You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

P3314WSA

#1

Scrubcadet10

Scrubcadet10

Good 'ol Pull-On......

ran great ever since i fixed it, but slowly got to where it doesn't want to idle.. and i kind of had to play with Low adjustment sometimes for it to idle good....it runs great with throttle up and cutting, just won't frickin idle. I screwed the L and H adjustments all the win and worked my way out... it will either fire once as i'm pulling the rope, it will fire up and idle for anywhere from 1 second to 3 seconds.. I'm wondering if it's sucking air... but the spark plug is a good color, just a tan-ish color.... no scoring that i can see on the P&C..

so what now....

ran great ever since i fixed it, but slowly got to where it doesn't want to idle.. and i kind of had to play with Low adjustment sometimes for it to idle good....it runs great with throttle up and cutting, just won't frickin idle. I screwed the L and H adjustments all the win and worked my way out... it will either fire once as i'm pulling the rope, it will fire up and idle for anywhere from 1 second to 3 seconds.. I'm wondering if it's sucking air... but the spark plug is a good color, just a tan-ish color.... no scoring that i can see on the P&C..

so what now....

#3

Scrubcadet10

Scrubcadet10

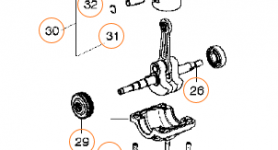

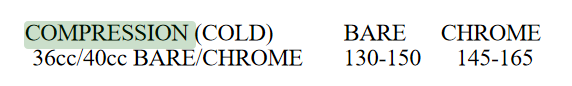

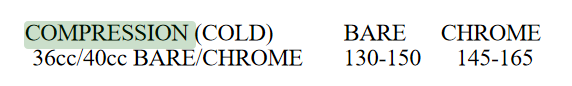

Guess looks ain't everything....lol...Compression, with the throttle held at wide open, barely pushing 90... and according to the SM,

and according to the SM,

I do not own a pressure tester as i do not work on 2 strokes for the general public... strictly 4 stroke ATV's/UTV's and 4 stroke air cooled. so mainly compression testing and leakdown testing....

I do not own a pressure tester as i do not work on 2 strokes for the general public... strictly 4 stroke ATV's/UTV's and 4 stroke air cooled. so mainly compression testing and leakdown testing....

#4

StarTech

StarTech

And most 2 cycles that I have learn needs at least 100 psi to run at idle.

Now the question is worth putting $50-$75 into it. If so both type 1 & 2 call for the same PNC 530071883/530071884 set. NCC Piston and Non coated cylinder.

Plus saw is actually a 42cc PNC wise. And can upgraded to a NCC Cylinder 530071885 and a non coated piston 530071882 at higher cost of course.

Before you ask no you can't put a NCC piston and a NCC cylinder. Done tried that years ago on a 4218 chainsaw which uses the same PNC sets.

NCC = Nickel Ceramic Coating

The Nickel burns off leaving only the ceramic coating.

Now the question is worth putting $50-$75 into it. If so both type 1 & 2 call for the same PNC 530071883/530071884 set. NCC Piston and Non coated cylinder.

Plus saw is actually a 42cc PNC wise. And can upgraded to a NCC Cylinder 530071885 and a non coated piston 530071882 at higher cost of course.

Before you ask no you can't put a NCC piston and a NCC cylinder. Done tried that years ago on a 4218 chainsaw which uses the same PNC sets.

NCC = Nickel Ceramic Coating

The Nickel burns off leaving only the ceramic coating.

#5

Scrubcadet10

Scrubcadet10

Thanks for the details, looks like most places comes out to around $60 at parts tree and jacks.... i would definitely like to do it for the learning portion of it as i have never torn down a chainsaw engine and i prefer to learn and make mistakes on my own dime.

I looked at Jacks, the parts are cheaper, but the difference in $ shipping brings up to the same as Parts Tree.

I looked at Jacks, the parts are cheaper, but the difference in $ shipping brings up to the same as Parts Tree.

#6

Scrubcadet10

Scrubcadet10

Heh, jackpot.. think i'll order from Small engine Pro's dealer out of FL, $58.00 shipped for the cylinder kit, piston, and bearing/seal assembly..

can anyone think of anything else that would be necessary?

can anyone think of anything else that would be necessary?

#7

StarTech

StarTech

Gasket set 530071894 (Intake and Exhaust gaskets)

And you will need either Permatex Ultra Black or Motoseal for sealing the lower crankcase. The Ultra Black is easier to work with.

And you will need either Permatex Ultra Black or Motoseal for sealing the lower crankcase. The Ultra Black is easier to work with.

#9

StarTech

StarTech

Wouldn't be the first I forgot to order a gasket. It is just I have done a lot of these clam shell engines. You could always come and put together the Stihl MS180C I have in a box right now. I had to replace the piston after a piston stop put a hole in it because someone over tighten the clutch. I was needing to get to oil pump drive gear as it was sticking causing the chain to move at idle.

It is the first time I tried using Motoseal and I don't really like it as it is runny. The PNC is back to together so now all I got to do is put everything else back in the right places. My first teardown of a Stihl 1130 engine.

It is the first time I tried using Motoseal and I don't really like it as it is runny. The PNC is back to together so now all I got to do is put everything else back in the right places. My first teardown of a Stihl 1130 engine.

#10

oldlawnguy

Given this is a complete teardown (nothing left to take apart you might as well replace the fuel lines, filter and primer bulb which is pretty cheap. I say this because on a 33cc 20 year old Homelite, I did a Walbro carb rebuild and it worked better, but was boggy when hitting throttle (kinda like it was fine then like I engaged the brake); scratched my head then I was thinking fuel lines/filter. I replace and that fixed the problem. Cross sectioned the filter and it was nasty, lines were not in good shape. Bought the line kit stuff at DadofBlueOrigin and there is all sort of kit there to buy in combos 6 ways to Sunday. I bought cylinder, piston, ring and coil at ProPartsDirect and picked them up so no sales tax or shipping. Good luck should take you about 4 hours if you do it all in one go, got to give the gasket 30 min to set before mounting cylinder under tension so you get a coffee break.

you might as well replace the fuel lines, filter and primer bulb which is pretty cheap. I say this because on a 33cc 20 year old Homelite, I did a Walbro carb rebuild and it worked better, but was boggy when hitting throttle (kinda like it was fine then like I engaged the brake); scratched my head then I was thinking fuel lines/filter. I replace and that fixed the problem. Cross sectioned the filter and it was nasty, lines were not in good shape. Bought the line kit stuff at DadofBlueOrigin and there is all sort of kit there to buy in combos 6 ways to Sunday. I bought cylinder, piston, ring and coil at ProPartsDirect and picked them up so no sales tax or shipping. Good luck should take you about 4 hours if you do it all in one go, got to give the gasket 30 min to set before mounting cylinder under tension so you get a coffee break.

Dalom 4Pcs 6-Feet Fuel Line w 530095646 Fuel Filter Primer Bulb for 2-Stroke Poulan Weed Eater Craftman Sthil Ryobi Homelite Chainsaw String Trimmer Leaf Blower 530058709 35879158 530071835

oldlawnguy

Do you have a clutch removal tool? I did this on a 46cc Homelite Pro. It was a lot of fun and leaning for me as well. Make sure you use new piston retainer rings (don't reuse old ones, hopefully part of your rebuild kit).Oooh yep, gasket set. Duh

Given this is a complete teardown (nothing left to take apart

Dalom 4Pcs 6-Feet Fuel Line w 530095646 Fuel Filter Primer Bulb for 2-Stroke Poulan Weed Eater Craftman Sthil Ryobi Homelite Chainsaw String Trimmer Leaf Blower 530058709 35879158 530071835

#11

StarTech

530031112

Now there is another version for the newer clutch style which has the pins further apart.

There is one other thing that will be present and that is the oil pump worn gear (spring). It will need removing to put on the seal.

StarTech

I do forget most here are not Pros. Yes the 530031112 tool is needed but but the OP can make an one time pin wrench to to remove it.Do you have a clutch removal tool? I did this on a 46cc Homelite Pro. It was a lot of fun and leaning for me as well. Make sure you use new piston retainer rings (don't reuse old ones, hopefully part of your rebuild kit).

530031112

Now there is another version for the newer clutch style which has the pins further apart.

There is one other thing that will be present and that is the oil pump worn gear (spring). It will need removing to put on the seal.

530031166 spring tool

#12

oldlawnguy

yup I used the 530031112 clutch tool as a DIY non professional... Few pros would consider a full 2-stroke rebuild fun

yup I used the 530031112 clutch tool as a DIY non professional... Few pros would consider a full 2-stroke rebuild fun

If these threads can help the read-only DIY members in their repairs that's great. The knowledge provided by the pros and advanced DIYers certainly has helped me learn a thing or two.

Thanks!

oldlawnguy

I do forget most here are not Pros. Yes the 530031112 tool is needed but but the OP can make an one time pin wrench to to remove it.

530031112

View attachment 57615

Now there is another version for the newer clutch style which has the pins further apart.

There is one other thing that will be present and that is the oil pump worn gear (spring). It will need removing to put on the seal.

View attachment 57616

530031166 spring tool

View attachment 57617

If these threads can help the read-only DIY members in their repairs that's great. The knowledge provided by the pros and advanced DIYers certainly has helped me learn a thing or two.

Thanks!

#13

Scrubcadet10

Scrubcadet10

It's got all new fuel lines, carb mount gaskets and new OEM (zama i think) carburetor. it sat for about 10 years and i got it running.

Do you have a clutch removal tool? I did this on a 46cc Homelite Pro. It was a lot of fun and leaning for me as well. Make sure you use new piston retainer rings (don't reuse old ones, hopefully part of your rebuild kit).

Given this is a complete teardown (nothing left to take apartyou might as well replace the fuel lines, filter and primer bulb which is pretty cheap. I say this because on a 33cc 20 year old Homelite, I did a Walbro carb rebuild and it worked better, but was boggy when hitting throttle (kinda like it was fine then like I engaged the brake); scratched my head then I was thinking fuel lines/filter. I replace and that fixed the problem. Cross sectioned the filter and it was nasty, lines were not in good shape. Bought the line kit stuff at DadofBlueOrigin and there is all sort of kit there to buy in combos 6 ways to Sunday. I bought cylinder, piston, ring and coil at ProPartsDirect and picked them up so no sales tax or shipping. Good luck should take you about 4 hours if you do it all in one go, got to give the gasket 30 min to set before mounting cylinder under tension so you get a coffee break.

Dalom 4Pcs 6-Feet Fuel Line w 530095646 Fuel Filter Primer Bulb for 2-Stroke Poulan Weed Eater Craftman Sthil Ryobi Homelite Chainsaw String Trimmer Leaf Blower 530058709 35879158 530071835

#15

StarTech

StarTech

Two. or if you just want to replace the seals Farmertec PJ14220 but you will need a press and the correct arbors. THis provided you wait 2-3 weeks.

https://www.farmertec.com/Chainsaw-...na-136-137-141-142-OEM-530056363-p226439.html

Another option is to order the bearing and seal sets.

https://www.farmertec.com/Chainsaw-...na-136-137-141-142-OEM-530056363-p226438.html

https://www.farmertec.com/Chainsaw-...na-136-137-141-142-OEM-530056363-p226439.html

Another option is to order the bearing and seal sets.

https://www.farmertec.com/Chainsaw-...na-136-137-141-142-OEM-530056363-p226438.html

#17

Scrubcadet10

Scrubcadet10

Chainsaw is tore down, minor scuffing on the piston, but there are some pretty decent score lines on the exhaust side of the cylinder.... definitely hanging a finger nail on 'em.

Just ordered the oil pump drive spring removal tool off amazon. $10... granted it was $3 other places, but when you factor in shipping, it was the same.

Just ordered the oil pump drive spring removal tool off amazon. $10... granted it was $3 other places, but when you factor in shipping, it was the same.

#18

StarTech

I always tune these to peak rpm and enrich to drop the rpms 50-100 rpms. It better to run a little rich than too lean. I seen too many over the years.

As for prices yes you are now using your head. It always been cost plus shipping for final cost here that gets items ordered. It can be a little strange when an Amazon vendor sells for less on Amazon then on their on website. I place an order for RX-1 and RX-2 diaphargm kits yesterday that were cheaper going through Amazon than going CTS website. Even the shipping were lower on Amazon. What was strange was that single kits were about the same as the two packs. Otherwords the two were less than the single kits which makes which kit half priced. (3.31 for two, or 1.655 ea). When I ordered 20 kits (actually 40) with shipping it was only 79.36 or 1.984 ea. which less than 3.31 ea before shipping at CTS website.

The same for my Xtreme PTO clutches I can go through Stens instead of Xtreme's website for better pricing overall. Plus I get a better shipping time when they have them in stock.

StarTech

Then you found the problem. Carbon build up can do this but most times running them too lean, too little or wrong oil, or simply straight gassed.Chainsaw is tore down, minor scuffing on the piston, but there are some pretty decent score lines on the exhaust side of the cylinder.... definitely hanging a finger nail on 'em.

Just ordered the oil pump drive spring removal tool off amazon. $10... granted it was $3 other places, but when you factor in shipping, it was the same.

I always tune these to peak rpm and enrich to drop the rpms 50-100 rpms. It better to run a little rich than too lean. I seen too many over the years.

As for prices yes you are now using your head. It always been cost plus shipping for final cost here that gets items ordered. It can be a little strange when an Amazon vendor sells for less on Amazon then on their on website. I place an order for RX-1 and RX-2 diaphargm kits yesterday that were cheaper going through Amazon than going CTS website. Even the shipping were lower on Amazon. What was strange was that single kits were about the same as the two packs. Otherwords the two were less than the single kits which makes which kit half priced. (3.31 for two, or 1.655 ea). When I ordered 20 kits (actually 40) with shipping it was only 79.36 or 1.984 ea. which less than 3.31 ea before shipping at CTS website.

The same for my Xtreme PTO clutches I can go through Stens instead of Xtreme's website for better pricing overall. Plus I get a better shipping time when they have them in stock.

#19

oldlawnguy

1. start Walbros at 1 1/4 for L H and Zamas at 2 for L H with T (throttle) screw all the way turned in.

2. tune L jet and back out T screw then back and forth until you have as little T screw as possible and idle around 2800 rpms and nice snappy trigger. Saw will run all day at 2800-2900 rpms with no surging or hunting.

3. tune H jet to 4-stroking and then (lean) turn in 1/4-1/2 or more turns to get to rich power side while in wood.

I have an el cheapo tach and found that around 11000-12000 rpms is around this range, but concerned about going too lean and burning out saw. Also don't want to be too rich and carbon up muffler either. Have searched and searched online and cannot find any manuals on WTO rpms. It's like to the info is behind the B&S Power Portal or something. Amazing what 1/8 or 1/16 or a turn will do to rpms and the patience required (while learning) to get a perfectly good saw tuned and running.

Amazing what 1/8 or 1/16 or a turn will do to rpms and the patience required (while learning) to get a perfectly good saw tuned and running.

I think it would be good to have a 2-stroke carb tuning 101 for Dummies 3 step guide for DIY stiffs like myself. Maybe if I can get enough input I'll actually start a thread on 2-stroke tuning for others to find when looking for help.

oldlawnguy

StarTech curious as to what's your tuning ballpark for us DIYers wrt the typical 33cc - 46cc home saws. I've been at it for a year now as a hobby; rebuilding some dead saws and through a lot of trial and error and help on this forum from the pros have pieced together (maybe incorrectly) that:Then you found the problem. Carbon build up can do this but most times running them too lean, too little or wrong oil, or simply straight gassed.

I always tune these to peak rpm and enrich to drop the rpms 50-100 rpms. It better to run a little rich than too lean. I seen too many over the years.

As for prices yes you are now using your head. It always been cost plus shipping for final cost here that gets items ordered. It can be a little strange when an Amazon vendor sells for less on Amazon then on their on website. I place an order for RX-1 and RX-2 diaphargm kits yesterday that were cheaper going through Amazon than going CTS website. Even the shipping were lower on Amazon. What was strange was that single kits were about the same as the two packs. Otherwords the two were less than the single kits which makes which kit half priced. (3.31 for two, or 1.655 ea). When I ordered 20 kits (actually 40) with shipping it was only 79.36 or 1.984 ea. which less than 3.31 ea before shipping at CTS website.

The same for my Xtreme PTO clutches I can go through Stens instead of Xtreme's website for better pricing overall. Plus I get a better shipping time when they have them in stock.

1. start Walbros at 1 1/4 for L H and Zamas at 2 for L H with T (throttle) screw all the way turned in.

2. tune L jet and back out T screw then back and forth until you have as little T screw as possible and idle around 2800 rpms and nice snappy trigger. Saw will run all day at 2800-2900 rpms with no surging or hunting.

3. tune H jet to 4-stroking and then (lean) turn in 1/4-1/2 or more turns to get to rich power side while in wood.

I have an el cheapo tach and found that around 11000-12000 rpms is around this range, but concerned about going too lean and burning out saw. Also don't want to be too rich and carbon up muffler either. Have searched and searched online and cannot find any manuals on WTO rpms. It's like to the info is behind the B&S Power Portal or something.

I think it would be good to have a 2-stroke carb tuning 101 for Dummies 3 step guide for DIY stiffs like myself. Maybe if I can get enough input I'll actually start a thread on 2-stroke tuning for others to find when looking for help.

#20

Scrubcadet10

Scrubcadet10

Steve's small engine saloon has a good video on tuning 2 strokes... that's how i tuned this poulan when i got it running... idled great and great throttle response with very very little bog.

#21

oldlawnguy

101 level would be say if you did a carb rebuild and/or picked up a used saw and previous owner messed with the jets. How would you tune from square 1 using initial settings etc. as I indicated above. It can be pretty tricky as a DIYer compared to a pro. As Steve said in the clip 1000 rpms too rich is fine to cut compared to 1000 rpms too lean. I'm interested in a general rule of thumb on H rpms on standard home saws. I realized certain models can have different rpms, that is why I referenced 4-stroking H jet and then back in to lean. 11-12K rpms appears to be around that and was looking for some general feedback as to if it's horseshoes and hand grenades close enough.

102 level would be taking it up a level but that's for the pros.

oldlawnguy

Yes this 12 min clip from SSES is very good for say a 100 level-- with limiter caps, your original saw, etc.Steve's small engine saloon has a good video on tuning 2 strokes... that's how i tuned this poulan when i got it running... idled great and great throttle response with very very little bog.

101 level would be say if you did a carb rebuild and/or picked up a used saw and previous owner messed with the jets. How would you tune from square 1 using initial settings etc. as I indicated above. It can be pretty tricky as a DIYer compared to a pro. As Steve said in the clip 1000 rpms too rich is fine to cut compared to 1000 rpms too lean. I'm interested in a general rule of thumb on H rpms on standard home saws. I realized certain models can have different rpms, that is why I referenced 4-stroking H jet and then back in to lean. 11-12K rpms appears to be around that and was looking for some general feedback as to if it's horseshoes and hand grenades close enough.

102 level would be taking it up a level but that's for the pros.

#22

B

bertsmobile1

B

bertsmobile1

All adjustable jet carbs should be done the same way

Rich till it 8 strokes then lean till it starts to miss and set 1/2 way between the two .

Best to err slightly on the rich side .

easy on the old carbs where too rich to too lean was between 1/2 & 3/4 of a turn.

Then EPA carbs came in with a finer taper on the needles and some of these the range too rich to too lean can be nearly 3 turns.

This was done on the assumption that every one who tunes them has a $ 20,000 exhaust gas analyser with the right bolt on collector and restrictor to mimick the muffler .

The misplaced logic is that the finer adjustment means the engine can be tuned to the exact right mixture down to 3 decimal places which is true, just so long as the tool is never used because what is perfect in the workshop will not be perfect under load ( which is why you set them a little rich ) and the really stupid thing about that is we have known this for near 100 years which is why dyno tuning was invented so car truck & motorcycle engines could be tuned under load.

Rich till it 8 strokes then lean till it starts to miss and set 1/2 way between the two .

Best to err slightly on the rich side .

easy on the old carbs where too rich to too lean was between 1/2 & 3/4 of a turn.

Then EPA carbs came in with a finer taper on the needles and some of these the range too rich to too lean can be nearly 3 turns.

This was done on the assumption that every one who tunes them has a $ 20,000 exhaust gas analyser with the right bolt on collector and restrictor to mimick the muffler .

The misplaced logic is that the finer adjustment means the engine can be tuned to the exact right mixture down to 3 decimal places which is true, just so long as the tool is never used because what is perfect in the workshop will not be perfect under load ( which is why you set them a little rich ) and the really stupid thing about that is we have known this for near 100 years which is why dyno tuning was invented so car truck & motorcycle engines could be tuned under load.

#23

StarTech

StarTech

Most non Stratified (air head) versions of the Walbro and Zama are initial set at a will start setting 1-1/2 turns out from lightly seated on each mixture screws per factory instructions. The Stratified versions are whole different beast but the idle (L) mixture is still initially tuned to 1-1/2 turn out from lightly seated. Now H can be several turns out as you turn in the carburetor Start with 2-3 turns.

As for tuning using a tach will get you a lot closer to the right setting but even then some saws need to tune while in use. Other\ words tuned while it actually being used in the cut. I don't trying toe set the mixture as you are cutting both slight fine tune adjustment in between cuts. This why I have test logs here at my shop. Stratified carburetors are picky about getting them tight for in the wood cuts. I had to work very out of the cut but failed in the cut.

As for tuning using a tach will get you a lot closer to the right setting but even then some saws need to tune while in use. Other\ words tuned while it actually being used in the cut. I don't trying toe set the mixture as you are cutting both slight fine tune adjustment in between cuts. This why I have test logs here at my shop. Stratified carburetors are picky about getting them tight for in the wood cuts. I had to work very out of the cut but failed in the cut.

#26

StarTech

StarTech

Yes.My carb has the extra air intake at the top.... stratified?

View attachment 57647(stock image)

#27

Scrubcadet10

Scrubcadet10

Still waiting on the parts i was told were in stock...6 days and not shipped, however compared to how long some of you on here have been waiting, I'll retain patience for awhile longer.

#28

Scrubcadet10

Scrubcadet10

parts keep getting pushed back.... from 8/10 to 8/13 expected ship date... may call Parts Tree and see if they have the parts in stock.. then cancel this order and order them from parts tree... ?

#29

StarTech

StarTech

Now you how some us that have shops are feeling. Can't get repairs done because we can't get the parts. Customers are pissed but there nothing we can do about when we depend on others to do their jobs.

#32

StarTech

StarTech

Miracles still happens apparently. My Kawasaki fuel pump just got shoved back another month. And the vendor that listed a some Rotary spindles and switches now says they haven't been a dealer for Rotary for over 20 yrs, Funny the pricing was current and their system accepted the order, but canceled the order the next day. Oh well didn't need the parts right away anyways so I order the spindles in January for stock and the seat switches on my next Stens order.

#33

Scrubcadet10

Scrubcadet10

Wow...

I got the parts today. I have the crank ready to go in, i was going to go ahead and put the carb insulator plate on, with the gasket, the 4 holes aren't tapped.... No threads... I got to looking and neither are the muffler bolt holes. At least the spark hole is tapped... Sheesh.

I got the parts today. I have the crank ready to go in, i was going to go ahead and put the carb insulator plate on, with the gasket, the 4 holes aren't tapped.... No threads... I got to looking and neither are the muffler bolt holes. At least the spark hole is tapped... Sheesh.

#34

Scrubcadet10

Scrubcadet10

According to my screw gauge. The carb bolts are #12-28. And the muffler screws are 1/4-28..

#35

Scrubcadet10

Scrubcadet10

Heh, I looked even closer the cylinder mounting holes aren't even tapped ad well... And none of these screws have the Self tapping look to em.

#36

StarTech

StarTech

You better double check yourself as the IPL has the intake screw as being M5-0.8 x 30mm and the cylinder screw are M6-1.00 x 25mm so the rest of the screws are most likely metrics too.

This why I both a SAE and a Metric tap and die sets with oddball taps.

This why I both a SAE and a Metric tap and die sets with oddball taps.

#37

Scrubcadet10

Scrubcadet10

You're right... My gauge did not have the correct metric for the muffler screws..

Much appreciated.

Much appreciated.

#38

StarTech

StarTech

And looks like the muffler screws are also M6-1.00.

When looking at the screws are they trilobular? If so they are self tappers.

I just wish every manufacture would one standard instead several different one like British threading. So glad I only ran across one machine with those. What a pain to find replacement screws.

When looking at the screws are they trilobular? If so they are self tappers.

I just wish every manufacture would one standard instead several different one like British threading. So glad I only ran across one machine with those. What a pain to find replacement screws.

#39

oldlawnguy

You may want to try self taping with original screws (steel into aluminum). I was successful in assembly all with original screws and they self tapped successfully. Went nice and slow especially for coil mounts and handle anti-shock mount on cyclinder.

oldlawnguy

The cylinder replacement for my Homelite came untapped as well.You're right... My gauge did not have the correct metric for the muffler screws..

Much appreciated.

You may want to try self taping with original screws (steel into aluminum). I was successful in assembly all with original screws and they self tapped successfully. Went nice and slow especially for coil mounts and handle anti-shock mount on cyclinder.

#40

Scrubcadet10

Scrubcadet10

Nope, they're just flat on the bottom.And looks like the muffler screws are also M6-1.00.

When looking at the screws are they trilobular? If so they are self tappers.

I just wish every manufacture would one standard instead several different one like British threading. So glad I only ran across one machine with those. What a pain to find replacement screws.

#41

Scrubcadet10

Scrubcadet10

i tried to go a little ways with a hand torx driver but it became too hard and i didn't feel like digging a screw out of a new cylinderThe cylinder replacement for my Homelite came untapped as well.

You may want to try self taping with original screws (steel into aluminum). I was successful in assembly all with original screws and they self tapped successfully. Went nice and slow especially for coil mounts and handle anti-shock mount on cyclinder.

#42

Scrubcadet10

Scrubcadet10

I guess those were Self tapping screws....? a little bit of liquid wrench helped. the cylinder is now sitting back in it's home all sealed up.

#43

oldlawnguy

oldlawnguy

I guess those were Self tapping screws....? a little bit of liquid wrench helped. the cylinder is now sitting back in it's home all sealed up.