You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

RPM for a 22" residential push mower

#1

G

GearHead36

G

GearHead36

I know that the blade tip speed is limited by ANSI to 19000 FPM. Which, on a 22" blade, equates to 3299RPM according to my calculator. I recently bought a tachometer, and found that my residential push mower, with a 22" blade, is running at 2750 RPM. So I started increasing it. When I got to 2950, it seemed like it was running really fast, and had a lot of vibration. So I backed it down to 2900, and the vibrations seem to get better. So my question is, of course, what speed should I set my engine to?

Engine: Briggs 128T05-5123-B.

Mower: 2011 Toro Recycler w/Personal Pace.

I still have the owner's manual and the engine manual. Neither mention engine RPM settings.

Not sure if this is the right forum, but the only other blade tip speed discussion I could find was in this forum.

Engine: Briggs 128T05-5123-B.

Mower: 2011 Toro Recycler w/Personal Pace.

I still have the owner's manual and the engine manual. Neither mention engine RPM settings.

Not sure if this is the right forum, but the only other blade tip speed discussion I could find was in this forum.

#3

G

GearHead36

G

GearHead36

Ok. My balance is one of those cheap cone things. So if blade balance is the problem, I may be limited to 2900 until I get something better. However, 2950 still just seemed to be fast. I watch small engine repair videos every so often, and 2950 seems faster than any of the engines I hear on the videos.

#6

G

GearHead36

G

GearHead36

I've only recently acquired a small engine tach, and I never trusted the dealer who sold the mower to me, so I wanted to adjust it "per spec". But I really couldn't find the spec. The only spec I could find is the 19000 FPM spec. Is it cutting well enough? Tough to say. I have a riding mower that cuts better. Is that because the RPMs on my push mower is too low? I don't know, but I'm interesting in finding out.Why are you wanting to up the rpm? Do you think it's not mowing well enough?

#7

woodstover

woodstover

It's 13yr old now, I would sharpen and balance the blade and not raise it more than 2900rpm. Sharp/balanced blades make all the difference. Running with an unbalanced blade just going to damage the engine. New blades are pretty cheap.I've only recently acquired a small engine tach, and I never trusted the dealer who sold the mower to me, so I wanted to adjust it "per spec". But I really couldn't find the spec. The only spec I could find is the 19000 FPM spec. Is it cutting well enough? Tough to say. I have a riding mower that cuts better. Is that because the RPMs on my push mower is too low? I don't know, but I'm interesting in finding out.

#8

StarTech

And hopefully the RPM meter is set to one count per revolution. But if the mower cuts well at 2900 rpm then just leave it at that. Usually you will have more Ft-Lb torque at the slower speed.

StarTech

Those cones usually has steps rings which poorly fit the blades so you could blade off center.Ok. My balance is one of those cheap cone things. So if blade balance is the problem, I may be limited to 2900 until I get something better. However, 2950 still just seemed to be fast. I watch small engine repair videos every so often, and 2950 seems faster than any of the engines I hear on the videos.

And hopefully the RPM meter is set to one count per revolution. But if the mower cuts well at 2900 rpm then just leave it at that. Usually you will have more Ft-Lb torque at the slower speed.

#9

B

bertsmobile1

B

bertsmobile1

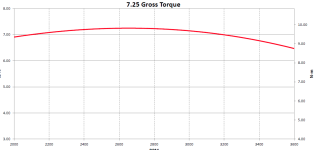

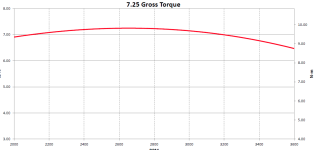

Governed engines usually run around 1000 rpm faster than peak torque

The reason for this is as the revs drop the torque increases to counter the load that is making the revs drop in the first place

So if that curve is the correct one for you engine then 2900 rpm is probably fine

What makes engine sound like they are running faster when they are not is a burned out muffler

The reason for this is as the revs drop the torque increases to counter the load that is making the revs drop in the first place

So if that curve is the correct one for you engine then 2900 rpm is probably fine

What makes engine sound like they are running faster when they are not is a burned out muffler

#10

kbowley

kbowley

The spec is 3100 to 3200 RPM's for a 21 or 22 walk behind. Those cone balancers are useless. Simply drive a large nail in the wall and wipe a bit of grease on it to balance. If it is a star hole, simply place a similar sized socket in the blade hole to balance. Balance is important on the long blades; even new blades are off many times. I simply grind a groove on the lift/back side of the blade to balance. I have a busy outdoor power equipment shop and use the this tool to balance. You simply can't beat one of these tachometers for small engines.

#11

G

GearHead36

It's definitely NOT running at 5800, so I'm pretty sure the tach is giving the right readings.

G

GearHead36

Is there a balancer out there that is better than the cones, but doesn't cost a fortune? I'm just a homeowner. I have several blades to maintain each year, but I don't have a need to balance hundreds of blades like a shop would, so I can't justify a top of the line balancer.Those cones usually has steps rings which poorly fit the blades so you could blade off center.

And hopefully the RPM meter is set to one count per revolution. But if the mower cuts well at 2900 rpm then just leave it at that. Usually you will have more Ft-Lb torque at the slower speed.

It's definitely NOT running at 5800, so I'm pretty sure the tach is giving the right readings.

#12

G

GearHead36

G

GearHead36

Doubtful on this engine. Yes, it's 13 yrs old, but it's never been stored outside. As far as I can remember, it's never even been rained on.What makes engine sound like they are running faster when they are not is a burned out muffler

#13

kbowley

kbowley

Sure is, drive a 3" nail straight into a stud leaving about 2" exposed, wipe a bit of grease on it and it is a far more accurate balancer. It sounds fast because you're used to having it so low. 3200 is ideal.Is there a balancer out there that is better than the cones, but doesn't cost a fortune? I'm just a homeowner. I have several blades to maintain each year, but I don't have a need to balance hundreds of blades like a shop would, so I can't justify a top of the line balancer.

It's definitely NOT running at 5800, so I'm pretty sure the tach is giving the right readings.

#14

G

GearHead36

G

GearHead36

Thanks for the balancer idea. The perception of high RPMs.... Yeah, I thought of that. The thing that causes me to think otherwise is the repair videos I watch. They all run the engines at about what mine is running now. 3200 is much faster than what those engines are running. Unless the video playback speed is off.Sure is, drive a 3" nail straight into a stud leaving about 2" exposed, wipe a bit of grease on it and it is a far more accurate balancer. It sounds fast because you're used to having it so low. 3200 is ideal.

#15

woodstover

woodstover

2800rpm looks to be the sweet spotThose cones usually has steps rings which poorly fit the blades so you could blade off center.

And hopefully the RPM meter is set to one count per revolution. But if the mower cuts well at 2900 rpm then just leave it at that. Usually you will have more Ft-Lb torque at the slower speed.

View attachment 68193

#16

kbowley

kbowley

My Pleasure. Not sure why you perceive 3200 as high, they are set from the factory between 3000 and 3200. The governor spring gets fatigued over time and may need an adjustment. I'm thinking once you get the blade balanced so that it runs smoothly you will get used to it. My only other thought is that your tach is giving you an incorrect reading. Watch this video beginning at 3:20 into it and have a listen as he sets it for 3200 RPMs. Here is another at the 13:00 minute mark.Thanks for the balancer idea. The perception of high RPMs.... Yeah, I thought of that. The thing that causes me to think otherwise is the repair videos I watch. They all run the engines at about what mine is running now. 3200 is much faster than what those engines are running. Unless the video playback speed is off.

#18

R

Rivets

R

Rivets

You might be going in the wrong direction. If the blade has not be changed, the back wing may be worn or gone. If that is the case, your cut will deteriorate very quickly. Second, Toro is picky about using their blades for best cut.

#19

G

GearHead36

G

GearHead36

Thanks for the video. His 2700 sounded a LOT like my 2750, so I'm pretty sure my tach is good.My Pleasure. Not sure why you perceive 3200 as high, they are set from the factory between 3000 and 3200. The governor spring gets fatigued over time and may need an adjustment. I'm thinking once you get the blade balanced so that it runs smoothly you will get used to it. My only other thought is that your tach is giving you an incorrect reading. Watch this video beginning at 3:20 into it and have a listen as he sets it for 3200 RPMs. Here is another at the 13:00 minute mark.

#20

G

GearHead36

G

GearHead36

A few years ago, I bought several Toro blades. I sharpen them a few times, but I swap them out for new when they get to looking too bad.You might be going in the wrong direction. If the blade has not be changed, the back wing may be worn or gone. If that is the case, your cut will deteriorate very quickly. Second, Toro is picky about using their blades for best cut.

#22

R

Rivets

R

Rivets

Is the thickness of the wing less than the blade thickness? If so that is part of the cut problem.

#23

S

slomo

S

slomo

3600 revs.

Best cutting/bagging /mulching, best cooling and best lubrication. End of message.

Best cutting/bagging /mulching, best cooling and best lubrication. End of message.

#24

woodstover

woodstover

Best way to cook your engine3600 revs.

Best cutting/bagging /mulching, best cooling and best lubrication. End of message.

#26

G

GearHead36

G

GearHead36

3600 RPM on a 22" blade results in a blade speed of 20735.3600 revs.

Best cutting/bagging /mulching, best cooling and best lubrication. End of message.

#28

S

slomo

S

slomo

Most pushers are 21" rated but not actually 21 or 22. They are say 20 and 3/4 or 7/8" for example. So slow down with the new buzz term of the day of blade tip speed. The grass police won't be by to arrest you.3600 RPM on a 22" blade results in a blade speed of 20735.\

#29

S

slomo

Follow your engine and or mower manuals for max revs.

S

slomo

All mine get cooked weekly. Still work like a new one. Matter of fact, this weekend, be doing some mo' cookin'.Best way to cook your engine

Follow your engine and or mower manuals for max revs.

#30

7394

7394

Yep, my antique B&S pusher is a 22" that the blade measures on the diagonal 22-5/8"Most pushers are 21" rated but not actually 21 or 22. They are say 20 and 3/4 or 7/8" for example.

#31

G

GearHead36

G

GearHead36

I'm not worried about the grass police. But I WOULD like my mower to work as designed. It's been a reliable workhorse over the years, but I've never been particularly satisfied with the cut quality.The grass police won't be by to arrest you.

#32

G

GearHead36

G

GearHead36

I still have my original paper mower and engine manuals, and they don't mention RPMs at all.Follow your engine and or mower manuals for max revs.

#33

C

*CPB*

www.allamericansharpener.com

www.allamericansharpener.com

C

*CPB*

Is there a balancer out there that is better than the cones, but doesn't cost a fortune? I'm just a homeowner. I have several blades to maintain each year, but I don't have a need to balance hundreds of blades like a shop would, so I can't justify a top of the line balancer.

It's definitely NOT running at 5800, so I'm pretty sure the tach is giving the right readings.

All American Mower Blade Balancer — All American Lawn Mower Blade Sharpener

Made in the USA, our mower blade balancer is a great combination of practical, functional, and simple. It works as a typical cone balancer, but with more precision. Our balancers are made with anodized aluminum and stainless steel. They are built to last a lifetime (just like our sharpeners). The bl

#34

D

Dwayne Oxford

..."can't beat one of these tachometers"...??

D

Dwayne Oxford

The spec is 3100 to 3200 RPM's for a 21 or 22 walk behind. Those cone balancers are useless. Simply drive a large nail in the wall and wipe a bit of grease on it to balance. If it is a star hole, simply place a similar sized socket in the blade hole to balance. Balance is important on the long blades; even new blades are off many times. I simply grind a groove on the lift/back side of the blade to balance. I have a busy outdoor power equipment shop and use the this tool to balance. You simply can't beat one of these tachometers for small engines.

..."can't beat one of these tachometers"...??

#35

thesilentone

thesilentone

You are chasing the holy grail.

Specification is one thing, regulation is another.

Despite a machine having an optimum design efficiency, it must also comply with a whole raft of regulation, such as hand arm vibration, noise and emissions.

In many cases, equipment leaves manufacturers set up to meet regulations as opposed to operate at optimum.

Specification is one thing, regulation is another.

Despite a machine having an optimum design efficiency, it must also comply with a whole raft of regulation, such as hand arm vibration, noise and emissions.

In many cases, equipment leaves manufacturers set up to meet regulations as opposed to operate at optimum.

#36

B

BTBO

B

BTBO

I too have a Magna-Matic blade balancer. It works like nothing else---very accurate. I have a ZTR and bought the MM thinking it was worth the price vs having to replace spindles prematurely.The spec is 3100 to 3200 RPM's for a 21 or 22 walk behind. Those cone balancers are useless. Simply drive a large nail in the wall and wipe a bit of grease on it to balance. If it is a star hole, simply place a similar sized socket in the blade hole to balance. Balance is important on the long blades; even new blades are off many times. I simply grind a groove on the lift/back side of the blade to balance. I have a busy outdoor power equipment shop and use the this tool to balance. You simply can't beat one of these tachometers for small engines.

#37

B

beeev

You can even check them for straight before wasting any time sharpening with the MM.

As far as the tachometer you bought, is it a quality piece or a Scamazon cheapie?

I would have trust issues on some knock offs.

When it comes to tools, get the best quality you can afford.

Buy once, cry once. The proven good stuff gives a lifetime of use/reliability imo.

B

beeev

Ditto here.I too have a Magna-Matic blade balancer. It works like nothing else---very accurate. I have a ZTR and bought the MM thinking it was worth the price vs having to replace spindles prematurely.

You can even check them for straight before wasting any time sharpening with the MM.

As far as the tachometer you bought, is it a quality piece or a Scamazon cheapie?

I would have trust issues on some knock offs.

When it comes to tools, get the best quality you can afford.

Buy once, cry once. The proven good stuff gives a lifetime of use/reliability imo.

#38

W

Wrenchit

A slightly bent crankshaft will cause vibration even with a perfectly balanced blade.

W

Wrenchit

The maximum torque achieved for your engine is between 2600 and 2800 RPM. It drops after that.I know that the blade tip speed is limited by ANSI to 19000 FPM. Which, on a 22" blade, equates to 3299RPM according to my calculator. I recently bought a tachometer, and found that my residential push mower, with a 22" blade, is running at 2750 RPM. So I started increasing it. When I got to 2950, it seemed like it was running really fast, and had a lot of vibration. So I backed it down to 2900, and the vibrations seem to get better. So my question is, of course, what speed should I set my engine to?

Engine: Briggs 128T05-5123-B.

Mower: 2011 Toro Recycler w/Personal Pace.

I still have the owner's manual and the engine manual. Neither mention engine RPM settings.

Not sure if this is the right forum, but the only other blade tip speed discussion I could find was in this forum.

A slightly bent crankshaft will cause vibration even with a perfectly balanced blade.

#39

G

GrumpyCat

G

GrumpyCat

I don't think HP/torque is the primary concern about RPM. In general the cut is better at higher speeds, so while the big deck of a rider has it's disadvantages the faster blade speed over a walk-behind has advantages.

#40

G

GrumpyCat

I like his "6" extension" balance technique.

G

GrumpyCat

Is it best to take the blade off before or after the Heineken?9:05 min

I like his "6" extension" balance technique.

#41

G

GearHead36

G

GearHead36

^ This. I think this is why my riders give a better cut than my walk behinds.I don't think HP/torque is the primary concern about RPM. In general the cut is better at higher speeds, so while the big deck of a rider has it's disadvantages the faster blade speed over a walk-behind has advantages.

#42

R

rdedrick

R

rdedrick

I watched three videos this guy did on balancing using an oscilloscope. I'm definitely going to try this one and maybe work my way up to a wheel balancer for my motorcycles.

www.youtube.com/watch?v=r6tFXC4Hk0I

www.youtube.com/watch?v=r6tFXC4Hk0I

#43

R

rachel11

R

rachel11

What brand tach are you using? I too feel like my mower is too slow. Can an old v8 tach from the 60s be used?I'm not worried about the grass police. But I WOULD like my mower to work as designed. It's been a reliable workhorse over the years, but I've never been particularly satisfied with the cut quality.

#44

R

rutbuster1

R

rutbuster1

This guy, Taryl Fixes All, and Chickanic are all good. Taryl cracks me up..........js9:05 min

#46

G

GearHead36

G

GearHead36

This one. I don't know about the v8 tach.What brand tach are you using? I too feel like my mower is too slow. Can an old v8 tach from the 60s be used?

#47

7394

7394

Good tach should have a place to select how many cylinders it is timing.(snip) . Can an old v8 tach from the 60s be used?

#48

T

TobyU

T

TobyU

You're going to get a whole lot of opinions on this, even more so than the correct way to sharpen a blade or whether new blades should be sharpened. LOL

I have done thousands of these mowers and I can tell you it's irrelevant what the spec is from the factory or what they claim they set them at because even out of the box they are so inconsistent it is absolutely pathetic.

It does no good to have a spec if you don't set things at spec.

Now a lot of the older guys are going to claim even higher speeds because a lot of these engines used to be rated at 3600 RPMs and you could even run them at that because the blades were shorter and if you go back far enough there were no legal requirements or maximum tip speeds.

The vast majority of these Toros come out of the box at 2880 or that's what my digital tach shows and what the last one showed too so maybe it's supposed to be 2850 or 2900 but my tach always gets stuck right at 2880. Lol

I said all the self-propelled ones at 2880 and I've also noticed that a lot of the cheaper push mowers come with a little bit higher RPMs so I tend to follow suit and put them right around 2950 to 3,000 or even 3050.

There's really little need to have these mowers at 3200 or faster because frankly, you're just wasting fuel and wearing out Parts a little bit more quickly and on a lot of them it makes the self-propelled kind of dragging you and trying to cut the grass too quickly.

Of course this varies when you have the personal pace versus the metal bail that you squeeze but you typically end up having to modulate the more manual style ones to keep the speed where you really want it to be of the drive and the cut.

Anything down around 2600 starts to become a little anemic.

I have found that 2880 works perfectly for the Toro 22-in self-propelled mowers.

If you're having a vibration issue then it's not the engine speed at all.

It either has a bent blade or likely it's had a blade strike and the crankshaft is slightly tweaked.

While it is true that normally a vibration is worse at higher speeds it's not always the case because of crazy harmonics and stuff we can't nearly comprehend, visualize or it really tests without equipment well beyond the scope any of us have.

Sometimes 200 RPMs one way or the other will make a noticeable difference and smoothness so play around with it some.

MORE importantly try to clock the blade one half turn around.

On most mowers you have the standard position and then you can rotate it 180° to do it in that position but some of the mowers with the Stars have five different positions you can put them on.

If someone would have told me before I start with my own eyes that rotating a blade 180° out or even one or two notches on a star pattern could make such a difference a vibration between daylight and dark I would have bet them $100 there's no way!

I would have lost $100!!

In fact I've shown a number of people this in person because it always astounds them..

It's not always the case but when conditions are just right and the crankshaft is tweaked in some certain way, a brand new blade, used one etc can be placed on one way and the vibrations can be so much you can barely stand to hold the handle but rotate the blade around 180° and no one could ever tell it had a blade strike or a bent or twisted crank.

So the takeaway from this is anytime you have a vibrating mower always try the blade in both or multiple positions to test it out to see which way is the smoothest.

Ask someone else missing, balancing on a nail stuck in the wall is more than you'll ever need to balance a lawn mower blade.

You are rarely get one that's severely out of balance and most the time they will hang level or maybe just two or three inches low on one side of the other or have a tendency to go down on one side which you can find tune by taking some metal off that side but when you actually get one that's out of balance soon as you put it on the nail one in will point straight to the ground!

All you have to do is basically get it in the center of the hole when you set the blade on the nail and then see where it goes.

It really isn't rocket science and this is quite accurate enough.

I have done thousands of these mowers and I can tell you it's irrelevant what the spec is from the factory or what they claim they set them at because even out of the box they are so inconsistent it is absolutely pathetic.

It does no good to have a spec if you don't set things at spec.

Now a lot of the older guys are going to claim even higher speeds because a lot of these engines used to be rated at 3600 RPMs and you could even run them at that because the blades were shorter and if you go back far enough there were no legal requirements or maximum tip speeds.

The vast majority of these Toros come out of the box at 2880 or that's what my digital tach shows and what the last one showed too so maybe it's supposed to be 2850 or 2900 but my tach always gets stuck right at 2880. Lol

I said all the self-propelled ones at 2880 and I've also noticed that a lot of the cheaper push mowers come with a little bit higher RPMs so I tend to follow suit and put them right around 2950 to 3,000 or even 3050.

There's really little need to have these mowers at 3200 or faster because frankly, you're just wasting fuel and wearing out Parts a little bit more quickly and on a lot of them it makes the self-propelled kind of dragging you and trying to cut the grass too quickly.

Of course this varies when you have the personal pace versus the metal bail that you squeeze but you typically end up having to modulate the more manual style ones to keep the speed where you really want it to be of the drive and the cut.

Anything down around 2600 starts to become a little anemic.

I have found that 2880 works perfectly for the Toro 22-in self-propelled mowers.

If you're having a vibration issue then it's not the engine speed at all.

It either has a bent blade or likely it's had a blade strike and the crankshaft is slightly tweaked.

While it is true that normally a vibration is worse at higher speeds it's not always the case because of crazy harmonics and stuff we can't nearly comprehend, visualize or it really tests without equipment well beyond the scope any of us have.

Sometimes 200 RPMs one way or the other will make a noticeable difference and smoothness so play around with it some.

MORE importantly try to clock the blade one half turn around.

On most mowers you have the standard position and then you can rotate it 180° to do it in that position but some of the mowers with the Stars have five different positions you can put them on.

If someone would have told me before I start with my own eyes that rotating a blade 180° out or even one or two notches on a star pattern could make such a difference a vibration between daylight and dark I would have bet them $100 there's no way!

I would have lost $100!!

In fact I've shown a number of people this in person because it always astounds them..

It's not always the case but when conditions are just right and the crankshaft is tweaked in some certain way, a brand new blade, used one etc can be placed on one way and the vibrations can be so much you can barely stand to hold the handle but rotate the blade around 180° and no one could ever tell it had a blade strike or a bent or twisted crank.

So the takeaway from this is anytime you have a vibrating mower always try the blade in both or multiple positions to test it out to see which way is the smoothest.

Ask someone else missing, balancing on a nail stuck in the wall is more than you'll ever need to balance a lawn mower blade.

You are rarely get one that's severely out of balance and most the time they will hang level or maybe just two or three inches low on one side of the other or have a tendency to go down on one side which you can find tune by taking some metal off that side but when you actually get one that's out of balance soon as you put it on the nail one in will point straight to the ground!

All you have to do is basically get it in the center of the hole when you set the blade on the nail and then see where it goes.

It really isn't rocket science and this is quite accurate enough.

#50

T

TobyU

Balancing a 22 inch lawn mower blade on a nail hanging in the wall is more than accurate enough for this type of equipment!!!

These mowers are used in often quite poor conditions and abused and the blades are very neglected.

They tend to be quite forgiving.

It's rare to find a lawn mower or at least there's a high percentage of them where when you rotate the blade around and Mark a spot on the deck and then rotate it around 180° to check, they are not lined up anyways.

This is often dude to slightly bent blades and also due to vent or ideally more accurately twisted crankshafts.

The reasons really don't matter but the current condition does.

My lawn mower blade can be quite out of balance and you still won't notice any increase vibrations on the handle but a crankshaft can be bent just a little bit to where it's barely visible which is far more bent than what a dial indicator would show you and it can vibrate like mad.

He can also have an extremely visible wobble and deflection from being perfectly straight, round, concentric, or whatever you want to call it in high tech engineering or machine shop terms... And it can be so smooth no one would ever tell there's any increased vibration on the handle.

It's not an exact science and there are some weird things that happen.

Regardless, if a blade is badly out of balance when you stick it on a nail the heavy end will turn and point straight to the ground..

Anything even close to hanging horizontally is fine for lawn mowers.

Worrying about anything else beyond this is simply applying some aspect of OCD to it, being pedantic, or making a mountain out of a molehill.

T

TobyU

You can tell yourself that, or think it, or tell as many people as you want but it won't be true.Trying to balance with a nail is as useless as not bothering at all

Balancing a 22 inch lawn mower blade on a nail hanging in the wall is more than accurate enough for this type of equipment!!!

These mowers are used in often quite poor conditions and abused and the blades are very neglected.

They tend to be quite forgiving.

It's rare to find a lawn mower or at least there's a high percentage of them where when you rotate the blade around and Mark a spot on the deck and then rotate it around 180° to check, they are not lined up anyways.

This is often dude to slightly bent blades and also due to vent or ideally more accurately twisted crankshafts.

The reasons really don't matter but the current condition does.

My lawn mower blade can be quite out of balance and you still won't notice any increase vibrations on the handle but a crankshaft can be bent just a little bit to where it's barely visible which is far more bent than what a dial indicator would show you and it can vibrate like mad.

He can also have an extremely visible wobble and deflection from being perfectly straight, round, concentric, or whatever you want to call it in high tech engineering or machine shop terms... And it can be so smooth no one would ever tell there's any increased vibration on the handle.

It's not an exact science and there are some weird things that happen.

Regardless, if a blade is badly out of balance when you stick it on a nail the heavy end will turn and point straight to the ground..

Anything even close to hanging horizontally is fine for lawn mowers.

Worrying about anything else beyond this is simply applying some aspect of OCD to it, being pedantic, or making a mountain out of a molehill.

#51

R

rachel11

R

rachel11

On inside of tach , it has settings for 4,6,8. I don't think they intended it for mowers . I just thought there might be a way to use it on 1 ot 2 cylinders.Good tach should have a place to select how many cylinders it is timing.

#52

R

rhkraft

R

rhkraft

High rpm's are hard on your engine. I have a 22inch push mower that runs slowly, maybe 2200 rpm, guessing. It cuts good, but the big plus is that I bought it new in 1990 and it is still running as good as it did 30 years ago. Of course I keep it in a shed and do annual maintenance. Keeping them out of the weather prevents most problems. I change the oil and air filter, but I never had to remove and clean the carburetor or gas tank. I did replace the rear wheels because I just wore them out. No engines are designed to run full boar all the time. As an example, my airplane has a 150 HP engine with a 7653 propeller, 76 is the diameter in inches and the 53 is inches of pitch. This means in level flight in standard conditions at 2500 rpm, the airplane moves forward 53 inches for each revolution of the prop, or 125 mph. You can do the math. The point I am making is that we firewall the engine for take-off and initial climb to clear obstacles, about 2600-2700 rpm, but as soon as the airplane clears the trees or buildings, we throttle back to 2500 rpm, normal cruise, as described by the manufacturer. Excess speed increases engine wear.

#53

7394

As to the wheels, of course all 4 of mine wore out. But I bored them plastic rims out to take bushings I made & installed.. No more cheap wheels situation.

7394

Cool, my 18 year old B&S Flathead 22" pusher still runs fine as well. I keep the blade sharp & it cuts beautifully.I did replace the rear wheels because I just wore them out.

As to the wheels, of course all 4 of mine wore out. But I bored them plastic rims out to take bushings I made & installed.. No more cheap wheels situation.

#54

G

GearHead36

G

GearHead36

True, but... these engines are typically rated at 3600 RPMs. I used to race go-karts. We ran horizontal shaft 5HP Briggs flatheads. The governors were removed, and the stock class engines ran considerably more than 3600 RPMs. If I had to guess, I'd say around 4500RPM. But I WILL admit, running an engine like that probably wouldn't allow it to last for decades. Point is, 3200 RPM is not overstressing the engine. Will it last longer at 2200 RPM? Probably. But then again, how many of these engines die from wearing out? Almost none. They usually die from abuse and/or lack of maintenance. I watch small engine repair videos, and when a dead engine is encountered, if it's a residential engine that had been used in a residential application, it almost always died from abuse/lack of maintenance. If it's a commercial engine that had been used commercially, it could go either way. It COULD have died from wear, but it's just as likely to have died from abuse/lack of maintenance. My main riding mower is commercial that had been subjected to abuse and lack of maintenance. It had 360 hrs on it when I got it, and I'm surprised it lasted that long. I found that the cooling fins were completely blocked. I don't see how the engine didn't self destruct. There were also several broken items on it as well.High rpm's are hard on your engine. <snip> Excess speed increases engine wear.

#55

E

Earthquake Landscaping

E

Earthquake Landscaping

This is Rumour Control...

These are the facts..

Some great posts, especially from "Toby U"..

To me, the worst thing is that a lot of newer mowers are running at reduced R.P.M., due to trying to meet emission standards. Bluntly, they don't cut well.. at all. I've had a few in where all I've done is set the governor to a higher R.P.M., and suddenly, they were cutting well, throwing the clippings properly ( either out the side chute, or into the collecting bag). Only downside to that, was that if they were self propelled ( one speed ), was that they now went significantly faster ..

..

As far as blade tip speed is concerned, a touch over isn't the end of the world. It's not like the blade will self destruct at a couple of hundred FPS over ANSI rating. It's like a ratchet strap tie down.. There's a difference between working load and bursting load.

Realistically, there really shouldn't be a significant increase in vibration between 2,500 R.P.M., and 3,600 R.P.M. A significant difference in vibration, points to a separate issue.. out of balance blade, bent output shaft, etc. It's like having an out of balance tire.. It may shake the car at 50 M.P.H., but not at 60 M.P.H., and then shake again at 70. It's called (IIRC), sympathetic, or harmonic vibration.

If you can't find the reason for the vibration, then just tune for the sweet spot, and be done with it.

Is it smooth.. does it cut and bag well? Walk away from the nuclear device.

These are the facts..

Some great posts, especially from "Toby U"..

To me, the worst thing is that a lot of newer mowers are running at reduced R.P.M., due to trying to meet emission standards. Bluntly, they don't cut well.. at all. I've had a few in where all I've done is set the governor to a higher R.P.M., and suddenly, they were cutting well, throwing the clippings properly ( either out the side chute, or into the collecting bag). Only downside to that, was that if they were self propelled ( one speed ), was that they now went significantly faster

As far as blade tip speed is concerned, a touch over isn't the end of the world. It's not like the blade will self destruct at a couple of hundred FPS over ANSI rating. It's like a ratchet strap tie down.. There's a difference between working load and bursting load.

Realistically, there really shouldn't be a significant increase in vibration between 2,500 R.P.M., and 3,600 R.P.M. A significant difference in vibration, points to a separate issue.. out of balance blade, bent output shaft, etc. It's like having an out of balance tire.. It may shake the car at 50 M.P.H., but not at 60 M.P.H., and then shake again at 70. It's called (IIRC), sympathetic, or harmonic vibration.

If you can't find the reason for the vibration, then just tune for the sweet spot, and be done with it.

Is it smooth.. does it cut and bag well? Walk away from the nuclear device.

#56

BWH

BWH

I've used the Magna-Matic balancer for over 10 years, looking back at the price it seems like a very reasonable piece of equipment today. I also have the Magna-Matic sharpener it's great and just doing a couple dozen blades around the neighborhood eventually pays me back.Ditto here.

You can even check them for straight before wasting any time sharpening with the MM.

As far as the tachometer you bought, is it a quality piece or a Scamazon cheapie?

I would have trust issues on some knock offs.

When it comes to tools, get the best quality you can afford.

Buy once, cry once. The proven good stuff gives a lifetime of use/reliability imo.

#57

B

bertsmobile1

Now I have zero idea if mower engines are actually balanced at all being that modern production tollerances are such that they probably can run without dynamic balancing.

I ride single cylinder motorcycles and we go to great lengths to get a nicely balanced engine around maximum torque then we gear the bike to have it running at those revs when riding at the usual road speeds .

B

bertsmobile1

The one thing you re missing is engine balance factorThis is Rumour Control...

These are the facts..

Some great posts, especially from "Toby U"..

To me, the worst thing is that a lot of newer mowers are running at reduced R.P.M., due to trying to meet emission standards. Bluntly, they don't cut well.. at all. I've had a few in where all I've done is set the governor to a higher R.P.M., and suddenly, they were cutting well, throwing the clippings properly ( either out the side chute, or into the collecting bag). Only downside to that, was that if they were self propelled ( one speed ), was that they now went significantly faster..

As far as blade tip speed is concerned, a touch over isn't the end of the world. It's not like the blade will self destruct at a couple of hundred FPS over ANSI rating. It's like a ratchet strap tie down.. There's a difference between working load and bursting load.

Realistically, there really shouldn't be a significant increase in vibration between 2,500 R.P.M., and 3,600 R.P.M. A significant difference in vibration, points to a separate issue.. out of balance blade, bent output shaft, etc. It's like having an out of balance tire.. It may shake the car at 50 M.P.H., but not at 60 M.P.H., and then shake again at 70. It's called (IIRC), sympathetic, or harmonic vibration.

If you can't find the reason for the vibration, then just tune for the sweet spot, and be done with it.

Is it smooth.. does it cut and bag well? Walk away from the nuclear device.

Now I have zero idea if mower engines are actually balanced at all being that modern production tollerances are such that they probably can run without dynamic balancing.

I ride single cylinder motorcycles and we go to great lengths to get a nicely balanced engine around maximum torque then we gear the bike to have it running at those revs when riding at the usual road speeds .

#58

S

sessman55

S

sessman55

I’ve set 22” blades at 3080 and 21” at 3140. Good torque and stays under the sound barrier.I know that the blade tip speed is limited by ANSI to 19000 FPM. Which, on a 22" blade, equates to 3299RPM according to my calculator. I recently bought a tachometer, and found that my residential push mower, with a 22" blade, is running at 2750 RPM. So I started increasing it. When I got to 2950, it seemed like it was running really fast, and had a lot of vibration. So I backed it down to 2900, and the vibrations seem to get better. So my question is, of course, what speed should I set my engine to?

Engine: Briggs 128T05-5123-B.

Mower: 2011 Toro Recycler w/Personal Pace.

I still have the owner's manual and the engine manual. Neither mention engine RPM settings.

Not sure if this is the right forum, but the only other blade tip speed discussion I could find was in this forum.

#59

S

Sue sharpener

S

Sue sharpener

You can check the engine manufacturer website. Briggs & Stratton or Techumseh has that information.I know that the blade tip speed is limited by ANSI to 19000 FPM. Which, on a 22" blade, equates to 3299RPM according to my calculator. I recently bought a tachometer, and found that my residential push mower, with a 22" blade, is running at 2750 RPM. So I started increasing it. When I got to 2950, it seemed like it was running really fast, and had a lot of vibration. So I backed it down to 2900, and the vibrations seem to get better. So my question is, of course, what speed should I set my engine to?

Engine: Briggs 128T05-5123-B.

Mower: 2011 Toro Recycler w/Personal Pace.

I still have the owner's manual and the engine manual. Neither mention engine RPM settings.

Not sure if this is the right forum, but the only other blade tip speed discussion I could find was in this forum.

#60

Y

ybor

Y

ybor

I did a lot of work in the 80's on how to cut grass efficiently. I was working on corded and cordless mowers for a large power tool and electric outdoor products company. You are correct on the 19000 FPM for max speed. We also found that dropping below 14000 FPM resulted in very poor cutting, more knocking the grass down rather than actually cutting it. As many have stated, blade sharpness and lift (suction) is also critical. Adding a little rake angle into the design also resulted in less power consumption on cordless units. Rake angle ensures the blade is slightly lower in the front of the deck versus the rear of the deck. On a push unit, this might mean setting the rear deck wheels for a slightly higher cut than the front wheels.I know that the blade tip speed is limited by ANSI to 19000 FPM. Which, on a 22" blade, equates to 3299RPM according to my calculator. I recently bought a tachometer, and found that my residential push mower, with a 22" blade, is running at 2750 RPM. So I started increasing it. When I got to 2950, it seemed like it was running really fast, and had a lot of vibration. So I backed it down to 2900, and the vibrations seem to get better. So my question is, of course, what speed should I set my engine to?

Engine: Briggs 128T05-5123-B.

Mower: 2011 Toro Recycler w/Personal Pace.

I still have the owner's manual and the engine manual. Neither mention engine RPM settings.

Not sure if this is the right forum, but the only other blade tip speed discussion I could find was in this forum.

#61

jekjr

jekjr

I see this discussion in numerous places. I am retired now but ran a lawn service for years. We ran Scag Tiger Cat mowers with Kawasaki engines on them primarily. When I stared cutting back on my business a few years before I completely retired I had four. I always had them set up to run 3600 RPM. I have seen them run 3500 hours plus and still be going strong running at that RPM. Set up correctly they would cut 14 day Bahia Grass all day long week in and week out. Over the years I noticed a few RPM drop would change the cut quality severely. I understand there is much debate on it but 99% of those who say differently never cut 14 day Bahia Grass.I know that the blade tip speed is limited by ANSI to 19000 FPM. Which, on a 22" blade, equates to 3299RPM according to my calculator. I recently bought a tachometer, and found that my residential push mower, with a 22" blade, is running at 2750 RPM. So I started increasing it. When I got to 2950, it seemed like it was running really fast, and had a lot of vibration. So I backed it down to 2900, and the vibrations seem to get better. So my question is, of course, what speed should I set my engine to?

Engine: Briggs 128T05-5123-B.

Mower: 2011 Toro Recycler w/Personal Pace.

I still have the owner's manual and the engine manual. Neither mention engine RPM settings.

Not sure if this is the right forum, but the only other blade tip speed discussion I could find was in this forum.

#62

G

GearHead36

G

GearHead36

I thought I'd follow up on this. I did a little more troubleshooting with my cheap cone balancer, and found that it has too much play, and can't be relied on for accurate balancing. So that leaves the Oregon and its clones, or taking my blades to a shop. Years ago, I took some blades to a "shop", which was someone's house that always had 10 or so mowers out front. He sharpened the blades, but didn't balance them. When I asked, he said that he took the same amount off each side, so they would still be balanced. Ok, Einstein... how do you know that they started out balanced? So I can't depend on someone like that for well balanced blades. And given discussions here like "My Friend got ripped off by the Dealer", I don't feel I can trust a dealer either. So if I want well balanced blades, it's up to me. The clones are hit and miss, even within the same mfr. I figured that if I balanced my blade with a clone, and the mower still vibrated, I'd suspect the balancer, and would wind up buying an Oregon anyway. So I bought the Oregon. I balanced my 22" blade, set the RPMs to 3200, and it's perfectly smooth. Well, as smooth as you'd expect from a mower engine. No excessive vibrations.

#63

ILENGINE

ILENGINE

You would be surprised by the number of repair shops that don't clean blades prior to sharpening or even own a blade balancer.I thought I'd follow up on this. I did a little more troubleshooting with my cheap cone balancer, and found that it has too much play, and can't be relied on for accurate balancing. So that leaves the Oregon and its clones, or taking my blades to a shop. Years ago, I took some blades to a "shop", which was someone's house that always had 10 or so mowers out front. He sharpened the blades, but didn't balance them. When I asked, he said that he took the same amount off each side, so they would still be balanced. Ok, Einstein... how do you know that they started out balanced? So I can't depend on someone like that for well balanced blades. And given discussions here like "My Friend got ripped off by the Dealer", I don't feel I can trust a dealer either. So if I want well balanced blades, it's up to me. The clones are hit and miss, even within the same mfr. I figured that if I balanced my blade with a clone, and the mower still vibrated, I'd suspect the balancer, and would wind up buying an Oregon anyway. So I bought the Oregon. I balanced my 22" blade, set the RPMs to 3200, and it's perfectly smooth. Well, as smooth as you'd expect from a mower engine. No excessive vibrations.

#64

G

GearHead36

G

GearHead36

After what I've read here... I'm not sure I'd be surprised.You would be surprised by the number of repair shops that don't clean blades prior to sharpening or even own a blade balancer.

#65

B

bertsmobile1

So an engine designed to run at 2750 will be balanced at 2750

But when it gets to 3600 the tiny bit out of balance at 2750 can become so chronic that the mower moves sideways

There is no such thing as an engine that is dynamically balance over the entire rev range unless it has a countershaft with a variable revolution rate .

I play with vintage motorcycles and when they were made, balance was very much trial & error off slide rule calculations .

Now days it is calculated to a very precise range and manufacturing tolerances are tight enough to keep vibrations to a minimum

B

bertsmobile1

When an engine is made it has a balance rpm range designed into it .I see this discussion in numerous places. I am retired now but ran a lawn service for years. We ran Scag Tiger Cat mowers with Kawasaki engines on them primarily. When I stared cutting back on my business a few years before I completely retired I had four. I always had them set up to run 3600 RPM. I have seen them run 3500 hours plus and still be going strong running at that RPM. Set up correctly they would cut 14 day Bahia Grass all day long week in and week out. Over the years I noticed a few RPM drop would change the cut quality severely. I understand there is much debate on it but 99% of those who say differently never cut 14 day Bahia Grass.

So an engine designed to run at 2750 will be balanced at 2750

But when it gets to 3600 the tiny bit out of balance at 2750 can become so chronic that the mower moves sideways

There is no such thing as an engine that is dynamically balance over the entire rev range unless it has a countershaft with a variable revolution rate .

I play with vintage motorcycles and when they were made, balance was very much trial & error off slide rule calculations .

Now days it is calculated to a very precise range and manufacturing tolerances are tight enough to keep vibrations to a minimum

#66

G

GearHead36

G

GearHead36

Where is that in the spec sheet? I've never seen such a spec. The ANSI blade tip speed limit for a 22" blade puts the engine RPMs at 3299, so the optimum RPMs IMO should be near that.When an engine is made it has a balance rpm range designed into it .

So an engine designed to run at 2750 will be balanced at 2750