manual ”Read Operators Manual thoroughly, should be under warranty take to reputable Stihl Dealer. Use 90 octane gasoline minimum plus Stihl 2-cycle oil.

If you mix the fuel yourself, use only

STIHL two-stroke engine oil or another

high-performance engine oil in

accordance with JASO FB, JASO FC,

JASO FD, ISO-L-EGB, ISO-L-EGC or

ISO-L-EGD"

Stihl oil not required.

#26

R

RevB

Years? Where did you come up with that? It will take me 20 seconds to teach you. It's not rocket science.

R

RevB

It takes years to be able to tune handheld 2-stroke equipment efficiently and effectively by ear and using a tachometer. Not something you can read and just turn a screw. Some are easier than others.

Years? Where did you come up with that? It will take me 20 seconds to teach you. It's not rocket science.

#27

Tiger Small Engine

Tiger Small Engine

I will send all my handheld carburetor adjustments your way then. Will save me a lot of time since you are that good and quick.Years? Where did you come up with that? It will take me 20 seconds to teach you. It's not rocket science.

#28

StarTech

StarTech

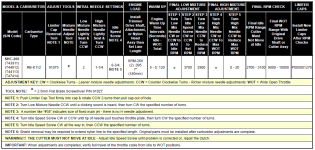

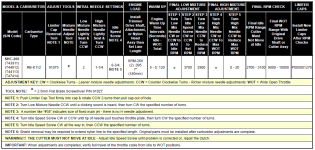

He must have some mighty good hearing if he can tell the difference between 11,000 rpms and 10,900 rpms. For me that takes a tach to done that. Even the idle settings should be done using a tach when tuning by the factory service manuals.

Here is an example where the max rpm are drop by 20 rpm though a mx rpm is allow it is still better to enrich a tad.

And this one of the simple tune ups on the Echo line.

Here is an example where the max rpm are drop by 20 rpm though a mx rpm is allow it is still better to enrich a tad.

And this one of the simple tune ups on the Echo line.

#29

F

Flatsix

Turning more out then 2.5 turns till rpm is just before reaching rev-limiter (say 9200 rpm) has no sense because at 2.5 turns it is already too rich. So I wonder how you can set the ideal mixture with the H-screw when you cannot hear the machine working at WOT like machines without rpm-limitation on it. There it would be possible by me : turning out till 9300 rpm and at the same time listening to the sound- when sound high then slightly reduce (turn out) till sound is heavier and that is it. But with rev-limitation you can forget that.?.

F

Flatsix

How to adjust the H-screw when you have a rev-limiter??? At 2.5 turns out (the standard setting) when opening WOT the rev-limiter comes in at 9300 rpm is it should. At 2.1/8 turns out (like it is set now) the rev-limiter kicks in at 9300 rpm. How can you adjust then because once the machine reaches the rev-limiter you hair that sound and no adjusting possible.Oké Fish, I understand and know all this, but the main problem on these engines is that there is a rev-limiter that kicks-in. So when you open the throttle you hear the motor going into the rpm-limiter. At 9300 rpm it will be finished and you hear it also that the sound is in the rev-limiter. So not easy to adjust that H-screw.

Turning more out then 2.5 turns till rpm is just before reaching rev-limiter (say 9200 rpm) has no sense because at 2.5 turns it is already too rich. So I wonder how you can set the ideal mixture with the H-screw when you cannot hear the machine working at WOT like machines without rpm-limitation on it. There it would be possible by me : turning out till 9300 rpm and at the same time listening to the sound- when sound high then slightly reduce (turn out) till sound is heavier and that is it. But with rev-limitation you can forget that.?.

#30

J

Johner

J

Johner

Take a micrometer and measure each jet see if a slight difference. Maybe you can't remove the jets?

#32

F

Flatsix

F

Flatsix

I think this is not done. I have several stihl motors with rev.limutation in them and they all start to produce that strange sound when it kicks in to prevent the motor to climb in higher rpm. It is supposed to work that way i think and not by adjusting the throttle cable of course then comes the question : how to adjust the H screw ...Have you tried adjusting the throttle cable to keep from over revving.

#33

StarTech

StarTech

What I am suggesting is running the engine at about 3/4 full throttle and try tuning this way as you are running off the main jet [and idle jet] and not just the idle jet. This should allow to tune the H mixture screw.

#34

T

TobyU

The average homeowner or newbie doesn't stand a chance either way so they need to get someone to show them how to do it a few times and then they can figure it out.

But you know me, compression testers and tachometers don't have much of a place in these repairs as far as I go.

I do use a digital attack on all the push mowers to set the RPMs but that's just because it's easier.

T

TobyU

I respectfully disagree. I guess it depends on the person or the ear who is listening.Okay you do need the Tach as going by ear just don't cut it.

Both the T and R are adjusted the same; unless, you have a Brazil setup which is slightly different on the R.

View attachment 66914

And I assuming the throttle cable has not been removed and reinstalled or otherwise messed with.

The average homeowner or newbie doesn't stand a chance either way so they need to get someone to show them how to do it a few times and then they can figure it out.

But you know me, compression testers and tachometers don't have much of a place in these repairs as far as I go.

I do use a digital attack on all the push mowers to set the RPMs but that's just because it's easier.

#35

StarTech

StarTech

IF your ear is that good then you should be read CW at 20+ words per minute. Here I was only get about 15 words to pass my General Class license test.Even they wanted to see written copy which I could keep up with the conversion.

#36

T

TobyU

You're lucky if you have a low speed and a high speed fuel mixture which obviously you do.

Many of the Zama carburetors have a mixture but it's hidden under a plastic plug which have to use a very tiny screw to screw into it and then pull it out and then use one of those smaller like Jewelers screwdrivers to adjust it which is the dumbest thing I've ever seen!

Then a lot of the newer cheaper carburetors don't have any mixture adjustments at all so there's nothing you can do as far as adjusting goes.

So here's the basic rule for these carburetors that have a low and a high speed. If they have limited caps take them off and throw them away..

Lol

Next, get you an adjustment tool that fits because it makes it far easier than trying to mess around with bullet connectors and the wrong style tool etc.

You're also not going to be able to have an exact number of turns to set these by because even manufacturers who give a specification, it's not exact it's just a basic starting point and it doesn't always work.

I keep hearing people tell me that humans don't like ambiguity but I'm sorry people are just going to have to learn to get over these things and understand that you don't always have a step-by-step to tell procedure to do everything in this world despite how much people try to make it so.

This is EXACTLY how people get into a situation where they say repeatedly they have done something and they think they've done it correctly but in reality they have it because their instructions are flawed.

Regardless, one and a half to two turns out from lightly seeded in will typically be enough to get the machine running if it's going to run and it doesn't have other problems which unfortunately is often the case.

So put them between one and a half and two turns out from lightly seated position and try to get it running possibly using the choke or the original lever etc.

Turn the total idle stop speed screw up a bit so we'll help it stay running if you do get it to start and can let it idle down.

If you can get it running try to adjust your high speed first..

To do this you have to have the throttle at wide open. If leans out and bogs and dies when you give it throttle try opening your screw a little bit more..

Once you get it to run at wide open throttle you adjust that one in and you'll see it speed up and then as you keep going you'll see it start to slow down a little bit because it leans out and then if you keep going it will die so don't go that far.

There's a slight difference doing a string trimmer or a blower versus doing a chainsaw but for the most part you really don't want to set it as close to lean as most people do especially when they try to tune by highest RPM but then some tell you to back it off slightly from the highest RPM which is kind of a convoluted method.

Go back and forth a few times to get a feel for what it does as you hold the throttle wide open and as you go in toward the lean side it starts to slow down then back it up to where it's nice and smooth and fast and then as you continue to open it up some more you'll hear it start to burble. That's the word I use for it - burble.

That's when it's getting too rich and you don't want to go that far so you just turn a little bit clockwise to lean it out and just a nudge more and I'm talking probably not even an eighth of a turn but definitely not a quarter.

You just don't want it to be too close so it gets into the rich verbal zone but you do want to be closer to that than closer to the lean side which is clockwise which makes it slow down.

Reason being, your engine will run cooler and the piston will be lubricated and run cooler and you'll get longer life this way that if you're running the edge of lean.

Then you let the throttle down and hopefully it stays running if not you'll have to adjust the low speed screw between a quarter and a half turn each direction until you can get it to run with the throttle in the minimum position.

Now you might have to slow down your total screw some because if you have it too far turned it keeps your throttle too far open and you're no longer actually in the idle circuit only of the carb.

But you do the high side and get it running well and then you do the low speed and then you will see that as you tighten the screw and lean it out it will speed up but don't go too far because that kills your response and it's too lean overall.

Back it out a little bit and usually somewhere between the two extremes is where you want it. You don't want it too close to the burble rich side because that tends to make them stall out and not sit there and idle nicely.

Once you get the low side adjusted nicely it should have nice instant response when you squeeze the trigger.

Sometimes a quarter turn one way or the other makes the world a difference on the revving up so adjust for best performance.

Then, I always go back and check the high side one more time because they do tend to have an effect on each other to a degree.

Do the same thing you did before with the throttle wide open and go to the lean side where it speeds up and then starts to lean out and then back it back down until it burbles and then tighten it clockwise a little bit so you're not at risk of burbling....

Then you should be done..

I know it's hard to explain and it sounds more complicated than the factory procedure or whatever but it only takes about 2 to 4 minutes to do one of these.

T

TobyU

Okay, here's the deal. I'm not even going to bother to read that owner's manual or service manual instructions because there's too many variations the way they send the equipment out.Hello,

I bought last year 2 hedgetrimmers STIHL HS82 - the "T" and the "R" version. They do good, only I see and hear that 1 of them, the "R" is running too rich because fumes , sound and more oil coming out of the exhaust.

I went to 2 Stihl-dealers here, but both don't seem to be able to adjust the machine as I wish.

I checked how many turns the "H"-sscrew was screwed out on both machines. The "R" had 2.5 turns out and the "T" had 2.1/8" turns out.

I have set the H also at 2.1/8" on my "R"-type and thought that then they would be the same, but I see that the "R" is still running too rich.

Then I asked STIHL-Belgium what the factory settings are for the hedgetrimmer HS82, they replied: turn H and L-screw both 1.1/2 turn out. Then turn the rpm on the L-screw as low as possible and the H-screw as high rpm as possible.

I know that the HS82 has a speed-limiter (9300 rpm) - so when I turn the H-screw it is difficult to hear because of that speedlimiter. I have also a tachometer.

Can somebody explain to me HOW I CAN SET THE H-screw CORRECTLY ON MY 2 HEDGETRIMMERS HS82. Both machines are the same when you only compare the motor. I can use my tachometer eventually.

HOW TO DO IT ??

Thanks for your technical advise.

You're lucky if you have a low speed and a high speed fuel mixture which obviously you do.

Many of the Zama carburetors have a mixture but it's hidden under a plastic plug which have to use a very tiny screw to screw into it and then pull it out and then use one of those smaller like Jewelers screwdrivers to adjust it which is the dumbest thing I've ever seen!

Then a lot of the newer cheaper carburetors don't have any mixture adjustments at all so there's nothing you can do as far as adjusting goes.

So here's the basic rule for these carburetors that have a low and a high speed. If they have limited caps take them off and throw them away..

Lol

Next, get you an adjustment tool that fits because it makes it far easier than trying to mess around with bullet connectors and the wrong style tool etc.

You're also not going to be able to have an exact number of turns to set these by because even manufacturers who give a specification, it's not exact it's just a basic starting point and it doesn't always work.

I keep hearing people tell me that humans don't like ambiguity but I'm sorry people are just going to have to learn to get over these things and understand that you don't always have a step-by-step to tell procedure to do everything in this world despite how much people try to make it so.

This is EXACTLY how people get into a situation where they say repeatedly they have done something and they think they've done it correctly but in reality they have it because their instructions are flawed.

Regardless, one and a half to two turns out from lightly seeded in will typically be enough to get the machine running if it's going to run and it doesn't have other problems which unfortunately is often the case.

So put them between one and a half and two turns out from lightly seated position and try to get it running possibly using the choke or the original lever etc.

Turn the total idle stop speed screw up a bit so we'll help it stay running if you do get it to start and can let it idle down.

If you can get it running try to adjust your high speed first..

To do this you have to have the throttle at wide open. If leans out and bogs and dies when you give it throttle try opening your screw a little bit more..

Once you get it to run at wide open throttle you adjust that one in and you'll see it speed up and then as you keep going you'll see it start to slow down a little bit because it leans out and then if you keep going it will die so don't go that far.

There's a slight difference doing a string trimmer or a blower versus doing a chainsaw but for the most part you really don't want to set it as close to lean as most people do especially when they try to tune by highest RPM but then some tell you to back it off slightly from the highest RPM which is kind of a convoluted method.

Go back and forth a few times to get a feel for what it does as you hold the throttle wide open and as you go in toward the lean side it starts to slow down then back it up to where it's nice and smooth and fast and then as you continue to open it up some more you'll hear it start to burble. That's the word I use for it - burble.

That's when it's getting too rich and you don't want to go that far so you just turn a little bit clockwise to lean it out and just a nudge more and I'm talking probably not even an eighth of a turn but definitely not a quarter.

You just don't want it to be too close so it gets into the rich verbal zone but you do want to be closer to that than closer to the lean side which is clockwise which makes it slow down.

Reason being, your engine will run cooler and the piston will be lubricated and run cooler and you'll get longer life this way that if you're running the edge of lean.

Then you let the throttle down and hopefully it stays running if not you'll have to adjust the low speed screw between a quarter and a half turn each direction until you can get it to run with the throttle in the minimum position.

Now you might have to slow down your total screw some because if you have it too far turned it keeps your throttle too far open and you're no longer actually in the idle circuit only of the carb.

But you do the high side and get it running well and then you do the low speed and then you will see that as you tighten the screw and lean it out it will speed up but don't go too far because that kills your response and it's too lean overall.

Back it out a little bit and usually somewhere between the two extremes is where you want it. You don't want it too close to the burble rich side because that tends to make them stall out and not sit there and idle nicely.

Once you get the low side adjusted nicely it should have nice instant response when you squeeze the trigger.

Sometimes a quarter turn one way or the other makes the world a difference on the revving up so adjust for best performance.

Then, I always go back and check the high side one more time because they do tend to have an effect on each other to a degree.

Do the same thing you did before with the throttle wide open and go to the lean side where it speeds up and then starts to lean out and then back it back down until it burbles and then tighten it clockwise a little bit so you're not at risk of burbling....

Then you should be done..

I know it's hard to explain and it sounds more complicated than the factory procedure or whatever but it only takes about 2 to 4 minutes to do one of these.

#37

T

TobyU

There's definitely a feel for it just like people who work with a lot of small engines can put a typical push more engine right at the proper RPMs they set them at without a tack whereas the average homeowner has no idea whether they're running it 2,200 RPMs or 4700 RPMs.

T

TobyU

Different type of ear! LOLIF your ear is that good then you should be read CW at 20+ words per minute. Here I was only get about 15 words to pass my General Class license test.Even they wanted to see written copy which I could keep up with the conversion.

There's definitely a feel for it just like people who work with a lot of small engines can put a typical push more engine right at the proper RPMs they set them at without a tack whereas the average homeowner has no idea whether they're running it 2,200 RPMs or 4700 RPMs.

#38

R

RevB

You said AND using a tachometer....which wasn't debated nor omitted. Yes...my hearing is pretty damn good.

R

RevB

He must have some mighty good hearing if he can tell the difference between 11,000 rpms and 10,900 rpms. For me that takes a tach to done that. Even the idle settings should be done using a tach when tuning by the factory service manuals.

Here is an example where the max rpm are drop by 20 rpm though a mx rpm is allow it is still better to enrich a tad.

View attachment 66943

And this one of the simple tune ups on the Echo line.

You said AND using a tachometer....which wasn't debated nor omitted. Yes...my hearing is pretty damn good.

#39

T

TobyU

I don't care what any of them say or any tech manual says.

800 RPM difference in a high revving two-stroke is pretty irrelevant anyways and as your adjusting them you're going to have a lot bigger RPM drop on the lean side and even on the rich side than that and it will be quite obvious.

In real world situation, you could have 6 people set up with 10 different machines and you could have a couple of them do it solely by here and experience, and the other ones do it by whatever method they want with whatever attack they choose.

When it's all said and done they would be no difference in the operation of the equipment OTHER than the all too common irregularities in the small carburetors that don't like to hold their tune and settings from minute to minute and from heat cycle to heat cycle and even from being cold to being hot but that has nothing to do with the actual tuning.

Let's assume we take 10 pieces of equipment that are very nice and forgiving and respond perfectly to the mixture screw adjustments and then intentionally make them out of adjustment then let our six people go at the adjusting.

I will never believe anyone needs a tach to set a two-stroke machine fuel mixtures.

Now wide open throttle RPMs is completely different story as I often use one of those for push mowers and riders but for setting the mixture is simply not necessary.

I guess the people to follow this mindset are the same ones who use an RPM gauge for a vacuum gauge when they set the carburetor on the old cars in the 70s and before.

I know the tech manuals told you to do that but it was still unnecessary and I always got those cars running better doing it by ear two or three times back and forth than doing what they said and turning the screw a certain way until a certain RPM reduction it was exhibited.

Of course within just a few years the way they told you to do things was not for the best running or best performance of the machine at all but rather being interfered with by emissions etc.

Regardless, experience and listening with your ear and knowing how to do it from again.. experience is how you get these things running the best not by some method in a shop manual.

I will go out there and say that the method in the shop manual is a bare minimum base place to start but it is NOT the best.

T

TobyU

But the whole premise of that is completely irrelevant.He must have some mighty good hearing if he can tell the difference between 11,000 rpms and 10,900 rpms. For me that takes a tach to done that. Even the idle settings should be done using a tach when tuning by the factory service manuals.

Here is an example where the max rpm are drop by 20 rpm though a mx rpm is allow it is still better to enrich a tad.

View attachment 66943

And this one of the simple tune ups on the Echo line.

I don't care what any of them say or any tech manual says.

800 RPM difference in a high revving two-stroke is pretty irrelevant anyways and as your adjusting them you're going to have a lot bigger RPM drop on the lean side and even on the rich side than that and it will be quite obvious.

In real world situation, you could have 6 people set up with 10 different machines and you could have a couple of them do it solely by here and experience, and the other ones do it by whatever method they want with whatever attack they choose.

When it's all said and done they would be no difference in the operation of the equipment OTHER than the all too common irregularities in the small carburetors that don't like to hold their tune and settings from minute to minute and from heat cycle to heat cycle and even from being cold to being hot but that has nothing to do with the actual tuning.

Let's assume we take 10 pieces of equipment that are very nice and forgiving and respond perfectly to the mixture screw adjustments and then intentionally make them out of adjustment then let our six people go at the adjusting.

I will never believe anyone needs a tach to set a two-stroke machine fuel mixtures.

Now wide open throttle RPMs is completely different story as I often use one of those for push mowers and riders but for setting the mixture is simply not necessary.

I guess the people to follow this mindset are the same ones who use an RPM gauge for a vacuum gauge when they set the carburetor on the old cars in the 70s and before.

I know the tech manuals told you to do that but it was still unnecessary and I always got those cars running better doing it by ear two or three times back and forth than doing what they said and turning the screw a certain way until a certain RPM reduction it was exhibited.

Of course within just a few years the way they told you to do things was not for the best running or best performance of the machine at all but rather being interfered with by emissions etc.

Regardless, experience and listening with your ear and knowing how to do it from again.. experience is how you get these things running the best not by some method in a shop manual.

I will go out there and say that the method in the shop manual is a bare minimum base place to start but it is NOT the best.

#40

R

rhkraft

R

rhkraft

Thanks Fish for the pages you showed. I do not have limiter caps on the machines - the airfilter is clean and as new and nice as a brandnew machine.

The STANDARDSETTING of the "H"-screw is 1.1/2 turn OPENED; this is the same as the people of STIHL-Belgium wrote.

But from 1.1/2 turns out to the optimal setting to have the right mix air/fuel : that is my question. HOW TO DO THIS TO OBTAIN THE RIGHT MIX AIR/FUEL by adjusting the H-screw.

At present both machines their "H" screw have I set to 2.1/8 turns out. I did so because my T-version was set on 2.1/8 out. The other was set at 2,5 turns out and I changed it to 2.1/8 - but for me still to rich....

HOW TO ??

#41

R

rhkraft

R

rhkraft

I have been working on 2 -cycle engines since they came out in yard tools. The factory L, H, and LA settings, i.e. screw turns from closed are a beginning point to get your engine running and keep it running. Adjust the idle (L) screw first. If the engine dies, adjust the LA (idle speed) until the engine will run without stalling. Then adjust the L screw until it runs smoothly. Turn the LA in until the engine runs at a desirable idle speed. If the idle is not smooth, adjust L a little until it is smooth. If the idle speed is correct and the engine idles well, all the powered machinery will be stopped. That is stopped, no creep or movement. The machine is safe. Now open the throttle to full power. The factory setting will maintain the right rpm. Only adjust the H screw if the engine is not smooth. If the engine is rich, it will run rough and may smoke - turn the H in. If the engine is running too lean it will stumble and may stop when the throttle is opened quickly. Adjust for smooth operation. Remember the factory settings are a place to start. Air density due to altitude does require re-adjustment.

Item 2. If the engine runs well at first but gets worse over time when you use it next time and needs to be re-adjusted, check this first. If the engine runs well when the tank is full, check the tank when the roughness starts. If the fuel level is down, the problem may be a cracked fuel line in the tank. The fuel pump will suck fuel through the crack when the tanks is full, but when the fuel level goes down and the crack is exposed to the air, the fuel pump will suck in some air and the engine will run rough. Changing the fuel line is an easy fix. Good Luck

Item 2. If the engine runs well at first but gets worse over time when you use it next time and needs to be re-adjusted, check this first. If the engine runs well when the tank is full, check the tank when the roughness starts. If the fuel level is down, the problem may be a cracked fuel line in the tank. The fuel pump will suck fuel through the crack when the tanks is full, but when the fuel level goes down and the crack is exposed to the air, the fuel pump will suck in some air and the engine will run rough. Changing the fuel line is an easy fix. Good Luck

#42

Tiger Small Engine

Tiger Small Engine

I am glad there are so many proficient handheld engine tuners out there. More than one way to skin a cat.I have been working on 2 -cycle engines since they came out in yard tools. The factory L, H, and LA settings, i.e. screw turns from closed are a beginning point to get your engine running and keep it running. Adjust the idle (L) screw first. If the engine dies, adjust the LA (idle speed) until the engine will run without stalling. Then adjust the L screw until it runs smoothly. Turn the LA in until the engine runs at a desirable idle speed. If the idle is not smooth, adjust L a little until it is smooth. If the idle speed is correct and the engine idles well, all the powered machinery will be stopped. That is stopped, no creep or movement. The machine is safe. Now open the throttle to full power. The factory setting will maintain the right rpm. Only adjust the H screw if the engine is not smooth. If the engine is rich, it will run rough and may smoke - turn the H in. If the engine is running too lean it will stumble and may stop when the throttle is opened quickly. Adjust for smooth operation. Remember the factory settings are a place to start. Air density due to altitude does require re-adjustment.

Item 2. If the engine runs well at first but gets worse over time when you use it next time and needs to be re-adjusted, check this first. If the engine runs well when the tank is full, check the tank when the roughness starts. If the fuel level is down, the problem may be a cracked fuel line in the tank. The fuel pump will suck fuel through the crack when the tanks is full, but when the fuel level goes down and the crack is exposed to the air, the fuel pump will suck in some air and the engine will run rough. Changing the fuel line is an easy fix. Good Luck

#43

T

TobyU

This is often the case where the service manuals show you the basic way to do it which will get the job done or close enough to perfection or maybe even perfection but people who do it all the time typically fine better more efficient ways to get to that same point.

T

TobyU

Yes, and more often than not, better ways than what the factory service manual shows.I am glad there are so many proficient handheld engine tuners out there. More than one way to skin a cat.

This is often the case where the service manuals show you the basic way to do it which will get the job done or close enough to perfection or maybe even perfection but people who do it all the time typically fine better more efficient ways to get to that same point.

#44

B

bertsmobile1

B

bertsmobile1

I have been tuning carbs since I was 12 and always do as rhkraft

Start with the idle ( L ) jet then the throttle stop then the main jet

OR in my case as they were mostly Amal carbs on motorcycles

Pilot air then slide cut away then needle jet then main jet

Golden rule in all things mechanical only adjust one thing at a time

Since buying the repair run I have tried the "factory" methods that seem to be getting more & more complicated on a daily basis and as far as I can see they are plain BS.

I will assume that EPA regulation compliance comes into play so at no time in the tuning sequence the engine cam be allowed to run rich for fear of the pollution extinguishing all life on the planet in a single day

With the exception of rotary valve carbs the idle jet supplies fuel 100% of the time so if it is not right then nothing else can be right

So you start there

For 60 years it has always been lean till the engine faulters, rich to the engine faulters then just a touch on the rich side of the mid point between the 2 extremes

With some of the fast reving 2 strokes I alter this slightly to rich till it 4 strokes then slowly lean off till upper RPM limit has been achieved as when doing 10,000+ rpm slightly too lean can damage the engine very quickly

Naturally it takes a bit of ear memory to be able to identify the very first sounds of running too lean and of course the leaning off has to be done VERY SLOWLY because on 2 strokes fuel can condense in the crank case so what seems to be right can actually become way too lean when this condensed fuel burns off

Start with the idle ( L ) jet then the throttle stop then the main jet

OR in my case as they were mostly Amal carbs on motorcycles

Pilot air then slide cut away then needle jet then main jet

Golden rule in all things mechanical only adjust one thing at a time

Since buying the repair run I have tried the "factory" methods that seem to be getting more & more complicated on a daily basis and as far as I can see they are plain BS.

I will assume that EPA regulation compliance comes into play so at no time in the tuning sequence the engine cam be allowed to run rich for fear of the pollution extinguishing all life on the planet in a single day

With the exception of rotary valve carbs the idle jet supplies fuel 100% of the time so if it is not right then nothing else can be right

So you start there

For 60 years it has always been lean till the engine faulters, rich to the engine faulters then just a touch on the rich side of the mid point between the 2 extremes

With some of the fast reving 2 strokes I alter this slightly to rich till it 4 strokes then slowly lean off till upper RPM limit has been achieved as when doing 10,000+ rpm slightly too lean can damage the engine very quickly

Naturally it takes a bit of ear memory to be able to identify the very first sounds of running too lean and of course the leaning off has to be done VERY SLOWLY because on 2 strokes fuel can condense in the crank case so what seems to be right can actually become way too lean when this condensed fuel burns off

#45

Hammermechanicman

Hammermechanicman

You would have enjoyed the Army's Basic Morse school at Ft. Devens MA. You had to be able to copy 18WPM in 12 weeks. You got to copy code for 8 hours a day. Flunking out got you sent to cook school or infantry. When I got out of Uncle Sam's employment I could do 25. But that was about a half century ago.IF your ear is that good then you should be read CW at 20+ words per minute. Here I was only get about 15 words to pass my General Class license test.Even they wanted to see written copy which I could keep up with the conversion.

#46

F

Flatsix

F

Flatsix

I am very happy with all your advise and documentation that you have sent in this thread. I still did not tune my famous HS82R - the only reason is that till now I have postponed the action because I am "affraid" to do it.

The adjusting of the LA and the L screw do not make me nervous : I am able to tune so that I have a good respons on the gas and at the same time I have a good idling. (I do turn L out till it runs very bad - then I do the opposit buy turning L-screw in till again it almost stalls. Then I take the middle (sweet) spot between these two positions. Then I turn slowly out till the point where it is low in rpm and just before it beginns to turn less smooth. That is the point where I set it, just before it beginns to run rougher)

I will do the "factory" setting with the procedure of 3300 rpm and then drop the rpm to 2800rpm with the L-screw, and see where it gets me. I will let you know my findings when I have done it...

But the setting of that "H"-screw is where I am affraid of, because I have never done it - so no experience with my ear - and not possible to depend on my rpm-meter as on the HS82 you find that rpm-limiter that kicks in.

I know that when turning out (richer) the burble/4-stroke sound comes - at the other side when turning IN (leaner) the high-sound of too lean comes. I have slowly turn out from the high lean-sound till the burble/4-stroke is there. Then turn slightly back IN till burble/4-stroke is gone. That is the point to set it?? Am I right?

When you are turning IN till burble goes away - do you set it so that there is still a slight burble/4-stroke - or do you turn till really all the burble is completely gone???

The adjusting of the LA and the L screw do not make me nervous : I am able to tune so that I have a good respons on the gas and at the same time I have a good idling. (I do turn L out till it runs very bad - then I do the opposit buy turning L-screw in till again it almost stalls. Then I take the middle (sweet) spot between these two positions. Then I turn slowly out till the point where it is low in rpm and just before it beginns to turn less smooth. That is the point where I set it, just before it beginns to run rougher)

I will do the "factory" setting with the procedure of 3300 rpm and then drop the rpm to 2800rpm with the L-screw, and see where it gets me. I will let you know my findings when I have done it...

But the setting of that "H"-screw is where I am affraid of, because I have never done it - so no experience with my ear - and not possible to depend on my rpm-meter as on the HS82 you find that rpm-limiter that kicks in.

I know that when turning out (richer) the burble/4-stroke sound comes - at the other side when turning IN (leaner) the high-sound of too lean comes. I have slowly turn out from the high lean-sound till the burble/4-stroke is there. Then turn slightly back IN till burble/4-stroke is gone. That is the point to set it?? Am I right?

When you are turning IN till burble goes away - do you set it so that there is still a slight burble/4-stroke - or do you turn till really all the burble is completely gone???

#47

B

bertsmobile1

B

bertsmobile1

OK

you need a resonable tacho

When you set the L and LA (throttle stop ) close the H fully so you are only running on the L jet as the engine was intended

Open the H jet engine running

If the engine speed picks up then the LA is out too far

Once you have your idle happy then open the H needle about 2 full turns Do a quick acceleration and the engine should 4 stroke ( miss rich )

If this happens then tighten the H watching the tach till you get to the prescribed maximum rpm

The high speed cut out is usually 10% higher than max RPM

you need a resonable tacho

When you set the L and LA (throttle stop ) close the H fully so you are only running on the L jet as the engine was intended

Open the H jet engine running

If the engine speed picks up then the LA is out too far

Once you have your idle happy then open the H needle about 2 full turns Do a quick acceleration and the engine should 4 stroke ( miss rich )

If this happens then tighten the H watching the tach till you get to the prescribed maximum rpm

The high speed cut out is usually 10% higher than max RPM

#48

T

TobyU

I have never used a tach for a two-stroke machine.

You also have to make sure if it's a string trimmer that you have the line out to the full length right to where the cutters will cut it off so you're getting proper RPM and proper resistance when you torque the engine up and rev it up from an idle otherwise your adjustments will be off.

With a string trimmer I find I like to get it to where the burble goes completely away and it smooths out and maybe even a little bit more but we're talking just to smidge nothing like a quarter or even 1/8 of a turn or maybe pushing 1/8 maximum because I don't want it to dip back down into the too rich when it's running.

However with a chainsaw it is often the best overall approach to have them a little bit rich when they're running with no load on them because then when you put the chain into actual wood it will need a little bit more gas and it will be at that perfect spot to where it's not rich and will be running it's best without being on the lean side.

T

TobyU

That style of a procedure is always worked nicely for me.I am very happy with all your advise and documentation that you have sent in this thread. I still did not tune my famous HS82R - the only reason is that till now I have postponed the action because I am "affraid" to do it.

The adjusting of the LA and the L screw do not make me nervous : I am able to tune so that I have a good respons on the gas and at the same time I have a good idling. (I do turn L out till it runs very bad - then I do the opposit buy turning L-screw in till again it almost stalls. Then I take the middle (sweet) spot between these two positions. Then I turn slowly out till the point where it is low in rpm and just before it beginns to turn less smooth. That is the point where I set it, just before it beginns to run rougher)

I will do the "factory" setting with the procedure of 3300 rpm and then drop the rpm to 2800rpm with the L-screw, and see where it gets me. I will let you know my findings when I have done it...

But the setting of that "H"-screw is where I am affraid of, because I have never done it - so no experience with my ear - and not possible to depend on my rpm-meter as on the HS82 you find that rpm-limiter that kicks in.

I know that when turning out (richer) the burble/4-stroke sound comes - at the other side when turning IN (leaner) the high-sound of too lean comes. I have slowly turn out from the high lean-sound till the burble/4-stroke is there. Then turn slightly back IN till burble/4-stroke is gone. That is the point to set it?? Am I right?

When you are turning IN till burble goes away - do you set it so that there is still a slight burble/4-stroke - or do you turn till really all the burble is completely gone???

I have never used a tach for a two-stroke machine.

You also have to make sure if it's a string trimmer that you have the line out to the full length right to where the cutters will cut it off so you're getting proper RPM and proper resistance when you torque the engine up and rev it up from an idle otherwise your adjustments will be off.

With a string trimmer I find I like to get it to where the burble goes completely away and it smooths out and maybe even a little bit more but we're talking just to smidge nothing like a quarter or even 1/8 of a turn or maybe pushing 1/8 maximum because I don't want it to dip back down into the too rich when it's running.

However with a chainsaw it is often the best overall approach to have them a little bit rich when they're running with no load on them because then when you put the chain into actual wood it will need a little bit more gas and it will be at that perfect spot to where it's not rich and will be running it's best without being on the lean side.

#49

J

Joed756

J

Joed756

I'm confused by 2.5 and 2.1/8", I read 2.5 as 2-1/2 rotations but I don't know what you mean by 2.1/8".

#50

T

TobyU

.25 or 1/4. Then half of that which would be 1/8 also 45°

T

TobyU

You have .5 turns - or 1/2 .I'm confused by 2.5 and 2.1/8", I read 2.5 as 2-1/2 rotations but I don't know what you mean by 2.1/8".

.25 or 1/4. Then half of that which would be 1/8 also 45°

#51

F

Flatsix

F

Flatsix

I finally did it : I have set the L and LA-screw according to the official papers that have been posted here - so the procedure of highest idle - then LA at 3300rpm and then the L at 2800 rpm. I did this twice and came twice with the L-screw +/- turned out at 1 turn. When the HS82R had worked so that the motor was good hot then the idle started slightly to wander around a little because ithis setting was a tad too lean. I turned the L-screw slightly out till a good popping and good idle. When I then look at the result then it shows 1.1/8" turn out, the setting that I had. So the "procedure" of Stihl manual does not work as it should for me....

The "H"-screw : I tried to turn in and out while motor-rpm almost at its max. (because the rpm-limiter kicks-in at 9300 rpm !!) and tried to hear when too lean or when too rich in order to set ist at the border of the rich side, but I cannot hear the differences, it must be something that you are used to do or hear because I cannot set the screw with my ears. So I left the screw at 2.1/8" where I know it is certainly not too lean as it smokes I little and the exhaust shows a little oil.

The difference between my 2 new HS82 is : the "T" smokes less and when throttle 95% open it begins to go in the rpm-limiter. My "R" smokes more but when throttle is opened 50 or 60% it goes into rpm-limiter. When I work with that machine I must always pay very good attention how much I open the throttle, as it goes quick in the limiter. My other is easier to work with because I can open the throttle much further, so easier to controle the throttle.

Could I change the throttle-respons on my "R", would that be an option so that I can open it till 90% /95% before the rpm-limiter cicks-in??

How to do because I see nowhere an adjusting screw for the throttle-cable - where is it hidden?

The "H"-screw : I tried to turn in and out while motor-rpm almost at its max. (because the rpm-limiter kicks-in at 9300 rpm !!) and tried to hear when too lean or when too rich in order to set ist at the border of the rich side, but I cannot hear the differences, it must be something that you are used to do or hear because I cannot set the screw with my ears. So I left the screw at 2.1/8" where I know it is certainly not too lean as it smokes I little and the exhaust shows a little oil.

The difference between my 2 new HS82 is : the "T" smokes less and when throttle 95% open it begins to go in the rpm-limiter. My "R" smokes more but when throttle is opened 50 or 60% it goes into rpm-limiter. When I work with that machine I must always pay very good attention how much I open the throttle, as it goes quick in the limiter. My other is easier to work with because I can open the throttle much further, so easier to controle the throttle.

Could I change the throttle-respons on my "R", would that be an option so that I can open it till 90% /95% before the rpm-limiter cicks-in??

How to do because I see nowhere an adjusting screw for the throttle-cable - where is it hidden?

#53

F

Flatsix

F

Flatsix

My problem with the STIHL HS82R is finally solved - for me in my mind it is closed and mostly because of your posts and advises here in this thread. So I thank all the folks that have given good advise to me : it has helped to finally adjust the hedgetrimmer so that in my mind I have satisfaction.

I had tuned it much more leaner then it was (2.1/8 turns instead of 2.1/2) - but I did not dare to make it more leaner although it seemed to me that at 2 turns it was nearly perfect - but as non-experienced guy I did not dare to set it that low. Now I had "the specialist" let have a look at it and he has set it at 2 turns out. When you open the throttle at max. then you hear the rpm-limiter come in.

The "L" and "LA" screw were set very good - so I have no problems with setting these screws. Now I know that I can set the "H"-screw like it should by listening + lookin at the exhaust-gases coming out. I had the confirmation that I needed from a very experienced person + all your posts. The procedure is very simple and no rocket-science at all : only you hae to know exactly what you are doing, that's all.

Thanks again

I had tuned it much more leaner then it was (2.1/8 turns instead of 2.1/2) - but I did not dare to make it more leaner although it seemed to me that at 2 turns it was nearly perfect - but as non-experienced guy I did not dare to set it that low. Now I had "the specialist" let have a look at it and he has set it at 2 turns out. When you open the throttle at max. then you hear the rpm-limiter come in.

The "L" and "LA" screw were set very good - so I have no problems with setting these screws. Now I know that I can set the "H"-screw like it should by listening + lookin at the exhaust-gases coming out. I had the confirmation that I needed from a very experienced person + all your posts. The procedure is very simple and no rocket-science at all : only you hae to know exactly what you are doing, that's all.

Thanks again

#54

T

TobyU

Are we talking about turns out from the fully but lightly seated position? That's what we should be talking about and in this situation two and a half is richer than 2 and 1/8 not leaner.

The further out counterclockwise you turn it, the richer it gets.

Then when you said you dare not set it at two turns which does make sense because that would be the leanest of all the three settings.

Then when you sad the so-called expert set it at two turns I'm not surprised because they often will adjust these things for maximum rpm or what some of the manuals say and a certain slight specified RPM drop from maximum rpm.

The problem with this is they don't always specify which way to turn them and some people don't pay attention and maybe turning them in leaner to get that drop as opposed to outricher but even still...

I simply and not going to subscribe to or agree to that theory of going by an RPM drop because I would rather give my engines some extra cooling and lubrication from running a little bit rich even close to the edge of four stroking or the burble as I call it.

Let's just say if we find the area and let's say we look at it like the hands of a clock and 10:00 is where the verbal starts and 2:00 is where it starts to slow down because it's leaning out.

Right at 12:00 to 1:00 it will sound great and be running really strong but I would far rather back out the screw counterclockwise towards the rich side to 11 maybe even 10 and a half because I want to be pushing the rich side all the time.

T

TobyU

I think I got a little confused by your numbers. You said you had it at 2 1/8 instead of 2 1/2 but you dare not go leaner.My problem with the STIHL HS82R is finally solved - for me in my mind it is closed and mostly because of your posts and advises here in this thread. So I thank all the folks that have given good advise to me : it has helped to finally adjust the hedgetrimmer so that in my mind I have satisfaction.

I had tuned it much more leaner then it was (2.1/8 turns instead of 2.1/2) - but I did not dare to make it more leaner although it seemed to me that at 2 turns it was nearly perfect - but as non-experienced guy I did not dare to set it that low. Now I had "the specialist" let have a look at it and he has set it at 2 turns out. When you open the throttle at max. then you hear the rpm-limiter come in.

The "L" and "LA" screw were set very good - so I have no problems with setting these screws. Now I know that I can set the "H"-screw like it should by listening + lookin at the exhaust-gases coming out. I had the confirmation that I needed from a very experienced person + all your posts. The procedure is very simple and no rocket-science at all : only you hae to know exactly what you are doing, that's all.

Thanks again

Are we talking about turns out from the fully but lightly seated position? That's what we should be talking about and in this situation two and a half is richer than 2 and 1/8 not leaner.

The further out counterclockwise you turn it, the richer it gets.

Then when you said you dare not set it at two turns which does make sense because that would be the leanest of all the three settings.

Then when you sad the so-called expert set it at two turns I'm not surprised because they often will adjust these things for maximum rpm or what some of the manuals say and a certain slight specified RPM drop from maximum rpm.

The problem with this is they don't always specify which way to turn them and some people don't pay attention and maybe turning them in leaner to get that drop as opposed to outricher but even still...

I simply and not going to subscribe to or agree to that theory of going by an RPM drop because I would rather give my engines some extra cooling and lubrication from running a little bit rich even close to the edge of four stroking or the burble as I call it.

Let's just say if we find the area and let's say we look at it like the hands of a clock and 10:00 is where the verbal starts and 2:00 is where it starts to slow down because it's leaning out.

Right at 12:00 to 1:00 it will sound great and be running really strong but I would far rather back out the screw counterclockwise towards the rich side to 11 maybe even 10 and a half because I want to be pushing the rich side all the time.