You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

New to me Tiger Cat

#1

S

Sonders

S

Sonders

Some of you may have seen my post while looking for a new Scag. The 12' Tiger Cat with 61" deck I ended up with is pretty nice. However I noticed earlier that with the deck up in transport position the right deck guide wheel rubs against the front caster wheel while going forward. Is that how it's supposed to be or is something out of whack?

#3

S

Sonders

S

Sonders

Here ya go Mad Mackie.

I mowed at 4" so it was still rubbing while mowing. I'm sure if the deck is dropped lower it wouldn't rub.

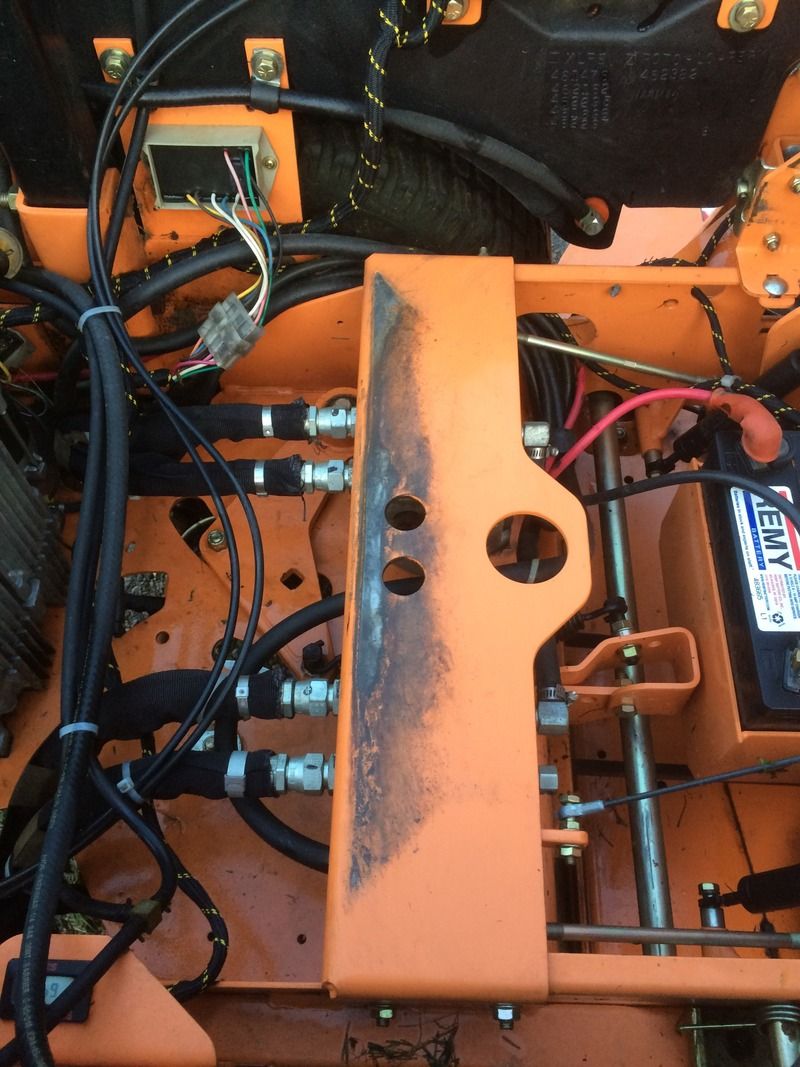

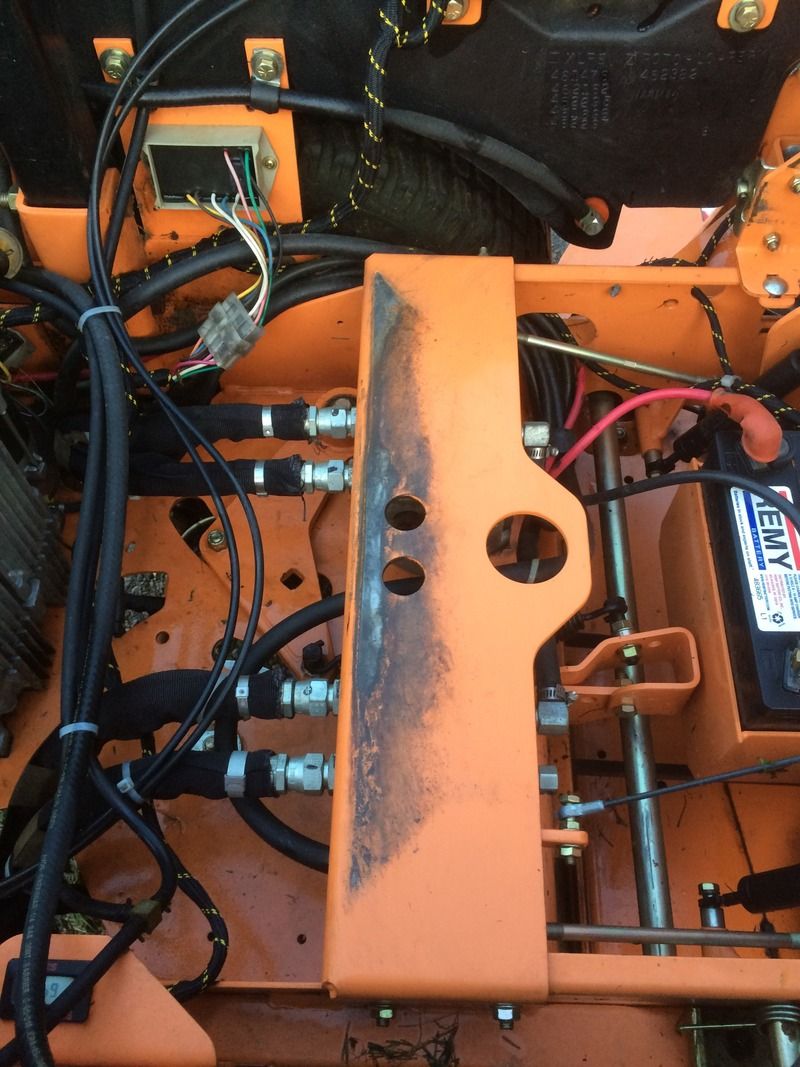

Also, under the seat base where these two open circles are, I looked in parts manual and looks like two retainer pins with springs go there? I assume to keep the seat base from rubbing on that lower plate?

And finally a shot of it after I cleaned all the caked grass clippings out from under deck from previous owner before I start using it.

I mowed at 4" so it was still rubbing while mowing. I'm sure if the deck is dropped lower it wouldn't rub.

Also, under the seat base where these two open circles are, I looked in parts manual and looks like two retainer pins with springs go there? I assume to keep the seat base from rubbing on that lower plate?

And finally a shot of it after I cleaned all the caked grass clippings out from under deck from previous owner before I start using it.

#4

W

whelch1

W

whelch1

The tiger cat doesn't come from the factory with flat free castors, they are an upgrade. I wonder if that's why they are rubbing? Also if they are bigger than normal, could that be why the deck has back rake?

#5

S

Sonders

S

Sonders

Probably so Welch. Didn't realize they didn't come with flat free casters. I know the new ones do. Just read in the manual that the deck is supposed to be level. I was thinking of my old TT w/ Advantage deck that was supposed to be 1/4" pitched forward.

#6

M

Mad Mackie

M

Mad Mackie

Several things that I noticed from your pics.

a. The seat switch and the support ring that it is mounted into are missing.

b. The seat support is missing the two springs that hold the seat off the seat switch when no one is on the seat.

c. The maximum front caster tire size for a 61" Tiger Cat is 13X6.5x6, check the tires to see what size they are.

d. The part number marked in red on the R/H front fork tells me that this is a replacement part. I wonder why it was replaced, possibly the PO had an incident with this machine and bent the original fork and possibly the front support, the weldment that holds the casters, may be bent causing the R/H front caster tire to come in contact with the anti-scalp wheel on the deck.

If you purchased this machine from a dealer, I suggest that you return it to them and ask them to restore it to the original configuration or return your money.

With no seat switch, this machine is a safety hazard to the operator.

Not only has this machine been "butchered", but it may have been damaged from an accident that involved the front suspension and possibly the machine frame and/or the deck. If the machine frame is bent in any way, then you will never be able to get the deck leveled correctly.

This machine may have more "hidden" problems that could haunt you later on.

Just my thoughts!!!

a. The seat switch and the support ring that it is mounted into are missing.

b. The seat support is missing the two springs that hold the seat off the seat switch when no one is on the seat.

c. The maximum front caster tire size for a 61" Tiger Cat is 13X6.5x6, check the tires to see what size they are.

d. The part number marked in red on the R/H front fork tells me that this is a replacement part. I wonder why it was replaced, possibly the PO had an incident with this machine and bent the original fork and possibly the front support, the weldment that holds the casters, may be bent causing the R/H front caster tire to come in contact with the anti-scalp wheel on the deck.

If you purchased this machine from a dealer, I suggest that you return it to them and ask them to restore it to the original configuration or return your money.

With no seat switch, this machine is a safety hazard to the operator.

Not only has this machine been "butchered", but it may have been damaged from an accident that involved the front suspension and possibly the machine frame and/or the deck. If the machine frame is bent in any way, then you will never be able to get the deck leveled correctly.

This machine may have more "hidden" problems that could haunt you later on.

Just my thoughts!!!

#7

M

Mad Mackie

M

Mad Mackie

I'm going to my local Scag dealer today or tomorrow and I will look at the 61" Tiger Cat that they have in stock.

#9

S

Sonders

S

Sonders

As I've been reading theough the operators manual I noticed it says to measure from top of deck because the bottom of Velocity deck is uneven. I was taking my measurements from all 4 bottom corners. I'll have to recheck that. Also looked through parts manual and I see the seat switch, but I can't find an actual drawing or part # for the ring it goes in that goes in the seat base. I'll have to trace the wiring harness and see what previous owner did with the plug for it. Really bummed about my purchase now.

#10

S

Sonders

S

Sonders

I checked the front casters when I got home today. They are 13x6.5-6/4.5. Also, checking deck level by measuring top of deck at all four corners shows it being dead on level. So thats good atleast.

#11

S

Sonders

S

Sonders

Also, had a chance to trace the wiring harness for seat switch and it runs up under the seat itself, then can't see it after that. So I assume it's under the bottom seat cushion.

#12

S

Scagman01a

S

Scagman01a

That deck is missing several decals to include velocity and 61 and scag above the castor arms. What I'm saying is it may have been repainted. If so, the damage may or may not have been repaired. That castor wheel is to close. Something is not right.

#13

S

Sonders

S

Sonders

I pulled the decals off. They were peeling so I went ahead and took them off and ordered all new ones.

#15

S

Sonders

S

Sonders

I've put 5 hrs on the mower since buying it and so far so good. Yard looks awesome and stripes out nicely. I'm happy with it so far.

The only thing I can think to do on the caster wheel is to grind it down slightly so it won't rub on tire, or drill a new hole slightly back in it's mounting bracket to move the caster wheel back a little bit. I haven't been able to find anything out of whack on the deck itself.

Also stopped by the Scag dealer close to work on lunch break last friday and looked at new one to compare a few things. It had suspension seat as well and didn't have seat switch and the 2 keeper springs in the lower seat support either; it was set up just like mine. So I assume the switch and springs only go in that support piece on the machines with basic seat and on ones with suspension seat the switch goes up in the base of the actual seat bottom.

The only thing I can think to do on the caster wheel is to grind it down slightly so it won't rub on tire, or drill a new hole slightly back in it's mounting bracket to move the caster wheel back a little bit. I haven't been able to find anything out of whack on the deck itself.

Also stopped by the Scag dealer close to work on lunch break last friday and looked at new one to compare a few things. It had suspension seat as well and didn't have seat switch and the 2 keeper springs in the lower seat support either; it was set up just like mine. So I assume the switch and springs only go in that support piece on the machines with basic seat and on ones with suspension seat the switch goes up in the base of the actual seat bottom.

#16

M

Mad Mackie

M

Mad Mackie

I was wondering about the seat switch and spring changes as your pic showed that the other welded on pieces for the switch and the springs were not there. I still don't see these changes in the parts manuals as yet.

I replaced the seat on my Tiger Cub with a similar one to yours, but no switch installed and no "Scag" name on the seat. This seat is much heavier that the stock seat was and compresses the springs holding down the seat switch with no one on the seat. Evidently Scag has dealt with this problem by removing the springs and seat switch from the support and putting the switch in the seat itself.

I will ask the manufacturer of the seat if a switch is available to be installed into the seat and if so I will make the change.

As for the caster touching the deck wheel, check if there are additional bolt holes that you can move the wheel bracket into to get more clearance from the R/H caster wheel.

I did notice in your pics that the electronic control module connector had dirt and dust in it. I clean the electrical connectors on my machine periodically with HP air. Dust in these connectors increases the possibility of electrical continuity problems. Years ago I tried conductive electrical connector grease on these type of connectors, but it made the dust and dirt accumulation much worse and difficult to cleanout, so I just inspect, clean and reconnect them.

If you plan to readjust the deck level, let me know and I will give you the basics of this adjustment procedure as the manual is somewhat confusing to follow making the process much more difficult.

I gotta hookup my trailer and get mowing, another hot one today, but I gotta do what I gotta do!!!!:laughing::biggrin::smile:

I replaced the seat on my Tiger Cub with a similar one to yours, but no switch installed and no "Scag" name on the seat. This seat is much heavier that the stock seat was and compresses the springs holding down the seat switch with no one on the seat. Evidently Scag has dealt with this problem by removing the springs and seat switch from the support and putting the switch in the seat itself.

I will ask the manufacturer of the seat if a switch is available to be installed into the seat and if so I will make the change.

As for the caster touching the deck wheel, check if there are additional bolt holes that you can move the wheel bracket into to get more clearance from the R/H caster wheel.

I did notice in your pics that the electronic control module connector had dirt and dust in it. I clean the electrical connectors on my machine periodically with HP air. Dust in these connectors increases the possibility of electrical continuity problems. Years ago I tried conductive electrical connector grease on these type of connectors, but it made the dust and dirt accumulation much worse and difficult to cleanout, so I just inspect, clean and reconnect them.

If you plan to readjust the deck level, let me know and I will give you the basics of this adjustment procedure as the manual is somewhat confusing to follow making the process much more difficult.

I gotta hookup my trailer and get mowing, another hot one today, but I gotta do what I gotta do!!!!:laughing::biggrin::smile:

#17

S

Sonders

S

Sonders

I tried lowering the caster wheel bracket to the lower setting, but it still rubs, so went ahead and put it back to top setting where it was. I was wondering about the connector having dust all over it; doesn't seem like a very good design to have it exposed like it is. Mad Mackie you actually talked me through leveling the deck on my old Turf Tiger a few yrs ago; what a pain that was. I like the way this one mows so I'm leaving it alone. Only thing that has me wondering now is if it stripes this good by itself, wonder how awesome the stripes would look with a Tiger Striper....... Don't think I'll be spending the $4-500 anytime soon to find out though haha.

#18

M

Mad Mackie

M

Mad Mackie

I went to my local Scag dealer today to get some parts. I looked over a new Tiger Cat with a suspension seat and saw where the seat springs and switch have been removed from the support and the seat switch relocated into the seat bottom.

I'm going to order a seat switch for my aftermarket suspension seat as it is available for Milsco/Michigan suspension seats.

Good to hear that your Tiger Cat is mowing fine!!!

I had forgot that we went thru deck leveling on your Turf Tiger a while back!!! Your Tiger Cat has the same deck suspension system.

Check out my post in the Briggs & Stratton form!!!

I'm going to order a seat switch for my aftermarket suspension seat as it is available for Milsco/Michigan suspension seats.

Good to hear that your Tiger Cat is mowing fine!!!

I had forgot that we went thru deck leveling on your Turf Tiger a while back!!! Your Tiger Cat has the same deck suspension system.

Check out my post in the Briggs & Stratton form!!!

#19

S

Sonders

S

Sonders

Right, I thought all the mounting of the deck looked the same width the only real difference being the addition of the quick side to side leveling bracket on the left side. Sometime if I get a chance I may try to pitch it 1/4" forward and see if it makes any difference.

Unplugged all the electrical plugs and gave them a good spray down with some electronic spray cleaner. Boy were they all dirty. Just about have it all cleaned up with fresh new decals as well. My wife thinks I'm crazy for spending money on decals, but I want it looking as clean as possible.

Unplugged all the electrical plugs and gave them a good spray down with some electronic spray cleaner. Boy were they all dirty. Just about have it all cleaned up with fresh new decals as well. My wife thinks I'm crazy for spending money on decals, but I want it looking as clean as possible.

#20

K

kwak

K

kwak

I have a picture I will post as soon as I can but I have a '13 Tiger Cat and in comparison it looks like either:

1. Your deck is pushed slightly forward and to the left

or

2. Your front wheel is bent back and to the right

I am at work right now so I can't post a picture but I will try to get it tonight.

1. Your deck is pushed slightly forward and to the left

or

2. Your front wheel is bent back and to the right

I am at work right now so I can't post a picture but I will try to get it tonight.

#21

S

Sonders

S

Sonders

I agree with you kwak; it has to be one of those. It must be the caster mount because the deck looks perfectly even as far as the back of the deck being in line with the rear tires. The spacing is the same on both that is. I was kind of wondering if it maybe has the wrong front bracket; maybe it's the bracket that goes on the 48-52" models. Wish it had a part number on it somewhere.

#22

S

Sonders

S

Sonders

I checked out a 48" Tiger Cat today and my theory of mine having the wrong front caster mounting arm is wrong. It has obviously shorter arm lengths. The right side arm on mine must be slightly bent back. I wonder if it could be heated and pulled back forward about an inch. My main concern with doing this would be chance of weakening the arm or warping it ever so slightly. As it is the mower tracks good and front casters are perfectly balanced still. I'd be afraid if I messed with that arm it would throw that off. For the time being I guess I'll live with it seeing as hiw all it is is a solid plastic gauge wheel slightly rubbing against a semi pneumatic solid tire. I don't think it's hurting anything.

#23

M

Mad Mackie

M

Mad Mackie

Hi Sonders,

I was at my local Scag dealer yesterday and they had just put a new Tiger Cat with a 61" deck in the show room. There is about 1.5" to 2" clearance between the R/H front caster and the deck anti-scalp wheel.

I would think that if this support was bent back that it would show where with some disturbed paint.

I was at my local Scag dealer yesterday and they had just put a new Tiger Cat with a 61" deck in the show room. There is about 1.5" to 2" clearance between the R/H front caster and the deck anti-scalp wheel.

I would think that if this support was bent back that it would show where with some disturbed paint.

#24

S

Sonders

S

Sonders

I agree Mackie. It has some touchup paint on the front of that brace; but not much. I need to get a picture straight on of the machine instead of the angled picture I originally posted. I think my easiest course of action is going to be to drill new hole in the guad wheel bracket to shift the wheel back about a 1/4 -1/2". I hate to mess with it much because it mows good and rides good as is.

#25

S

Steve0853

S

Steve0853

Mad Mackie,

Please reply with your deck leveling instructions. I have a nice fine 2012 Turf Tiger 31 HP water cooled with a 61 inch deck and I believe I have it leveled perfectly, but it doesn't cut as pretty as my old worn out 2002 Grasshopper 225. Also, my sister has an old Toro 72 inch that looks like Fred Sanford wouldn't take it home, but it cuts smoother and faster without leaving sprigs standing up than my fine much newer Turf Tiger.

I checked the level according to the manual. I have measured the deck on all four corners on a level concrete floor and the height is the same on all four corners and the chains are tight. I keep sharp blades on it at all times.

Thanks for your help.

Please reply with your deck leveling instructions. I have a nice fine 2012 Turf Tiger 31 HP water cooled with a 61 inch deck and I believe I have it leveled perfectly, but it doesn't cut as pretty as my old worn out 2002 Grasshopper 225. Also, my sister has an old Toro 72 inch that looks like Fred Sanford wouldn't take it home, but it cuts smoother and faster without leaving sprigs standing up than my fine much newer Turf Tiger.

I checked the level according to the manual. I have measured the deck on all four corners on a level concrete floor and the height is the same on all four corners and the chains are tight. I keep sharp blades on it at all times.

Thanks for your help.

#26

S

Sonders

S

Sonders

Speaking of touch up paint. I ordered a can. There are a few spots of rust on top right rear corner of deck where previous owner had a block off plate mounted. Whats best method to apply the touch up paint on mower deck? Just sand down the spots, clean real good then spray just like would on anything else? Then do I need some type of clearcoat over it or is this paint hold up good on its own?

#27

M

Mad Mackie

M

Mad Mackie

Sonders,

I think that Scag machines are powdercoat painted. I would sand and then mask off the area then spray it. If I get back to my Scag dealer soon, I will take a pic of the 61" Tiger Cat if it is still there. I had my cell phone with me, but it is new to me and I might get to know how to use it before I turn 80!! I'm 71 now!!!

I think that Scag machines are powdercoat painted. I would sand and then mask off the area then spray it. If I get back to my Scag dealer soon, I will take a pic of the 61" Tiger Cat if it is still there. I had my cell phone with me, but it is new to me and I might get to know how to use it before I turn 80!! I'm 71 now!!!

#28

S

Sonders

S

Sonders

Yeah I'm going to try to stop at dealer tomorrow and get a better look at 61" model. May try to measure distance or something of arms for comparison.

#29

M

Mad Mackie

M

Mad Mackie

Steve0853,

Here are the basics of correct Scag deck leveling.

Flat and level area to place the machine on.

Correct tire pressure.

Position the deck height adjuster in 3 1/2" position, unlock the deck.

I measure the actual blade height with a small tool that I made up. I will take a pic of it and post it, I'm not sure where it is at the moment, tool boxes are in my trailer.

Clean or new blades installed.

The front deck hanger levers are a fixed unit. Basically one piece as far as we are concerned, no adjustment other than the fine adjustment on the left front chain.

The rear hanger levers are independent from each other, and are held inposition by the rods that connect them to the front hanger levers.

The rear of the deck are the only leveling adjustments. Moving the nuts on the rods will change the adjustment.

Position the outboard blades forward and check the height at the blade tip forward and aft.

The forward facing blade tip should be 1/8 to 3/16 of an inch lower than the rear facing blade tip.

When you have performed these adjustments to both sides of the deck, and know the blade height, then you adjust the height to match the adjustable stop by turning the short rod. Raise up the deck to lock it and make sure that the deck up stops are not stopping the deck from locking in the up position.

You may need to reposition the deck height position pin to more closely match the actual blade height and readjust the short rod so the deck will lock in the up position.

Here are the basics of correct Scag deck leveling.

Flat and level area to place the machine on.

Correct tire pressure.

Position the deck height adjuster in 3 1/2" position, unlock the deck.

I measure the actual blade height with a small tool that I made up. I will take a pic of it and post it, I'm not sure where it is at the moment, tool boxes are in my trailer.

Clean or new blades installed.

The front deck hanger levers are a fixed unit. Basically one piece as far as we are concerned, no adjustment other than the fine adjustment on the left front chain.

The rear hanger levers are independent from each other, and are held inposition by the rods that connect them to the front hanger levers.

The rear of the deck are the only leveling adjustments. Moving the nuts on the rods will change the adjustment.

Position the outboard blades forward and check the height at the blade tip forward and aft.

The forward facing blade tip should be 1/8 to 3/16 of an inch lower than the rear facing blade tip.

When you have performed these adjustments to both sides of the deck, and know the blade height, then you adjust the height to match the adjustable stop by turning the short rod. Raise up the deck to lock it and make sure that the deck up stops are not stopping the deck from locking in the up position.

You may need to reposition the deck height position pin to more closely match the actual blade height and readjust the short rod so the deck will lock in the up position.

#30

C

clay45

C

clay45

Sorry I'm not at my Tiger Cat but I know one of my wheels is a tad forward of the other. The arm they attach to appears as if it could be shifted right or left in the mount. If thats true it could be that yours has somehow been nudged too far left causing the right side wheel to be too close to the deck.

Just a thought.

Regards,

Clay

Just a thought.

Regards,

Clay

#31

M

Mad Mackie

M

Mad Mackie

Due to the design of the deck, the right front caster wheel is set farther forward than the left to allow clearance.

#32

S

Sonders

S

Sonders

Thats kinda what I figured that the right wheel is supposed to be slightly forward of the left wheel. Didn't get a chance to stop by dealer saturday so going to try to run over on lunch break one day this week and get a better look. The right arm has got to be bent slightly back on mine, about the only possibility I can come up with.

In other news I got my replacement decals put on to freshen it up. Going to sand the bad spots on the deck this weekend and get them painted.

In other news I got my replacement decals put on to freshen it up. Going to sand the bad spots on the deck this weekend and get them painted.

#34

S

Sonders

S

Sonders

Thanks for posting up kwak. I went to dealer today and measured the width from top of caster left to right. Mine is exactly an inch further apart. I'll try to pull the front caster mount bar off sometime and maybe put it in vise and try to rig up a way to use porta-power on it or something.

#35

S

Steve0853

Thanks Mackie. I'm going to level my deck this weekend.

S

Steve0853

Steve0853,

Here are the basics of correct Scag deck leveling.

Flat and level area to place the machine on.

Correct tire pressure.

Position the deck height adjuster in 3 1/2" position, unlock the deck.

I measure the actual blade height with a small tool that I made up. I will take a pic of it and post it, I'm not sure where it is at the moment, tool boxes are in my trailer.

Clean or new blades installed.

The front deck hanger levers are a fixed unit. Basically one piece as far as we are concerned, no adjustment other than the fine adjustment on the left front chain.

The rear hanger levers are independent from each other, and are held inposition by the rods that connect them to the front hanger levers.

The rear of the deck are the only leveling adjustments. Moving the nuts on the rods will change the adjustment.

Position the outboard blades forward and check the height at the blade tip forward and aft.

The forward facing blade tip should be 1/8 to 3/16 of an inch lower than the rear facing blade tip.

When you have performed these adjustments to both sides of the deck, and know the blade height, then you adjust the height to match the adjustable stop by turning the short rod. Raise up the deck to lock it and make sure that the deck up stops are not stopping the deck from locking in the up position.

You may need to reposition the deck height position pin to more closely match the actual blade height and readjust the short rod so the deck will lock in the up position.

Thanks Mackie. I'm going to level my deck this weekend.

#38

M

Mad Mackie

M

Mad Mackie

Here are pics and a description of my blade height measuring tool.

The long nut is for connecting threaded rods together. This nut is threaded to 3/8-16.

The top bolt and nut are at a fixed setting.

The bottom bolt is from an appliance and originally had a plastic shoe on it. As it has a large flat head, it works fine for this application.

As this is threaded to 16 threads per inch, one full turn is 1/16" for easy measurement.

I have marked both the bolt and long nut so I can count the turns.

It is setup at a low height of 2 1/2" and extends up to 3 1/2" in 1/16" increments.

Click on the links to the jpegs.

The yellow John Deere gauge is a pain to work with, but available at a JD dealer.

Have fun!!!

The long nut is for connecting threaded rods together. This nut is threaded to 3/8-16.

The top bolt and nut are at a fixed setting.

The bottom bolt is from an appliance and originally had a plastic shoe on it. As it has a large flat head, it works fine for this application.

As this is threaded to 16 threads per inch, one full turn is 1/16" for easy measurement.

I have marked both the bolt and long nut so I can count the turns.

It is setup at a low height of 2 1/2" and extends up to 3 1/2" in 1/16" increments.

Click on the links to the jpegs.

The yellow John Deere gauge is a pain to work with, but available at a JD dealer.

Have fun!!!

Attachments

#39

M

Mad Mackie

M

Mad Mackie

Hi Sonders,

There is no doubt that the front weldment is bent back at the right caster. This part is available from Scag but no doubt pricey!!!

You can remove this piece and take it to a frame straightening shop, you will need to get the measurements from another 61" Tiger Cat.

I have the same suspension seat on my machine that I put on. As it is much heavier than the stock seat and doesn't have a switch in it, I'm going to add two more seat springs. I have the pieces from Scag and will weld in the two seat springs after I makeup the mounts for them.

I only have a small area to put the new sear springs.

As you machine was originally equipped with the suspension sear with a switch, the seat support doesn't have these installed in it.

Fortunately this support is easily removed from the machine making this job fairly easy.

There is no doubt that the front weldment is bent back at the right caster. This part is available from Scag but no doubt pricey!!!

You can remove this piece and take it to a frame straightening shop, you will need to get the measurements from another 61" Tiger Cat.

I have the same suspension seat on my machine that I put on. As it is much heavier than the stock seat and doesn't have a switch in it, I'm going to add two more seat springs. I have the pieces from Scag and will weld in the two seat springs after I makeup the mounts for them.

I only have a small area to put the new sear springs.

As you machine was originally equipped with the suspension sear with a switch, the seat support doesn't have these installed in it.

Fortunately this support is easily removed from the machine making this job fairly easy.

#40

S

Sonders

S

Sonders

Would be nice if they made these with individual bolt on arms that can be replaced cheaper like on the Turf Tiger. Definitely going the bending route vs buying a new one.

I was wondering what those springs looked like. I had thought of adding them to mine just so the seat base plate wouldn't rub on that bottom piece. But like you mentioned the suspension seat is to heavy for those springs, I won't waste my money on them.

I was wondering what those springs looked like. I had thought of adding them to mine just so the seat base plate wouldn't rub on that bottom piece. But like you mentioned the suspension seat is to heavy for those springs, I won't waste my money on them.

#42

S

Steve0853

S

Steve0853

Mad Mackie,

Thanks for posting the blade adjustment instructions. I did mine Saturday morning and it improved the cut dramatically. I had previously done the deck leveling using the manual, but I don't think it included the instructions to have the front facing blade tip 1/8 to 3/16 lower than the rear facing tip. My front facing blade tips were nearly 1/2 inch lower than the rear facing tips.

Thanks for posting the blade adjustment instructions. I did mine Saturday morning and it improved the cut dramatically. I had previously done the deck leveling using the manual, but I don't think it included the instructions to have the front facing blade tip 1/8 to 3/16 lower than the rear facing tip. My front facing blade tips were nearly 1/2 inch lower than the rear facing tips.

#43

S

Sonders

S

Sonders

Just an update.....this past weekend I disassembled the front end and took the entire front mounting piece over to my dads shop to try and get it back in place as it should be. Put it in vise, heated with torch and was able to get it pulled back in about 1/2". After it cooled I hit the area with some oem paint and now can't even tell anything was done to it. It doesn't have as much clearance as they do from factory, but I fixed my wheel rub issue so I'm happy. I was afraid to mess with it much more and risk screwing it up.

On a side note I also scored a nice used Tiger Striper kit for $100. I'll give it a try. If I don't like it I should be able to atleast get my money back out of it.

On a side note I also scored a nice used Tiger Striper kit for $100. I'll give it a try. If I don't like it I should be able to atleast get my money back out of it.

#44

M

Mad Mackie

M

Mad Mackie

After looking at a new 61" Tiger Cat at my local dealer, I looked at my 20 ton press to see if the front suspension would fit into the press frame for straightening, I think that it would go. I have straightened cast steel front axles on Case/Ingersoll GTs with mild heat.

On the 61" Tiger Cub/Cats that is a long extension to the right front caster. With the Velocity decks, Scag extended them slightly more compared to machines that have the Advantage decks with a smaller chute opening.

On the 61" Tiger Cub/Cats that is a long extension to the right front caster. With the Velocity decks, Scag extended them slightly more compared to machines that have the Advantage decks with a smaller chute opening.