Hi to everyone,

I got a used trimmer FS45 curved shaft. The carburetor had a faulty check valve, so I changed it and now the engine runs great, but I noticed a new problem.

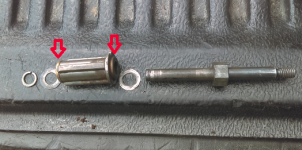

After a few minutes of mowing, the head starts to turn with difficulty. I think it happens when I slam it into the ground and that plastic nut tightens. After that, the head and the last 10 cm of the shaft become extremely hot. if I loosen the nut a little, the head turns freely again. I took off my head and examined the bearing. The bearing seems fine to me, there is grease, it turns freely and if I drive at full throttle for a few minutes without the head, there is nothing hot. The hex plastic slot for the nut on the head is slightly damaged, I think someone misplaced it in the past. There is no grass around the head for it to stick to. I cleaned the part of the guard that goes around the head and it sure doesn't get stuck.

My question is whether to change the head or is the problem somewhere else. The shaft is lubricated. I don't have a picture of the head right now, but I think the original is a stihl. Is it possible that the head is standing crooked due to a damaged fit, and because of that it continues to heat up and deform further?!?

I have an FS36 with an older type of head (completely black), can the heads be replaced to see if that is the problem. I ask this because my FS45 and FS36 are not in the same place and I need to remove the head and bring it to another location. Sorry for the long text, I hope someone has an idea how to solve the problem. Thank you in advance.

Danijel

I got a used trimmer FS45 curved shaft. The carburetor had a faulty check valve, so I changed it and now the engine runs great, but I noticed a new problem.

After a few minutes of mowing, the head starts to turn with difficulty. I think it happens when I slam it into the ground and that plastic nut tightens. After that, the head and the last 10 cm of the shaft become extremely hot. if I loosen the nut a little, the head turns freely again. I took off my head and examined the bearing. The bearing seems fine to me, there is grease, it turns freely and if I drive at full throttle for a few minutes without the head, there is nothing hot. The hex plastic slot for the nut on the head is slightly damaged, I think someone misplaced it in the past. There is no grass around the head for it to stick to. I cleaned the part of the guard that goes around the head and it sure doesn't get stuck.

My question is whether to change the head or is the problem somewhere else. The shaft is lubricated. I don't have a picture of the head right now, but I think the original is a stihl. Is it possible that the head is standing crooked due to a damaged fit, and because of that it continues to heat up and deform further?!?

I have an FS36 with an older type of head (completely black), can the heads be replaced to see if that is the problem. I ask this because my FS45 and FS36 are not in the same place and I need to remove the head and bring it to another location. Sorry for the long text, I hope someone has an idea how to solve the problem. Thank you in advance.

Danijel