You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

Murray 24583 40" snow thrower worm drive question

#1

B

beaverplt

B

beaverplt

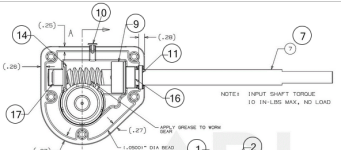

In the recent round of snowstorms here in Wisconsin, the brass auger gear inside the worm drive shredded. I got a new gear and ran into what I think is a problem with the reassembly. The collar on one side of the worm gear is not held in tightly. I've marked the area in blue in the picture. It looks like there's a flange missing. I'm sure I didn't lose any parts, but just in case I've looked all over my workspace and can't find anything that might remotely resemble a flange. Of course, there isn't a schematic for this particular assembly for me to be sure it is missing . At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

#2

J

Jack17

J

Jack17

Hi BP.

Look closely at the worm part of it. See where most of wear is happening? I think that a bushing of sort is missing all the way on the right side, right before spacer/sleeve bearing that engages gear housing. If you were to insert something there the whole gap marked in blue would disappear.

Look closely at the worm part of it. See where most of wear is happening? I think that a bushing of sort is missing all the way on the right side, right before spacer/sleeve bearing that engages gear housing. If you were to insert something there the whole gap marked in blue would disappear.

#3

S

SeniorCitizen

S

SeniorCitizen

If you get the parts determined , i recommend replacing the worm drive as well as the spur gear . A new gear won't correct the worm drive problem but the worm drive problem will cause the gear to fail prematurely .

#4

B

beaverplt

B

beaverplt

That was my original intention after seeing the damage caused when I disassembled the unit. Unfortunately, due to the age of the blower, all those items are discontinued. The brass gear was easy as it is the same gear used in many MTD blowers. I've not found another worm gear yet. With more snow coming, I've got to get this thing useable soon.If you get the parts determined , i recommend replacing the worm drive as well as the spur gear . A new gear won't correct the worm drive problem but the worm drive problem will cause the gear to fail prematurely .

#5

B

beaverplt

B

beaverplt

I might have found a worm gear shaft that is the same size. I'm waiting for an answer to a question I asked about the size. If it is the correct size, then all I need to do is get the current impeller off of the shaft. I've been attempting that over the past two days. It's so rusted on that all the PB blaster and heat I've tried are not budging it. So, I might be looking for an impeller as well.

#6

S

SeniorCitizen

S

SeniorCitizen

I've taken a few parts apart that seemed stuck forever but i can't find a murray impeller and shaft to look at and possibly determine what you're up against .

#7

B

beaverplt

B

beaverplt

Over the past week, I've tried everything I know of short of cutting the impeller off. Obviously, that would require a new impeller along with a shaft. I'm going back to a thought I had about getting a shim in the gap. I'll see where that thought takes me.

#8

K

kjonxx

K

kjonxx

Looks like half the rear bushing is gone, also to remove the impeller I have cut along tube with cutting wheel then after its off weld it back up when its on the shaft.In the recent round of snowstorms here in Wisconsin, the brass auger gear inside the worm drive shredded. I got a new gear and ran into what I think is a problem with the reassembly. The collar on one side of the worm gear is not held in tightly. I've marked the area in blue in the picture. It looks like there's a flange missing. I'm sure I didn't lose any parts, but just in case I've looked all over my workspace and can't find anything that might remotely resemble a flange. Of course, there isn't a schematic for this particular assembly for me to be sure it is missingView attachment 67649. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

#9

B

barny57

B

barny57

Yeah where the guys got it outlined in blue you’re missing something they’re probably a plastic spacerIn the recent round of snowstorms here in Wisconsin, the brass auger gear inside the worm drive shredded. I got a new gear and ran into what I think is a problem with the reassembly. The collar on one side of the worm gear is not held in tightly. I've marked the area in blue in the picture. It looks like there's a flange missing. I'm sure I didn't lose any parts, but just in case I've looked all over my workspace and can't find anything that might remotely resemble a flange. Of course, there isn't a schematic for this particular assembly for me to be sure it is missingView attachment 67649. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

#10

R

RevB

R

RevB

You

In the recent round of snowstorms here in Wisconsin, the brass auger gear inside the worm drive shredded. I got a new gear and ran into what I think is a problem with the reassembly. The collar on one side of the worm gear is not held in tightly. I've marked the area in blue in the picture. It looks like there's a flange missing. I'm sure I didn't lose any parts, but just in case I've looked all over my workspace and can't find anything that might remotely resemble a flange. Of course, there isn't a schematic for this particular assembly for me to be sure it is missingView attachment 67649. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Than

You were never supposed to open this thing up...In the recent round of snowstorms here in Wisconsin, the brass auger gear inside the worm drive shredded. I got a new gear and ran into what I think is a problem with the reassembly. The collar on one side of the worm gear is not held in tightly. I've marked the area in blue in the picture. It looks like there's a flange missing. I'm sure I didn't lose any parts, but just in case I've looked all over my workspace and can't find anything that might remotely resemble a flange. Of course, there isn't a schematic for this particular assembly for me to be sure it is missingView attachment 67649. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks, it was only sold as a unit. What crappy engineering. The roll pin kind of intimates that the worm is replaceable. Wherever you got the gear enquire if there is a matching worm. Failing that, take some measurements and see if there is a worm that comes close dimensionally. May have to cut it down in length or bore it out but a machine shop can handle that....unless you're a machinist. Or look for a set that can be adapted.

#11

R

RevB

www.mcmaster.com

www.mcmaster.com

R

RevB

In the recent round of snowstorms here in Wisconsin, the brass auger gear inside the worm drive shredded. I got a new gear and ran into what I think is a problem with the reassembly. The collar on one side of the worm gear is not held in tightly. I've marked the area in blue in the picture. It looks like there's a flange missing. I'm sure I didn't lose any parts, but just in case I've looked all over my workspace and can't find anything that might remotely resemble a flange. Of course, there isn't a schematic for this particular assembly for me to be sure it is missingView attachment 67649. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

McMaster-Carr

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

#12

R

RevB

R

RevB

In the recent round of snowstorms here in Wisconsin, the brass auger gear inside the worm drive shredded. I got a new gear and ran into what I think is a problem with the reassembly. The collar on one side of the worm gear is not held in tightly. I've marked the area in blue in the picture. It looks like there's a flange missing. I'm sure I didn't lose any parts, but just in case I've looked all over my workspace and can't find anything that might remotely resemble a flange. Of course, there isn't a schematic for this particular assembly for me to be sure it is missingView attachment 67649. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

In the recent round of snowstorms here in Wisconsin, the brass auger gear inside the worm drive shredded. I got a new gear and ran into what I think is a problem with the reassembly. The collar on one side of the worm gear is not held in tightly. I've marked the area in blue in the picture. It looks like there's a flange missing. I'm sure I didn't lose any parts, but just in case I've looked all over my workspace and can't find anything that might remotely resemble a flange. Of course, there isn't a schematic for this particular assembly for me to be sure it is missingView attachment 67649. At this point, I'm wondering if I can shim the collar to fit tighter to the roll pin. Thanks

#13

StarTech

StarTech

It looks like the bushing was installed wrong. As installed it would have never prevented the worm gear walking itself out except for the large bushing that normally ride on the flange of the bronze bushing. Also appears to be missing a grease seal.

#14

B

beaverplt

B

beaverplt

RevB, you are correct. The whole assembly was only available as a complete unit. Unfortunately, it's discontinued. I had to improvise something. I ended up installing washers to take up the gap. It works turning it by hand, but I haven't been able to field test it yet as the bearing I need to hold it in the housing is also discontinued. Of course, I learned that the hard way as the company I ordered it from never told me it was discontinued. They just canceled the order. I found a similar bearing and should get it tomorrow.

#15

J

jono252525

J

jono252525

Your bushing colar should be inside close to the worm gear and you need to install a oil seal at the external casing witch is missing right now.

#16

B

beaverplt

B

beaverplt

That bushing is as close to the worm gear as it can get due to the roll pin. The oil seal is back in place now that I've reassembled it.

#19

B

beaverplt

B

beaverplt

Ahh, Got it. Unfortunately, that bushing is no longer available. Also, because I couldn't get the impeller off the shaft, I would not have been able to put it on. That is why I had to add washers in the form of C clips between what's left of the original bushing and the thrust collar. It is definitely Jerry-Rigged, so we will see how it works. If it does, great. If it doesn't, plan B

#20

S

SeniorCitizen

S

SeniorCitizen

It's common to apply heat in the wrong place when heat is needed to pull 2 items apart .

#21

StarTech

StarTech

It also can be the wrong kinda of heat. You must heat fast and localized as you can. Otherwords a propane bottle torch just won't do.

It is sorta like the silver solder job I did a couple days. Using a different stronger silver solder a propane torch just barely soften the solder although the rest of what was heated was nearly hot enough. I switch over to my ACE/Ox welder and it immediately melted and seeped into the joint. I using 45% silver solder due to high vibration joint area on a compressor.

And if you are good you can even use ACE/Ox torch to cut pulleys off without damaging the metal shafts and the seals.

It is sorta like the silver solder job I did a couple days. Using a different stronger silver solder a propane torch just barely soften the solder although the rest of what was heated was nearly hot enough. I switch over to my ACE/Ox welder and it immediately melted and seeped into the joint. I using 45% silver solder due to high vibration joint area on a compressor.

And if you are good you can even use ACE/Ox torch to cut pulleys off without damaging the metal shafts and the seals.

#22

S

SeniorCitizen

S

SeniorCitizen

If we heat the hub portion that's stuck it can't expand because the outer periphery hasn't expanded . Example : with a 4ft.diameter bull wheel that weighs a few hundred the outer rim is heated with a couple of rose buds and the torches heating down the spokes occasionally . Sometimes they will come loose while we can still hold the hub in our hand .That propeller is no different when using heat . Heating a turbo charger propeller at the hub first will crack that expensive piece of special metal nearly every time .

#23

B

beaverplt

B

beaverplt

I don't have an oxy/acetylene unit available. I tried the propane torch, heating the impeller, hoping to make it expand off the shaft. At this point it's a moot point. I've got it back together and will see what happens. I'm pretty confident that my solution will work. Time will tell.

#24

Castleford

I was lucky enough to acquire a 20 ton press years ago and with a combination of heat & penetrating oil

the press got it off.

I used a method that an older fellow showed me years ago which was to assemble the shaft and impeller/flywheel assembly whatever in the press and apply as much pressure as you deem safe/appropriate.

Don't worry if it doesn't pop right off.....I was told by my teacher, " just leave it like that over night & many times when you come back the next day it will have popped off overnight"

If after 24 hours it's still stuck try a combination of heat and rapping around the collar with a ball peen hammer.

In my case I left the assembly overnight and while working in the shop the next afternoon it popped off while my back was turned, a godawfull loud report like a gun shot......

Castleford

I've had the same problem as you (getting the impeller off the shaft).I don't have an oxy/acetylene unit available. I tried the propane torch, heating the impeller, hoping to make it expand off the shaft. At this point it's a moot point. I've got it back together and will see what happens. I'm pretty confident that my solution will work. Time will tell.

I was lucky enough to acquire a 20 ton press years ago and with a combination of heat & penetrating oil

the press got it off.

I used a method that an older fellow showed me years ago which was to assemble the shaft and impeller/flywheel assembly whatever in the press and apply as much pressure as you deem safe/appropriate.

Don't worry if it doesn't pop right off.....I was told by my teacher, " just leave it like that over night & many times when you come back the next day it will have popped off overnight"

If after 24 hours it's still stuck try a combination of heat and rapping around the collar with a ball peen hammer.

In my case I left the assembly overnight and while working in the shop the next afternoon it popped off while my back was turned, a godawfull loud report like a gun shot......