Howdy! I have a YTH 24V48 rider.

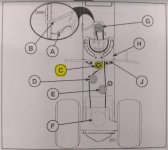

Something went terribly wrong trying to replace the stationary idler pully -- part “C” in the attached diagram.

It should have been VERY simple, as in the video below. But when I went to take the pully off, the post (coming down from the top of the chassis) came loose – and the whole assembly is now flopping around.

Problem is: I STILL cannot get the pully off, as the nut just spins with the bolt coming down through the chassis. I also can’t tighten it back up. So you’re probably thinking, “Just put a wrench or a socket on the other side of the post, from the top-side”, right? Well, from the top-side of the mower, there’s nothing to be seen. I’m not sure if the fastener is sandwiched between two pieces of metal (the chassis and the body) or what. But there’s definitely not anything to get a socket, or a wrench on, from the top side.

Any ideas?

Thanks!

-Nathan

[ATTACHREUSE]

Something went terribly wrong trying to replace the stationary idler pully -- part “C” in the attached diagram.

It should have been VERY simple, as in the video below. But when I went to take the pully off, the post (coming down from the top of the chassis) came loose – and the whole assembly is now flopping around.

Problem is: I STILL cannot get the pully off, as the nut just spins with the bolt coming down through the chassis. I also can’t tighten it back up. So you’re probably thinking, “Just put a wrench or a socket on the other side of the post, from the top-side”, right? Well, from the top-side of the mower, there’s nothing to be seen. I’m not sure if the fastener is sandwiched between two pieces of metal (the chassis and the body) or what. But there’s definitely not anything to get a socket, or a wrench on, from the top side.

Any ideas?

Thanks!

-Nathan

[ATTACHREUSE]