You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

One jet fell out of the pickup tube

#1

P

Poodlehead

P

Poodlehead

MN: 407677 0258 E1

The last time the mower ran great and the next time I started it, the mower ran bad like it was starving for fuel.

I pulled the float bowl and found one of the two jets from the pickup tube in the bottom of the bowl along with the O-ring that seals between the float bowl and pickup tube.

I'm unable to find any parts breakdown showing the 2 small jets that go into the pickup tube so I'm looking for advice.

Do I just push the jet back in, replace the O-ring with one the same size(hopefully)?

Buy replacement O-ring from B&S? Are the jet O-rings available from B&S (can't find parts breakdown showing them)?

Buy aftermarket PU tube with what looks like to be the correct O-ring?

Buy replacement Nikki carb for less than $40?

Thanks in advance for any advice.

The last time the mower ran great and the next time I started it, the mower ran bad like it was starving for fuel.

I pulled the float bowl and found one of the two jets from the pickup tube in the bottom of the bowl along with the O-ring that seals between the float bowl and pickup tube.

I'm unable to find any parts breakdown showing the 2 small jets that go into the pickup tube so I'm looking for advice.

Do I just push the jet back in, replace the O-ring with one the same size(hopefully)?

Buy replacement O-ring from B&S? Are the jet O-rings available from B&S (can't find parts breakdown showing them)?

Buy aftermarket PU tube with what looks like to be the correct O-ring?

Buy replacement Nikki carb for less than $40?

Thanks in advance for any advice.

Attachments

#2

StarTech

StarTech

Briggs only sells the jets with the o-rings, but not just the o-rings. And yes they are just pushed in. The o-ring is what holds them in place. Except with your version of the carb the larger o-ring also helps keep them in place.

Just go to either a JD or Kawasaki dealer and buy the o-rings. BUt more than just what you need as they are ting and easily blown away. Also don't mixthe jets up as they are different sizes.

Just go to either a JD or Kawasaki dealer and buy the o-rings. BUt more than just what you need as they are ting and easily blown away. Also don't mixthe jets up as they are different sizes.

#3

P

Poodlehead

P

Poodlehead

So if I go to JD and buy M153076 o-ring, I should be able to push my jet back in the correct spot of the pickup tube, then push my larger new o-ring up inside the pickup tube so it will hold the jets in place, and put the bowl back on? The o-ring shows to be in stock locally, so that will be great if it's that easy

If there is a gasket/o-ring between the bowl and carb base, would you please provide that PN as well? I think it might be B&S PN 690994, but the bowl looks different (no ears) in my parts breakdown

Thank you so much for your help!

If there is a gasket/o-ring between the bowl and carb base, would you please provide that PN as well? I think it might be B&S PN 690994, but the bowl looks different (no ears) in my parts breakdown

Thank you so much for your help!

#4

StarTech

StarTech

What in your picture is the upgraded fuel bowl, the steel fuel is no longer available. The bowl gasket is the same one 690994. The replace bowl (798778) comes with the gasket and a new fuel solenoid. Many have been replaced as the steel bowl rusts up to where it is no longer usable.

Now the new bowl is pricey compared when I last brought them but just make me a lot more when I sell the ones I got.

Now the new bowl is pricey compared when I last brought them but just make me a lot more when I sell the ones I got.

#5

P

Poodlehead

P

Poodlehead

Thank you for the detailed info.

I just ordered both o-rings from JD. They show I should be able to pickup at the local dealer in a couple of hours. Hopefully that is the case...

Thanks again!

I just ordered both o-rings from JD. They show I should be able to pickup at the local dealer in a couple of hours. Hopefully that is the case...

Thanks again!

#6

F

Forest#2

F

Forest#2

Here is a link to some info about your Nikki (Briggs) carb. How to ID which kit or parts you need.

The 2nd link is how to work on your carb.

Use the Briggs name when looking for part numbers on-line.

You tube video part 1: (newer style aluminum float bowl Nikki) USE KIT 54832 @ $7

I've found individual Nikki Briggs parts at a reasonable price at a place I stumbled onto called sawzillaparts.com and shipping is reasonable.

I've also found the itty bitty jet o-rings on flea bay in packages of 10 or more reasonable in bulk. Note in the video how to put the jet and o ring onto a paper clip so as for more user friendly operation. I use a small hollow shaft nut driver and a wire as a guide to press the jets back into place.

Pay attention to what star tech says about the aluminum bowl vs the steel bowl. They are different sized o rings (aluminum bowl vs steel bowl) and o rings from o ring kits will not get a go.

The 2nd link is how to work on your carb.

Use the Briggs name when looking for part numbers on-line.

I've found individual Nikki Briggs parts at a reasonable price at a place I stumbled onto called sawzillaparts.com and shipping is reasonable.

I've also found the itty bitty jet o-rings on flea bay in packages of 10 or more reasonable in bulk. Note in the video how to put the jet and o ring onto a paper clip so as for more user friendly operation. I use a small hollow shaft nut driver and a wire as a guide to press the jets back into place.

Pay attention to what star tech says about the aluminum bowl vs the steel bowl. They are different sized o rings (aluminum bowl vs steel bowl) and o rings from o ring kits will not get a go.

#7

P

Poodlehead

P

Poodlehead

Thank you so much for those excellent vids. Now I wished I had waited and bought this entire kit. It even has the jet o-rings, but...

I didn't make it to JD to pickup my parts today. Hopefully I'll get those tomorrow and get it back together.

I just checked out Sawzillaparts and I'm definitely adding it to the top of my supplier list.

Thank you!

I didn't make it to JD to pickup my parts today. Hopefully I'll get those tomorrow and get it back together.

I just checked out Sawzillaparts and I'm definitely adding it to the top of my supplier list.

Thank you!

#8

P

Poodlehead

P

Poodlehead

I picked up my parts today and have good and bad news. The bowl o-ring is correct, but the M153076 o-ring IS for the tiny jets. I got 2 of them so I'll use a new o-ring on the jet that fell out.

However, I still need the large O-ring that holds the jets in and seals the bowl.

Would anyone know what the PN is for the bigger o-ring that goes in the white pickup tube to hold the jets in place and seal the bowl? Or maybe I should just buy the 54832 kit that has that o-ring and others and be done with it?

Thank you for your time and help! I'm beginning to feel like I own a boat

However, I still need the large O-ring that holds the jets in and seals the bowl.

Would anyone know what the PN is for the bigger o-ring that goes in the white pickup tube to hold the jets in place and seal the bowl? Or maybe I should just buy the 54832 kit that has that o-ring and others and be done with it?

Thank you for your time and help! I'm beginning to feel like I own a boat

#10

StarTech

StarTech

Why does everyone like to bad mouth Nikki carbs? It is mainly because they just don't take time to understand them. I have no repairing the Nikki, Walbro, or others.

Nikki carbs are quite easy to repair once you understand how they are put together.

I very seldom have to replace a carburetor but there are exceptions especially when needle seats not available to replace leaky ones.

Nikki carbs are quite easy to repair once you understand how they are put together.

I very seldom have to replace a carburetor but there are exceptions especially when needle seats not available to replace leaky ones.

#11

P

Poodlehead

. I guess there's not a JD number? I hate paying shipping, but...

. I guess there's not a JD number? I hate paying shipping, but...

Anyway, I'm going to order the kit (54832) that Forest#2 provided. It is only $7, plus $6 shipping.

I got a couple other items so I feel better about shipping...

I will update all when I have more info...

Thank you all for the input and help!

P

Poodlehead

Well in my head I thought I didDidn't ask for that PN.

Briggs 841653 / Kawasaki 92055-7016 should be the correct one.

Anyway, I'm going to order the kit (54832) that Forest#2 provided. It is only $7, plus $6 shipping.

I got a couple other items so I feel better about shipping...

I will update all when I have more info...

Thank you all for the input and help!

#12

F

Forest#2

The carb you mention is not the correct one for his engine.

His is the 2 barrel Nikki type that does not like ethanol gas. part number for his might be 791230 but he did not post up his engine code.

I've had better luck re-kitting a real Nikki 2 barrel vs rolling the dice and trying to replace the dual throat type with a Clone. If I try a Clone I use Amazon prime that has the free returns.

But the Nikki dual throat 2 barrels do have a learning curve. (and expensive if replaced with the real thing) I know some mechanics tht only replace the real Nikki's with the expensive real deal replacements so as to get the customers mowers back in service faster.

Some twin engines use the more user friendly single barrel carb (similar to the one you posted) and carb work on them is easier especially if they are a Walbro.

Seems like Briggs and Ford motor company should merge. Seems when both of them have a good thing going they make a major engineering change to make things worse for the repair people and to get deeper into the consumers pocket book fast. (Ford's slogan "We had a better idea" was only in the Model A and T days before they tried aluminum trucks and EV's)

F

Forest#2

Dude if it is a Nikki Six carb, put the Walbro version on. I just did one on a Snapper 28 RER with 13.5hp Briggs single. Ordered OEM Briggs parts for the Nikki. Never again. Even OEM Briggs parts in the Nikki, didn't fit right blah blah. Too many o-rings and seals mess. Way over engineered POS.

New Walbro clone runs like a top. Never have to worry about it again. This is a Ebay Chinese clone of the Walbro. Took it all apart. Found no issues. Set the fuel/float level only, small potatoes. I did buy what was the most expensive Chinese version I think I could find. Pass on the cheapest version. Had trouble with those in the past.

View attachment 69371

The carb you mention is not the correct one for his engine.

His is the 2 barrel Nikki type that does not like ethanol gas. part number for his might be 791230 but he did not post up his engine code.

I've had better luck re-kitting a real Nikki 2 barrel vs rolling the dice and trying to replace the dual throat type with a Clone. If I try a Clone I use Amazon prime that has the free returns.

But the Nikki dual throat 2 barrels do have a learning curve. (and expensive if replaced with the real thing) I know some mechanics tht only replace the real Nikki's with the expensive real deal replacements so as to get the customers mowers back in service faster.

Some twin engines use the more user friendly single barrel carb (similar to the one you posted) and carb work on them is easier especially if they are a Walbro.

Seems like Briggs and Ford motor company should merge. Seems when both of them have a good thing going they make a major engineering change to make things worse for the repair people and to get deeper into the consumers pocket book fast. (Ford's slogan "We had a better idea" was only in the Model A and T days before they tried aluminum trucks and EV's)

#13

Tiger Small Engine

Tiger Small Engine

Nikki carburetors are my least favorite to work on of all the brands, let’s put it that way.Why does everyone like to bad mouth Nikki carbs? It is mainly because they just don't take time to understand them. I have no repairing the Nikki, Walbro, or others.

Nikki carbs are quite easy to repair once you understand how they are put together.

I very seldom have to replace a carburetor but there are exceptions especially when needle seats not available to replace leaky ones.

#14

StarTech

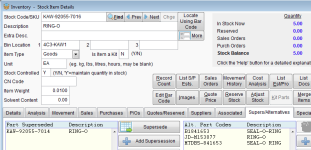

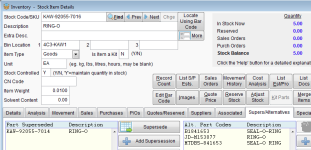

But here is the cross. And update my system with the cross too.

This is how my system now has the crosses.

StarTech

Well I never had crossed the o-ring until today to the JD part number as I usually go the Kawasaki PNs as I get them a lot cheaper from my kawasaki distributor and cut out the middle man JD.Well in my head I thought I did. I guess there's not a JD number? I hate paying shipping, but...

Anyway, I'm going to order the kit (54832) that Forest#2 provided. It is only $7, plus $6 shipping.

I got a couple other items so I feel better about shipping...

I will update all when I have more info...

Thank you all for the input and help!

But here is the cross. And update my system with the cross too.

This is how my system now has the crosses.

#15

P

Poodlehead

P

Poodlehead

I haven't been to the Kawa dealer in many years because their prices usually were outrageous... So far I've had good luck with JD having most parts in stock They have this part in stock so I ordered and should be able to pickup on Monday

So your last screen shot shows the equivalent part number from JD, Kawa, MTD, and Briggs?

StarTech, it's obvious that you must be a parts man 'somewhere' with much better resources than a common man like me.

Thank you so much for all the info and help!

So your last screen shot shows the equivalent part number from JD, Kawa, MTD, and Briggs?

StarTech, it's obvious that you must be a parts man 'somewhere' with much better resources than a common man like me.

Thank you so much for all the info and help!

#16

B

bertsmobile1

B

bertsmobile1

He just keeps a better inventory than most .

Kawakasi parts are realistic

You have just been spoiled over the years because B & S parts were always way too cheap .

A gasket that costs 10¢ to make can often be $ 10 by the time it passes through a couple of sets of hands and gets to a dealer.

In fact if I just ordered 1 gasket it would have either a $ 25 or $ 15 delivery fee charged against it .

Invoicing costs some where between $ 2 & $ 10 and then there is storage picking & packing .

The sticky invoice envelopes stuck on packages cost 5¢ each

It all adds up very quickly .

I am just about to finish a Toro Greensmaster ( ***** of a machine to service ) and the courier delivery of parts for it is over $ 100 while my labour is only $ 142 .

Kawakasi parts are realistic

You have just been spoiled over the years because B & S parts were always way too cheap .

A gasket that costs 10¢ to make can often be $ 10 by the time it passes through a couple of sets of hands and gets to a dealer.

In fact if I just ordered 1 gasket it would have either a $ 25 or $ 15 delivery fee charged against it .

Invoicing costs some where between $ 2 & $ 10 and then there is storage picking & packing .

The sticky invoice envelopes stuck on packages cost 5¢ each

It all adds up very quickly .

I am just about to finish a Toro Greensmaster ( ***** of a machine to service ) and the courier delivery of parts for it is over $ 100 while my labour is only $ 142 .

#17

StarTech

StarTech

But storage space is at a premium here now. Otherwords I running out places to storage parts. I really need to stop restocking parts sold as I need to prepare to shut down the business. Getting into that retirement age range now.

And it takes a lot work to just keep up with all the cross references. Example here the Briggs o-ring costs $10.79, JD's is $2.48, and the Kawasaki is $1.55. So I would not agree that the Kawasaki prices are out of line. Now the local guys are going to be higher as they got overhead to cover,

And Bert Briggs is no longer cheap to buy here, since that investment company brought them. One of the Nikki fuel bowls that I was buying for $30 is now over $100. Good thing I brought 5 of them when they were $30.

But as Bert said shipping cost has to figured in when ordering parts. There are time I pay more for a part as I needing other OEM parts that another distributor cheaper on but is then split among the parts as I only pay one shipping charge and not two charges. And sometimes I do buy locally if I am out and don't an order ready for the distributor but driving to JD for the part would be a 60 mile round trip and over an hour and half that I am not in the shop. An example of paying more a part from a different vendor is the gas tank that I brought this week. It was $10 higher from one vendor with free shipping. But regular vendor would had charged me $15 shipping. So I saved $5. Still had to charge more than suggested retail. I just don't get that good of a discount on MTD parts. Matter of fact I having to tack on a 5% GPM on the retail prices just to cover the shipping costs.

This is why I try to have multiple sources for the same part which does require knowing different part numbers. Running a small business does help as I do have to keep an inventory on hand if I going to keep the cost in line.

So this is how I keep my cost down and the customers do benefit too as the repair bills are lower too. As long I make a good profit and the customer saves money we both are happy.

And it takes a lot work to just keep up with all the cross references. Example here the Briggs o-ring costs $10.79, JD's is $2.48, and the Kawasaki is $1.55. So I would not agree that the Kawasaki prices are out of line. Now the local guys are going to be higher as they got overhead to cover,

And Bert Briggs is no longer cheap to buy here, since that investment company brought them. One of the Nikki fuel bowls that I was buying for $30 is now over $100. Good thing I brought 5 of them when they were $30.

But as Bert said shipping cost has to figured in when ordering parts. There are time I pay more for a part as I needing other OEM parts that another distributor cheaper on but is then split among the parts as I only pay one shipping charge and not two charges. And sometimes I do buy locally if I am out and don't an order ready for the distributor but driving to JD for the part would be a 60 mile round trip and over an hour and half that I am not in the shop. An example of paying more a part from a different vendor is the gas tank that I brought this week. It was $10 higher from one vendor with free shipping. But regular vendor would had charged me $15 shipping. So I saved $5. Still had to charge more than suggested retail. I just don't get that good of a discount on MTD parts. Matter of fact I having to tack on a 5% GPM on the retail prices just to cover the shipping costs.

This is why I try to have multiple sources for the same part which does require knowing different part numbers. Running a small business does help as I do have to keep an inventory on hand if I going to keep the cost in line.

So this is how I keep my cost down and the customers do benefit too as the repair bills are lower too. As long I make a good profit and the customer saves money we both are happy.

#18

P

Poodlehead

That is great that you can look up parts and cross reference PNs! Do you have a subscription to have access to better diagrams and part numbers lookup and x-references?

P

Poodlehead

Congratulations on reaching the 'golden years'; I turned 65 last year and seem to be busier now than before, lol!I really need to stop restocking parts sold as I need to prepare to shut down the business. Getting into that retirement age range now.

That is great that you can look up parts and cross reference PNs! Do you have a subscription to have access to better diagrams and part numbers lookup and x-references?

#19

StarTech

StarTech

Not really on the IPLs but most my vendors do provide the look-ups. What I have is from experience on where to look a particular OEM parts. It like I know where to look the Kawasaki engines that the US JD don't want us doing. Basically trying to force techs like me to only buy from them as they use unique PNs for the same Kawasaki parts.

The crosses are from working on various equipment and I just keep entering them in my system as I find them. It has come really handy during the Covid out break and the current lack of parts (lots of back orders). I have had one OEM to say a part is NLA when it is actually not as another OEM still carry it. Of some are proprietary means a company has exclusive rights to it.

And as you found out here some just won't tell us of the individual parts as they are wanting to buy an assembled part.

I really glad my Auto Manager software provider (Adminsoft) has worked with me on getting it fully functioning as he intend from the get go. I do drive him nuts at times when things don't work right. Of course I have to be the one with largest inventory database that he has using his software. We still finding induced bugs every so often. WE had to stop data logging changes as the software has a limit of 2 gigs and something he has being logged is causing the system to error out. It is something that will eventfully cause us a problem even in the stock database as I am current at 780 megs of data.

The crosses are from working on various equipment and I just keep entering them in my system as I find them. It has come really handy during the Covid out break and the current lack of parts (lots of back orders). I have had one OEM to say a part is NLA when it is actually not as another OEM still carry it. Of some are proprietary means a company has exclusive rights to it.

And as you found out here some just won't tell us of the individual parts as they are wanting to buy an assembled part.

I really glad my Auto Manager software provider (Adminsoft) has worked with me on getting it fully functioning as he intend from the get go. I do drive him nuts at times when things don't work right. Of course I have to be the one with largest inventory database that he has using his software. We still finding induced bugs every so often. WE had to stop data logging changes as the software has a limit of 2 gigs and something he has being logged is causing the system to error out. It is something that will eventfully cause us a problem even in the stock database as I am current at 780 megs of data.

#20

P

Poodlehead

P

Poodlehead

That's super cool that you had the foresight years ago to start documenting parts and xref PNs.

Yes, I'm old school too and would rather replace what needs replacement instead of throw away and buy new assy.

Thanks again for your help and responses. I greatly appreciate it!

What part of the country are you located in, just curious...

Yes, I'm old school too and would rather replace what needs replacement instead of throw away and buy new assy.

Thanks again for your help and responses. I greatly appreciate it!

What part of the country are you located in, just curious...

#22

P

Poodlehead

When I installed the big O-ring in the pickup tube, I think I pushed it too far in the pickup tube so the O-ring partially blocks the jets...

Not positive, but hopefully I'll get out there tomorrow to see if that's the problem...

Looking forward to cooler weather

P

Poodlehead

I got it started, but it's stumbling like it's real lean and won't idle... I got to thinking about it and think I know what the problem is...Did you get the Nikki to fly high and smooth?

When I installed the big O-ring in the pickup tube, I think I pushed it too far in the pickup tube so the O-ring partially blocks the jets...

Not positive, but hopefully I'll get out there tomorrow to see if that's the problem...

Looking forward to cooler weather

#23

F

Forest#2

If it does not idle good after you check the large o ring. Review the Nikki carb two barrel Idle circuit at this link. Note #12 in part 2. This is for the steel bowl but your idle circuit is the same. These idle circuits need cleaned. What I have done to get a good run W/O removing the carb fram a engine is remove the 3 screws from the top plate and take low pressure air 25 pounds and not direct inject into the holes under the plate, just blow air across the channels (use eye protection because this also will blow gas up out of the bowl) You can easily make the flat gasket for the top plate or turn it upside down if not torn and lightly smear vaseline across the dry hard gasket and re-install. This quite often clears the idle jet circuit. If this don't work use a tag wire and clean the idle jets hole from the top with the carb off and with the bowl removed you can see light through the jet holes at #12 blue and #5 by looking at a light on the bowl side. Also I make flat gaskets (gasket material from a automotive) for the intake to head where the O rings are. The double the gaskets so as they are about 3/32-1/8 inch thick.

The old o-rings sometimes do not seal good for re-use and the later kits sometimes includes the 1/8 inch thick flat gaskets.

Link to carb repairs: See the Nikki 2 barrel types and review part 1 and 2.

https://outdoorpowerinfo.com/repairs/

F

Forest#2

If you watch the video I sent the big o ring is suppose to be on the raised portion in the bowl instead of the pickup tube and it seats itself into the pickup tube as the bowl is installed. (this is casually mentioned at about 5:40-6:00 of the first part of the video when he pulls off the bowl) Apply just a light smear of vaseline to the o ring. Make sure it's not mashed or distorted. I doubt if this o ring is what is causing your issue unless the o ring got push up against a jet. It seals the bottom of the emulsion tube so as the solenoid shuts off all gas to the jets when the 12v is removed and pevents a backfireI got it started, but it's stumbling like it's real lean and won't idle... I got to thinking about it and think I know what the problem is...

When I installed the big O-ring in the pickup tube, I think I pushed it too far in the pickup tube so the O-ring partially blocks the jets...

Not positive, but hopefully I'll get out there tomorrow to see if that's the problem...

Looking forward to cooler weather

If it does not idle good after you check the large o ring. Review the Nikki carb two barrel Idle circuit at this link. Note #12 in part 2. This is for the steel bowl but your idle circuit is the same. These idle circuits need cleaned. What I have done to get a good run W/O removing the carb fram a engine is remove the 3 screws from the top plate and take low pressure air 25 pounds and not direct inject into the holes under the plate, just blow air across the channels (use eye protection because this also will blow gas up out of the bowl) You can easily make the flat gasket for the top plate or turn it upside down if not torn and lightly smear vaseline across the dry hard gasket and re-install. This quite often clears the idle jet circuit. If this don't work use a tag wire and clean the idle jets hole from the top with the carb off and with the bowl removed you can see light through the jet holes at #12 blue and #5 by looking at a light on the bowl side. Also I make flat gaskets (gasket material from a automotive) for the intake to head where the O rings are. The double the gaskets so as they are about 3/32-1/8 inch thick.

The old o-rings sometimes do not seal good for re-use and the later kits sometimes includes the 1/8 inch thick flat gaskets.

Link to carb repairs: See the Nikki 2 barrel types and review part 1 and 2.

https://outdoorpowerinfo.com/repairs/

#24

J

Johner

J

Johner

Once had a problem finding very small O-rings. Had the right size fuel line, cut 2 peaces the thickness of the O-ring and used them for my for the repair. Had a pic. how I did it but can not find the picture.

#25

P

Poodlehead

P

Poodlehead

I was able to easily find those o-rings this time, but that's a good idea about making them IF you have the right size line... That's worth remembering, thanks!Once had a problem finding very small O-rings. Had the right size fuel line, cut 2 peaces the thickness of the O-ring and used them for my for the repair...

#27

P

Poodlehead

That is a great video and if I have to pull off the carb, I'll definitely follow that vid and your suggestions very closely.

Thank you again! I'll update once I do something...

P

Poodlehead

Thank you! The carb is still on the mower so in addition to Vaseline, I pushed the bigger o-ring up in there to make sure the jets didn't fall out. I shouldn't have done that...Edited post #23 about the o ring you mentioned.

That is a great video and if I have to pull off the carb, I'll definitely follow that vid and your suggestions very closely.

Thank you again! I'll update once I do something...

#28

P

Poodlehead

P

Poodlehead

Well the O-ring pushed too far up in the pickup tube wasn't the problem. It still runs like crap, even above idle, like it's not getting enough fuel. I'll try removing the top plate and blow low air pressure through the idle circuit, but not expecting it to fix the problem. Hopefully I'll be wrong

Will update when I've done something . Thanks!

. Thanks!

Will update when I've done something

#29

F

Forest#2

F

Forest#2

Look at the pictures at outdoor link of the jet holes under the top plate.

When the carb is off the engine and the bowl off the carb you can see light through two of the holes looking towards the bowl.

On the other end of the channels from the jet holes is just small slits and a tag wire will not go through them. They come out inside the carb throat behind the throttle butterfly. You can also use the spray can carb cleaner in this area when the carb is off. If either side of these is restricted the carb will be upset both high and low.

The flat gasket under the plate must seal good when re-installed. If it's deeply compressed I turn it upside down or make another one then coat it with grease to soften the dried gasket.

Wear eye protection at all times when trying to clean the jet holes.

When the carb is off the engine and the bowl off the carb you can see light through two of the holes looking towards the bowl.

On the other end of the channels from the jet holes is just small slits and a tag wire will not go through them. They come out inside the carb throat behind the throttle butterfly. You can also use the spray can carb cleaner in this area when the carb is off. If either side of these is restricted the carb will be upset both high and low.

The flat gasket under the plate must seal good when re-installed. If it's deeply compressed I turn it upside down or make another one then coat it with grease to soften the dried gasket.

Wear eye protection at all times when trying to clean the jet holes.

#30

F

Forest#2

F

Forest#2

You may know this. (just mentioning another Nikki thing for this type carb)

Seems little strange that the large o ring is in the bottom of the plastic pickup tube when you pull the bowl. (it's quite common to see the o ring stay in the emulsion tube when the bowl is first removed instead of remaining in the bowl for re-assembly.)

The o ring should be in the bowl when installing the bowl because if it's in the pickup tube under the jets it can get pushed up too high by the bowl casting and upset the Nikki jets fuel intake.

Seems little strange that the large o ring is in the bottom of the plastic pickup tube when you pull the bowl. (it's quite common to see the o ring stay in the emulsion tube when the bowl is first removed instead of remaining in the bowl for re-assembly.)

The o ring should be in the bowl when installing the bowl because if it's in the pickup tube under the jets it can get pushed up too high by the bowl casting and upset the Nikki jets fuel intake.

#31

P

Poodlehead

P

Poodlehead

I was hoping the o-ring being pushed too far up in the pickup tube was my issue, but it wasn't. After removing the bowl yesterday, I put the O back on the bowl with Vaseline like you suggested, and reinstalled the bowl, but it made no difference.

One last thing I'm going to do before pulling the carb. With it running, spray carb cleaner around the sealing gaskets to see if it gets better. If it does, I know I have a leaking gasket issue.

Either way, once the carb comes off, I'm going through it. In addition to the jet and fuel passages, I'm assuming there should be some air passage that I need to make sure are clear too? Thank you!

One last thing I'm going to do before pulling the carb. With it running, spray carb cleaner around the sealing gaskets to see if it gets better. If it does, I know I have a leaking gasket issue.

Either way, once the carb comes off, I'm going through it. In addition to the jet and fuel passages, I'm assuming there should be some air passage that I need to make sure are clear too? Thank you!

#32

P

Poodlehead

P

Poodlehead

Finally an update:

After rebuilding the carb with new internal rubbers and cleaning the internal passages with wire, carb cleaner and compressed air, it runs better, but still still doesn't 'feel/sound' right.

I also sealed the plastic intake seams and put sealer between the carb and intake due to bowing on the plastic intake causing a leak.

I mowed for about 30 mins and it did ok, but it seems to cough occasionally, especially at lower speed.

There was a thin metal 'swirl plate' in the kit that I installed on the throttle side of the intake. It's supposed to be an update to swirl the air/fuel mixture, but I'm thinking about removing it to see if it helps.

I checked the plugs and I 'think' they look ok, but open to input. Thank you!

After rebuilding the carb with new internal rubbers and cleaning the internal passages with wire, carb cleaner and compressed air, it runs better, but still still doesn't 'feel/sound' right.

I also sealed the plastic intake seams and put sealer between the carb and intake due to bowing on the plastic intake causing a leak.

I mowed for about 30 mins and it did ok, but it seems to cough occasionally, especially at lower speed.

There was a thin metal 'swirl plate' in the kit that I installed on the throttle side of the intake. It's supposed to be an update to swirl the air/fuel mixture, but I'm thinking about removing it to see if it helps.

I checked the plugs and I 'think' they look ok, but open to input. Thank you!

Attachments

#33

F

Forest#2

F

Forest#2

Post up a picture of the swirl plate you mention?

If it did not have one when you took it apart I probably would have not used such.

I do not trust the rubber intake o rings. I take flat gasket material and make paper gasket about 3/32 inch thick. You can even use a cereal box but about 2 or 3 layers of the cardboard box needed and I use permatex gasket sealer sparringly. You do not want any silcone gasket material to get loose and go into the intake.

If the rubber o rings are still stuck in the intake manifold I just leave them in place or you can disgauard, but do not trust old ones for a good seal.

Some of the newer kits have 3/32 inch thick fiber gaskets to replace the o rings. (note that the plastic intake manifold has steel bushings to limit the tightening of the manifold. The intake to head bolts can be tight but the manifold not sealed good due to the steel hollow bushings.

Be sure your spark plugs are gapped properly and I would install new ones in reference to the spit at low speed and make sure the magneto air gaps are same. Might have to just run it awhile under load and maybe eventually see that all valve lashes are ok. If the spit is back through the carb eventually check the intake valve lash. Sometimes you can see which side of the carb has the spit back if the breather is removed.

Them type carbs can sometimes really cause you you get some good Nikki Carb experience.

Be really sure you re-connected the breather hose on the back of the air intake.

You can confirm such with the breather removed. If you leave it loose the engine is eating dirt.

If it did not have one when you took it apart I probably would have not used such.

I do not trust the rubber intake o rings. I take flat gasket material and make paper gasket about 3/32 inch thick. You can even use a cereal box but about 2 or 3 layers of the cardboard box needed and I use permatex gasket sealer sparringly. You do not want any silcone gasket material to get loose and go into the intake.

If the rubber o rings are still stuck in the intake manifold I just leave them in place or you can disgauard, but do not trust old ones for a good seal.

Some of the newer kits have 3/32 inch thick fiber gaskets to replace the o rings. (note that the plastic intake manifold has steel bushings to limit the tightening of the manifold. The intake to head bolts can be tight but the manifold not sealed good due to the steel hollow bushings.

Be sure your spark plugs are gapped properly and I would install new ones in reference to the spit at low speed and make sure the magneto air gaps are same. Might have to just run it awhile under load and maybe eventually see that all valve lashes are ok. If the spit is back through the carb eventually check the intake valve lash. Sometimes you can see which side of the carb has the spit back if the breather is removed.

Them type carbs can sometimes really cause you you get some good Nikki Carb experience.

Be really sure you re-connected the breather hose on the back of the air intake.

You can confirm such with the breather removed. If you leave it loose the engine is eating dirt.

#34

P

Poodlehead

P

Poodlehead

I hear ya about not changing anything, but I was 'going for the gusto'! I really suck at taking pictures along the way, but here is a link I found talking about the Swirl Plate and reference to the Briggs service bulletin.

I used both new rubber O rings and paper gaskets where the intake bolts to the heads. The bushings are built into the mounting bolts with 'shoulders' to keep from smashing the o-rings too tight. The shoulder is pushing against the paper gasket instead of the metal surface of the head. I guess what you are saying is to use either the paper gaskets or o-rings, but not both???

Yes, I need to replace plugs and check ALL the gap settings before I dynamite this mower...

And YES, I need to make sure the breather hose is connected properly. I think I forgot about it when reassembling...

Thank you!

I used both new rubber O rings and paper gaskets where the intake bolts to the heads. The bushings are built into the mounting bolts with 'shoulders' to keep from smashing the o-rings too tight. The shoulder is pushing against the paper gasket instead of the metal surface of the head. I guess what you are saying is to use either the paper gaskets or o-rings, but not both???

Yes, I need to replace plugs and check ALL the gap settings before I dynamite this mower...

And YES, I need to make sure the breather hose is connected properly. I think I forgot about it when reassembling...

Thank you!

#35

StarTech

StarTech

The problem area is not where the intake mounts to the heads but is where the carburetor mounts to the intake. It can warp to where the is no seal in the center between the two barrels of the two barrel Nikki carburetors. I had to replace intakes because of this.

#36

P

Poodlehead

I'm going to pull the shroud off, run the engine, and spray some carb cleaner around the mating surfaces to see if anything changes... Thank you!

P

Poodlehead

Yes I saw that when I mounted the intake to the carb, so I ran some gasket sealer between the carb and gasket.The problem area is not where the intake mounts to the heads but is where the carburetor mounts to the intake.

I'm going to pull the shroud off, run the engine, and spray some carb cleaner around the mating surfaces to see if anything changes... Thank you!

#37

F

Forest#2

F

Forest#2

You say:

I guess what you are saying is to use either the paper gaskets or o-rings, but not both???

Yes you can use both. Sometimes the old square shouldered o rings do not want to go back in place so I just give them a toss.

Keep in mind that a slight spit can be due to carbon buildup inside the cylinder on top of the piston, as it gets hot the fuel/carbon can ignite when valve is part way open.

I've never had a problem that I noticed where the carb mounts to the intake manifold. I'll start watching that closer and start using a straight edge.

When you have the shroud off running the engine watch into the cab intake, sometimes you can see which cylinder side of the two barrel carb is spitting back if it's a carbon or intake valve issue. (the two sides of the carb are isolated from each other. I've actually seen one side of them carbs completely dead, engine only running on one cylinder, give it a squirt of fuel into the carb throat on the dead side and momentarily get a live cylinder. This is not your problem, I'm just indicating that them carbs can really be a brain teaser with some of their issues)

I guess what you are saying is to use either the paper gaskets or o-rings, but not both???

Yes you can use both. Sometimes the old square shouldered o rings do not want to go back in place so I just give them a toss.

Keep in mind that a slight spit can be due to carbon buildup inside the cylinder on top of the piston, as it gets hot the fuel/carbon can ignite when valve is part way open.

I've never had a problem that I noticed where the carb mounts to the intake manifold. I'll start watching that closer and start using a straight edge.

When you have the shroud off running the engine watch into the cab intake, sometimes you can see which cylinder side of the two barrel carb is spitting back if it's a carbon or intake valve issue. (the two sides of the carb are isolated from each other. I've actually seen one side of them carbs completely dead, engine only running on one cylinder, give it a squirt of fuel into the carb throat on the dead side and momentarily get a live cylinder. This is not your problem, I'm just indicating that them carbs can really be a brain teaser with some of their issues)

#38

P

Poodlehead

P

Poodlehead

Well I pulled the shroud off, fired it up and listened closer. I think the occasional cough is actually coming out the exhaust, not through the carb. Spraying carb cleaner around the joints while the motor was running didn't change anything, so I don't think I have any air leaks.

The coils gaps are about a business card thickness gap,which I'm thinking is ok.

I think my next step will be to remove that damn Swish Plate and see what happens...

I've looked at many YouTube vids and that's where I found out about the plastic intake bowing and did confirm mine was bowed/leaking.

I did take a couple pics showing the air gap using a blue straight edge and the bows at each end of the captured nuts on the intake.

The coils gaps are about a business card thickness gap,which I'm thinking is ok.

I think my next step will be to remove that damn Swish Plate and see what happens...

I've looked at many YouTube vids and that's where I found out about the plastic intake bowing and did confirm mine was bowed/leaking.

I did take a couple pics showing the air gap using a blue straight edge and the bows at each end of the captured nuts on the intake.

Attachments

#39

P

Poodlehead

Before I removed the swirl plate, I fired it up one last time this morning and to my surprise, it seemed to run much better! I put the cover with air cleaner on it, mowed for over an hour, ran great, and no coughs!

Thank you all for your help!

P

Poodlehead

I think that must have been it...Might have to just run it awhile under load

Before I removed the swirl plate, I fired it up one last time this morning and to my surprise, it seemed to run much better! I put the cover with air cleaner on it, mowed for over an hour, ran great, and no coughs!

Thank you all for your help!

#40

F

Forest#2

F

Forest#2

I had not read your post #34 carefully.

Some good info in your post #34 link about the swirl plate.

The service bulletin mentioned in your link indicates the swirl plate for black smoke at some temps due to the fuel not atomizing correctly. (some of the carb engines did not use it) I've noticed that the carb throttle plates will sometimes hang up on a swirl plate if it's not aligned properly as the bolts are tightened.

Keep a heads up that a paper gasket is needed on each side of the eyebrow swirl plate.

I try to stay away from ethanol gas especially when a dual throat Nikki is involved. I also install a white inline fuel filter just before the fuel pump. White type is usually a finer filter for use with fuel pump vs the red coarser filter that is for gravity feed (no fuel pump)

Keep in mind what I told you in a previous post about quite often when a Dual throat Nikki has been running good and all at once instead of removing the carb for cleaning try removing the 3 screw top plate and use low pressure air directed at the slit channels in the very top of the carb under the plate. If you do not have access to a air compressor 20 lb air just try canned carb cleaner pressure. Blow nozzle from air compressor is best.

Be careful of bowl gas spewing upward towards your eyes. This is flushing the tiny jet slits down into the carb bowl and towards the carb throat.

Some good info in your post #34 link about the swirl plate.

The service bulletin mentioned in your link indicates the swirl plate for black smoke at some temps due to the fuel not atomizing correctly. (some of the carb engines did not use it) I've noticed that the carb throttle plates will sometimes hang up on a swirl plate if it's not aligned properly as the bolts are tightened.

Keep a heads up that a paper gasket is needed on each side of the eyebrow swirl plate.

I try to stay away from ethanol gas especially when a dual throat Nikki is involved. I also install a white inline fuel filter just before the fuel pump. White type is usually a finer filter for use with fuel pump vs the red coarser filter that is for gravity feed (no fuel pump)

Keep in mind what I told you in a previous post about quite often when a Dual throat Nikki has been running good and all at once instead of removing the carb for cleaning try removing the 3 screw top plate and use low pressure air directed at the slit channels in the very top of the carb under the plate. If you do not have access to a air compressor 20 lb air just try canned carb cleaner pressure. Blow nozzle from air compressor is best.

Be careful of bowl gas spewing upward towards your eyes. This is flushing the tiny jet slits down into the carb bowl and towards the carb throat.

#41

P

Poodlehead

P

Poodlehead

I still have it in there, but if I have any issues I'll jerk it out.

Good info on the fuel filters. I need to add one pronto.

I know how to look at my old threads now and will do so, if needed

Thanks again!

Good info on the fuel filters. I need to add one pronto.

I know how to look at my old threads now and will do so, if needed

Thanks again!