You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Ryobi ZT480E - No Movement, but blades turn on.

#1

F

ford.brad

F

ford.brad

Good Afternoon All,

I recently picked up a Ryobi ZT480E, the 75AH variant for relatively cheap. Everything appears to work, except for the motion. I've already ruled out the seat sensor as the blades will engage normally, but will not when the connection is removed. What's interesting is the beeping I hear from the Safety Interlock System only triggers when I move the left side control arm, but does not for the right side control arm. I am expecting the issue is either a limit switch or the accelerator on the right side, but neither part seems to have a part number in the diagrams. I wanted to see if anyone else had a similar issue or maybe a product specific diagnostic manual like the one J provided for the RY48110. Thanks for any experience you can share.

(As an aside, I do know the 75AH SLA are terrible and likely to die within a year. Once they do the plan is to replace with ~200AH of LiFePO4 and a 150A BMS)

I recently picked up a Ryobi ZT480E, the 75AH variant for relatively cheap. Everything appears to work, except for the motion. I've already ruled out the seat sensor as the blades will engage normally, but will not when the connection is removed. What's interesting is the beeping I hear from the Safety Interlock System only triggers when I move the left side control arm, but does not for the right side control arm. I am expecting the issue is either a limit switch or the accelerator on the right side, but neither part seems to have a part number in the diagrams. I wanted to see if anyone else had a similar issue or maybe a product specific diagnostic manual like the one J provided for the RY48110. Thanks for any experience you can share.

(As an aside, I do know the 75AH SLA are terrible and likely to die within a year. Once they do the plan is to replace with ~200AH of LiFePO4 and a 150A BMS)

#3

F

ford.brad

F

ford.brad

StarTech, this manual is everything I could ask for. Thank you. I was able to verify it was an issue with the hall effect sensor as it did 8 beeps. I did double check the transducer by swapping the left and right control arms and still managed to get motion on my left wheel. I am planning to get some gator clips tomorrow to make it a little easier to swap between the channels, but I did see the expected 0-5V between yellow and black hall sensor wires.Count the beeps and compared to the chart in the following manual.

#4

Tiger Small Engine

Tiger Small Engine

Good thing you know how to work on this mower. Most shops will not work on a Ryobi battery powered tool or up to a mower. I will not work on gas Ryobi handheld equipment or battery anything.StarTech, this manual is everything I could ask for. Thank you. I was able to verify it was an issue with the hall effect sensor as it did 8 beeps. I did double check the transducer by swapping the left and right control arms and still managed to get motion on my left wheel. I am planning to get some gator clips tomorrow to make it a little easier to swap between the channels, but I did see the expected 0-5V between yellow and black hall sensor wires.

#5

F

ford.brad

F

ford.brad

I've read as such from the forum posts. It's part of why I got such a good deal. I feel confident I can trace down the problem, though most of my tools are not ryobi.Good thing you know how to work on this mower. Most shops will not work on a Ryobi battery powered tool or up to a mower. I will not work on gas Ryobi handheld equipment or battery anything.

#6

StarTech

I don't know why you avoiding the 2 cycle Ryobi (TTI) handhelds. Now some techs just hate 2 cycles of all types. My brother was one of them.

I can understand the lack of parts for the battery powered handhelds. They are just as easy to fix as if they were a Homelite, Poulan, or other handheld 2 cycle. Just finding the IPLs and parts are harder sometimes. Depending on your distributor PartSmart will have the IPLs. I just repaired two Ryobi chainsaws last week.

For me Gardner is the TTI parts distributor.

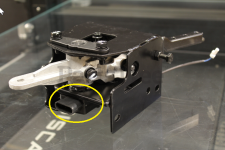

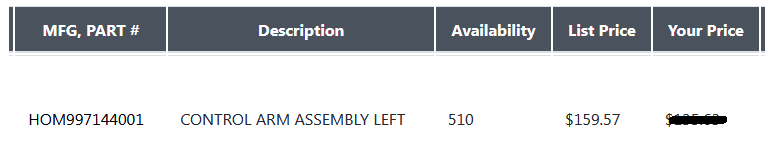

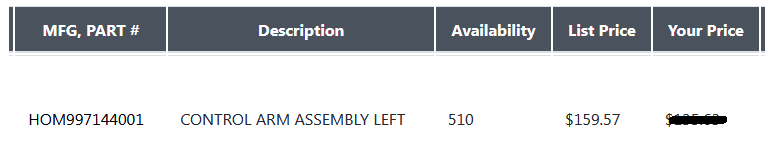

Even this RY48ZTR75 IPLs are listed on the Gardner PartSmart. Those sensors (they calling them Accelerators) doesn't have a PN listed. I need to get with Gardner tech support to see if they can provide a PN for the sensors only or what assembly they are part of.

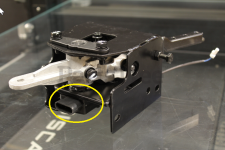

Can you verify where the sensors are located in the control boxes (I have yet to see one these battery ZTRs in my shop)? If they are the control assemblies are about $160 list and apparently they are failing a lot as the vendor only has over 500 in stock.

We all will have a steep learning curve on these battery powered mowers just as we did when EFI first came out for automobiles. So all got to pull together what knowledge we got and share for the benefit of all of us.

StarTech

Good thing you know how to work on this mower. Most shops will not work on a Ryobi battery powered tool or up to a mower. I will not work on gas Ryobi handheld equipment or battery anything.

I don't know why you avoiding the 2 cycle Ryobi (TTI) handhelds. Now some techs just hate 2 cycles of all types. My brother was one of them.

I can understand the lack of parts for the battery powered handhelds. They are just as easy to fix as if they were a Homelite, Poulan, or other handheld 2 cycle. Just finding the IPLs and parts are harder sometimes. Depending on your distributor PartSmart will have the IPLs. I just repaired two Ryobi chainsaws last week.

For me Gardner is the TTI parts distributor.

StarTech, this manual is everything I could ask for. Thank you. I was able to verify it was an issue with the hall effect sensor as it did 8 beeps. I did double check the transducer by swapping the left and right control arms and still managed to get motion on my left wheel. I am planning to get some gator clips tomorrow to make it a little easier to swap between the channels, but I did see the expected 0-5V between yellow and black hall sensor wires.

Even this RY48ZTR75 IPLs are listed on the Gardner PartSmart. Those sensors (they calling them Accelerators) doesn't have a PN listed. I need to get with Gardner tech support to see if they can provide a PN for the sensors only or what assembly they are part of.

Can you verify where the sensors are located in the control boxes (I have yet to see one these battery ZTRs in my shop)? If they are the control assemblies are about $160 list and apparently they are failing a lot as the vendor only has over 500 in stock.

We all will have a steep learning curve on these battery powered mowers just as we did when EFI first came out for automobiles. So all got to pull together what knowledge we got and share for the benefit of all of us.

#7

F

ford.brad

When I contacted PartsTree . com about the accelerator/transducer they responded 'these part numbers don't exist because they are only part of the entire harness and cannot be sold separately.'

The only thing I found online for it so far is maybe a supplier or clone of it from a company called "YEAPHI". Looks very similar, but only has the one photo.

F

ford.brad

The Accelerator or Angle Transducer is located within the control arm assembly. (Photo of Homelite 997144001 Control Arm Assembly, Left)I don't know why you avoiding the 2 cycle Ryobi (TTI) handhelds. Now some techs just hate 2 cycles of all types. My brother was one of them.

I can understand the lack of parts for the battery powered handhelds. They are just as easy to fix as if they were a Homelite, Poulan, or other handheld 2 cycle. Just finding the IPLs and parts are harder sometimes. Depending on your distributor PartSmart will have the IPLs. I just repaired two Ryobi chainsaws last week.

For me Gardner is the TTI parts distributor.

Even this RY48ZTR75 IPLs are listed on the Gardner PartSmart. Those sensors (they calling them Accelerators) doesn't have a PN listed. I need to get with Gardner tech support to see if they can provide a PN for the sensors only or what assembly they are part of.

Can you verify where the sensors are located in the control boxes (I have yet to see one these battery ZTRs in my shop)? If they are the control assemblies are about $160 list and apparently they are failing a lot as the vendor only has over 500 in stock.

We all will have a steep learning curve on these battery powered mowers just as we did when EFI first came out for automobiles. So all got to pull together what knowledge we got and share for the benefit of all of us.

When I contacted PartsTree . com about the accelerator/transducer they responded 'these part numbers don't exist because they are only part of the entire harness and cannot be sold separately.'

The only thing I found online for it so far is maybe a supplier or clone of it from a company called "YEAPHI". Looks very similar, but only has the one photo.

#8

StarTech

StarTech

Well that BS from Partstree as it being part of the harness when the 997144001 image clearly shows it on it. And do your leg work on the 997144001 as my distributor listing for a lot less retail.

And wiring harness doesn't show those sensors as part of it.

Now here is something you could do pull one of the control arm assembly and look for the OEM of sensor and their part number. A lot of the time it would be there. Then you could search for that part number.

And wiring harness doesn't show those sensors as part of it.

Now here is something you could do pull one of the control arm assembly and look for the OEM of sensor and their part number. A lot of the time it would be there. Then you could search for that part number.

#9

F

ford.brad

F

ford.brad

Luckily I think my transducers are fine. I did snag a part number off the left control arm of TJ563A YP 201218(photo attached) for anyone trying to source one.Well that BS from Partstree as it being part of the harness when the 997144001 image clearly shows it on it. And do your leg work on the 997144001 as my distributor listing for a lot less retail.

View attachment 68028

And wiring harness doesn't show those sensors as part of it.

View attachment 68029

Now here is something you could do pull one of the control arm assembly and look for the OEM of sensor and their part number. A lot of the time it would be there. Then you could search for that part number.

Attachments

#10

StarTech

StarTech

Available on alibaba. The problem is the info is in Russia.

Yp,Yuxin Для Езды На Мотоцикле И Ztr,Запасные Части,Датчики Углового Положения - Buy Angle Position Sensors,Angle Position Sensors,Angle Position Sensors Product on Alibaba.com

Yp,Yuxin Для Езды На Мотоцикле И Ztr,Запасные Части,Датчики Углового Положения - Buy Angle Position Sensors,Angle Position Sensors,Angle Position Sensors Product on Alibaba.com

russian.alibaba.com

#11

F

ford.brad

F

ford.brad

That is dead on for looks. I feel that I have narrowed it down to my rear right drive motor. I have done the following:

Tested left side drive system - functional, but only after rotating the right tire a few times(presumably to give the motor controller some hall sensor feedback to stop beeping)

Tested each Transducer by swapping left and right control arms - problem stayed with the right drive system.

Tested motors and motor controllers per the guide provided - values within expectations for resistance and diode voltage.

Swapped the motor controllers and hall sensors (Effectively operating the left side wheel with the right side controller) - issue remained on right side drive system.

Removed the right side motor from the gearbox and did not detect any undue mechanical resistance in transmission while manually rotating.

Attempted to test the right side hall effect sensor as in the guide provided. Can not detect voltage change between yellow wire and black wire.

My next step is to look for a fit for purpose connector or salvage one to make sure I can properly tie into the hall effect sensor for testing. I've been using needles and gator clips and it is not ideal due to flex. Everything I've seen points to a bad hall sensor in the right side motor which I may just replace unless I can source the sensor itself.

I'll update this thread if I learn anything new.

Tested left side drive system - functional, but only after rotating the right tire a few times(presumably to give the motor controller some hall sensor feedback to stop beeping)

Tested each Transducer by swapping left and right control arms - problem stayed with the right drive system.

Tested motors and motor controllers per the guide provided - values within expectations for resistance and diode voltage.

Swapped the motor controllers and hall sensors (Effectively operating the left side wheel with the right side controller) - issue remained on right side drive system.

Removed the right side motor from the gearbox and did not detect any undue mechanical resistance in transmission while manually rotating.

Attempted to test the right side hall effect sensor as in the guide provided. Can not detect voltage change between yellow wire and black wire.

My next step is to look for a fit for purpose connector or salvage one to make sure I can properly tie into the hall effect sensor for testing. I've been using needles and gator clips and it is not ideal due to flex. Everything I've seen points to a bad hall sensor in the right side motor which I may just replace unless I can source the sensor itself.

I'll update this thread if I learn anything new.

#12

Tiger Small Engine

I love two strokes and work on them all the time. I DO NOT nor will I work on any battery powered outdoor power equipment by choice. Has nothing to do with Ryobi (which I find subpar anyway). It is my way of not agreeing with nor supporting battery equipment.

Tiger Small Engine

I don't know why you avoiding the 2 cycle Ryobi (TTI) handhelds. Now some techs just hate 2 cycles of all types. My brother was one of them.

I can understand the lack of parts for the battery powered handhelds. They are just as easy to fix as if they were a Homelite, Poulan, or other handheld 2 cycle. Just finding the IPLs and parts are harder sometimes. Depending on your distributor PartSmart will have the IPLs. I just repaired two Ryobi chainsaws last week.

For me Gardner is the TTI parts distributor.

Even this RY48ZTR75 IPLs are listed on the Gardner PartSmart. Those sensors (they calling them Accelerators) doesn't have a PN listed. I need to get with Gardner tech support to see if they can provide a PN for the sensors only or what assembly they are part of.

Can you verify where the sensors are located in the control boxes (I have yet to see one these battery ZTRs in my shop)? If they are the control assemblies are about $160 list and apparently they are failing a lot as the vendor only has over 500 in stock.

We all will have a steep learning curve on these battery powered mowers just as we did when EFI first came out for automobiles. So all got to pull together what knowledge we got and share for the benefit of all of us.

I love two strokes and work on them all the time. I DO NOT nor will I work on any battery powered outdoor power equipment by choice. Has nothing to do with Ryobi (which I find subpar anyway). It is my way of not agreeing with nor supporting battery equipment.

#13

StarTech

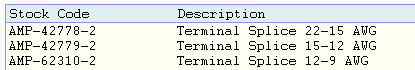

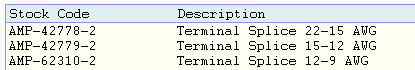

As for battery powered equipment I have personally work on a lot of equipment that used batteries as their main source of power, just not lawn care equipment. But if thing keeps going the way it is we will need to yield and learn how to repair this new battery powered equipment. It look like every OEM is getting into the act of making some sort of a battery powered mower. It at first be mostly consumer equipment but it will make it way into commercial soon too. BTW I even have worked of coffee pots and hair dryers over the years. Always needed those terminal splices and didn't even knew where get them until a few years ago. It was the same with my suppliers they didn't know either. Just took finding the right supplier. Now I stock and use them over the butt connectors; although, I need to use some heat shrink tubing most times to insulate them. Just easier to work them into the harnesses and where the wires are running.

My main issue with the newer battery powered equipment is the lack of info and parts. On this Ryobi discussion here, they at least came to the same conclusion that we must have these things. Now it will be up to us independent shop that are willing to learn new things that will help keep the customer equipment repaired; although, it will give a lot of headaches to all that is involved until we too learn these new battery systems. Plus there is no way their dealer only shops are going handle the overload of repairs.

Now I give the OP at lot credit here for he is willing to apply what he knows from other equipment and is willing to share with us too. I greatly appreciate it myself as I am willing myself to learn this to help my customers that have jumped on to the bandwagon of battery powered equipment. Just now from this one thread I done learn a few new things including finding that troubleshooting PDF and that my distributor's PartSmart has the IPLs (Rev 2 and Rev 4) and that the distributor is a lot more reasonable on the parts. Partstree is just way over priced of these parts.

The problem here is that I have only a limited time left to learn this equipment on the fly as I am entering the 65 and up club very soon. Matter of fact I am signing up for SS and Medicare today.

But you must be willing to learn new things or you will end up failing in life period as we must always be learning new things our entire life be it this equipment or say cook a new meal or deal with a new medical problem. Here I am learning to deal with Afib now and the diet that is related to it.

StarTech

The way you posted it gave me the impression that you hated all Ryobi equipment including the two strokes. Plus you got to remember the Homelite is also under TTI wing now. But a lot of the old Homelite chainsaws are simply dying off now due to lack of parts from the former owners.I love two strokes and work on them all the time. I DO NOT nor will I work on any battery powered outdoor power equipment by choice. Has nothing to do with Ryobi (which I find subpar anyway). It is my way of not agreeing with nor supporting battery equipment.

As for battery powered equipment I have personally work on a lot of equipment that used batteries as their main source of power, just not lawn care equipment. But if thing keeps going the way it is we will need to yield and learn how to repair this new battery powered equipment. It look like every OEM is getting into the act of making some sort of a battery powered mower. It at first be mostly consumer equipment but it will make it way into commercial soon too. BTW I even have worked of coffee pots and hair dryers over the years. Always needed those terminal splices and didn't even knew where get them until a few years ago. It was the same with my suppliers they didn't know either. Just took finding the right supplier. Now I stock and use them over the butt connectors; although, I need to use some heat shrink tubing most times to insulate them. Just easier to work them into the harnesses and where the wires are running.

My main issue with the newer battery powered equipment is the lack of info and parts. On this Ryobi discussion here, they at least came to the same conclusion that we must have these things. Now it will be up to us independent shop that are willing to learn new things that will help keep the customer equipment repaired; although, it will give a lot of headaches to all that is involved until we too learn these new battery systems. Plus there is no way their dealer only shops are going handle the overload of repairs.

Now I give the OP at lot credit here for he is willing to apply what he knows from other equipment and is willing to share with us too. I greatly appreciate it myself as I am willing myself to learn this to help my customers that have jumped on to the bandwagon of battery powered equipment. Just now from this one thread I done learn a few new things including finding that troubleshooting PDF and that my distributor's PartSmart has the IPLs (Rev 2 and Rev 4) and that the distributor is a lot more reasonable on the parts. Partstree is just way over priced of these parts.

The problem here is that I have only a limited time left to learn this equipment on the fly as I am entering the 65 and up club very soon. Matter of fact I am signing up for SS and Medicare today.

But you must be willing to learn new things or you will end up failing in life period as we must always be learning new things our entire life be it this equipment or say cook a new meal or deal with a new medical problem. Here I am learning to deal with Afib now and the diet that is related to it.

#14

F

ford.brad

F

ford.brad

Brief update: I cut free the hall effect sensor from the right side motor. I tested per the guide again just to rule out the connectors.

I now have an order in to ryobi.partstree for the drive motor, PN 997157001. I could not identify any model number besides what shows in the diagram. Even the hall sensor is unlabeled.

I now have an order in to ryobi.partstree for the drive motor, PN 997157001. I could not identify any model number besides what shows in the diagram. Even the hall sensor is unlabeled.

#15

Tiger Small Engine

I learn everyday. I choose not to work on battery equipment. The customer decided to buy a cheaper off brand piece of equipment (Troy Bilt, Craftsman, Ryobi, Poulan, etc.). Now when it comes to repair, they will have to find a shop(good luck), fix it themselves (good luck), or throw it away and buy a new one(most likely).

My neighbor bought a Ryobi battery zero turn mower. Came with lead acid batteries and is dead after about 2.5 years. It is a $4000 boat anchor now. Nearest service center is 100 miles away in Arkansas. This is what some customers are running into. Meanwhile the gas zero turn is chugging along 20 years later.

Tiger Small Engine

The way you posted it gave me the impression that you hated all Ryobi equipment including the two strokes. Plus you got to remember the Homelite is also under TTI wing now. But a lot of the old Homelite chainsaws are simply dying off now due to lack of parts from the former owners.

As for battery powered equipment I have personally work on a lot of equipment that used batteries as their main source of power, just not lawn care equipment. But if thing keeps going the way it is we will need to yield and learn how to repair this new battery powered equipment. It look like every OEM is getting into the act of making some sort of a battery powered mower. It at first be mostly consumer equipment but it will make it way into commercial soon too. BTW I even have worked of coffee pots and hair dryers over the years. Always needed those terminal splices and didn't even knew where get them until a few years ago. It was the same with my suppliers they didn't know either. Just took finding the right supplier. Now I stock and use them over the butt connectors; although, I need to use some heat shrink tubing most times to insulate them. Just easier to work them into the harnesses and where the wires are running.

View attachment 68048View attachment 68049

My main issue with the newer battery powered equipment is the lack of info and parts. On this Ryobi discussion here, they at least came to the same conclusion that we must have these things. Now it will be up to us independent shop that are willing to learn new things that will help keep the customer equipment repaired; although, it will give a lot of headaches to all that is involved until we too learn these new battery systems. Plus there is no way their dealer only shops are going handle the overload of repairs.

Now I give the OP at lot credit here for he is willing to apply what he knows from other equipment and is willing to share with us too. I greatly appreciate it myself as I am willing myself to learn this to help my customers that have jumped on to the bandwagon of battery powered equipment. Just now from this one thread I done learn a few new things including finding that troubleshooting PDF and that my distributor's PartSmart has the IPLs (Rev 2 and Rev 4) and that the distributor is a lot more reasonable on the parts. Partstree is just way over priced of these parts.

The problem here is that I have only a limited time left to learn this equipment on the fly as I am entering the 65 and up club very soon. Matter of fact I am signing up for SS and Medicare today.

But you must be willing to learn new things or you will end up failing in life period as we must always be learning new things our entire life be it this equipment or say cook a new meal or deal with a new medical problem. Here I am learning to deal with Afib now and the diet that is related to it.

I learn everyday. I choose not to work on battery equipment. The customer decided to buy a cheaper off brand piece of equipment (Troy Bilt, Craftsman, Ryobi, Poulan, etc.). Now when it comes to repair, they will have to find a shop(good luck), fix it themselves (good luck), or throw it away and buy a new one(most likely).

My neighbor bought a Ryobi battery zero turn mower. Came with lead acid batteries and is dead after about 2.5 years. It is a $4000 boat anchor now. Nearest service center is 100 miles away in Arkansas. This is what some customers are running into. Meanwhile the gas zero turn is chugging along 20 years later.

#16

F

ford.brad

The reason I selected this mower was because of a certain channel "Aging Wheels" that upgraded their 'first' gen 54" variant to LiFePO4 and realized I could double the battery capacity and upgrade to LiFePO4 at nearly 200AH within the same dimensions for less than the OEM battery replacement cost. Getting it at a bargain only helped.

Your neighbor might be interested to know that many folks drop in LiFEPO4 batteries for relatively cheap to replace the OEM batteries and have good success. It's a mistake Ryobi shouldn't force the customer to fix, but it's better than a boat anchor.

F

ford.brad

The first generation of Ryobi Lawn mowers(ZT and RY series) are a lesson in Self Sabotage in regards to Ryobi brand loyalty. Anyone who knows batteries would have never paired the cheap lead acid batteries when it's fully expected DoD is beyond 50% every mow cycle. They threw it out and marked it up as a cash grab - which is a disservice to everyone. They have improved slightly in the newer gen, but they rely on Li-ion battery packs that are removable and waste space rather than committing to a proper LiFePO4 which would provide the longest cycle life(besides going LTO, but those aren't anywhere near as power dense).I learn everyday. I choose not to work on battery equipment. The customer decided to buy a cheaper off brand piece of equipment (Troy Bilt, Craftsman, Ryobi, Poulan, etc.). Now when it comes to repair, they will have to find a shop(good luck), fix it themselves (good luck), or throw it away and buy a new one(most likely).

My neighbor bought a Ryobi battery zero turn mower. Came with lead acid batteries and is dead after about 2.5 years. It is a $4000 boat anchor now. Nearest service center is 100 miles away in Arkansas. This is what some customers are running into. Meanwhile the gas zero turn is chugging along 20 years later.

The reason I selected this mower was because of a certain channel "Aging Wheels" that upgraded their 'first' gen 54" variant to LiFePO4 and realized I could double the battery capacity and upgrade to LiFePO4 at nearly 200AH within the same dimensions for less than the OEM battery replacement cost. Getting it at a bargain only helped.

Your neighbor might be interested to know that many folks drop in LiFEPO4 batteries for relatively cheap to replace the OEM batteries and have good success. It's a mistake Ryobi shouldn't force the customer to fix, but it's better than a boat anchor.

#17

StarTech

StarTech

That is your right to refuse but I think in the long run you will miss out on the initial learning phase. It better to learn when only a few these are around than when it is all that is out there.

This battery powered phase is going to be a real pain for techs as we gradually learn how to repair along with the OEMs constantly making improvements. Plus our governments is basically forcing this down our throats so we must adapt. Just look at how states like Calif are passing laws that basically is forcing their population to switch to battery powered equipment. And this state is already has an electrical grid that is over taxed (unable to keep with the demand) already. Even in my rural area of Tennessee we now having black outs during the peak usage times.

Battery power will work for the city dwellers with small lawns but for us with bigger lawns it will take a heck a lot improvement before it is ready for prime time.

I once repaired electronic equipment down to component level. Now with surface mount components it is nearly impossible to repair as most of the components are not even available so it is board level repairs now. and some those replacement boards are not even available.

But as you probably already found out several of the OEMs are now not even providing parts for the newer engines that are being used on their or other OEM equipment. I had two engines last year that I could not parts for and both were less than a year old. One was a Briggs and the other a Loncin. It coming down to buy our junk and screw you when you need it fixed. Now this is their business decision to force us to buy new equipment every few years just to keep their factories humming along and their bank accounts busting at the seams.

I am still searching for an IPL on the Loncin G300FA engine. Even Loncin has refused to provide it as I have requested it via email.

Li-ion = lithium-ion

LiFePO4 = lithium iron phosphate battery

This battery powered phase is going to be a real pain for techs as we gradually learn how to repair along with the OEMs constantly making improvements. Plus our governments is basically forcing this down our throats so we must adapt. Just look at how states like Calif are passing laws that basically is forcing their population to switch to battery powered equipment. And this state is already has an electrical grid that is over taxed (unable to keep with the demand) already. Even in my rural area of Tennessee we now having black outs during the peak usage times.

Battery power will work for the city dwellers with small lawns but for us with bigger lawns it will take a heck a lot improvement before it is ready for prime time.

I once repaired electronic equipment down to component level. Now with surface mount components it is nearly impossible to repair as most of the components are not even available so it is board level repairs now. and some those replacement boards are not even available.

But as you probably already found out several of the OEMs are now not even providing parts for the newer engines that are being used on their or other OEM equipment. I had two engines last year that I could not parts for and both were less than a year old. One was a Briggs and the other a Loncin. It coming down to buy our junk and screw you when you need it fixed. Now this is their business decision to force us to buy new equipment every few years just to keep their factories humming along and their bank accounts busting at the seams.

I am still searching for an IPL on the Loncin G300FA engine. Even Loncin has refused to provide it as I have requested it via email.

Li-ion = lithium-ion

LiFePO4 = lithium iron phosphate battery

#19

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

So in our shop, we work on anything I can get in the shop. We are a bit more electrical savvy as rotable rebuilders (starters, alternators and generators). Because of this open attitude, we do get some jobs referred from other shops, over 100 OEM's we are authored for, and nearly all generators come our way, and jobs other's failed to solve end up here pushing us to learn. Many of these jobs are higher return when you prepare the customer for the extensive diagnostics you may have to undergo. We do not get board, we can push some projects out as nobody does better, keeping good diagnostic details is imperative. Enjoy the learning and the challenge and the reward.Good thing you know how to work on this mower. Most shops will not work on a Ryobi battery powered tool or up to a mower. I will not work on gas Ryobi handheld equipment or battery anything.

#20

F

ford.brad

F

ford.brad

I'm back and with good news. I was able to get a replacement drive motor for the zero turn directly from ryobitools. It did take about 13 days to get it delivered, but after dropping it in the diagnostic beeps went away. The mower is now fully assembled and runs just fine, besides the smaller SLA battery draining quickly in my yard. My next task will be to upgrade to a custom 200AH LiFePO4 battery system sized for my lawn, but I appreciate the help provided here in this forum to get it moving to begin with.

Cheers!

Cheers!

#21

StarTech

StarTech

And I am glad that you kept us updated as to your progress and solution. It will help at least me in the future when one comes in with this problem. Besides you have already help me too as I now have the troubleshooting guide and know where to get the parts.

#22

Tiger Small Engine

It will not get to the point where all there is out there is battery equipment. I asked 2 of the local Stihl dealers while talking with them, what percentage of gas vs battery on handheld equipment they have. They both said 90% gas and 10% battery. This is after 2-3 years of pushing hard by the government, media, and big corporations for battery power. There are millions of pieces of gas powered equipment in the United States. I will be retired and out of small engines by the time all there is to work on is battery powered equipment (potentially). Meanwhile those evil dirty fossil fuels are churning and burning to make all the plastic, and the equipment itself, and powering the electricity to charge the battery. Happy Easter!

Tiger Small Engine

That is your right to refuse but I think in the long run you will miss out on the initial learning phase. It better to learn when only a few these are around than when it is all that is out there.

It will not get to the point where all there is out there is battery equipment. I asked 2 of the local Stihl dealers while talking with them, what percentage of gas vs battery on handheld equipment they have. They both said 90% gas and 10% battery. This is after 2-3 years of pushing hard by the government, media, and big corporations for battery power. There are millions of pieces of gas powered equipment in the United States. I will be retired and out of small engines by the time all there is to work on is battery powered equipment (potentially). Meanwhile those evil dirty fossil fuels are churning and burning to make all the plastic, and the equipment itself, and powering the electricity to charge the battery. Happy Easter!

#23

VRR.DYNDNS>BIZ

VRR.DYNDNS>BIZ

We have had a warranty repair with similar issues which was the drive controller.Good Afternoon All,

I recently picked up a Ryobi ZT480E, the 75AH variant for relatively cheap. Everything appears to work, except for the motion. I've already ruled out the seat sensor as the blades will engage normally, but will not when the connection is removed. What's interesting is the beeping I hear from the Safety Interlock System only triggers when I move the left side control arm, but does not for the right side control arm. I am expecting the issue is either a limit switch or the accelerator on the right side, but neither part seems to have a part number in the diagrams. I wanted to see if anyone else had a similar issue or maybe a product specific diagnostic manual like the one J provided for the RY48110. Thanks for any experience you can share.

(As an aside, I do know the 75AH SLA are terrible and likely to die within a year. Once they do the plan is to replace with ~200AH of LiFePO4 and a 150A BMS)

#24

F

ford.brad

F

ford.brad

I did also suspect that. For my particular issue I still had one working wheel so I did swap testing for the motor controllers and was able to verify that both controllers could run the known working motor. I did the same swap test on the control arms to verify they were providing correct feedback to the controller.We have had a warranty repair with similar issues which was the drive controller.