You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Snow thrower attachment belt issues

- Thread starter RJRichard

- Start date

More options

Export threadbob_mclaugh

Forum Newbie

- Joined

- Feb 10, 2015

- Threads

- 0

- Messages

- 1

Hi BLKRIV95, NorsemanNorseman -

Was wondering if your roller mod for your Craftsman snow thrower worked for you. I did the same rod mod that other forums recommended last spring (before truly testing it out on snow) but I finally tried it out today. The auger belt did not break or slip off and had a good straight line/angle in the down position but my conduit pipe (as a roller) over the threaded rod made too much heat as well. It wasn't too bad but wondering if your 2" rollers and a longer belt did the trick.

If it worked good, can you post or email some pictures on your final product? I was thinking of using some type of ball bearing roller / pulley for the threaded rod but couldn't find a small enough item for my threaded rod and also use the same 114" auger belt.

Thanks

Andy

Do either of you have any photos or more details about where and how you made you guide attachments. I am just going through the same problem now. Everything seemed fine the first season or so, but I can't keep a belt on it now - clearly out of alignment when the blower is in the down position

Thanks

Bob

boltonandy

Forum Newbie

- Joined

- Jan 20, 2016

- Threads

- 0

- Messages

- 1

Also looking for any info on what has worked for members who have had auger belt issues.

I run the blower for about 5-10 seconds and the belt is thrown each time.

I run the blower for about 5-10 seconds and the belt is thrown each time.

islandnupe

Forum Newbie

- Joined

- Feb 3, 2017

- Threads

- 0

- Messages

- 1

Also looking for any info on what has worked for members who have had auger belt issues.

I run the blower for about 5-10 seconds and the belt is thrown each time.

I've had my setup for 5 years and I started having auger belt throw issues a few weeks ago. I typically buy belts from vbeltsupply.com (PIX B111K Blue Kevlar Belt 114'' sku AAF3&189 and A53K Blue Kevlar Belt 55'' sku AAF2&135 ). It turns out that I hadn't been properly setting the tension on the auger. The hairpin cotter needs to be attached to the end of the spring and not the chain. See page 24 of the manual. Also, I'd suggest picking up a few extra springs for both the engine and auger clutches.

Grasshoppa

Forum Newbie

- Joined

- Jan 6, 2020

- Threads

- 0

- Messages

- 1

B111K Commercial Kevlar Belt

5/8" Top Width X 114" Outside Measurement X Aramid (Kevlar) - OVER 100 B111K BELTS IN STOCK!

$33 vs $100 for a craftsman belt. No brainer. I got two plus shipping was less than one craftsman belt.

as stated before, make sure the cotter pin for the belt tension is attached to the spring and not the chain. Also, engage the thrower while in the up position and then lower it to the ground. if engaged while down, the torque tends to pull it off of the guide pulley.

Last edited:

AVB

Well-Known Member

- Joined

- Dec 13, 2019

- Threads

- 0

- Messages

- 200

Just note that the image of the belt on searspartsdirect shows a raw edge belt. And using a cloth covered belt does makes a difference on some applications.

Anyway at least most of us have enough sense not to buy these below..

Ebay crazy vendor

Anyway at least most of us have enough sense not to buy these below..

Ebay crazy vendor

John Hotmer

Forum Newbie

- Joined

- Mar 5, 2020

- Threads

- 0

- Messages

- 1

Note; This snowblower was designed when tractors made 15Hp at 2400 rpm.

My 2006 husky makes 22Hp at 3600rpm.

I have found that reducing the throttle when blowing eliminates throwing and breaking of the belt.

If needed, full throttle is good for short periods.

The recommended belt is the best belt.

If you do try another belt make it a 5V wedge type belt designed for flexibility.

It is the sharp bend between the auger pulley and the small pullies in the blower assembly that causes the belt issues at higher than 2400 rpm.

My 2006 husky makes 22Hp at 3600rpm.

I have found that reducing the throttle when blowing eliminates throwing and breaking of the belt.

If needed, full throttle is good for short periods.

The recommended belt is the best belt.

If you do try another belt make it a 5V wedge type belt designed for flexibility.

It is the sharp bend between the auger pulley and the small pullies in the blower assembly that causes the belt issues at higher than 2400 rpm.

Last edited:

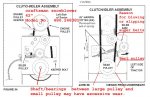

The upper larger pulley runs through the transmission plate and connects to the smaller pulley by the use of a shaft. The shaft is held into place by two bearings. From the factory the bearings are not a tight fit on the shaft and over time wear groves on the shaft. The slop between the shaft and pulleys allows the small pulley to wobble and spit the belt. Also if the small pulley has a dent or bend where the belt rides this will cause premature wear.If the pulleys aren't in alignment, that belt is going to work its way off every time.