You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Personal SRX75

#1

Scrubcadet10

Scrubcadet10

Put a new starter on my SRX75 today. A new solenoid as well. https://www.dbelectrical.com/produc...5-rx75-srx75-sx75-130-lawn-mower-snd0006.html

I used a DB electrical starter, and this is the first time i've had to modify one of their starters to fit. It appears the mounting holes in the starter weren't drilled straight, it'd go about half way, or a little less, on and stop.... tried the old original Denso starter, and it slid right on and off.

After making sure there were no other physical obstructions, if you looked straight down at the starter, you could tell the stud hole was angling right, while the stud (Which is straight) appeared to angle to the left,.. i knew it had to be a manufacturing defect, of some sort. Any way, i resolved the issue by using a 23/64 drill bit to drill out one mounting hole and then it slid right on. Snug with very little slop. Bolted it down, then when putting the starter solenoid back on, i somehow managed to pinch the webbing between my thumb and pointer finger with my U-Joint socket adapter.... no clue how i did it, but it hurt for a few seconds. And SOMEHOW when i was mounting the starter, i managed to crimp the batt + wire ring connector for the starter and broke it, luckily i was able to put a new end on without losing any length, got it heatshrinked and taped up.

Anyway, it cranked right up, and now i get on to replacing the spindle bearings..

I used a DB electrical starter, and this is the first time i've had to modify one of their starters to fit. It appears the mounting holes in the starter weren't drilled straight, it'd go about half way, or a little less, on and stop.... tried the old original Denso starter, and it slid right on and off.

After making sure there were no other physical obstructions, if you looked straight down at the starter, you could tell the stud hole was angling right, while the stud (Which is straight) appeared to angle to the left,.. i knew it had to be a manufacturing defect, of some sort. Any way, i resolved the issue by using a 23/64 drill bit to drill out one mounting hole and then it slid right on. Snug with very little slop. Bolted it down, then when putting the starter solenoid back on, i somehow managed to pinch the webbing between my thumb and pointer finger with my U-Joint socket adapter.... no clue how i did it, but it hurt for a few seconds. And SOMEHOW when i was mounting the starter, i managed to crimp the batt + wire ring connector for the starter and broke it, luckily i was able to put a new end on without losing any length, got it heatshrinked and taped up.

Anyway, it cranked right up, and now i get on to replacing the spindle bearings..

#2

bkeller500

bkeller500

Sounds like a fun project ( especially when you get good results ) . It's funny how one thing always leads to another but over time you gather enough skills and wisdom to tackle those unexpected challenges. Good luck on those spindle bearings. Are you just replacing the upper and lower bearings or the whole spindle?

#3

Scrubcadet10

Scrubcadet10

Upper and LowerSounds like a fun project ( especially when you get good results ) . It's funny how one thing always leads to another but over time you gather enough skills and wisdom to tackle those unexpected challenges. Good luck on those spindle bearings. Are you just replacing the upper and lower bearings or the whole spindle?

#4

bkeller500

bkeller500

I read on these forums that you need to use a name brand bearing ( not Chinese if you can help it ) and that if you purchase a sealed bearing you can remove the seals so the bearings can be lubricated as you add grease to the spindles thru the grease Zerks ongoing. Am I correct?Upper and Lower

#5

Scrubcadet10

Scrubcadet10

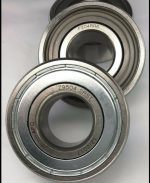

I purchased 2 PGN bearings... I usually remove the seals and pack with high temp Wheel bearing grease

#6

Scrubcadet10

Scrubcadet10

anyone know the number of the Spindle bearings, apparently 62042RS aren't them... i don't feel like waiting a week for the JD dealership to get them, but i may have to.

Part Number

JD9296

Part Number

JD9296

#7

StarTech

StarTech

JD9296 > Z9504RST

You could buy some from Carnell for 3.99 ea as they fit the follow:

APPLICATION:

Allis-Chalmers #536986

Ariens #54120

Bolens #1185828

John Deere #JD9296

Rotary #09-484

Simplicity #108202

Snapper 13313

Yazoo #204-060

Lilliston: 20-50-094

Swapper: 10696

IHC: 465003R91

I usually buy them in lots of 10 or 25 depends how they are flying off the shelf. I current have 14 of them in inventory.

| Height | 19/32"/ 15.494mm |

| Inside Diameter | 3/4"/ 19.05mm |

| Outside Diameter | 1-25/32"/ 45.225mm |

You could buy some from Carnell for 3.99 ea as they fit the follow:

APPLICATION:

Allis-Chalmers #536986

Ariens #54120

Bolens #1185828

John Deere #JD9296

Rotary #09-484

Simplicity #108202

Snapper 13313

Yazoo #204-060

Lilliston: 20-50-094

Swapper: 10696

IHC: 465003R91

I usually buy them in lots of 10 or 25 depends how they are flying off the shelf. I current have 14 of them in inventory.

#9

Scrubcadet10

Scrubcadet10

Thanks to star, i got the correct bearings in today... then put them in the freezer for a little while and they pushed right in, of course i start putting the shaft in and then forget, the bottom bearing is sandwiched by 2 spiral circlips so i forgot to put the last clip in, can't do that with the shaft in... well.. you could but, it risks bloodying the knuckles and gouging the fingers pretty badly.

That's my biggest problem, i always get about 2 steps ahead of myself.

That's my biggest problem, i always get about 2 steps ahead of myself.

#10

B

bertsmobile1

B

bertsmobile1

Regularly have to assemble engines that I did not pull apart .

Simple solution is to lay out the parts in reverse order before you start

That way it becomes obvious what tools will be needed and you don't end up forgetting the internal bits like locating rings or spacers

Or in my case get 1/2 way through & realize you have lost some of the fasteners .

Simple solution is to lay out the parts in reverse order before you start

That way it becomes obvious what tools will be needed and you don't end up forgetting the internal bits like locating rings or spacers

Or in my case get 1/2 way through & realize you have lost some of the fasteners .

#11

StarTech

StarTech

Hmmm Good to know about the clips, I was thinking they were snap rings.

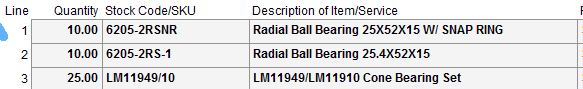

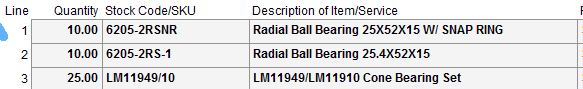

I just got in 6205-2RS-1 bearings I ordered. I was surprised how fast the PO office got them from Memphis,Tn PO this morning to my Lincoln County mailbox in a matter of an hour. Boy is their tracking screwed up. But at least it didn't three weeks like the last time.

The is only $171.16 in bearings only and it wont take long to use them up. I was out of all them except the Lm11949/10 which I was down to only 5 sets.

Boy am I covered up in work. The warm weather brought out equipment from storage over the Winter months. Now if it would just stop raining everytime I turn around. I got a rain free day today but rain is already on the radar for tonight, tomorrow and Wednesday. Oh time to put away the parts I just got and order some more commercial storage boxes.At least their size and shapes dont change like the ones that I started using from the Dollar Store back in 2009. Got to keep the mice at bay. Using milk crates for the bearings.

And now Bert don't you have many coffee cans full of all those spare screws? I went to work as a copier repair tech and the previous tech had dozens of cans full of screws he never bother to put back.

I just got in 6205-2RS-1 bearings I ordered. I was surprised how fast the PO office got them from Memphis,Tn PO this morning to my Lincoln County mailbox in a matter of an hour. Boy is their tracking screwed up. But at least it didn't three weeks like the last time.

The is only $171.16 in bearings only and it wont take long to use them up. I was out of all them except the Lm11949/10 which I was down to only 5 sets.

Boy am I covered up in work. The warm weather brought out equipment from storage over the Winter months. Now if it would just stop raining everytime I turn around. I got a rain free day today but rain is already on the radar for tonight, tomorrow and Wednesday. Oh time to put away the parts I just got and order some more commercial storage boxes.At least their size and shapes dont change like the ones that I started using from the Dollar Store back in 2009. Got to keep the mice at bay. Using milk crates for the bearings.

And now Bert don't you have many coffee cans full of all those spare screws? I went to work as a copier repair tech and the previous tech had dozens of cans full of screws he never bother to put back.

#12

Scrubcadet10

Scrubcadet10

#14

B

bertsmobile1

I have little cabinet draws full of B & S fasteners, another with Stihl ones etc etc

Usually found when I change the solvent in the parts washer or behind the parts washer which is outside the workshop

I got a 5 gallon bin full of this sort of stuff so I sat down with a thread gauge and lots of plastic peanut butter jars ( no glass in my workshop )

First sort by thread type & size , and remember we have BSW & BSF to deal with along with unified & metric

Most of those have stayed that way till I need a particular bolt so I will sort through the sorted by size jar and remove all of that bolt as I now know where it came from so it goes into the makers specific drawers .

Same story when I wreck stuff I will have 2 bins for say an MTD mower, one for the MTD bolts & another for the engine makers bolts .

I try do the same for springs & other stuff .

B

bertsmobile1

NoAnd now Bert don't you have many coffee cans full of all those spare screws? I went to work as a copier repair tech and the previous tech had dozens of cans full of screws he never bother to put back.

I have little cabinet draws full of B & S fasteners, another with Stihl ones etc etc

Usually found when I change the solvent in the parts washer or behind the parts washer which is outside the workshop

I got a 5 gallon bin full of this sort of stuff so I sat down with a thread gauge and lots of plastic peanut butter jars ( no glass in my workshop )

First sort by thread type & size , and remember we have BSW & BSF to deal with along with unified & metric

Most of those have stayed that way till I need a particular bolt so I will sort through the sorted by size jar and remove all of that bolt as I now know where it came from so it goes into the makers specific drawers .

Same story when I wreck stuff I will have 2 bins for say an MTD mower, one for the MTD bolts & another for the engine makers bolts .

I try do the same for springs & other stuff .

#15

StarTech

StarTech

Don't you just like all the threads types. Seesh can't everyone just use the same system. I reckon they do it just to be pain and so they can sell more tools. Luckily I only normally deal with SAE and metric screws here and rarely a British screw size.

I just found this year that the Kawasaki engines are using an oil pressure unit that use 1/8 BSPT threads. Our normal pipe threads in the 1/8 size is 27 tpi and the British 1/8 is 28 tpi and slightly smaller.

And yes I have a couple drawers of reclaim fasteners myself. I usually get them as I part out mowers and other things.

I just found this year that the Kawasaki engines are using an oil pressure unit that use 1/8 BSPT threads. Our normal pipe threads in the 1/8 size is 27 tpi and the British 1/8 is 28 tpi and slightly smaller.

And yes I have a couple drawers of reclaim fasteners myself. I usually get them as I part out mowers and other things.

#18

B

bertsmobile1

B

bertsmobile1

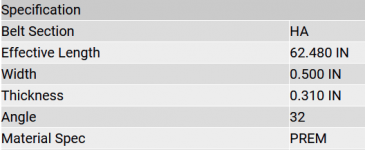

The 266 belt is supposed to be an exact replacement

The 248 belts are just wrapped kevlar belts in standard lengths

When the tension is applied via a spring there is some lattitude with the belt lengths

In most cases +/- a little works fine

As pulleys wear I often fit a smaller belt to compensate for the smaller effective pulley diameters .

Back when engineers were real engineers things like decks would be designed to take a standard common belt

All of the local Australian ride ones use plain polly belts in whole inch sizes .

Belt makers have plug in design application so you plug in the pulley size, torsional load & centres & the app spits out the belt length

Thus you get a 201 23/64" belt when in reality the 1 & 23/64" is total rubbish and only true when the deck pulleys are in line with the engine pulley .

Almost nothing I regularly work on has original size belts because I usually either fit a smaller one as above or an alernative belt that is substantially cheaper

When you get to ZTR belts which are all well over 100" +1" to -2" makes no difference , particularly if the tension spring is adjustable .

So for instance the deck belt on a Dixon Ram 60" is $ 278 .

Replace the eye bolt and you can fit a 2" shorter belt for $ 110 or a longer belt for $ 105

One customer changed to 7/8 standard belts on his which are $ 40 each

They last 3 to 4 years against the kevlar belts which are good for 3 to 5 years but at that price he does not care if they need replacing every year

They do wear the pulleys more though .

The 248 belts are just wrapped kevlar belts in standard lengths

When the tension is applied via a spring there is some lattitude with the belt lengths

In most cases +/- a little works fine

As pulleys wear I often fit a smaller belt to compensate for the smaller effective pulley diameters .

Back when engineers were real engineers things like decks would be designed to take a standard common belt

All of the local Australian ride ones use plain polly belts in whole inch sizes .

Belt makers have plug in design application so you plug in the pulley size, torsional load & centres & the app spits out the belt length

Thus you get a 201 23/64" belt when in reality the 1 & 23/64" is total rubbish and only true when the deck pulleys are in line with the engine pulley .

Almost nothing I regularly work on has original size belts because I usually either fit a smaller one as above or an alernative belt that is substantially cheaper

When you get to ZTR belts which are all well over 100" +1" to -2" makes no difference , particularly if the tension spring is adjustable .

So for instance the deck belt on a Dixon Ram 60" is $ 278 .

Replace the eye bolt and you can fit a 2" shorter belt for $ 110 or a longer belt for $ 105

One customer changed to 7/8 standard belts on his which are $ 40 each

They last 3 to 4 years against the kevlar belts which are good for 3 to 5 years but at that price he does not care if they need replacing every year

They do wear the pulleys more though .

#19

StarTech

StarTech

I have differ on that Bert. I had a JD 737 the needed a new mule belt. I got in what was supposedly the right length belt in an after market belt. I could not it on. I measured it and it was nearly 3/4 shorter than the JD belt. I went and got the JD belt which measure as spec'd and it barely went on.

Plus on especially MTD CVT systems you better have the OEM belt as the after markets belts just don't work.

I finally had to get a belt measurer that can handle up to 200" belts as so many of the after markets are either too short or too long. I had so much trouble with A&I belts coming in 1-2" short I just gave up on them. They are very good belts but I can't fit them properly they are of no use. I actually got rid of a $1000 of them from my inventory because of this. I had regional sales rep to come out last and ask me why I quit buying the belts and I explained to him the problems. When a small shop like stops buying a $2000 in belts each year it does get their attention; although, they still haven't resolved the problem as he said no other shop is complaining about the belts.

Plus on especially MTD CVT systems you better have the OEM belt as the after markets belts just don't work.

I finally had to get a belt measurer that can handle up to 200" belts as so many of the after markets are either too short or too long. I had so much trouble with A&I belts coming in 1-2" short I just gave up on them. They are very good belts but I can't fit them properly they are of no use. I actually got rid of a $1000 of them from my inventory because of this. I had regional sales rep to come out last and ask me why I quit buying the belts and I explained to him the problems. When a small shop like stops buying a $2000 in belts each year it does get their attention; although, they still haven't resolved the problem as he said no other shop is complaining about the belts.

#20

B

bertsmobile1

B

bertsmobile1

There are some cases where the OEM or OEM Spec belt is essential but that is not the norm .

It is a bit different over there where you don't get stung $ 200 for a hydro belt for one model then find one 1/2" shorter for $ 75 .

It took a long time for me to come to grips with mower belts but now i have it has made a big difference to my bottom line & my customers running costs .

It is a bit different over there where you don't get stung $ 200 for a hydro belt for one model then find one 1/2" shorter for $ 75 .

It took a long time for me to come to grips with mower belts but now i have it has made a big difference to my bottom line & my customers running costs .

#21

StarTech

StarTech

Yes there can be big price differences. What I just wish is for stated sizes of after market be the actual size of the belt being sent. You probably know as well I do different specs can affect the fit and sizing. Yes I do have a few model here that uses a size smaller belt that the spec'd belts. And of course my personal MTD mower is running a 5/8 deck as I just kept burning up the 1/2 belt due the grass I cut and the larger engine that is on it. I actually running a Husqvarna sized belt on it.

At one time I used a lot A&I as they were the size they stated on the belt sleeve but that no longer the case. I had to change many customer installed A&I belts because of this. I also had problems with Stens belts, not a lot, but still every once a while I get that is long than the stated size which of course causes problems. I can trust more than A&I. It seems so far the PIX belts are what they say they are size wise.

MTD products is the exception as they use odd belts and you general have to use their belts especially when it come to drive belts.

Oh well off to the bank with all the millions I made last week of repairs.? Barely enough to even pay the bills.

At one time I used a lot A&I as they were the size they stated on the belt sleeve but that no longer the case. I had to change many customer installed A&I belts because of this. I also had problems with Stens belts, not a lot, but still every once a while I get that is long than the stated size which of course causes problems. I can trust more than A&I. It seems so far the PIX belts are what they say they are size wise.

MTD products is the exception as they use odd belts and you general have to use their belts especially when it come to drive belts.

Oh well off to the bank with all the millions I made last week of repairs.? Barely enough to even pay the bills.

#22

Scrubcadet10

Scrubcadet10

Placed an order on JD website for the belt at about 9:00 this morning and 20 minutes later the local dealer called and said it was ready for pickup.

#23

Scrubcadet10

Scrubcadet10

Got the belt on... trick is to route around the spindle then the idlers.

Fired it up, tested it out for about 1 minute and it wanted to die... under load.. wouldn't run great at full throttle, idle, it was okay, found the fuel line coming out of the tank (it goes from 3/8" i.d. to 1/4" i.d.) the 3/8" piece has definitely seen better days and is collapsing.

Fired it up, tested it out for about 1 minute and it wanted to die... under load.. wouldn't run great at full throttle, idle, it was okay, found the fuel line coming out of the tank (it goes from 3/8" i.d. to 1/4" i.d.) the 3/8" piece has definitely seen better days and is collapsing.

#24

S

SamB

S

SamB

Quoting the wonderful Roseanne Roseannadanna:..."It just goes to show you,It's always something!"Got the belt on... trick is to route around the spindle then the idlers.

Fired it up, tested it out for about 1 minute and it wanted to die... under load.. wouldn't run great at full throttle, idle, it was okay, found the fuel line coming out of the tank (it goes from 3/8" i.d. to 1/4" i.d.) the 3/8" piece has definitely seen better days and is collapsing.

#25

Scrubcadet10

Scrubcadet10

New 3/8" fuel line and she's ready for the spring/summer now.

The bad part about working on other peoples stuff, i tend to neglect my own equipment of preventative care.

The bad part about working on other peoples stuff, i tend to neglect my own equipment of preventative care.

#26

StarTech

StarTech

I think most of us mechanic are usually guilty of that. I always fixing others equipment and having to patch up mine until I can get spare time to do the job right. Right now I patched up my rear differential in my truck until I can get around to replacing the planetary and satellite gears along with RH axle and bearings. It drivable but I don't like it as I know what is wrong with it. The damage was found when I was repairing an axle seal leak.

Just more cost than I have money to fix right now but in the Summer I will get it done when I have the spare change. It one those things running a seasonal business. This year's budget is already in the red quite bit until the repairs are completed and I get paid. It kinda strange to my books showing just a small negative figure but is how I account for part purchases. They not wrote off until parts are sold. Boy I hate running on a shoe string budget. Sometimes it is a sewing string budget.

Just more cost than I have money to fix right now but in the Summer I will get it done when I have the spare change. It one those things running a seasonal business. This year's budget is already in the red quite bit until the repairs are completed and I get paid. It kinda strange to my books showing just a small negative figure but is how I account for part purchases. They not wrote off until parts are sold. Boy I hate running on a shoe string budget. Sometimes it is a sewing string budget.