You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Export thread

John Deere ZTRak 375 Battery Charging issues

#1

D

Doug from Ohio

D

Doug from Ohio

1-season-old JD ZTRak with a Briggs 25 horse. I removed the battery over the winter and stored it in the basement. (I never recharged it but have come to learn a trickle charge was needed so I have since purchased one.) So this spring I placed factory battery back into service and it fired right up and started weekly from April-Sept with weekly cuts. Then all of a sudden the factory issue battery just died. So I bought a new Die Hard from auto parts store and placed it into service. I tested it with my Klein MM600 today and noticed it reads 12.25 volts after 1.5 hours in service which seems very low to me. id like to check the stator output but noticed it’s a 1-wire yellow coming down out of shroud to the voltage regulator and single red going from VR to the battery. Not sure how I can test the stator output without a two-wire lead. Any direction will be greatly appreciated. Also I don’t have the Briggs model number with me at the moment if that’s important to have. I can follow directions if anyone has the sequence and multimeter settings so I don’t blow it up.

#2

B

bertsmobile1

B

bertsmobile1

Unplug the yellow wire start the engine & run full speed

AC volts between the yellow wire & engine should be higher than 28V

Plug the yellow wire back in and unplug the red wire

Should be DC 13 V or better between the wire & the engine

Check the body of the rectifier to engine , should read 0 Ω.

If not locate the ground strap connected to the mounting bolt which will be broken somewhere ,

IF it is bad then make a new one and test the red wire again.

AC volts between the yellow wire & engine should be higher than 28V

Plug the yellow wire back in and unplug the red wire

Should be DC 13 V or better between the wire & the engine

Check the body of the rectifier to engine , should read 0 Ω.

If not locate the ground strap connected to the mounting bolt which will be broken somewhere ,

IF it is bad then make a new one and test the red wire again.

#3

D

Doug from Ohio

D

Doug from Ohio

Thanks Bertsmobile. i will conduct the check list on Saturday…sorry to ask dumb questions but just confirming that my MM should be on “AC” and use red test lead to test the yellow wire coming down from stator…correct? And switch to “DC”and use the red test lead when testing the red wire. Correct? Also does it matter where on the rectifier I test for ohm/continuity? Thanks for your response above…appreciatedUnplug the yellow wire start the engine & run full speed

AC volts between the yellow wire & engine should be higher than 28V

Plug the yellow wire back in and unplug the red wire

Should be DC 13 V or better between the wire & the engine

Check the body of the rectifier to engine , should read 0 Ω.

If not locate the ground strap connected to the mounting bolt which will be broken somewhere ,

IF it is bad then make a new one and test the red wire again.

#4

ILENGINE

Also before going through the stator regulator testing try testing the voltage at the battery with the mower running full throttle and see what the voltage at the battery is. 13.5 or so at the battery means it is charging.

ILENGINE

Correct. But you will need to check the red wire on the mower side of the regulator because the red wire on the regulator may not have any output depending on style of regulator because some require battery voltage input to the regulator to close the internal switches to allow battery charging.Thanks Bertsmobile. i will conduct the check list on Saturday…sorry to ask dumb questions but just confirming that my MM should be on “AC” and use red test lead to test the yellow wire coming down from stator…correct? And switch to “DC”and use the red test lead when testing the red wire. Correct? Also does it matter where on the rectifier I test for ohm/continuity? Thanks for your response above…appreciated

Also before going through the stator regulator testing try testing the voltage at the battery with the mower running full throttle and see what the voltage at the battery is. 13.5 or so at the battery means it is charging.

#5

D

Doug from Ohio

D

Doug from Ohio

Yes I did check the battery today at full throttle and it actually tested lower than 12.25…it was something like 12.15VCorrect. But you will need to check the red wire on the mower side of the regulator because the red wire on the regulator may not have any output depending on style of regulator because some require battery voltage input to the regulator to close the internal switches to allow battery charging.

Also before going through the stator regulator testing try testing the voltage at the battery with the mower running full throttle and see what the voltage at the battery is. 13.5 or so at the battery means it is charging.

#6

D

Doug from Ohio

1. Checked stator Voltage first. THIS TESTED AT 47 AC VOLTS.

2. Checked DC Voltage BACK to the battery. THIS TEST SHOWED 12.2V. Then turned motor ON at FULL throttle. THIS TEST SHOWED 12.13V.

3. Then checked Voltage Regulator ground.

Check VR for proper ground. THIS TEST SHOWED “OL” plus and intermittent beeping and a range of numbers that fluctuated between 2.6 and 10.0. This test never fell below 1.6 with a constant tone sounding.

Any ideas on what I should do next?

D

Doug from Ohio

Ok here’s the results of your prescription.Unplug the yellow wire start the engine & run full speed

AC volts between the yellow wire & engine should be higher than 28V

Plug the yellow wire back in and unplug the red wire

Should be DC 13 V or better between the wire & the engine

Check the body of the rectifier to engine , should read 0 Ω.

If not locate the ground strap connected to the mounting bolt which will be broken somewhere ,

IF it is bad then make a new one and test the red wire again.

1. Checked stator Voltage first. THIS TESTED AT 47 AC VOLTS.

2. Checked DC Voltage BACK to the battery. THIS TEST SHOWED 12.2V. Then turned motor ON at FULL throttle. THIS TEST SHOWED 12.13V.

3. Then checked Voltage Regulator ground.

Check VR for proper ground. THIS TEST SHOWED “OL” plus and intermittent beeping and a range of numbers that fluctuated between 2.6 and 10.0. This test never fell below 1.6 with a constant tone sounding.

Any ideas on what I should do next?

#7

B

bertsmobile1

B

bertsmobile1

AC 47 volts is good so the stator is OK

If you have the voltage regulator that is screwed into the dip stick tube, make up a wire with a ring terminal at both ends

One end bolted to the engine and the other under the head of the bolt that holds the rectifier on.

When the bigger VR is fitted with 2 bolts I make a ground strap for each bolt

Then check the DC voltage from the red wire to the engine when running full speed

If it is less than the battery voltage engine off then the regulator is cactus

If it is more than the battery voltage engine off but the voltage across the battery terminals is lower than the voltage at the red wire then the red wire is broken some where between the regulator & the battery

If you have the voltage regulator that is screwed into the dip stick tube, make up a wire with a ring terminal at both ends

One end bolted to the engine and the other under the head of the bolt that holds the rectifier on.

When the bigger VR is fitted with 2 bolts I make a ground strap for each bolt

Then check the DC voltage from the red wire to the engine when running full speed

If it is less than the battery voltage engine off then the regulator is cactus

If it is more than the battery voltage engine off but the voltage across the battery terminals is lower than the voltage at the red wire then the red wire is broken some where between the regulator & the battery

#8

D

Doug from Ohio

D

Doug from Ohio

P.S. I would check the ground strap as you recommended but don’t know where to look for that. Please advise and I will check it.Ok here’s the results of your prescription.

1. Checked stator Voltage first. THIS TESTED AT 47 AC VOLTS.

2. Checked DC Voltage BACK to the battery. THIS TEST SHOWED 12.2V. Then turned motor ON at FULL throttle. THIS TEST SHOWED 12.13V.

3. Then checked Voltage Regulator ground.

Check VR for proper ground. THIS TEST SHOWED “OL” plus and intermittent beeping and a range of numbers that fluctuated between 2.6 and 10.0. This test never fell below 1.6 with a constant tone sounding.

Any ideas on what I should do next?

the VR on this model JD is bolted directly to a metal shroud that is bolted to engine body…it’s not bolted to dipstick tubeAC 47 volts is good so the stator is OK

If you have the voltage regulator that is screwed into the dip stick tube, make up a wire with a ring terminal at both ends

One end bolted to the engine and the other under the head of the bolt that holds the rectifier on.

When the bigger VR is fitted with 2 bolts I make a ground strap for each bolt

Then check the DC voltage from the red wire to the engine when running full speed

If it is less than the battery voltage engine off then the regulator is cactus

If it is more than the battery voltage engine off but the voltage across the battery terminals is lower than the voltage at the red wire then the red wire is broken some where between the regulator & the battery

#9

D

Doug from Ohio

D

Doug from Ohio

I just read in the Briggs & Stratton alternator/charging manual I found online that “there is NO bench test for the voltage regulator.” I find that hard to believe so I am checking with the forum experts…is this true?

#10

StarTech

StarTech

Typically no you cant them on the bench. They must tested in a live circuit. This because you can not access the discrete components. Most everything is encapsulated in epoxy.

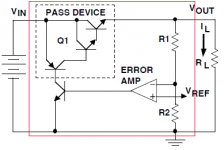

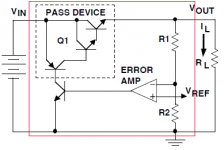

Here is example of a voltage regulator. Everything inside the red box is encapsulated; unless, it is mounted on a circuit with discrete components. Also in the case of the Briggs regulators they have rectifiers changing the stator AC output into a pulsing DC voltage. You particular engine's IPL show a single wire stator which means half wave rectification is being done. If you had a two wire stator then full wave rectification would done. This is also inside the voltage regulator module.

The following only the regulations portion of these modules.

Here is example of a voltage regulator. Everything inside the red box is encapsulated; unless, it is mounted on a circuit with discrete components. Also in the case of the Briggs regulators they have rectifiers changing the stator AC output into a pulsing DC voltage. You particular engine's IPL show a single wire stator which means half wave rectification is being done. If you had a two wire stator then full wave rectification would done. This is also inside the voltage regulator module.

The following only the regulations portion of these modules.

#11

B

bertsmobile1

B

bertsmobile1

You can not test a regulator / rectifier fully sitting on the work shop bench without expensive test gear as you would find in an electrical workshop that fixes TV's

You can check to see if it is working properly mounted on the engine

As Star said, it is a works so leave it alone or does no work so replace it situation they are not repairable .

In a mower workshop the usual method is to swap it with a known good one as that takes about 90 seconds to do .

What I am trying to get you to do is test to see if it is working so you know if the unit is faulty or the wires taking the power back to the battery are faulty.

On single wire rectifiers there was a ground strap that went from the right rear cowl mounting bolt to the single mounting bolt for the rectifier

It should go under the plastic blower housing directly against the metal crankcase then loop down& go under the regulator.

This wire shakes around a lot in use and is prone to breaking where the terminal is crimped onto the wire so you get a random make & break situation.

When I replace them I use double heat shrink over the terminal to support the wire .

You can check to see if it is working properly mounted on the engine

As Star said, it is a works so leave it alone or does no work so replace it situation they are not repairable .

In a mower workshop the usual method is to swap it with a known good one as that takes about 90 seconds to do .

What I am trying to get you to do is test to see if it is working so you know if the unit is faulty or the wires taking the power back to the battery are faulty.

On single wire rectifiers there was a ground strap that went from the right rear cowl mounting bolt to the single mounting bolt for the rectifier

It should go under the plastic blower housing directly against the metal crankcase then loop down& go under the regulator.

This wire shakes around a lot in use and is prone to breaking where the terminal is crimped onto the wire so you get a random make & break situation.

When I replace them I use double heat shrink over the terminal to support the wire .

#12

StarTech

StarTech

Side question here since you said ran it 1.5 hrs. If you were using the electric PTO during this time, have you test it for under 7 amps current draw or that it resistance measures 1.7 ohms or higher? These PTO electric clutches can partially short and still operate. I had one here that was pulling over 18 amps last year/. One pulling 9 amps or more will over tax a 9 amp system and drain the battery as the fuel solenoid needs to be powered during the same time.

#13

D

Doug from Ohio

D

Doug from Ohio

Yes I was using the PTO since those 1.5 hrs were spent cutting the lawn. I’d be willing to test continuity but really need to see a how-to instructional video. I’m a noob with the multimeter and accessing these things isn’t easy for me to just dive in. The problem is there are very few instructional videos on YouTube for the new John Deere zero turns. I am still under warranty for this mower until March 2022 unless this is an easy diagnostic procedure I may elect to have it serviced and let the dealer figure it out. I really do appreciate this forum however because this thing will be out of warranty and JD wants an arm and a leg to extend the warranty…it’s approx $300 a year And $500 for 3 years Coverage.Side question here since you said ran it 1.5 hrs. If you were using the electric PTO during this time, have you test it for under 7 amps current draw or that it resistance measures 1.7 ohms or higher? These PTO electric clutches can partially short and still operate. I had one here that was pulling over 18 amps last year/. One pulling 9 amps or more will over tax a 9 amp system and drain the battery as the fuel solenoid needs to be powered during the same time.

#14

D

Doug from Ohio

D

Doug from Ohio

Thank you! I will definitely replace the VR…I’m hoping it’s under covered under warranty by JD since the mower is only 1.5 yrs old and I have a 2 yr warranty. I will try and get the exploded view of the charging system and see if I can locate the ground wire. If you happen to have a link please share. Thanks again for help!You can not test a regulator / rectifier fully sitting on the work shop bench without expensive test gear as you would find in an electrical workshop that fixes TV's

You can check to see if it is working properly mounted on the engine

As Star said, it is a works so leave it alone or does no work so replace it situation they are not repairable .

In a mower workshop the usual method is to swap it with a known good one as that takes about 90 seconds to do .

What I am trying to get you to do is test to see if it is working so you know if the unit is faulty or the wires taking the power back to the battery are faulty.

On single wire rectifiers there was a ground strap that went from the right rear cowl mounting bolt to the single mounting bolt for the rectifier

It should go under the plastic blower housing directly against the metal crankcase then loop down& go under the regulator.

This wire shakes around a lot in use and is prone to breaking where the terminal is crimped onto the wire so you get a random make & break situation.

When I replace them I use double heat shrink over the terminal to support the wire .

#15

B

bertsmobile1

B

bertsmobile1

You won't get warranty unless you take it to a dealer

Then you play warranty roulette because if it is determined not to be a warranty item then you get stuck with a service fee.

If the wire has failed then it will be warranty

Not sure how you would stand with a failed regulator, the USA boys will know better than I

Down here the answer is NO

for electrical items because they can not rule out abuse like running with a flat battery or out of adjustment clutch unless the mower has a service history from a technician who is recognised by JD as being a qualified person.

Then you play warranty roulette because if it is determined not to be a warranty item then you get stuck with a service fee.

If the wire has failed then it will be warranty

Not sure how you would stand with a failed regulator, the USA boys will know better than I

Down here the answer is NO

for electrical items because they can not rule out abuse like running with a flat battery or out of adjustment clutch unless the mower has a service history from a technician who is recognised by JD as being a qualified person.

#16

D

Doug from Ohio

D

Doug from Ohio

Ok so today I got back to testing the DCV coming out of the voltage regulator red wire that charges the battery… it was all over the place. I couldn’t get a constant reading. What does that mean?Side question here since you said ran it 1.5 hrs. If you were using the electric PTO during this time, have you test it for under 7 amps current draw or that it resistance measures 1.7 ohms or higher? These PTO electric clutches can partially short and still operate. I had one here that was pulling over 18 amps last year/. One pulling 9 amps or more will over tax a 9 amp system and drain the battery as the fuel solenoid needs to be powered during the same time.

#17

H

hlw49

H

hlw49

Kohler makes a tester for their regulators and it will test the Kawasaki and Generac as well. Might test the Briggs as well but I usually just test the Briggs like Bert said. Or actually that is the way Briggs says to check them.

#18

GasSniffer

GasSniffer

Sounds like a bad regulator, I would call the dealer and let them mess with it. Especially if it is still under warranty. Check if there is a service charge and how much it is and what is or is not covered. You may be able to find a nomenclature on the VR and just buy one off the internet and install it yourself if warranty doesn't cover it and the service charge is more expensive than the part. Just double check the wiring/grounds first for good measure, it never hurts.Ok so today I got back to testing the DCV coming out of the voltage regulator red wire that charges the battery… it was all over the place. I couldn’t get a constant reading. What does that mean?

#19

B

bertsmobile1

They break off at the crimp.

Fabricate another one and run it from an engine bolt to the regulator mounting bolt

Make sure the contact places aere clean & tight then test the red wire again.

B

bertsmobile1

This is what you see if the ground strap is bad so it randomly makes and breaks contact.Ok so today I got back to testing the DCV coming out of the voltage regulator red wire that charges the battery… it was all over the place. I couldn’t get a constant reading. What does that mean?

They break off at the crimp.

Fabricate another one and run it from an engine bolt to the regulator mounting bolt

Make sure the contact places aere clean & tight then test the red wire again.

#20

D

Doug from Ohio

D

Doug from Ohio

Thanks Bert. I will look for the grounding strap on Saturday when I get back to the mower. Any diagram of where that ground strap is specifically located would be an immense help to me. I could not find it on any of the Briggs exploded views or the John Deere site. Anybody know where the grounding strap is for a 2020 JD ZTrak 375R? It’s engine #44S9770045G1This is what you see if the ground strap is bad so it randomly makes and breaks contact.

They break off at the crimp.

Fabricate another one and run it from an engine bolt to the regulator mounting bolt

Make sure the contact places aere clean & tight then test the red wire again.

#21

D

Doug from Ohio

D

Doug from Ohio

Yes I will remove the VR and reinstall it to ensure ground to the chassis. I did check with the dealer and the machine is still under warranty. So that’s a positive start!Sounds like a bad regulator, I would call the dealer and let them mess with it. Especially if it is still under warranty. Check if there is a service charge and how much it is and what is or is not covered. You may be able to find a nomenclature on the VR and just buy one off the internet and install it yourself if warranty doesn't cover it and the service charge is more expensive than the part. Just double check the wiring/grounds first for good measure, it never hurts.

#22

B

bertsmobile1

Kohler mount theirs inside the plastic blower housing, same story

The rectifiers both use make the ground contact through the case so it has to be connected to a metal part of the engine.

B & S usually run a strap from under the rear blower housing bolt to one of the rectifier mounting bolts

The single wire rectifiers have it under the rectifier between it & the dip stick tube

The bigger 2 ( or more ) wire ones do the same thing to one of the two mounting bolts.

Now I do not have the technical manual for your mower so I do not know if JD used the original B & S set up or have the rectifier mounted to the mower frame

If it is mounted to the frame then undo the bolts clean them, the rectifier around the bolt holes and the holes in the frame

If mounted on the dip stick tube make up 2 new ground straps, one to the blower housing bolt & another to the starter motor mounting bolt .

Belts & braces

Kohler use either a wire strap or a flat metal bar in the bower housing, both are prone to fracture after prolonged use

B

bertsmobile1

B & S usually mount their regulators on the plastic dip stick tube, which being plastic is not groundedThanks Bert. I will look for the grounding strap on Saturday when I get back to the mower. Any diagram of where that ground strap is specifically located would be an immense help to me. I could not find it on any of the Briggs exploded views or the John Deere site. Anybody know where the grounding strap is for a 2020 JD ZTrak 375R? It’s engine #44S9770045G1

Kohler mount theirs inside the plastic blower housing, same story

The rectifiers both use make the ground contact through the case so it has to be connected to a metal part of the engine.

B & S usually run a strap from under the rear blower housing bolt to one of the rectifier mounting bolts

The single wire rectifiers have it under the rectifier between it & the dip stick tube

The bigger 2 ( or more ) wire ones do the same thing to one of the two mounting bolts.

Now I do not have the technical manual for your mower so I do not know if JD used the original B & S set up or have the rectifier mounted to the mower frame

If it is mounted to the frame then undo the bolts clean them, the rectifier around the bolt holes and the holes in the frame

If mounted on the dip stick tube make up 2 new ground straps, one to the blower housing bolt & another to the starter motor mounting bolt .

Belts & braces

Kohler use either a wire strap or a flat metal bar in the bower housing, both are prone to fracture after prolonged use

#23

D

Doug from Ohio

D

Doug from Ohio

Today after mowing for approx 60 mins the PTO failed to engage. Brand new battery 3 weeks ago snd it finally ran down after not being charged. I charged it back to 12.60 DCV and left a new trickle charge on it. This confirms the VR is toast.

#24

B

bertsmobile1

As we have been trying to tell you

Could be the VR or the ground strap

But it is your money so if you want to spend $ 30 on a new VR only to find you needed a new 10¢ terminal on the ground wire , that is your decision.

If you are going to continue to run the mower in this condition then take the plug off arectifier or there is a good chance you will burn out the stator .

B

bertsmobile1

All it confirms is that the power from the alternator is not getting back to the batteryToday after mowing for approx 60 mins the PTO failed to engage. Brand new battery 3 weeks ago snd it finally ran down after not being charged. I charged it back to 12.60 DCV and left a new trickle charge on it. This confirms the VR is toast.

As we have been trying to tell you

Could be the VR or the ground strap

But it is your money so if you want to spend $ 30 on a new VR only to find you needed a new 10¢ terminal on the ground wire , that is your decision.

If you are going to continue to run the mower in this condition then take the plug off arectifier or there is a good chance you will burn out the stator .

#25

D

Doug from Ohio

D

Doug from Ohio

All it confirms is that the power from the alternator is not getting back to the battery

As we have been trying to tell you

Could be the VR or the ground strap

But it is your money so if you want to spend $ 30 on a new VR only to find you needed a new 10¢ terminal on the ground wire , that is your decision.

If you are going to continue to run the mower in this condition then take the plug off arectifier or there is a good chance you will burn out the stator .

I checked the grounding strap and it’s secure. I will unplug the stator AC wire coming into the Volt Regulator (rectifier) as you have recommended.All it confirms is that the power from the alternator is not getting back to the battery

As we have been trying to tell you

Could be the VR or the ground strap

But it is your money so if you want to spend $ 30 on a new VR only to find you needed a new 10¢ terminal on the ground wire , that is your decision.

If you are going to continue to run the mower in this condition then take the plug off arectifier or there is a good chance you will burn out the stator .

#26

B

bertsmobile1

Internally broken or corroded wires can feel quite good.

Probably barking up the wrong tree but I have this thing about spending more of a customers money than is necessary

B

bertsmobile1

What you were asked to do was to check it electricallyI checked the grounding strap and it’s secure. I will unplug the stator AC wire coming into the Volt Regulator (rectifier) as you have recommended.

Internally broken or corroded wires can feel quite good.

Probably barking up the wrong tree but I have this thing about spending more of a customers money than is necessary

#27

R

Richard Milhous

Not common, but a BASTARD when it happens. Hard to trace at all, and the slightest jiggle or temperature change can make or break the connection.

Far more common are intermittent make/break connection problems from loose/dirty connections. Feels solid, looks good... may even look clean on dissassembly. Without a resistance test, you can't be sure unless it's shiny and tight. Battery terminals are especially evil.

R

Richard Milhous

Internally broken or corroded wires can feel quite good.

Not common, but a BASTARD when it happens. Hard to trace at all, and the slightest jiggle or temperature change can make or break the connection.

Far more common are intermittent make/break connection problems from loose/dirty connections. Feels solid, looks good... may even look clean on dissassembly. Without a resistance test, you can't be sure unless it's shiny and tight. Battery terminals are especially evil.

#28

B

bertsmobile1

But we have raised several generations of drongoes who can not live unless they can can quote numbers even when they have no idea what the numbers mean

How many times have you seen stuff like 3.785 kΩ or 11.234 V quoted

B

bertsmobile1

But very easy to diagnose by using a jumper which is why O keep telling people to toss the multimete and use a test lamp that has a reasonable load , like an old head light globe or bypass with a patch cord or jumper.Not common, but a BASTARD when it happens. Hard to trace at all, and the slightest jiggle or temperature change can make or break the connection.

Far more common are intermittent make/break connection problems from loose/dirty connections. Feels solid, looks good... may even look clean on dissassembly. Without a resistance test, you can't be sure unless it's shiny and tight. Battery terminals are especially evil.

But we have raised several generations of drongoes who can not live unless they can can quote numbers even when they have no idea what the numbers mean

How many times have you seen stuff like 3.785 kΩ or 11.234 V quoted

#29

D

Doug from Ohio

D

Doug from Ohio

It’s definitely a bad VR. I do appreciate you guys and the steady feedback. Thanks again.

#30

R

Richard Milhous

Berts you are just seeing things wrong because you are in the wrong hemisphere where the electromagnetic currents run backwards. In America (TM) they wouldn't sell a meter with three decimals of precision unless it had three decimals of accuracy! 11.234 V means just that, not 11.233 or 11.235. In Chinesium We Trust!

R

Richard Milhous

But very easy to diagnose by using a jumper which is why O keep telling people to toss the multimete and use a test lamp that has a reasonable load , like an old head light globe or bypass with a patch cord or jumper.

But we have raised several generations of drongoes who can not live unless they can can quote numbers even when they have no idea what the numbers mean

How many times have you seen stuff like 3.785 kΩ or 11.234 V quoted

Berts you are just seeing things wrong because you are in the wrong hemisphere where the electromagnetic currents run backwards. In America (TM) they wouldn't sell a meter with three decimals of precision unless it had three decimals of accuracy! 11.234 V means just that, not 11.233 or 11.235. In Chinesium We Trust!

#31

B

bertsmobile1

And it is real fun when I reply so the battery is only reading 11.2 that is way too low and most come back with NO IT IS 11,234 as if the 0.034 actually meant some thing.

I had one galah who was giving me grief because the coil resistance was low so I told him to push harder on the probes and tell me what the DVM read

After a couple or readings it went up enough to read in spec so I finished off with "There you go you have fixed it " and hung up .

B

bertsmobile1

So does 11.234 mean your battery is any better than mine that reads 11.2 ?Berts you are just seeing things wrong because you are in the wrong hemisphere where the electromagnetic currents run backwards. In America (TM) they wouldn't sell a meter with three decimals of precision unless it had three decimals of accuracy! 11.234 V means just that, not 11.233 or 11.235. In Chinesium We Trust!

And it is real fun when I reply so the battery is only reading 11.2 that is way too low and most come back with NO IT IS 11,234 as if the 0.034 actually meant some thing.

I had one galah who was giving me grief because the coil resistance was low so I told him to push harder on the probes and tell me what the DVM read

After a couple or readings it went up enough to read in spec so I finished off with "There you go you have fixed it " and hung up .

#32

D

Doug from Ohio

D

Doug from Ohio

Ok final update on the voltage regulator on my ZTrak. The JD dealer replaced it under warranty!it also received the winter special with new oil, lube, blades sharpened and new fuel filter, which is why I am writing back. When I winterized the mower I placed fuel stabilizer in the tank and ran the engine for 5 minutes according to the directions. I looked down at the new fuel filter and noticed it was empty. how is that possible with the engine continuing to operate? I could’ve swore before it went into service I could see the filter was filled with gas. Sorry for this question but what I saw seems strange.

#33

B

bertsmobile1

B

bertsmobile1

Depending upon which filter was fittted the outlet could be anywhere from the very edge of the canister to the furthest edge of the element

Thus when fitted vertically with the outlet side up you get an airlock.

When a customer whinges about that I simply fit the filter backwards.

Makes no difference to the operation which way the fuel flows, there are no check valves

Right way pound & the curd is on the outside of the element where you can see it

Wrong way round and the crud is on the inside where you can not see it easily.

If it really urks you you can fill the filter upside down to remove the air bubble then cap the end with your finger while you fit it to the hoses ( easier said than done )

Thus when fitted vertically with the outlet side up you get an airlock.

When a customer whinges about that I simply fit the filter backwards.

Makes no difference to the operation which way the fuel flows, there are no check valves

Right way pound & the curd is on the outside of the element where you can see it

Wrong way round and the crud is on the inside where you can not see it easily.

If it really urks you you can fill the filter upside down to remove the air bubble then cap the end with your finger while you fit it to the hoses ( easier said than done )

#34

D

Doug from Ohio

D

Doug from Ohio

Thank you for that reply but how does that account for the clear plastic showin as empty? How is the fuel getting to the carburetor?

#35

B

bertsmobile1

B

bertsmobile1

Because it is not empty, it just looks that way.

Note the colour of the paper filter, it will be darker because it is wet with fuel

You might need a strong light & magnifier to see the fuel but it is in there .

Note the colour of the paper filter, it will be darker because it is wet with fuel

You might need a strong light & magnifier to see the fuel but it is in there .